5 Tips for Sizing an Air Conditioner

So you’re getting a new air conditioner! Well, what size should you get? Unfortunately, too many contractors use only one input for sizing an air conditioner. Yup. To them, it’s just a matter of floor area. Forget the windows, the insulation levels, and the air leakage. All you need to do is make sure you have one ton of air conditioning capacity for each 500 square feet of floor area. Heck, even Good Housekeeping did better than that.

With that warning, let’s look at some tips you can use to make sure you get a properly sized air conditioner.

1. Know how much cooling you need

For new homes that haven’t been built yet, there’s only one good way to size an air conditioner. You need to have a load calculation done. (The same applies to heat pumps, furnaces, boilers, or any kind of heating and cooling equipment.) For homes in the US, the standard way to do this is to use Manual J, the load calculation protocol from the Air Conditioning Contractors of America (ACCA).

For existing homes, you can use Manual J as well. As long as you get accurate information for the house to plug into the software, the results will help you size the air conditioner appropriately. But you may have a better option.

If the air conditioner is still working well, you can measure the runtime when your home is at “design conditions.” That means you see how many minutes per hour the AC runs when you keep the thermostat at your desired setpoint (or 75 °F per ACCA) and the outdoor temperature is at the outdoor design temperature for your location.

Even if—or especially if—you’re still years away from replacing an air conditioner, you can use this technique to see how well your current system cools the house. I did this in the condo I lived in a decade ago.

2. Don’t oversize

One of the results of using floor area to size an air conditioner is that it almost always results in oversizing. Air conditioners that are oversized have several drawbacks:

- Higher upfront cost

- Noisier

- May lead to reduced comfort

- Less ability to dehumidify

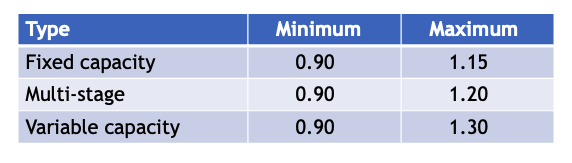

Here are the sizing limits from ACCA Manual S.

As you can see, the most oversizing allowed in this standard is 30 percent. For fixed capacity systems, which is what the great majority of homes have, the limit is only 15 percent. Because of the realities of available air conditioner sizes, you may end up more than 15, 20, or 30 percent above the cooling load. Building codes usually allow you to go to the next available size if the lower size won’t meet the Manual S sizing limits.

3. Don’t be (too) afraid of undersizing

Here’s the thing. A Manual J load calculation still results in a cooling load that’s about 10 to 20 percent higher than the cooling the house actually needs. So if you undersize according to the calculated, you may be just about right. With a smaller system, you can invert that list of disadvantages above and have an air conditioner that’s less expensive, quieter, creates more comfort, and removes more humidity.

I should know. I’ve done it in my own house. I have variable capacity Mitsubishi heat pumps that I had installed in 2019. We’ve been through plenty of days where we hit design conditions. We’ve also been through a heat wave and an arctic blast, both in 2022. And guess what? We did just fine.

Now, take another look at that table in the previous section. Notice that it also indicates a minimum air conditioner capacity that’s 10 percent below the cooling load.

I’m not saying that undersized systems always lead to comfort and efficiency. Yes, there are cases where a new air conditioner is undersized too aggressively or without proper load calculations. Replacing the air conditioner is one way to solve that problem, but you also could look for ways to reduce the cooling load.

4. Long run-times are a good thing

A properly sized air conditioner should run just about continuously at the design conditions. Why? Because when you follow the ACCA Manual J and Manual S protocols, the air conditioner capacity should be pretty close to the cooling load. (See that table above.)

When the AC is running 60 minutes per hour, those long run-times help in several ways. They create constant mixing of the air in the house. That leads to more uniform temperatures. Long run-times also do better at reducing the humidity. And if you’ve got a good setup with high-efficiency filtration, you get the added bonus of better indoor air quality.

5. Consider multi-stage or variable capacity

A fixed-capacity air conditioner operates at only one speed. It’s either on or its off. There is no in-between. The main reason so many air conditioners get oversized is that contractors don’t want to get called back because it’s not cooling the house. And they don’t have control over all the variables, like air leakage and occupant behavior.

But what if you could size the air conditioner to meet the design conditions and then have another gear to shift into that would do more cooling? Part-load conditions are what our homes experience far more often than design or extreme loads. So, what if you could undersize the air conditioner so that it would meet that lower cooling load?

