How to Grade the Installation Quality of Insulation

Six years ago, RESNET published a major revision of the HERS Standards, called…wait for it: the 2006 National Mortgage Industry Home Energy Rating Systems Standards. One important new feature in the standards was the grading of insulation installation quality. Before this change, R-13 insulation installed poorly (as shown below right) was equivalent to any other R-13 insulation, including insulation with impeccable installation quality (as shown at left). If you know any HERS raters, you’ve probably heard the debates about the various types of insulation and the poor quality of installation they sometimes see. (OK, you’re right; it’s more than sometimes.) Just last week I wrote about the discussion of banning batt insulation.

So, how exactly does this system of grading the installation quality of insulation work? Raters have been doing it for six years now, so it’s time for the rest of you to find out what they’re doing. First, a brief overview:

A home energy rating includes energy modeling to see how energy efficient a home is or will be. Most HERS ratings have been done for new homes that are seeking to qualify for a program’s label or certification, such as the ENERGY STAR new homes program. The rater gathers all the information about the building envelope, the heating and cooling systems, ventilation, water heating, lights, and appliances. The data go into the energy rating software, which does the calculations and comes up with estimated annual consumption and costs as well as a number called the HERS Index.

includes energy modeling to see how energy efficient a home is or will be. Most HERS ratings have been done for new homes that are seeking to qualify for a program’s label or certification, such as the ENERGY STAR new homes program. The rater gathers all the information about the building envelope, the heating and cooling systems, ventilation, water heating, lights, and appliances. The data go into the energy rating software, which does the calculations and comes up with estimated annual consumption and costs as well as a number called the HERS Index.

The 3 grades: I, II, and III

The R-value of the insulation in all the insulated building assemblies (walls, ceilings, floors) can have a big effect on the results. Now that raters put a grade on the installation quality, it helps the rater develop a more accurate energy model of the home. When a rater goes in and looks at the insulation, they’ve got to record each assembly as having a Grade I, Grade II, or Grade III insulation installation quality.

Grade I is the best. This means that the insulation is installed according to the manufacturer’s instructions. It completely fills the cavity in the case of air-permeable insulation and also is encapsulated on six sides (with an exception for IECC climate zones 1-3). It’s cut around electrical junction boxes, split around wires and pipes, and generally not compressed.

Grade II is second best. There’s some allowance for imperfections in the installation but overall, it’s still not too bad. The HERS Standards say a Grade II installation can have “moderate to frequent installation defects: gaps around wiring, electrical outlets, plumbing and other intrusions; rounded edges or “shoulders”; or incomplete fill…”

Grade III is the lowest grade. It has “substantial gaps and voids.”

The energy rating software models these three grades differently. When the rater enters Grade I, the software calculates according 100% of the cavity insulation having the R-value entered. When the rater enters Grade II, the software models the cavities as having 98% of their area insulated to the given R-value and 2% uninsulated. For Grade III, 95% of the cavity area is calculated with the given R-value and 5% is treated as uninsulated. (The reason for these particular numbers should become clear to you below.)

The 2 parameters for assigning the grade

When the HERS rater is inspecting the insulation installation quality, they look at two parameters:

- Missing insulation

- Compression and incompletely filled areas

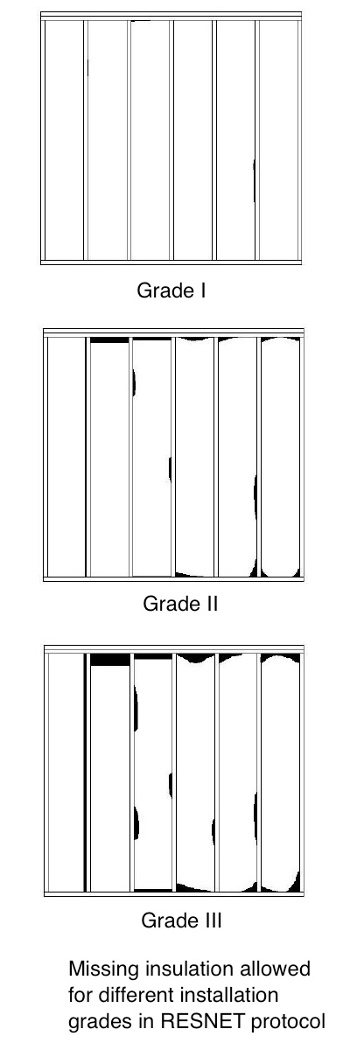

Missing insulation. When a cavity in a building assembly has insulation installed in a way that leaves gaps, that affects the amount of heat that flows across the building envelope. More heat will pass through assemblies that have gaps. The more gaps there are, the worse the grade it gets. Here’s how the HERS Standards relate missing insulation to grade:

- Grade I: “Occasional very small gaps are acceptable.” In another place, the Standards say, “if the exterior sheathing is visible from the building interior through gaps in the cavity insulation material, it is not considered a ‘Grade I’ installation.”

- Grade II: Up to 2% missing insulation

- Grade III: Between 2% and 5% missing insulation

If you’re wondering what happens when you do an inspection and find that more than 5% of an assembly is missing insulation, the answer is that you have to break out the uninsulated part and model it separately. If it’s new construction, you’ll probably be telling the builder to finish insulating, but in existing homes, sometimes you have to model the uninsulated part.

The diagrams below, taken from the HERS Standards (Appendix A, pages A-11 to A-16), show visually what the rater should be looking for.

