Lstiburek Has New Ventilation Standard—Resistance May Not Be Futile

“ASHRAE 62 is the only national consensus standard document there is. Follow 62.2. Resistance is futile.” So said Dr. Max Sherman last summer in a presentation for the Building America Technical Update meeting. (Download pdf official report here.) That statement about resistance being futile isn’t generally a line you want pinned to you if you’re trying to win hearts and minds, but I asked Sherman about it. There’s a whole lot more to the story, too, so read on.

“Resistance is futile.” Martin Holladay dug up this quote for his article on the battle over residential ventilation recently. When I asked Sherman about it, he told me that he used it to “indicate that rather than try to make 62.2 go away it was better to work the ASHRAE process to propose improvements.”

At first, I thought his saying that “Resistance is futile” was quite illuminating†, perhaps putting him in league with the Borg. I wasn’t at the meeting, however, but according to Sherman, “The tone was light and bantering not overbearing or borgish.”

The stage is set

The details about the residential ventilation battle have been covered extensively here and at Green Building Advisor several times already this year (see my list of related articles below), including Martin Holladay’s recent article, How Much Fresh Air Does Your Home Need? Martin’s article has dozens of comments, including at least 9 from people at the highest levels of the battle (Joe Lstiburek, Paul Francisco, and Paul Raymer). And of course, you should read Joe’s article, Unintended Consequences Suck, for his take on how ASHRAE has gone off-course with the 62.2 standard.

To recap, ASHRAE 62.2 is the residential ventilation standard used by some programs and building/energy codes. It uses either a formula or a table to determine the amount of mechanical ventilation needed in low-rise residential buildings. The 2010 version automatically included an infiltration credit of 2 cfm per 100 square feet of conditioned floor area. The 2013 version took it out and made homes qualify for any infiltration credit. Thus, the 2013 version yields higher ventilation rates than the 2010 version.

Many people already thought the 2010 version called for ventilation rates that were too high, especially for humid climates. A 3 bedroom, 2500 square foot house would need 55 cfm according to 62.2-2010. The same house would need 105 cfm in the 62.2-2013 version.

In addition, Joe Lstiburek has argued that a blower door can’t tell you how much ventilation you need in a house. “Fact is that you don’t know where the holes are with a blower door test. You don’t know the pressures across those holes. You don’t know the nature of the holes,” wrote Joe in a comment addressed to Michael Blasnik in that article.

Lstiburek also pointed out in another comment that we don’t have research data relating blower door results, ventilation rates, and indoor air quality. “No epi studies were done…This has all been guess work. No health studies exist. No baselines have ever been measured.” Without data, he says, any ventilation rates we propose are mere guesses.

Suffice it to say that the battle has been heated. Max Sherman and Joseph Lstiburek, both with PhDs and heavy credentials in the world of building science, have been on opposite sides of the issue for years. Now, it’s about to enter a new phase.

Building Science Corporation’s new ventilation standard

Sherman may be correct about ASHRAE 62.2 being the “only national consensus standard document there is,” but that doesn’t mean that resistance is futile. Joe Lstiburek and Building Science Corporation (BSC) are about to release their own residential ventilation standard. That’s right. We’re about to have competing standards in the marketplace. As Joe told me recently, “In the marketplace of ideas, better ideas will win.”

Here’s a quick overview of the features in BSC’s new ventilation standard, which is still in draft form:

- It’s for new, code-compliant homes only.

- The formula is similar but yields lower ventilation rates than ASHRAE 62.2-2013.

- The rate gets modified by 3 parameters: balance, distribution, and mixing.

- There’s no infiltration credit.

- There’s no adjustment in ventilation rates for different climate zones.

- There’s no provision for ventilation based on sensors of CO2, relative humidity, or any other indoor air components.

- It has other requirements similar to 62.2 (intermittent ventilation, local exhaust, garage separation, filtration…)

New homes. Having it apply only to new homes throws the infiltration credit out the window and leaves existing homes on their own regarding the need for mechanical ventilation. That makes it easier to have a good standard because it isn’t trying to do too many things.

