Combobulating the Perfect Wall – The Basics of Control Layers

Have you thought about the best wall to build a wall? In my Building Science 101 article, I mentioned that buildings need to control the flow of heat, air, and moisture to perform well. Does the standard stick-built, wall with its cladding, housewrap, sheathing, framing, and cavity insulation, do the job well enough?

Have you thought about the best wall to build a wall? In my Building Science 101 article, I mentioned that buildings need to control the flow of heat, air, and moisture to perform well. Does the standard stick-built, wall with its cladding, housewrap, sheathing, framing, and cavity insulation, do the job well enough?

Have you thought about the best wall to build a wall? In my Building Science 101 article, I mentioned that buildings need to control the flow of heat, air, and moisture to perform well. Does the standard stick-built, wall with its cladding, housewrap, sheathing, framing, and cavity insulation, do the job well enough?

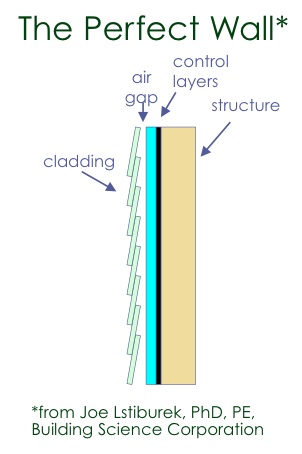

A couple of years ago, I got to hear Joe Lstiburek speak at Greenprints in Atlanta on what he called the Perfect Wall. It was one of those Aha! moments for me because he elucidated perfectly the functions of the various components in our wall assemblies and laid out the perfect way to put it all together to get the best performance. Plus, it works in all climate zones! He gives credit to the Canadians for originally developing the idea, but I think he’s the one who applied the perfect name to it – The Perfect Wall. (The link takes you to his paper on this topic at the Building Science Corporation website. You should definitely read it.)

As I mentioned in my post last year about Lstiburek’s Building Science Summer Camp, Dr. Joe broke the wall down into its basic components: structure and control layers (plus finishes, electrical, and mechanicals, but those aren’t important for what we’re talking about here). The control layers do the following:

- Rain control

- Air control

- Vapor control

- Thermal control

As Joe says in his article, these four control layers are listed in order of importance. If rain is getting into the wall, who cares about infiltration? If you don’t have a good air barrier, worrying about the details of the vapor retarder is pointless.

So, if a wall is made of structure and control layers, what’s the perfect way to assemble them? With all four control layers on the outside of the structure, of course. As Lstiburek puts it:

Remember we really do want to protect that darn structure—especially for the sake of making the structural engineers life more happy. Expansion, contraction, corrosion, decay, ultra violet radiation, and almost all bad things all are functions of temperature.

So, not only do the drainage plane, air barrier, and vapor retarder go on the outside, so does the insulation. In fact, if you’re putting the vapor retarder on the outside, you have to put the insulation there, too. Otherwise, you could end up with condensation inside the wall cavity in cold climates.

Below is a diagram of the Perfect Wall. I’ve shown the insulation in light blue and the drainage plane, air barrier, and vapor retarder in black.

I think a lot of our problems in buildings is that we intermingle structure and control layers, and we don’t pay enough attention to the details at the interesections of roofs, ceilings, walls, and floors. As my friend and former colleague, Mike Barcik, likes to say, think of the house as a beer cooler – it needs continuous control layers all the way around. In Lstiburek’s article, he discusses how the Perfect Wall laid horizontally becomes the Perfect Floor or Perfect Ceiling, with proper attention paid to the intersections.

I don’t know that we’ll see houses adopt the Perfect Wall concept en masse, but builders who qualify their homes in ENERGY STAR Version 3 are being pushed in that direction by the requirement for reducing thermal bridging. The Perfect Wall is a concept that makes perfect sense – if your goal is to create a building that works.

This Post Has 14 Comments

Comments are closed.

Good blog Allison. In our

Good blog Allison. In our climate (Zone 5, cold and also pretty dry) we don’t worry about vapor retarders and they aren’t in our code requirements either. So long as we have a good air barrier we’re set. (New Mexico)

So, the insulation belongs

So, the insulation belongs outside the cavity? What about the concept that the insulation must contact the air barrier, and further that the air barrier belongs on the warm in winter side of the insulation?

Allison, The Perfect Wall is

Allison, The Perfect Wall is also known as the 100 year or 500 year wall.

It is expected to last 100 to 500 years and it may take 100 to 500 years to pay for it.

