Does Your Air Barrier Work in Both Directions?

Do you want a good air barrier on your house? Of course, you do. No one who knows anything at all about building science believes that old myth that a house needs to breathe. We want airtight houses, but then we want mechanical ventilation to bring in fresh air from outside (well, at least as fresh as you can get from your outside).

Do you want a good air barrier on your house? Of course, you do. No one who knows anything at all about building science believes that old myth that a house needs to breathe. We want airtight houses, but then we want mechanical ventilation to bring in fresh air from outside (well, at least as fresh as you can get from your outside).

The air barrier’s job is to minimize the amount of air that crosses the building enclosure between conditioned and unconditioned spaces. Does all of the air moving across the building enclosure always go the same way? No. It goes both ways. The amount of outside air that leaks in is matched by the amount of inside air that leaks out. (Sometimes the air leaking in or out is intentional, and we call that ventilation.)

Once you understand that air can move both ways, it’s clear that you’d want an air barrier that works in both directions. Right? But when we test homes for air leakage, we pretty much always test them in only one direction: from outside to in. We put the house under negative pressure with a blower door and then measure the air flow through the fan, which tells us how much air is leaking in through the building enclosure.

I’ve written in the past about how house wrap is far from ideal as an air barrier. It can be a great drainage plane, however, and that should really be its primary purpose when you use it on the outside of a house. (As some unfortunate homeowners in Kentucky found out recently, trying to build a house without any kind of drainage plane leads to trouble.)

A research project comparing house wrap to taped sheathing

A couple of years ago, I did a little research project† for Huber Engineered Woods. (Disclosure: They were Energy Vanguard’s client and paid for this work.) They wanted to find out how air leakage through their Zip System wall sheathing compared to house wrap. Our objective was to test the same home for both infiltration and exfiltration with two different air barrier conditions:

- House sheathed with OSB; house wrap installed according to manufacturer’s instructions to serve as air barrier.

- House sheathed with Zip System wall sheathing and roof decking. All seams and openings taped as specified in manufacturer’s instructions.

The builder framed the house as normal. They used Zip Wall sheathing and Zip Roof decking but left the walls untaped for the first test. They installed house wrap over the walls and sealed according to the manufacturer’s instructions. They set all windows and doors and sealed the house to the point where we could do the blower door testing. They also taped the Zip Roof decking and sealed all penetrations since the ceiling drywall was not in place.

The air leakage test results

When the house was ready to be tested with house wrap, we ran single-point blower door tests in two configurations – positive pressure and negative pressure, both at 50 Pa relative to outdoors.

After the first test, the builder removed the house wrap and taped the Zip Wall seams. They had the house ready for the taped-sheathing test 10 days after our first test, so we came in and retested the house, as before.

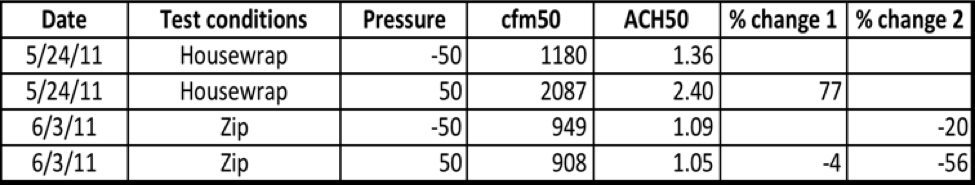

The results for both tests are below. The ACH50 is based on the house volume of 52,113 cubic feet.

The first test showed an enormous difference between the negative pressure (infiltration) and positive pressure (exfiltration). The exfiltration rate was 77% higher than the infiltration rate. (Shown in % change 1 column above)

The second test showed marked improvement in both the infiltration rate (20% lower) and exfiltration rate (56% lower). (Shown in % change 2 column above)

Putting the results in perspective

Even with the house wrap, this house was very tight, having infiltration and exfiltration rates of 1.36 and 2.40 ACH50, respectively. As we observed, the builder had taken great care to seal the house wrap completely, and that effort showed in the results.

In a typical installation, the bottom edge of the house wrap is left unsealed. Seams are often taped poorly or left untaped. Numerous rips and tears keep the house wrap from lying flat. Sometimes siding installers cut the house wrap in the corners because the house wrap doesn’t lie flat there. If this house had the typical amount of extra leakage sites that these problems introduce, the initial test would have shown significantly higher leakage.

