Go Up, Go Small, and Get Those Ducts Inside Conditioned Space

If you want to do something really stupid with the ducts for a heating and air conditioning system, put them in an unconditioned attic. In cold climates, designers, builders, and contractors know this and, for the most part, avoid it. They also have basements as an alternative location. In hot climates, designers, builders, and contractors do the really stupid thing all the time. I’ve written about alternatives in the past, but over the holidays I came across a paper showing what might just be the solution you’ve been looking for.

If you want to do something really stupid with the ducts for a heating and air conditioning system, put them in an unconditioned attic. In cold climates, designers, builders, and contractors know this and, for the most part, avoid it. They also have basements as an alternative location. In hot climates, designers, builders, and contractors do the really stupid thing all the time. I’ve written about alternatives in the past, but over the holidays I came across a paper showing what might just be the solution you’ve been looking for.

Meet the plenum truss

The Building America program has done a lot of great research on what works in high performance homes. Even better, they make the information available to all of us and publish the results on their website. One of their research partners is IBACOS, a company based in Pittsburgh, and they recently published a report titled Measure Guideline: Implementing a Plenum Truss for a Compact Air Distribution System (pdf).

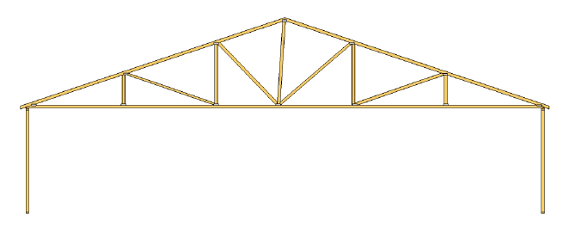

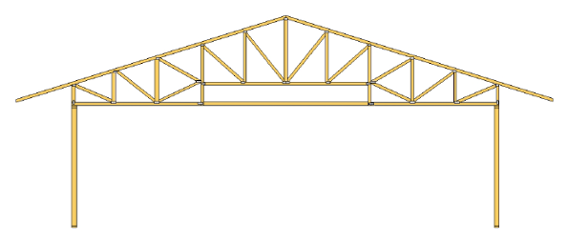

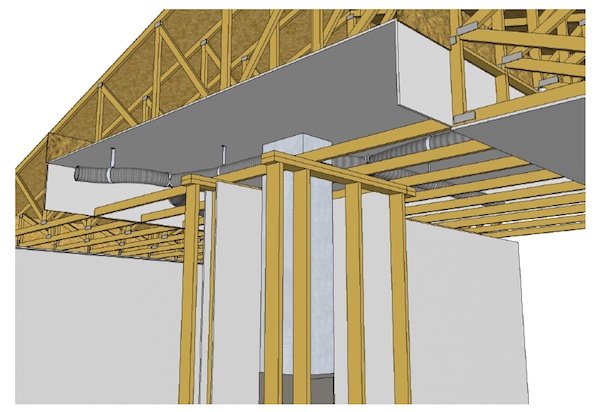

The basic idea is to use a modified roof truss so you can leave your ductwork above the ceiling plane in a home but also get it into conditioned space. Before we get to the modified truss, though, let’s take a look at the standard truss.

There are a lot of different kinds of trusses, but a typical one looks something like the one shown above. The modified plenum truss that’s shown in the IBACOS paper looks like this:

If you look closely, you’ll see a few changes, but the main one of interest here is that open rectangular area in the middle. It creates what they call a reverse bulkhead, since it’s above the ceiling plane instead of below. That’s where the ducts will go.

How to use the plenum truss reverse bulkhead

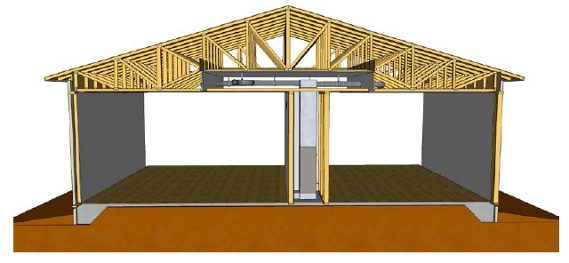

First, IBACOS did this project with a production builder in California. The homes were all one-story, slab-on-grade, single family detached homes. They didn’t have crawl spaces, basements, or framed floor systems to run the ducts in. The objective was to get the homes to pass the 2012 International Energy Conservation Code (IECC) using the option for ducts inside the building enclosure.

