How NOT to Retrofit a Furnace in a Spray Foam Insulated Attic

A while back I wrote about the incompatibility of putting an atmospheric combustion furnace in a sealed attic. Most often the attic is sealed by installing spray foam insulation at the roofline, thus bringing the attic inside the building enclosure and turning it into conditioned space (directly or indirectly). The good news is that some installers understand this problem and seek to address it. The bad news is what some of them do.

A while back I wrote about the incompatibility of putting an atmospheric combustion furnace in a sealed attic. Most often the attic is sealed by installing spray foam insulation at the roofline, thus bringing the attic inside the building enclosure and turning it into conditioned space (directly or indirectly). The good news is that some installers understand this problem and seek to address it. The bad news is what some of them do.

Combustion air retrofits

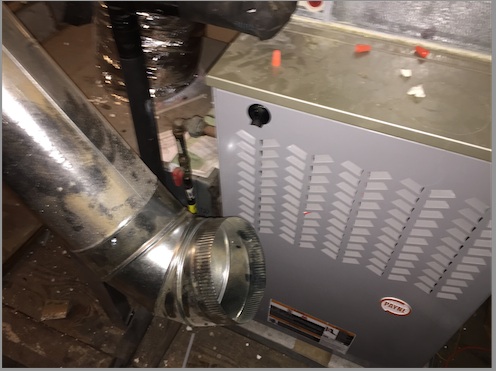

The photo above is a case in point. The furnace was up in the attic before the spray foam was installed. The homeowner hired a spray foam contractor to improve the building enclosure but the budget didn’t include enough money to change out the furnace at the same time.

I don’t know if the combustion air retrofit you see above was done by the spray foam installer or the HVAC contractor, but in either case, this one’s almost certainly not going to work. Here are the main problems:

- Inadequate duct size. They used a 4″ flex duct that you usually see on bath fans (which have their own problems), and it ran at least 20′ to the place where it exited the attic. This would not meet the code requirement for combustion air inlets.

- Poor duct installation. The duct wasn’t pulled tight, further reducing the air flow through the duct.

- Tape over furnace louvers. The louver area is designed to allow the proper amount of combustion air to enter the furnace. By covering some of them with tape, the installer of this retrofit may be guaranteeing the opposite of what they were aiming for: less combustion air, not more.

The photo below shows a better installation. The duct looks like it’s 6″ or 8″ in diameter, and it’s made of rigid metal. Both of those things will allow more air to move through.

And that air might even move toward the furnace instead of away from it. Of course, there’s no guarantee of that. As my friend David Richardson likes to say, combustion air doesn’t care which way we show the arrows pointing on our diagram.

Air flows from areas of higher pressure to areas of lower pressure. Under some circumstances, air might flow out through that inlet rather than in.

What should you do instead?

In my opinion, atmospheric combustion appliances have no place in sealed attics. If you’re spending the money on a such a significant improvement to the building enclosure, you should also budget for sealed combustion equipment or go all electric. If you can’t do it all at once, at least install low-level carbon monoxide monitors and start saving for your HVAC retrofit.

Related Articles

The #1 Question to Ask before Putting Spray Foam in Your Attic

5 Reasons Bath Fans Have Such Poor Air Flow

Will Open-Cell Spray Foam Insulation Really Rot Your Roof?

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 24 Comments

Comments are closed.

And expanding just a bit

And expanding just a bit further, even the knock down vent pipe, at six inches in diameter would be woefully inadequate for a typical furnace’s demand for combustion ventilation air.

And expanding just a bit

And expanding just a bit further, even the knock down vent pipe, at six inches in diameter would be woefully inadequate for a typical furnace’s demand for combustion ventilation air.

If ever there were a perfect

If ever there were a perfect use for a ducted or ductless mini-split… this is it. Three mini-heads in my sealed attic, ductless for attic itself, two ducted for the lower floor. Works great.

So, they create a nice tight

So, they create a nice tight attic, then punch a 4 or 6-inch hole to the outside. No longer a sealed attic. One step forward, one step backward.

The same goes for crawlspaces

The same goes for crawlspaces. Combustion devices (air and water heating)complicate supply and exhaust, making it difficult to separate the venting and intake. Adding these penetrations along with drain lines affects the architectural appearance.

If ever there were a perfect

If ever there were a perfect use for a ducted or ductless mini-split… this is it. Three mini-heads in my sealed attic, ductless for attic itself, two ducted for the lower floor. Works great.

So, they create a nice tight

So, they create a nice tight attic, then punch a 4 or 6-inch hole to the outside. No longer a sealed attic. One step forward, one step backward.