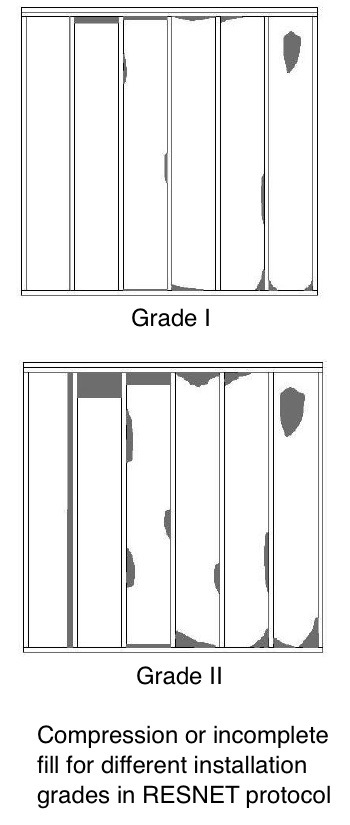

Compression and incomplete fill. Compression is a common problem with fiberglass batt insulation because the batts are often not cut to the proper size for the cavity.

- Grade I: Up to 2% of the area can have compression or incomplete fill. If a spot is incompletely filled, it must be depleted no more than 30% to attain Grade I. In other words, no more than 20 square feet of each 1000 square feet can have this problem, and even those 20 square feet must be filled to at least 70% of their intended depth.

- Grade II: Up to 10% of the area can have compression or incomplete fill and again must be filled to at least 70% of their intended insulation depth.

- Grade III: Unspecified. I take this to mean that any compression or incomplete fill that lies outside the bounds specified for Grade I or Grade II would garner that assembly a Grade III.

The diagram below, again taken from the HERS Standards, shows what these conditions would look like.

Making the grade

Most of the time, assigning a grade to an insulation installation isn’t really so hard. Sometimes, you look at it and see immediately that it’s Grade I. Other times, it’s immediatley obvious that it’s Grade III. The difficulty comes in when you’re on the boundary between I and II or between II and III. That’s when you might need to dig a little deeper and get out your measuring tape. If you want to learn more about this, download a copy of the HERS Standards (link below) and read pages A-11 through A-16 in Appendix A.

Putting a grade on the installation of insulation and doing inspections before drywall goes into new homes were two of the biggest changes that RESNET and ENERGY STAR introduced six years ago. New homes that have gone through this process have gotten a lot better as a result.

Allison Bailes of Atlanta, Georgia, is a speaker, writer, building science consultant, and the founder of Energy Vanguard. He has a PhD in physics and writes the Energy Vanguard Blog. He is also writing a book on building science. You can follow him on Twitter at @EnergyVanguard.

Related Articles

2006 National Mortgage Industry Home Energy Rating System Standards(pdf)

Rare Grade I Fiberglass Batt Insulation Sighting

ENERGY STAR Version 3 Requires Grade I Insulation

Green Curmudgeons, Architects, and Outlawing Batt Insulation

Comments are closed.

This Post Has 7 Comments

Comments are closed.

Allison,

Allison,

Does the HERS rating account for both an air barrier as a separate, distinct layer and the impact of thermal bridges?

I’ve found it easier to

I’ve found it easier to figure out the Uavg and use that value for both HERS modeling and Manual J for some parts of the house.

For whatever reason, code officials don’t think floor insulation needs to achieve anything close to its R-19 rating at Grade I. The real result is more like R-2 – R-5. The builders don’t care to fix it in Georgia. However, they’d never get away with it in California.

When in doubt, go with what the homeowner will “see” in their energy bills!

Allison, For my Energy Star

Allison, For my Energy Star Homes, I have a piece of scrap Polycarbonate. About 15 inches by 3 feet. It is marked off with a Sharpie to show square feet and inches. Since I already know, from the plans, the square footage of the walls, this makes the measurement easier.

if insulation is not

if insulation is not inspected it is consitered grade 3.

if it was manditory that an intermediate inspection of insulation then we would have less problems with insulation.

at the same time the thermal bypass check list could be done.

Using spray foam resolves

Using spray foam resolves these issues.

From our experience, we’ve

From our experience, we’ve concluded that unless insulation artists, Grade 1 insulation is next to impossible as such we make up for it by adding 1 inch of continuous STYROFOAM to the outside of the building in Climate Zone 5.

Terry H.:

Terry H.: Yes, the air barrier is included when the rater enters the infiltration rate into the software. Thermal bridges get accounted for when they specify the framing details (type of framing, size of framing members, and spacing). It’s not perfect since most ratings are done using the default framing factors built into the software.

Sam Y.: I’m not sure how you’re substituting Uavg for R-value and grade, but it sounds like you’re going beyond what the HERS Standards call for. Yeah, you’re absolutely right about floor insulation. I generally believe that fiberglass batts are a poor choice for framed floors, even though that’s mostly what builders use.

John N.: That’s a great idea! Do you use it on every rating inspection? Or do you find that you’re able to assign a grade without it most of the time?

Debbie: Yes, I didn’t mention that in the article above, but whenever the rater cannot see the insulation, it’s got to be entered as Grade III. Thanks for bringing that up.

Bob: Actually, spray foam is subject to the same grading protocol, as are all types of insulation. I’ve seen Grade I batts and Grade III spray foam. See my article from a couple of years ago called 4 Pitfalls of Spray Foam Insulation.

Jerry F.: If you’re using fiberglass batts, yes, Grade I is very difficult. As you noted, adding some continuous insulation helps to make up for the defects and is the only way to qualify a home for ENERGY STAR Version 3 if it doesn’t get Grade I.