Ventilation rates. Here’s the main formula:

Qv = 0.01 Afloor + 7.5 (Nbr + 1) — Draft BSC standard

To say it in words, the ventilation required (Qv) is 1 cfm for each 100 square feet of conditioned floor area (Afloor) plus 7.5 cfm per person. The number of people is defined as the number of bedrooms (Nbr) plus 1.

This formula is identical to the formula for 62.2-2010. It’s lower than 62.2-2013 because that standard requires:

Qv = 0.03 Afloor + 7.5 (Nbr + 1) — ASHRAE 62.2-2013

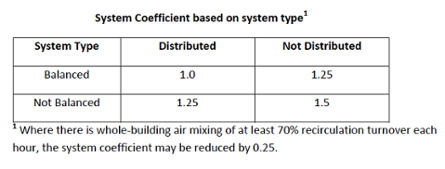

Now that’s not the final result for the BSC ventilation rate because you have to factor in what type of ventilation system is being installed. If it’s a balanced system and the air is distributed, you use the number straight from the formula. If it’s balanced but not distributed (defined as delivering ventilation air to the common area and each bedroom), multiply by 1.25. If it’s not balanced but distributed, you multiply by 1.25. If it’s neither balanced nor distributed, you multiply by 1.5. The table below shows how it works.

Note also that in addition to balance and distribution, mixing of the air in the home can affect the ventilation rate. If the home has all three—balanced and distributed ventilation with air-mixing—it knocks the required ventilation rate down by 25%. The result of all this is that that 3 bedroom, 2500 sf home, which would need 55 cfm to meet 62.2-2010 and 105 cfm to meet 62.2-2013, would need anywhere from 41 cfm to 83 cfm under the BSC standard.

Infiltration credit. This has been one of the thorniest issues in 62.2. It’s basically there because of weatherization programs that air-seal existing homes and need to know at what airtightness should they add a mechanical ventilation system. As I mentioned above, Lstiburek disagrees with the premise that a blower door can tell you how much ventilation a home needs. They sidestep the whole issue of existing homes, though, by making a standard for new homes only.

In 62.2, the infiltration credit applies to both new and existing homes. The committee has decided that air leaking into the house through random holes in the building enclosure can qualify as ventilation air. Even though that standard is titled, Ventilation and Acceptable Indoor Air Quality in Low-Rise Residential Buildings, there’s no IAQ justification for allowing infiltration to count as ventilation. It could be coming from the garage or the attic or the vented crawl space. Air from those places generally makes indoor air quality worse, not better.

Climate zones and sensors. The new BSC standard includes no provisions for adjustments based on climate zones. According to Lstiburek, you can make a convincing argument that cold climates need more ventilation, but you also can make a convincing argument that hot, humid climates need more ventilation. In the end, he says, it’s best to have a one-size-fits-all standard and leave the variations to the occupants.

On the topic of CO2 or relative humidity sensors controlling the ventilation systems, Joe wrote a while back, “CO2 and humidity are not good proxies for good air quality. They are better than nothing. But not much better.” So the BSC standard has no provisions for changing the ventilation rate based on those factors.

Kitchen and bath exhaust fan. One difference between ASHRAE and BSC in the local exhaust is that the kitchen and bathrooms must have standalone exhaust fans only. Their standard does not allow continuous exhaust at a lower rate as does 62.2. “Get the stuff out quickly and effectively. Then turn these fans off,” Joe said.

Ventilation quality gets recognized

One of the most important aspects of this new standard is that it recognizes that not all ventilation systems are created equal. Exhaust-only ventilation relies entirely on random leaks in the building enclosure. Supply-only systems have numerous problems themselves. Balanced systems are the best, but they’re more expensive.

ASHRAE 62.2 pays no heed to how well a system ventilates, however. Its main focus is on ventilation rates, which Lstiburek contends are not based on solid science. The new BSC standard “penalizes poor systems and rewards good systems,” Joe said. If the system “sucks and blows,” you can use a lower rate. If it sends the ventilation air throughout the house, you can use a lower rate. If the air in the house gets mixed well, you can use a lower rate.

The launch of BSC-01

As I mentioned above, this standard is still in draft form and hasn’t been released yet. Some details may change before the final release, but the bones of it are mostly in place now. The official launch of Building Science Corporation’s first standard, BSC-01, is set for early August, during the Westford Symposium on Building Science (affectionately known as Building Science Summer Camp, the official meeting of the Building Science “Illuminati†“).