The same goes for crawlspaces

The same goes for crawlspaces. Combustion devices (air and water heating)complicate supply and exhaust, making it difficult to separate the venting and intake. Adding these penetrations along with drain lines affects the architectural appearance.

I had a client who had built

I had a client who had built a million dollar plus home and paid a premium to have foam insulation and an encapsulated attic. A huge attic at that. <br /> <br />Unfortunately, the HVAC contractor punched eight huge code-compliant holes (two each) for 4 atmospheric furnaces. On top of that, the 4 air conditioners were oversized. The home grew lots of mold in the first year. But this story has a happy ending. <br /> <br />The builder, realizing his error, agreed to pay to replace all four 80%/13 SEER systems. I specified significantly smaller 15 SEER heat pumps, one of which is dual fuel with a 95% sealed combustion furnace. Since then, the client reports very acceptable RH levels during summer and lower energy bills overall.

I had a client who had built

I had a client who had built a million dollar plus home and paid a premium to have foam insulation and an encapsulated attic. A huge attic at that.

Unfortunately, the HVAC contractor punched eight huge code-compliant holes (two each) for 4 atmospheric furnaces. On top of that, the 4 air conditioners were oversized. The home grew lots of mold in the first year. But this story has a happy ending.

The builder, realizing his error, agreed to pay to replace all four 80%/13 SEER systems. I specified significantly smaller 15 SEER heat pumps, one of which is dual fuel with a 95% sealed combustion furnace. Since then, the client reports very acceptable RH levels during summer and lower energy bills overall.

ALL gas heaters comes with

ALL gas heaters comes with combustion blowers. <br /> <br />I do agree with the article, but <br />these are not atmospheric, natural heaters. <br />

<b>mike</b>: I

<b>mike</b>: I think maybe we use slightly different definitions of the term "atmospheric combustion appliance." How I use it, which is consistent with what I’ve seen almost everywhere else, is that an atmospheric combustion appliance is one that pulls its combustion air from the surrounding space. That’s true of natural draft, induced combustion (fan assisted), and induced draft appliances. <br /> <br />Also, see the followup I wrote to this article: <br /> <br /><a href="http://energyvanguard.com/blog-building-science-HERS-BPI/bid/77743/The-Problem-of-Getting-Air-for-Atmospheric-Combustion-Appliances"><i>The Problem of Getting Air for Atmospheric Combustion Appliances</i></a> <br /> <br />There I go into more detail about what code says about venting atmospheric combustion appliances. <br /> <br /> <br />

ALL gas heaters comes with

ALL gas heaters comes with combustion blowers.

I do agree with the article, but

these are not atmospheric, natural heaters.

mike: I

mike: I think maybe we use slightly different definitions of the term “atmospheric combustion appliance.” How I use it, which is consistent with what I’ve seen almost everywhere else, is that an atmospheric combustion appliance is one that pulls its combustion air from the surrounding space. That’s true of natural draft, induced combustion (fan assisted), and induced draft appliances.

Also, see the followup I wrote to this article:

The Problem of Getting Air for Atmospheric Combustion Appliances

There I go into more detail about what code says about venting atmospheric combustion appliances.

Everyone is partially correct

Everyone is partially correct but partially wrong. And, we live in a world where an insulation contractor (hopefully one with true building science practices in mind) needs to earn a profit while balancing it with doing it right job for the client and health and safety. True, a closed combustion or heat pump would be preferable but spending $20k for spray foam AND a new system (especially when the current system may be just fine) is not practical and has no payback and I just can’t advise this as a building science expert. Two, mechanical building code and NFPA dictates how much combustion air is required and as long as we stick to it (without permanently opening a hole) then we’re following code. And don’t we have 50 gallon gas water heaters, gas stoves, and sometimes even furnaces in conditioned space quite often and code allows this per their mathematical required volume of air needed? Based on the volume of the attic, it may – per code and the math – be adequate (and especially with all the attic floor penetrations on a typical retrofit). However, for health & safety reasons, per code, and that extra little warm cozy touch we install a CO detector and have an experienced mechanical contractor install a motorized damper that opens to allow outside air in ONLY when the furnace turns on which would of course be during winter time only – very few days in the South – and when its relatively dry outside. It remains closed year long and opens only during the few minutes that the furnace is on. CO detector takes care of the extra safety touch. The motorized damper takes care of code and maintaining an enclosed attic environment. And we’re not asking the homeowner to triple/quadruple the price of the job with a new HVAC system to give him his increased level of efficiency with the properly spray-foamed R-20+ roofline. The client gets a per code job done right and we stay in business by satisfying all the previous comments. Im surprised we’re the only ones doing this where were located but we still are apparently. Of course with new construction its a totally different game and obviously needs to be a closed combustion or heat pump from the get-go.