Here is a video about "

Here is a video about “The Perfect Wall”

http://www.bestofbuildingscience.com/WM_burek1.html

Amanda:

Amanda: Vapor retarders are a topic that’s not well understood by most people. A lot of people are convinced they need a vapor ‘barrier’ but don’t know why or where to put it. In dry climates and mixed climates, they’re unnecessary. And, as I said above, if you haven’t sealed the air leaks, which allow a lot more vapor to cross the envelope, vapor retarders are irrelevant anyway.

John N.: Yes, the insulation must still be in contact with the air barrier, no matter where you put it. Insulation on the outside (sometimes called ‘outsulation’) is usually an air barrier itself (e.g., foam board), so that solves the problem. It also solves the problem of where to put the air barrier and vapor retarder. I’ll write more about this later.

John B.: In the Lstiburek article, Joe talks about the details of the 500 year wall, but I guess I missed the bit about the price tag being as high as the lifetime. But yeah, doing things the right way does have a higher first cost. When you look at ROI or lifecycle assessment, though, I believe it comes it out as one of the best options. Thanks for the video link! For those of you who want to click to see it, here you go: Joe Lstiburek talking building science and the Perfect Wall.

The concept of insulation on

The concept of insulation on the outside serves two objectives: thermal bridging and condensation. A discussion of wall design begs the question of how climate zone impacts placement of the vapor control layer.

In cold climates, vapor control should be on the inside, while in hot-humid, it belongs on the outside (always the warm surface). In dry climates, as Amanda noted, a vapor retarder is unnecessary, especially with insulation on the exterior.

In mixed climates (a large part of the country), Joe advocates putting the vapor control layer in the middle of the insulation sandwich.

I consulted with Joe in 1998 when I was designing my previous home in Charlotte. I had XPS on the outside, R19 on the inside, and two layers of 15-lb building felt applied on the wood sheathing. At the time, code required a vapor retarder on the inside wall. He advised that I go with kraft-faced insulation just to satisfy the inspector (as opposed to poly). However, you never want two vapor control layers, so he suggested that I wait until after the inspection and slice a big X in the facing of each batt with a razor! A few years later, he and Betsy convinced the state to change the code.

Allison, I just saw your

Allison, I just saw your comment. I’ll check out Joe’s video later, but it looks like he’s changed his recommendation regarding placement of vapor retarder since my project. The Perfect Wall diagram in the paper shows vapor control layer in middle of sandwich, which he says will work in *all* climate zones.

What do you think of the ZIP

What do you think of the ZIP board system?

Stephen: I

Stephen: I like Zip Wall sheathing by Huber. It saves on labor, does a better job with the drainage plane than housewrap, and reduces air leakage, too. It relies heavily on the tape, but they seem to have a really good tape that can take it. [In full disclosure, Huber Engineered Woods is a client, and we’ve done some work with them on the Zip system. I’ve been recommending it longer than they’ve been a client, however.]

Applying the Perfect Wall to

Applying the Perfect Wall to an ICF wall is my concern. I’m building an ICF home using IntegraSpec Forms. My concern is that for the Wall to be “perfect” it must control water then Air, Vapor and Thermal. During assembly of the forms this would seem to imply that I must use some kind of maybe low-expand spray foam “sealing and gluing” each form on sides and top/bottom??? According to the manufacture this is not necessary. I can’t simply use sealing tape on the outside to form the seal because the Integra-Spec has preformed drainage plane grooves in the form.

I guess I am worried about Water Vapor pumping moisture into the concrete and thus into my home here in my Zone 4 humid region of coastal Virgina.

What should I do? Am I over doing this on the ICF form?

Thank you!

Eric: If

Eric: If your ICFs come with an integrated drainage plane, just follow your manufacturer’s instructions and you should be fine.

Eric wrote: “I am

Eric wrote: “I am worried about Water Vapor pumping moisture into the concrete and thus into my home..”

Concrete is an air barrier and has a very low perm rating (e.g., retards vapor diffusion). However, the large volume of water contained in fresh concrete will slowly diffuse into the structure (as well as to the outside). Since drywall has a higher perm rating than than the EPS, there’s little chance that moisture will be trapped. And since the diffusion rate is very slow, it is unlikely to overload a properly ventilated building. Likewise, the exterior rain-shield and cladding needs to be vapor open. So as Allison said, follow the manufacturer’s instructions and guidance.

Eric:

Eric: Another property that helps you out here is that concrete has a great ability to act as a hygric buffer. That is, it can store a lot more water than a wood frame wall. As long as you don’t have a major flaw in the moisture management system, a little water getting in won’t hurt.

Allison, David,

Allison, David,

Thank you for putting my mind at ease. Now on to picking siding… Some say Acrylic Stucco is somehow synergistic with ICF’s. Does anyone know why this is so? Perhaps it does a better job of the “perfect wall” with respect to the control of Water & Air part of the perfect wall strategy?