Also, since this was a large house, much of the wall sheathing did not break over studs or plates (see photo below). Many of the seams that fell over open areas in the framing showed large gaps, as shown in the photos below. These gaps can allow a lot of air through, and that’s probably why the exfiltration result was so much higher than the infiltration result in the house wrap test.

With the house under positive pressure, air from inside moved out through those gaps, blowing the house wrap out like a balloon. Once outside the sheathing, the air finds holes in the house wrap and escapes. Of course, with cladding installed, the house wrap wouldn’t be able to expand as much. With the house under negative pressure, the house wrap was pulled into the gaps, sealing the sheathing almost as well as the tape did in the second test.

Still, even with such a low starting point for the air leakage rates, the taped Zip Wall sheathing performed significantly better – 20% for infiltration and 56% for exfiltration – than the house wrap used as the air barrier. Because the house wrap installation was better than normally observed in the field, these improvement numbers can be taken as a lower limit of how much better Zip Wall sheathing will perform compared to houses that rely on house wrap, at least when comparing houses of similar wall complexity. In smaller houses where all or most of the sheathing breaks over studs and plates, the effect may be less pronounced.

Further investigation ideas

The really neat thing about the project is that we used the same house to test two different systems. In the end, though, this was only one house, and it wasn’t finished. It would be nice to see this work extended to more houses with more configurations.

One obvious test that would be nice to see is the difference in air leakage for house wrap and taped sheathing after the cladding and drywall are installed and the house is finished. There’s a huge difference between positive and negative pressure air leakage before cladding and drywall, but how big would it be at the end?

Another set of experiments to pursue would be looking at the effect of different cladding types. Then look at the effect of the different methods for putting air gaps between cladding and sheathing: furring strips, wrinkled house wraps…

Takeaways

As I wrote in 2010 (before Huber ever contacted us), house wrap is not an ideal air barrier. If the builder takes great care, house wrap can perform well as an air barrier, but the typical installation leaves a lot of holes. What this research shows, at least for a house without cladding, is that house wrap works better for buildings under negative pressure than for those under positive pressure.

The key takeaway from this initial work is that if you’re looking for really high levels of airtightness, you should seal the sheathing when you use house wrap. Taped sheathing‡ products, like the Zip System or taped foam board, will probably have lower air leakage than homes with house wrap and unsealed sheathing.

Related Articles

5 Reasons House Wrap Is Not an Air Barrier

The 3 Rules of Air Leakage (Plus a Bonus!)

It’s the Hole – Understanding What a Blower Door Is for

Footnotes

† I say it was a ‘little’ research project because it wasn’t a scientifically rigorous study whose results establish a general truth. It’s one quick look at a particular phenomenon and it deserves more study. I worked on the project with Al Landers, PhD (now retired), Allen Sealock, and Danko Davidovic, PhD. Danko is a real building scientist with a degree from one of the best places to study building science: Penn State.

‡ Tape is quite the controversial topic in building science circles, and some people don’t trust it. Joe Lstiburek, PhD, PE, is not one of those people. “Residentially we now use tapes on wood sheathings and foam sheathings to provide water management and air management. So how well do these systems actually work? Now? Real well. In the early days? Not so good.” Read his article, Stuck on You.

This Post Has 11 Comments

Comments are closed.

This is a very important

This is a very important point, and I’m a big fan of your writing, but I have to take issue with your statement that positive pressure ventilation is the most common recommendation for humid climates.

I assume that you are pointing at fan cycler type systems that positively pressurize a house by introducing outside air using the HVAC air handler with a 4″ or 6″ vent from the outside to the return air vent.

But the most recommended system I see is to de-pressurize the home with exhaust-only ventilation using bath fans on timers and/or w/ constant low cfm exhaust ventilation or to use an exhaust fan depressurize a sealed crawl space relative to the building interior.

Once again, I am amazed at

Once again, I am amazed at how much effort is put into trying to work out all of the inherent problems with stick framed wood based construction. Concrete based systems such as ICF or Superior Walls pre-cast insulated concrete panels virtually eliminate all of these issues.

Sorry Allison, but leaving

Sorry Allison, but leaving out the silliness of positive pressure is a good recommendation a house will not leak more with a positive pressure system.