Here’s what they did:

1. Install the air handler in a mechanical closet inside the house. This takes some space from inside the house, but it makes the unit more accessible and keeps it in conditioned space.

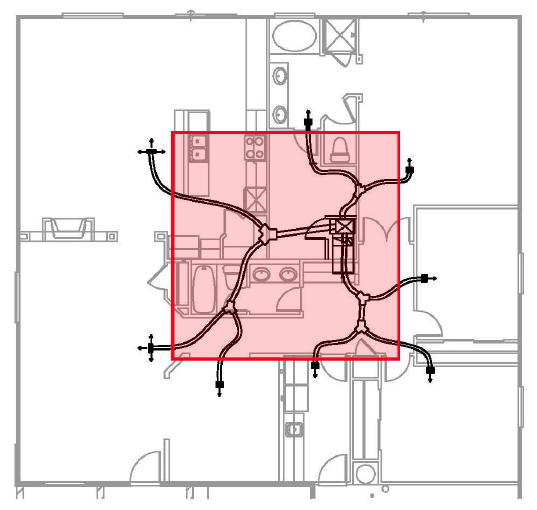

2. Use a compact duct system so ducts don’t have to go out to the perimeter of the house. With high performance windows, we don’t need to put supply vents at the perimeter. Proper register choice can get enough air to the perimeter.

3. Install and seal an air barrier over the top and sides of the reverse bulkhead. The pressure and thermal boundary of the conditioned space moves from the ceiling to the outer surfaces of the reverse bulkhead.

4. Put most of the ducts inside the reverse bulkhead. The IBACOS paper shows a little bit of ductwork coming out of the reverse bulkhead into the unconditioned attic. They don’t really discuss that except to say that you need to seal all the penetrations.

5. Insulate the ceiling, including the top and sides of the reverse bulkhead. Insulate the top of the reverse bulkhead and the rest of the flat ceiling as normal. (I like blown insulation for that.) If you’re going to use blown insulation, be sure to install dams on the sides of the reverse bulkhead to keep the insulation at the full depth all the way across the top. Insulate and sheathe the sides of the reverse bulkhead as you would any other attic kneewall.

Benefits and costs

The main benefit is that you get most of the ductwork into conditioned space. You also get to do it without insulating the whole roof deck (generally done with spray foam insulation) or dropping bulkheads below the main ceiling plane.

The cost of the trusses may be higher, but that could be offset by reducing the size of the HVAC system as a result of getting the ducts inside the conditioned space. Going with a compact duct system could reduce the cost further.

IBACOS did some energy modeling and found reductions in source energy (from 123 MMBtu/yr to 112 MMBtu/yr), HERS Index (from 54 to 52), and annual energy costs (from $1274 to $1158). They’re also doing long-term monitoring of the test house and will be publishing the results of that soon, too.

If you’re building homes and still putting ducts in unconditioned attics, it’s time to adopt a new method. This could be the one that will work for you.

Related Articles

Case Closed: Get Those Air Conditioning Ducts out of the Attic

Keep Out! – One Place NEVER to Put HVAC System Ducts

5 Good Ways & 1 Bad Way to Get Your Ducts Inside Conditioned Space

Image credits: Photo of ducts in attic by Energy Vanguard. All other images from IBACOS paper on Building America research.

This Post Has 24 Comments

Comments are closed.

But it’s just so much easier

But it’s just so much easier to keep using the 500sqft per ton rule that’s been around since the 60’s and shove everything in the attic. Who cares if the Ductwork and air handling equipment are baking in a 140 degree attic while trying to deliver 55 degree air? After all, the builder isn’t paying the power bills.