Everyone is partially correct

Everyone is partially correct but partially wrong. And, we live in a world where an insulation contractor (hopefully one with true building science practices in mind) needs to earn a profit while balancing it with doing it right job for the client and health and safety. True, a closed combustion or heat pump would be preferable but spending $20k for spray foam AND a new system (especially when the current system may be just fine) is not practical and has no payback and I just can’t advise this as a building science expert. Two, mechanical building code and NFPA dictates how much combustion air is required and as long as we stick to it (without permanently opening a hole) then we’re following code. And don’t we have 50 gallon gas water heaters, gas stoves, and sometimes even furnaces in conditioned space quite often and code allows this per their mathematical required volume of air needed? Based on the volume of the attic, it may – per code and the math – be adequate (and especially with all the attic floor penetrations on a typical retrofit). However, for health & safety reasons, per code, and that extra little warm cozy touch we install a CO detector and have an experienced mechanical contractor install a motorized damper that opens to allow outside air in ONLY when the furnace turns on which would of course be during winter time only – very few days in the South – and when its relatively dry outside. It remains closed year long and opens only during the few minutes that the furnace is on. CO detector takes care of the extra safety touch. The motorized damper takes care of code and maintaining an enclosed attic environment. And we’re not asking the homeowner to triple/quadruple the price of the job with a new HVAC system to give him his increased level of efficiency with the properly spray-foamed R-20+ roofline. The client gets a per code job done right and we stay in business by satisfying all the previous comments. Im surprised we’re the only ones doing this where were located but we still are apparently. Of course with new construction its a totally different game and obviously needs to be a closed combustion or heat pump from the get-go.

Let me start by saying how

Let me start by saying how much I have learned from this blog. Great information on many issues.

I have some questions related to ventilating a home with spray foam insulation and would really value the opinions of you guys.

I work in the HVAC control field, particularly DDC. I am in the process of building a 2200 sq ft. home in South Georgia. I have chosen to go with spray foam insulation (SPF) in the roof deck along with SPF in the walls. I am having a Carrier variable speed split systems installed that will be duct in the attic. I am creating a completely sealed attic space. Over the past month I have really tried to educate myself on the standards that need to be observed when utilizing SPF and have some concerns about ventilating my house for air changes.

My contractor is recommending that I install a stand alone ERV that mounts in the ceiling (FV-04VE1). Because I’m in the industry I am not an easy sell and I have ALOT of questions. Why cant I just install a differential pressure sensor (DPS) in my living space and a DPS in my crawlspace that is vented and control an outside air damper that is ducted into my return. I could create a slight positive pressure on my home and maintain it when different exhaust are called for in my home. Would I be able to not worry as much about the air changes if I went this route.

Another option…I can have an ERV installed in the following manner: Duct the ERV supply and return to my AHU return. This would provide my air changes, then put a damper on the exhaust side of the ERU and control it to building pressure.

I had one offer from a different mechanical contractor to just duct in a fresh air intake to my return duct and set the damper and leave it. I don’t quite like this idea due to the humidity and heat in South GA. I think the smart thing to do would be temper the air before feeding it to my return but I really want to control the ERU. I cant see putting that extra load on my unit. I’m paying all the $$$ for a 18 Seer unit and SPF to save on the power bill.

I would love to hear some opinions on this and preferably in the next couple of days. I am done with framing and the electricians are going to begin wiring next week.

@Cole, this article is about

@Cole, this article is about atmospheric furnaces in encapsulated attics. Your question is about ventilation strategies.

Tying an ERV into your main duct system is probably not the best idea, especially that particular model. It has almost no available static.

Given your immediate time frame, I recommend you seek professional advice from someone who doesn’t have a conflict of interest. You are welcome to contact me through my website. (Note: this is not an offer for free consulting.)

Let me start by saying how

Let me start by saying how much I have learned from this blog. Great information on many issues.

I have some questions related to ventilating a home with spray foam insulation and would really value the opinions of you guys.

I work in the HVAC control field, particularly DDC. I am in the process of building a 2200 sq ft. home in South Georgia. I have chosen to go with spray foam insulation (SPF) in the roof deck along with SPF in the walls. I am having a Carrier variable speed split systems installed that will be duct in the attic. I am creating a completely sealed attic space. Over the past month I have really tried to educate myself on the standards that need to be observed when utilizing SPF and have some concerns about ventilating my house for air changes.