Such an instrument is the Turbo-Thermo-Encabulator Max. Oops! Sorry. That’s something else. What I’m really talking about here is a multi-stage or variable capacity air conditioner. They can run at low speed most of the time and the shift or ramp up when necessary.

Beware, though. This more advanced equipment isn’t a panacea. In humid climates, you may be more likely to need supplemental dehumidification with this type of equipment because it often has less capacity to remove moisture. And sometimes it’s done incorrectly, creating more problems. One thing to be aware of if you go this route is that it’s still important not to oversize. Quite a few people believe there are no downsides to oversizing, but that’s just not true.

There you have five good tips for sizing an air conditioner. And let me leave you with one final note. The load calculation doesn’t tell you what size air conditioner you need. It just tells you how much cooling you need. The Manual S protocol takes you that next step to sizing the air conditioner properly.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a popular book on building science. He also writes the Energy Vanguard Blog. For more updates, you can subscribe to our newsletter and follow him on LinkedIn.

Related Articles

Air Conditioner Sizing: Load Calculations vs Rules of Thumb

How to Read Manual J Load Calculation Reports

My Undersized Mini-Split Heat Pump in a Heat Wave

My Big Fat Oversized Air Conditioner

How Many Tons of Air Does Your HVAC System Move?

Comments are welcome and moderated. Your comment will not appear below until approved.

This Post Has 21 Comments

Comments are closed.

Measuring runtime at design temp seems like a pretty straightforward method to verify correct sizing. Is there a downside to down-sizing a unit with an existing duct system, such as less effective distribution?

John: A benefit of downsizing the unit on an existing duct system is that lower air flow may make it work better. Many duct systems are undersized and have too much resistance. But most registers are oversized, so putting in a smaller system with less air flow will mean they’re even more oversized.

In many cases there is no downside.the exception would be if and that’s a strong IF the duct system is grossly oversized and located in a unconditioned space. The reality is most duct systems are pushing somewhere near 700-900 FPM so going smaller will in many cases lead towards quieter more efficient equipment.

Another side effect would be even with clossley sized equipment is you would get some reheat to drive longer run times further improving MRT & Dehumidification.

I would like to challenge Allison’s statement: “In humid climates, you may be more likely to need supplemental dehumidification with this type of equipment because it often has less capacity to remove moisture. ”

Some early multi-stage equipment did not reduce the indoor airflow rate when running at low capacity, thus there was a significant reduction in latent capacity. Most of us figured this out and now run appropriate airflow rates at all capacities, thus maintaining latent capacity.

Roy: I think it all depends on the particular equipment. I believe you manufacturers figured out the big problems, like the one you mentioned. But variable capacity systems generally have higher sensible heat ratios (SHR). The two Mitsubishi variable capacity heat pumps in my house, for example, both have SHRs above 0.9. The submittal for the 6,000 BTU/hr ductless unit says it has an SHR of 0.96. Now, I’m pretty sure those numbers aren’t accurate because my house stays drier than you’d think based on those numbers.

Also, some mini-splits don’t decrease the air flow enough to keep the air flow rate per unit of capacity (cfm/ton) the same. Higher cfm/ton means less dehumidification.

My comments were about ducted equipment. Most ducted equipment manufacturers that I know try to have lower SHR’s, typically 0.70 to 0.75. Since they have to rate at higher external static pressures than ductless units, it generally doesn’t help to go to higher airflow rates because the blower power goes up faster than the compressor power comes down. Most ducted equipment also has user settings for reducing the airflow from 400 cfm/ton down to 350 or even lower to get better latent capacity in humid climates. Few installers take advantage of this.

There was an interesting paper at the Purdue Conference last summer that compared the field performance of a fully ducted system to a ductless multi-split system in the same house. The ducted system had higher latent capacity, better humidity control, and higher overall efficiency than the ductless system.

This comparison was ton for ton ? Do you have a link to the paper

Both systems were sized for that particular house, which was a research house on the University of Texas-Tyler campus. I believe the author was Nelson Fumo. I am not able to provide a link to this paper. You would have to contact Purdue University directly to get access to it.

https://docs.lib.purdue.edu/cgi/viewcontent.cgi?article=3320&context=iracc

“Few installers take advantage of this”

Not only did my installer not take advantage of this, they recommended against it. On my York HMH7 (variable capacity inverter system) with variable speed air handler (York AVC36), they insisted that I must keep the air handler set at 1200 cfm for this 3 ton system, because you cannot even consider deviating from 400 cfm/ton. I will concede that this is not a communicating system (it uses a standard 24 volt thermostat), but nonetheless, it seems it should be able to adjust itself within a safe operating range. Unfortunately, I could not get any guidance from the installer about what this range may be. I would love to cut the air speed back to make the system quieter and dehumidify better.