So how are you suppose to get

So how are you suppose to get a 4×8 sheet of drywall on the secondary ceiling plane? That is a lot of extra labor to cut them to fit between the 2′ joist spacing, not to mention the lack or room to work, especially on the kneewalls. Don’t get me wrong, nice idea, I just see quality issues with the actual application.

Considering the optimum

Considering the optimum location for balancing dampers is at the the trunk takeoff for branch runouts, looks like TAB would need to be done before ceiling below plenum is finished. That is, ceilings in finished spaces below plenum would need to be installed after test & balance, & where the takeoffs are not in the mechanical ‘room.’ (Also need to be careful of leaving room for proper maintenance of air handler-furnace. And hopefully nothing but sealed combustion furnaces are considered for use in envelopes any more.)

This design cincept has been

This design cincept has been around for at least the last 20-30 years. It is one of the first advanced framing tricks I saw in the early days of developing and promoting EE building concepts.

So easy to implement, but you have to do it right the first time. Going back to fix after trim iut is very messy. Also, duct leakage can be disguised because the ceiling cavity can act as part of the duct plenumn. If airflows are not checked, and balanced, the ducts could test tight to outside.

In the construction industry, good ideas can take 30, 40, 50 years to be recognized and accepted. Makeing thus a long term carreer choice. We can conduct the same classes, and studies for an entire carreer, and still not exhaust the market potential. 😉

Bob: Some

Bob: Some builders do care. Codes are getting better.

Josh: I’ve seen drywall hangers work. They’re amazing. Yeah, it’ll be a little extra work but certainly within the realm of what’s possible.

Dan O.:

Dan O.: All good points. The paper doesn’t discuss testing and balancing (TAB) the ducts for proper air flow, but they’d definitely have to do that step before installing the lower drywall. And as you say, it’s most often not done, but since this was a monitored research project, I’m sure they did here. Not sure what the builder’s standard procedure is, though.

geoff h.: Yeah, I’ve seen different forms of these trusses before. Well, I should say I’ve seen photos, diagrams, and articles about them. I still haven’t seen one in a real house yet. You wrote: “We can conduct the same classes, and studies for an entire carreer, and still not exhaust the market potential.” And write the same blog articles, too!

Clayton D.

Clayton D.: Yep. The buried, encapsulated duct method has been on my list to write about for a while now. It’s not so much about what’s best as it is what works best for a particular builder or application.

Here’s a direct link to the JLC article you mentioned:

Buried and Encapsulated Ducts

Allison:

Allison:

Why not just put a step in the bottom of the truss? Don’t have the bottom chord extend through the area reserved for ducting. After all the mechanicals, etc. (could include plumbing, electrical, HRV ducting, fire sprinkler lines) are in, frame it off and cover with drywall as needed. Yes, a little more drywall, framing and labor but I think this method would be a much easier installation for everyone.

Allison thanks for taking the

Allison thanks for taking the time and publishing this research paper that we did.

Curtis J.:

Curtis J.: That sounds like a good idea. It would definitely make the drywall installation easier.

Anthony G.: You’re welcome. I’m glad I saw your tweet about it over the holidays.

Clayton D/Allison:

Clayton D/Allison:

Then you have Code officials like some of these in SE PA that require all attic duct work to be raised and supported above the attic insulation.

“I am from the Government. I am here to help you.”

As a homeowner, I see the

Everybody uses a valid Manual J to size and Manual D to design ductwork, right? And make no errors, and the model is always faithful to reality? . I think it is highly important to have access because so many things have to be done over. Perhaps some variation of this design, can specifically address the damper issue.

As a homeowner, I see the inaccessibility of dampers as a really big drawback. To plan to “get it right the 1st time” is fine, but to make the do-over so much more difficult compared to other conventions, is a real cost. I’ve never bought a new house yet, and am always running into things that weren’t done right the 1st time.