My contractor is recommending that I install a stand alone ERV that mounts in the ceiling (FV-04VE1). Because I’m in the industry I am not an easy sell and I have ALOT of questions. Why cant I just install a differential pressure sensor (DPS) in my living space and a DPS in my crawlspace that is vented and control an outside air damper that is ducted into my return. I could create a slight positive pressure on my home and maintain it when different exhaust are called for in my home. Would I be able to not worry as much about the air changes if I went this route.

Another option…I can have an ERV installed in the following manner: Duct the ERV supply and return to my AHU return. This would provide my air changes, then put a damper on the exhaust side of the ERU and control it to building pressure.

I had one offer from a different mechanical contractor to just duct in a fresh air intake to my return duct and set the damper and leave it. I don’t quite like this idea due to the humidity and heat in South GA. I think the smart thing to do would be temper the air before feeding it to my return but I really want to control the ERU. I cant see putting that extra load on my unit. I’m paying all the $$$ for a 18 Seer unit and SPF to save on the power bill.

I would love to hear some opinions on this and preferably in the next couple of days. I am done with framing and the electricians are going to begin wiring next week.

@Cole, this article is about

@Cole, this article is about atmospheric furnaces in encapsulated attics. Your question is about ventilation strategies.

Tying an ERV into your main duct system is probably not the best idea, especially that particular model. It has almost no available static.

Given your immediate time frame, I recommend you seek professional advice from someone who doesn’t have a conflict of interest. You are welcome to contact me through my website. (Note: this is not an offer for free consulting.)

Why in the discussion of

Why in the discussion of attic retrofits & gas furnaces does the conversation always focus on the combustion air the furnace needs to operate, and never seem to hear about the safety side of it. The scary fact is that you have a unit that is emitting carbon monoxide, and yet there is no concern about the safety of the building occupant. Fact is that no matter what you do to that unit, the carbon monoxide levels are going to increase in that building assembly/envelope. Seems like people are missing out on the real dangers here. I am a spray foam installer in DFW, and it is amazing the misunderstanding about the real concerns of a gas furnace in an encapsulated attic assembly. Long story short is that people’s lives are being unnecessarily put at risk. Consult with any major manufacturer for yourself about it all whether it be foam manufacturer or HVAC manufacturer.

Why in the discussion of

Why in the discussion of attic retrofits & gas furnaces does the conversation always focus on the combustion air the furnace needs to operate, and never seem to hear about the safety side of it. The scary fact is that you have a unit that is emitting carbon monoxide, and yet there is no concern about the safety of the building occupant. Fact is that no matter what you do to that unit, the carbon monoxide levels are going to increase in that building assembly/envelope. Seems like people are missing out on the real dangers here. I am a spray foam installer in DFW, and it is amazing the misunderstanding about the real concerns of a gas furnace in an encapsulated attic assembly. Long story short is that people’s lives are being unnecessarily put at risk. Consult with any major manufacturer for yourself about it all whether it be foam manufacturer or HVAC manufacturer.

You’re right, Adam. I should

You’re right, Adam. I should have said more about that in this article, but I’m wondering if you missed the last sentence of the article: “If you can’t do it all at once, at least install low-level carbon monoxide monitors and start saving for your HVAC retrofit.” I’ve written about combustion safety many times in this blog, so your statement about there being “no concern about the safety of the building occupant” certainly isn’t true here.

Now, having said that, the chances of backdrafting a furnace with an inducer fan (like the ones in the article) are pretty small unless it’s common-vented with a natural draft water heater. That means the CO produced in the combustion will almost never have a chance to get into the living space.

Still, any house with combustion appliances or an attached garage should have a low-level CO monitor. (See my link at the end of the article for the difference between a low-level monitor and a UL certified detector.)

You’re right, Adam. I should

You’re right, Adam. I should have said more about that in this article, but I’m wondering if you missed the last sentence of the article: "If you can’t do it all at once, at least install low-level carbon monoxide monitors and start saving for your HVAC retrofit." I’ve written about combustion safety many times in this blog, so your statement about there being "no concern about the safety of the building occupant" certainly isn’t true here.

Now, having said that, the chances of backdrafting a furnace with an inducer fan (like the ones in the article) are pretty small unless it’s common-vented with a natural draft water heater. That means the CO produced in the combustion will almost never have a chance to get into the living space.

Still, any house with combustion appliances or an attached garage should have a low-level CO monitor. (See my link at the end of the article for the difference between a low-level monitor and a UL certified detector.)