Standards, codes, and programs

Standards are recommendations only. A lot of organizations make standards. Sometimes different organizations make competing standards. Take the case of BPI’s existing home energy audit standard and the flack they’ve gotten from ACCA, ICC, AHRI, and 10 other organizations. What matters is which standard gets adopted by building codes and programs.

Currently, ASHRAE 62.2 is used in several places, mainly because it’s been the only show in town. It’s deeply embedded in the ENERGY STAR new homes program, with many requirements therein taken straight from 62.2-2010.

Game on

As with the competition for adoption between BPI’s and ACCA’s energy audit standards, soon BSC will be giving ASHRAE some competition for residential ventilation standards. You can read a lot of the details of the debate between Max Sherman and Joe Lstiburek in Martin Holladay’s article, but so far it’s all been over what should and should not be included in ASHRAE 62.2.

With a competing standard soon to appear in the marketplace, organizations looking for guidance will have alternatives beyond just adopting 62.2 or not. Joe is confident that his new standard will get adopted in more places than 62.2.

In fact, I think he’s really looking forward to the battle. His response to Max Sherman’s statement that “resistance is futile” is:

“Game on.”

See these two followup interviews, too:

Interview with Dr. Joe Lstiburek — The Ventilation Debate Continues

ASHRAE 62.2 Committee Chair Predicts Confusion & Frustration from BSC-01

Related Articles

Residential Ventilation Smackdown — The Battle Over Simplicity

A Blower Door Can’t Tell You How Much Mechanical Ventilation You Need

Why Do Airtight Homes Need Mechanical Ventilation?

How Much Fresh Air Does Your Home Need? by Martin Holladay, Green Building Advisor

Unintended Consequences Suck by Joseph Lstiburek, Building Science Corporation

Footnote

† Max Sherman has made other comments that aren’t helpful to his cause either. In an ongoing discussion on ventilation in the Building Science Community group on LinkedIn, he’s taken to calling unspecified opponents of his ideas the “Illuminati.” For example, in discussing odors, he wrote that “the kind of sub-standard system certain illuminati argue for would be fine” if controlling odors were the only necessity. So first he talks like a Borg, and then he accuses his opponents of being part of a secret society bent on controlling world affairs.

This Post Has 16 Comments

Comments are closed.

Interesting &

Interesting & surprised about the size – especially as Joe is one that sizes things to 62.2.10 & then rolls it back so it only runs 50 or 60% of the time.

>”and leaves

>”and leaves existing homes on their own regarding the need for mechanical ventilation”

“They sidestep the whole issue of existing homes, though, by making a standard for new homes only.”< Since a good part of the 62.2.10 revisions were done to help guide the weatherization and home performance market as homes got tightened up and it became possible to need mechanical in these situations what is the solution there? I remember in a thread a few years ago our good friend David Butler saying something like , “it is hard for me to imagine ever getting an existing home tight enough to need to add mechanical ventilation.” (David feel free to correct me if I am misquoting here) Is that what we are to assume Joe is saying by not addressing existing homes?

Hey Sean, I certainly don’t

Hey Sean, I certainly don’t claim to have read everything Joe has ever put in writing, but my read of his 50% approach was 50% of the recommend rate. Now averaged hourly, this could represent a 50% run time. But it just as easily (or even more easily) represent 50% of the continuous airflow rate–some equipment comes standard with these variable speed controls.

-M

Sorry Michael If I wasn’t

Sorry Michael If I wasn’t clear, but he makes sure that the unit can bring in necessary levels required by 62.2 & then sets it up to only run 50/60% of the time – if they feel stuffy it can be bumped up. (Kinda of curious how many need that)

Hey Sean,

Hey Sean,

You were clear. My point was that I’ve never heard Joe say to let systems run 50/60% of the time as the recommended approach.

When I’ve heard Joe say this, or seen him write it, I’ve seen him talk about designing capacity at 150% of 62.2 (2010) and delivering at 50% of 62.2. I’ve never heard him say that is to be met only by running 50% of the time. Yes, some units or controls could delivery 50% of the rate using strategy of adjusting run time. I’ve just never heard Joe say that run time was the recommended way or the only way to do it. Another way to get to 50% of 62.2 is by modulating the flow rate down to 50% of 62.2. This is very easy to do on unit designed with variable speed motors and controls–some of which are integral to units by design.