Allison I was think more

Allison I was think more along the lines of chopped up custom homes I deal with as a rater and as a builder from time to time. Work great for homes on center hall colonial principle. if builder isn’t willing to switch to blown insulation it will require additional inspection which in my area PA and NJ will be an extra charge and delay. When inspections are only done on certain day. Smaller duct sizes are only a small decease in material. Still takes as long to install. those trusses will cost more. there will be an extra layer of drywall and taping involved which will be an extra trip charge from drywall contractor. This is a good way to help show builders other ways. Labor seldom ever changes as far aas a reduced cost. There are many things to consider. do we build a room in the attic for the furnace? extra cost. do we enlarge the house to place the furnace in conditioned space? or make a room smaller? With a slab home theese are address already. all options need to be weighted is all i was saying. Nothing new in this truss design we have used it before.

What about covering ducts with blown insulation equal to the ceiling R value when possible? As I read EStar 3.1 that won’t work. It is up to guys like use to point this design out to builders and designers. Experience tells me the average builder will do business as usual. I have lost many builders to EStar 3. We as an industry need to build more efficient homes. we need to do it in a way that the homeowner can still have all the whistles and bells and afford the home of their dreams not some entity.

In the diagram I notice a portion of the duct work is still in unconditioned space. Like so many design ideas we need to weight them. seems all designs have some good and some bad.

Enjoy all your post.

Allison,

Allison,

I enjoyed this article, and it makes me think about a concept that I always emphasize to my colleagues, “Don’t solve the wrong problem.”

The reason why we keep talking about putting duct work in conditioned space is the lack of commitment to properly sealing the duct connections. If this is done properly and the ducts are insulated properly, their location in unconditioned space should be a minimal issue.

The larger problem from our experience is the air handler, itself. I consider this the HVAC industry’s dirty little secret. I have some photos of the innards of a brand new unit we took apart last year. When you see the photos, you realize that the unit was never designed to seal against air leaks. A wiring harness was routed right through the plenum on the intake side of the fan.

Out of curiosity, I called the manufacturer and asked them to route my call to tech service. I asked if they manufactured a unit with air tight seals. At first, the tech did not understand my question. So I posed it another way. “My refrigerator has gaskets that seal against air leaks. When I was in the attic, your unit was blowing cold air out sufficient to blow my hair back. The temperature in the attic was 145. Do you have a unit with gaskets that would keep this from happening?”

The tech responded, ” Now I understand your question. Our units are supposed to be site sealed by the contractor.”

I thanked him for the information, thinking how absurd it would be to have the contractor disassemble the unit to hunt down the myriad internal leaks in a brand new air handler.

Hopefully, this shines a light on one of the real problems in our business. I will not reveal the manufacturer but lets say it is a big one.

My mother had a saying – Strain the gnat and swallow the camel.

We building scientists opine about all the ways to reconfigure the building to accommodate shoddy equipment design and construction.

Thanks for the great work you do in educating us on best practices. I would be happy to hear your thoughts on this issue, as well.

Barry Westbrook

President, DocAir LLC

Franklin, Tennessee

Regarding access to balancing

Regarding access to balancing dampers… you have the same issue when HVAC is installed in floor system between two levels or in drop soffits.

Mark’s point regarding damper access is spot on. In homes with finished basements, I try to steer towards a drop ceiling. Attractive ceiling tiles are available. Makes life easier for future electrical, low voltage and plumbing changes as well.

@A Hyde, the requirement to support ducts over the insulation is appropriate. But I’m not sure why you think it would apply in this case.

@Barry, ASHRAE Standard 193P

@Barry, ASHRAE Standard 193P defines a test procedure for cabinet leakage (2% at 1″WC). California and possibly other states now require this for all air handlers so all the majors now offer AHU’s that meet this. You just need to know what to look for in the specs.