It will leak the same amount as the fan can deliver, just like an exhaust only will pull in as much as the fan can exhaust.

Michael C.

Michael C.: Maybe it’s different in North Carolina, but I see next to no one promoting negative pressure here in the Southeast. Why is this happening in NC? (By the way, I’ve taken out the part about positive pressure ventilation because I wasn’t thinking clearly when I wrote it. See my response to Sean below.)

Tom D.: Because stick building is what most people in the industry are familiar and inertia can take things a long, long way, even when they don’t make the most sense. There’s also cost, preference, embodied energy, and other factors that play into it, but yes, if we were interested in ease of air-sealing, ICFs and SIPs would definitely be carrying the day.

Sean L.: D’oh! Wasn’t thinking clearly when I wrote that and have removed it. Thanks, Sean.

“Of course, with

“Of course, with cladding installed, the house wrap wouldn’t be able to expand as much.” True but now your house wrap “ballon” has thousands of unsealed holes from the cladding fasteners. These add up.

Hi Allison,

Hi Allison,

You mention at one point that house wrap is often not sealed at the bottom, and seem to suggest this is one of several possible installation errors.

But isn’t this done intentionally? So as to provide a weep path for any moisture that might get trapped between the sheathing and the wrap?

And if that’s true, then that would seem to further reinforce the argument that house wrap is really a rain screen, and not an air barrier at all (even though it might incidentally function).

~ John

I love this site. I come from

I love this site. I come from the structural side of the business in that I build only hurricane resistant homes. Stopping water intrusion is a basic requirement and that leads to a very tight construction. Needing a properly designed HVAC system is a byproduct of this. I think it is interesting that Energy Star requires the sealing of electrical boxes in exterior walls. One could infer from that requirement that they assume the wall cavity to be already compromised from an air infiltration perspective. The junction between the wall system and the foundation is just one of many places this can occur. As my homes are monolithic from the ground all the way up, I have eliminated this problem.

So where do liquid applied

So where do liquid applied air barriers fit into this scenario?

Michael, while exhaust

Michael, while exhaust ventilation may be the most of what you’ve seen, it is definitely the least recommended option for humid climates in building science circles, and I would alter Allison’s statement to say that because there are lots of balanced (ERV’s) systems going in. Also, there are a dew ways to provide positive pressure ventilation, all better than the duct-into-return strategy.

Typically the biggest reason for the large difference in envelope leakage between negative & positive pressure envelope leakage tests are the exhaust fan dampers, though I assume these exhaust runs weren’t in place in this case.

The Passive House program requires positive and negative pressure envelope leakage tests (averaging the number if I’m not mistaken).

I remain a skeptic of tape. I’m not sure we know it’s still going to be providing a good seal in 30+ years. Accelerated testing & all that – we’ve been down that road with building paper… Also, it’s not just tape, but a system that is more prone to failure. Mastic tape on HVAC systems is a good example. It can, and usually does, stick so good that you practically need power tools to remove it. Other times it’s falling off all by itself.

Alison, I can see why Huber

Alison, I can see why Huber would want to have this test conducted and the results are not surprising. However the test is incomplete and verdict is still out on Huber’s ZIP System. The limitation I see with the ZIP System is:

Will the tape hold out all of the water and what happens to moisture that becomes trapped within the cavity or sheathing? We all know that trapped moisture is an inevitability in nearly any building envelope and unless I am mistaken, the ZIP sheathing is nearly impervious (2-3 perms). Which leads to my response to the question of where do liquid applied membranes fall in this discussion. They are clearly superior to both of the test subjects for the following reasons:

1 they are a highly effective air barrier.

2. they will shed liquid like water off a duck’s back.

3. they are vapor permeable and unlike the test subjects they act like a wick to expel moisture from the substrate they are applied to. In northern climates house wrap can actually trap moisture between itself and a highly performing wall construction that is inherently air tight and carries a high R value.

As the bar rises on overall building performance the need for a “virtual living skin”, as MS Polymer liquid membranes can provide, will be increasingly important.

We have new builder, at least

We have new builder, at least new to us, who wants to use BluskinVP. We suggested we do a similar set of BD tests.

I’ll get back to all when it transpires.