I like Joe’s design approach. I’m just not sure it requires the run-time approach you’ve mentioned, nor the implicit question accompanying it. (Nor that the run-time adjustment is actually a principal part of Joe’s approach.)

Cheers,

Mike

Sean L.:

Sean L.: Good point, Sean. I hadn’t thought to ask Joe about how this standard meshes with that statement.

Jeremy B.: No, I don’t think you can assume Joe believes existing homes will never need ventilation. He lives in a 19th century existing home that I’m pretty sure he’s tightened up enough to require a ventilation system. (I know it’s tight enough to pull air in through the fireplace downstairs when they turn on an exhaust fan upstairs.) I think he’s focusing on new homes here to make the standard simpler. Perhaps he’ll comment and clear it up.

M: Here’s what Joe said:

Our approach is to design and install a controlled ventilation system that is capable of ventilating at 1.5 times the current ASHRAE Standard 62.2 recommended rate, commissioning the system at 60% of the current ASHRAE Standard 62.2 recommended rate and giving control of the ventilation system to the occupant and telling them they can turn it up, turn it down or turn it off.

It’s from footnote #4 in his article, Just Right and Airtight.

AB: Yes, I’ve seen exactly

AB: Yes, I’ve seen exactly that from Joe–and heard him say it, too. And from comments on your very own blog he adds: “We recommend ‘sizing’ systems at 1.5 times the ASHRAE rate to provide a large ‘reserve’ capacity. We “commission” them at 0.5 times the ASHRAE rate and give control to the occupant.”

In the bit you quoted, you’ll notice it says “60% of the current ASHRAE Standard 62.2 recommended rate”. Key word: “rate”. Whether 50% or 60% (at least he’s consistent!) these statements say nothing about modifying run times, and I think it’s important to not imply that modifying run times is integral to the recommendation (unless it is! I just don’t think that’s what I’ve seen Joe say). I only raise it because some people will say the run time issue is important–and that risks distracting the conversation from the overall rate question.

(BTW, I don’t think that a 50% partial-hour run time is a horrendous approach.)

Or, since I’m doing a poor

Or, since I’m doing a poor job explaining what I mean, let me use an example. Looking at this

Our approach is to design and install a controlled ventilation system that is capable of ventilating at 1.5 times the current ASHRAE Standard 62.2 recommended rate, commissioning the system at 60% of the current ASHRAE Standard 62.2 recommended rate and giving control of the ventilation system to the occupant and telling them they can turn it up, turn it down or turn it off.

Let’s say for example that ASHRAE 62.2 says a home needs 100cfm of ventilation. (I work best with round numbers so I don’t overtax both brain cells.)

Using the above methodology to determine the desired flow at 60% of 100cfm, one could simply deliver 60cfm. No need to modify run times!

Of course, you could choose to run equipment delivering 100cfm for 36 minutes every hour and get the same hourly rate.

However, there is nothing about the recommended approach cited that inherently required reducing run times if you tackle this at the design stage with the appropriate equipment and controls selection.

I could, continuing the example and specifying a piece of equipment, use an Ultimate Air RecoupAerator, dial it back to 60cfm continuous ventilation and still have a nominal capacity at 200% of ASHRAE 62.2. I don’t think Joe would object to the excess capacity about the 150% level.

Now, I chose an ERV for the example. Can we have an argument about ERV v. HRV?

Cheers,

Mike

Mike: Yes,

Mike: Yes, that’s how I’ve always interpreted his statement, too. You change the rate, not the runtime.

When you run a ventilation fan intermittently, you need to increase the total volume of ventilation air because continuous ventilation is more effective. Both 62.2 and BSC-01 define the factors you have to use to increase the ventilation if you’re doing that. See Table 4.2 in 62.2 to see how they define it. BSC is still refining theirs.

“Without data, he says,

“Without data, he says, any ventilation rates we propose are mere guesses.”

Are we exchanging one set of guesses for another?

well…its official…I’m an

well…its official…I’m an energy nerd. I’ve been waiting all day to get home to read this article!!!