Allison,

Allison,

Recently visited our daughter in Florida; she has a slab-on-grade, single-story, no basement home similar to the one illustrated (except built sometime in the ’50s). The biggest issue I see with this modified raised-heel truss is the difficulty of maintaining integrity when future modifications are needed (and there will be future modifications – there have been many in my daughter’s house over the decades). I would also think that the additional costs for the specialized trusses, additional labor/materials in sealing/insulating the reverse bulkhead, and additional drywall labor would far exceed the cost of spray foam on the roof underside – especially considering the low roof slopes typically found in non-snow load regions (less square feet). Plus recent insurance analysis of hurricane and tropical storm damage now leads to recommendations for non-vented attic spaces in storm-prone areas.

Allison, this works well. I

Allison, this works well. I recently built a small in-law apartment behind my house. I spent a lot of time thinking about my duct work and air handler location, so I have no duct run over 20 feet, and all of my duct work was installed in a tray recess designed into the bottom chord of the roof truss. We drywalled the space then hung the ductwork, then installed my ceiling below, as Curtis suggested in an earlier post. This is not a super popular installation to pitch to an unsympathetic HVAC contractor, but it is easily doable. Another approach I’ve seen is to drop the ceiling in the second floor hallway, and use that as the duct space. With the popularity of 9′ ceilings, an 8′ hallway works fine.

I try to all flex under 5′

I try to all flex under 5′ long with the rev bulkhead I can do that. I do find the grills you pick must be the higher end not just the stamped grill so the draft does not dump down your back.

Nice post Allison

Nice post Allison

I have been studying various construction technicians to lower the power consumption in a new residential home for me and my wife in the Atlanta GA area. I have looked into moving HVAC ducts into the conditioned space. But it seem to be a rather expensive move to make for a one story home. Not doubt every problem has a solution and normally comes with new problems.

The illustration showing registers located in the center of rooms would make for uneven temperatures throughout the rooms. Registers should be located against exterior walls or furthest point from room opening/return.

@ Clayton D

Thanks for the link on the Buried and Encapsulated Ducts. I read the entire 89 page test report, and believe this one of the most economical solution I have found yet to get within a razors edge of the efficiency of Ducts in a conditions space.

Using Deeply Buried Encapsulated Ducts

ccSPF Duct Spray Foam ($1.89/ft2) (Stated in Report)

Thermaflex 8″ Flex Duct (R-8.0 = 2 1/4″)

Cost to Spray Duct about $6.18 Lf

Would love to hear more opinions from others on Buried and Encapsulated Ducts.

@Richard:

@Richard: moving ducts in an existing house is rarely cost effective. Better to make sure ducts are tight and well insulated, seal the ceiling, etc.

BTW, in tight homes built to current code, there’s no rationale for locating diffusers at perimeter. Returns just need to be strategically located to ensure no feedback.

Buidding America will conduct a free webinar on March 20: Ducts in Conditioned Space (includes deeply buried encapsulated ducts) GoToMeeting.

Not sure if this blog is

Not sure if this blog is still active but here goes. I live in Eastern Canada so outside cold is my concern. I am building a 2000 sq ft one story on slab. I was thinking of building with 9′ ceilings and installing duct work and plumbing in a tray ceiling or build with a 10′ ceiling and dropping the entire ceiling 1′.

Would either of these methods be practical?

John:

John:

I think framing down the entire ceiling might be a bit much but without knowing what your floor plan looks like, I could be wrong. As a designer, I try to take the minimalist approach and look for parts (ceilings)of the room layouts, such as hallways, and use them for placement of ducting inside the condtioned area. Of course all this needs to be worked out with your HVAC designer.

Lately many of my designs have been for radiant floor heating in tight ICF homes, so I am mostly dealing with trying to find where the HRV/ERV ducting can be installed.

For Eastern Canada, I hope you have a good handle on providing a good thermal break for your slab edges as well as planning to install continuous insulation under your slab. Thermal energy loves to find cold/cooler places to migrate to, so you definitely don’t need to be warming up the soil under/around your home at the expense of operating your heating system more than you need to.

Just my 2 cents worth. Good luck.

@John, either strategy is a

@John, either strategy is a good way to have ducts inside the envelope. However, you need to make sure the upper ceiling is air tight.