Probably a setting on the setup to adjust fan speed. Mine has two” “normal” and “quiet” Quiet seems to be on fan speed lower than Normal

Great concise article!

Thank you for the interesting article, topics that has always interested me. I do EnerGuide evaluations for homes in Ontario and right now we’re recommending heat pumps for home owners looking to ungrade their heating system and electrify. As we are heating dominant here, the cooling loads tend to be smaller than the heating loads in a typical home, when a homeowner installs a heat pump sized to heat their home, naturally it results in an oversized ‘AC’. We also recommend variable capacity units but as stated in the article this doesn’t fully solve the issue. On top of issues with humidity levels are there other unforseen consequences of this type of upgrade?

Do you have any rules of thumb for tons per square foot?

I would love to ask a customer 3 questions:

1. How many square feet is your house?

2. What year was it built?

3. How many tons of AC do you have?

If they say … 2,500, 1968, 7 tons … I could say … with proper air sealing and with some added equipment (especially dehumidification), we could get you down to … 4 tons?

BTW — that’s my house. And I live in Dallas. 🙂

Didn’t realize this comment hadn’t been approved when I posted the comment below. 🙂

Allison – Enjoyed chatting at your book event in Austin in May!

(Thought I posted this question the other day … so if I posted it on another blog, sorry for the repetition.)

This post gets to one of my key questions. I’m in roofing and solar and am learning the home performance side of things. Bought a blower door and am learning to use it.

My question is about a rule of thumb or set of guidelines for helping homeowners understand the appropriateness of their current level of cooling. I’m in Dallas, and we oversize EVERYTHING! 🙂

What inputs would you need to give a reasonable response?

My thought is

1. Size of the home

2. Year the home was built

3. Tons of AC

Let’s use my home.

1. 2,535

2. 1966

3. 7 tons (2 ton and 2.5 ton for downstairs. 2.5 ton for upstairs)

At 1 ton per 362 square feet, that can’t be great. I think I’m oversized at my current level of air sealing. Once I run my blower door test and have that number (I’m betting north of 20), I can come up with a reasonable target.

Without more info though, could you say something like … “A house that age and size should be at 500 sqft/ton … or 700 sqft/ton … or ???

Appreciate any and all input.

Best,

Travis Jones

I recently got quotes for a new Carrier Infinity natural gas furnace and heat pump for a house in Minnesota. The furnace has a DC variable speed blower and modulated gas capability. One of the salesman stated that they use a computer program that imports previous energy usage data from the utility companies to determine the size unit needed. He stated that Model J heat load calculations were not needed. Just wondering if anyone has any thoughts on the use of this type of program? Thanks.

Nice article, but as a licensed HVAC contractor myself, it pains me to hear your perception and experience with contractors. It is our job to perform load calculations for all installations and ensure maximum efficiency and durability. If you run into a company that does not live up to this standard of quality, then you aren’t getting the value you are being promised.

On a second note, your system is only as good as it’s weakest link. Undersized ducts combined with oversized systems make for a tragically inefficient and uncomfortable system. Very little attention is paid to duct sizing, and that requires additional calculating by the contractor. Visual inspections inform you of any leakage, poor insulation, and overall poor design issues.

I agree wholeheartedly that the consumer should be as well informed as possible. This allows for a more productive conversation with the contractor, leading to a greater level of overall satisfaction and pride of ownership.

I have a carrier infinity furnace and heat pump/AC. We sized it for minimal cooling loads only to find out that determined max airflow by the infinity variable blower. Had I go up a ton in size to get enough airflow to cool bedrooms.

Interesting, can you share your match-up models? And what your design vs actual cfm output was?

I am only a homeowner so I don’t know what am hvac contractor would, but the carrier infinity I own (2018 gas furnace and heat pump AC) has a range of cfm, and that range was defined when the size of the AC was put into the computer. Even with the best energy settings I had too many registers for the cfm the blower would produce and the airflow out each register was so low in two bedrooms that they wouldn’t cool. Sizing up the AC seemed to fix the problem as then the cfm increased. Sorry I can’t be more helpful