…and further articles concerning ventilation.

ashrae 62.2 just isn’t getting it done in my hot humid state.

not that I’ve relied upon ashrae for proper ventilation. instead

I’ve applied what Joe taught us in 2005.

build tight & ventilate right.

my projects have properly sized equipment, dehumidification stays at 50%, and fresh air is filtered, measured & ducted to return side of system.

with proper sized system vs ahu &/or two stage equipment..dehumidifiers aren’t always necessary as long as 50% RH is maintained.

the sheer arrogance of the statement ‘resistace is futile’…wth??

game on indeed…lets play!!

go joe!!

Jeremy wrote: <

Jeremy wrote:

> I remember in a thread a few years ago our good friend David Butler saying something like , “it is hard for me to imagine ever getting an existing home tight enough to need to add mechanical ventilation.” (David feel free to correct me if I am misquoting)

I shudder to think anyone remembers what I wrote several years ago! I can’t find the quote (I’m usually pretty good at digging up old stuff) but I suspect there’s missing context. I’ve been involved in several gut rehab projects that required MV. Beyond that, it obviously depends on how tight the house is to start with.

Here’s my take on the ventilation debate: I like Joe’s approach for new construction. Unlike the ASHRAE 62.2 Committee, BSC is not encumbered by the political process inherent in consensus standard writing.

As for older unsealed homes, as others have noted here and in other forums, there comes a point at which the prescribed MV rate would be overwhelmed by infiltration. That’s not to say that leaky homes will necessarily have good IAQ, but just that it doesn’t make sense to ventilate until and unless you get the home tight enough for it to actually do any good.

Unfortunately, there’s no way to define a threshold prescriptively that works for all homes. That’s why we have brains, and why we do research. More of both are needed.

Just a few quick thoughts as

Just a few quick thoughts as I catch back up on this – a friend of mine posted a picture of his first deck he built 11 years ago, which was a pretty good looking job. Would he build the same deck today or get the same response if it was one he built today – no due to more knowledge, changing codes, etc…

The same is true here – the field is building science & things / understandings change which is one reason I caution many to pay careful attention to the dates on BSC, GBA & other sites as they may not be the best / most current way to do things. While it maybe fun occasionally to play a do you remember when you said…

As for adjusting the rate versus flow, I am actually sure I heard Joe say he used a timer once, but personally I don’t care. There are pros & cons to both approaches, and down here anyone running one 24×7 is looking for humidity issues. Along those lines, is there really any need to have one running when no one is out all day?

So just curious Jeremy, what discussion do you want to have on ERV vrs HRV? – All I will say is if one is dumb (not often that I use that word but it applies) enough to use it to primarily exhaust kitchen & bath air they had better be using an HRV.

To Sean – A broad based

To Sean – A broad based negative statement like “if one is dumb enough to use it to primarily exhaust kit & bath air, they had better be using an HRV” may be poor positioning on your part and misleading. Having installed many systems just this way in a cold climate, it can work better with an ERV than an HRV when the inside moisture load is considered. i.e. a very well sealed basement area and only 2 people. The ERV is easily able to handle the moisture load and actually can make it more comfortable for those 2 people by hedging against dryness during the cold dry winter. I would not recommend it in my home right now with 4 teenagers, 2 big dogs to go along with the adults. One size fits all may not be the best approach. But lets leave the name calling out of the picture. Cheers

Hey Sean,

Hey Sean,

I our climate zone here in Cincinnati,Ohio ERV is the only choice between the 2. I do however agree with you about not using it to exhaust Kitchen and bath air and leave those to local ventilation sources. I do know many however that don’t believe it matters. I also don’t install them unless they can be independently ducted.

I am among those who have

I am among those who have been outspoken against using an ERV as the only exhaust for high-use showers in tight homes. The risk is real, but as Kurt said, it’s not necessarily a problem.

Since it’s impossible to predict a homeowner’s internal moisture loads, I advise clients to install dedicated exhaust fans in baths unless they go with an HRV (dedicated kitchen exhaust is a given). And I give them a brief primer on winter mold risk. They can choose to use the fans or not depending on the amount of moisture they generate, and how cool they allow the nooks and crannies of the home to get.

The ERV/HRV decision depends on several factors, but let’s not further derail this discussion.