A Day with Professor Straube at the Building Science Experts’ Session

Oh, where do I start? Professor John Straube spoke all day yesterday at Building Science Corporation’s Experts’ Session. His topic was mechanical systems for low-load buildings. You know that expression about how the information comes at you so fast in some classes that it’s like drinking from a firehose? With Professor Straube, it’s like trying to drink from a tsunami! The guy has not only a phenomenal knowledge but he’s also a fantastic teacher and incredibly witty.

Oh, where do I start? Professor John Straube spoke all day yesterday at Building Science Corporation’s Experts’ Session. His topic was mechanical systems for low-load buildings. You know that expression about how the information comes at you so fast in some classes that it’s like drinking from a firehose? With Professor Straube, it’s like trying to drink from a tsunami! The guy has not only a phenomenal knowledge but he’s also a fantastic teacher and incredibly witty.

Oh, where do I start? Professor John Straube spoke all day yesterday at Building Science Corporation’s Experts’ Session. His topic was mechanical systems for low-load buildings. You know that expression about how the information comes at you so fast in some classes that it’s like drinking from a firehose? With Professor Straube, it’s like trying to drink from a tsunami! The guy has not only a phenomenal knowledge but he’s also a fantastic teacher and incredibly witty.

There’s no way I can give you a good overview of everything he talked about because he really covered the whole gamut of this topic. So, I’ll throw out a few morsels of his wisdom here and encourage you to attend one of his workshops if you ever get the chance. You may also get the opportunity some day to buy his book on this topic. Last night Joe Lstiburek and others strongly encouraged him to get this knowledge into a book, and I hope he does.

Mechanical systems for low-load buildings

Building enclosures have improved dramatically in the past two decades. We have more insulation, better windows, and sealed air barriers. Many homes have peak heating loads of 15 to 30 thousand BTU per hour (kBTU/hr)–even in cold climates. Yet most heating equipment available doesn’t go that low in capacity. About the smallest furnace you can get is 40 kBTU/hr.

Professor Straube mentioned that he’s been talking with HVAC equipment manufacturers about this for about a decade, and they just don’t get it. Carrier and Trane, he said, have told him they don’t sell low capacity equipment because no one’s buying it. They failed to see that if the equipment is not available, no one can buy it so of course they’re not buying it because it’s not available. Evidently those discussions haven’t turned the corner yet.

Straube covered a lot of ground in his presentation. After introducing the need for low-capacity mechanical systems and the lack of conventional equipment, he dove into the details of the different systems available, how they work, what some of the limitations are, and how difficult it is to do it right.

One of the big obstacles is cost. “We’re beyond talking about saving money on equipment for low-load houses,” he said, because they don’t. If you’re a spray foam contractor, for example, trying to get builders to bite on the higher cost of foam because of savings they’ll see from smaller mechanical systems, it’s not gonna happen.

You can get a 46 kBTU/hr 95 AFUE furnace for $697. If you want something with less capacity, you could go for a boiler, tankless water heater, or mini-split heat pump, all of which are significantly higher in cost. Same is true of air conditioners. When you go from a 2 ton system to a 1.5 ton system, it costs more and is less efficient, too. So if you want a low-load building to have a low-capacity mechanical system, get used to higher cost.

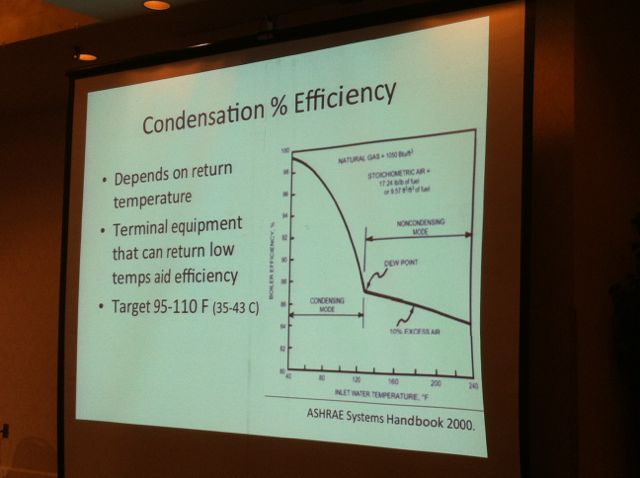

In the first half of the day, Straube went through some of the basics of efficiency ratings (SEER, EER, and COP), details about condensing boilers and furnaces, and combo systems (using one system to provide heat and domestic hot water). He talked about some of the problems with condensing systems and the temperature of the entering water or air. (See photo of his slide on this below.)

After lunch, the discussion turned to heat pumps, both conventional, ground source, and mini-splits. He blasted the idea of using desuperheaters on ground-source heat pumps to get hot water because they’re usually not very cost-effective and don’t give you much hot water. Ground-source heat pumps work well in school-sized buildings, he said, but not so well for low-load buildings or really big buildings. He also said that he has not seen any third party data on GSHP efficiency showing a COP higher than about 3. Since the industry doesn’t include pump or blower energy in their COP calculations, their numbers are higher but don’t give the complete picture.

Since the topic was mechanical systems, there was also a lot of talk about water heating. Combo systems give you both heat and hot water, and some people use water heaters just for space heating, too. Straube mentioned that HVAC and DHW need to come together.

Looking back over my notes now, I still can’t believe how much material he covered. It really was a tsunami of information. I won’t go into the details, but here are a few more topics he hit upon:

- Chillers

- CO2 refrigerant air-to-water heat pumps, which allow true hot water production because they can get higher temperatures

- Electric resistance heat – OK in some cases for low-load buildings

- Pellet stoves and boilers

- Dehumidification

- Legionnaire’s disease

- Heat pump water heaters

- Distribution of thermal energy – air, water, radiant

There was a ton of information thrown at us yesterday.

The wit of Professor Straube

Here are a few of the many witticisms we were treated to yesterday:

Caveat Emptor is Latin for, “You’re gonna get screwed.”

Cats are IAQ problems and you’d have to pass them through the HRV to solve that problem. But they’re not really a cat anymore after that.

Recirculating range hoods don’t solve the IAQ problem. It’s like a recirculating toilet. The stuff just goes round and round and never leaves.

In San Francisco, it never gets really hot or really cold. Buildings are there mainly to keep people away from your stuff.

It’s taken America 10 years to realize that tankless water heaters work better with tanks.

If you ever get a chance to go to one of his talks, I guarantee you won’t have any trouble staying awake and engaged.

A great reason to be a GBA Pro!

Not everyone can take the time to go off to New England for two days to attend a session like this. The good news is that many people watched the whole thing from their home or office because Green Building Advisor ran a livecast of the sessions. Anyone could have signed up through Building Science Corporation for the regular fee of $395 per day. GBA Pro members, however, got access to the livecast as part of their membership. What a deal! They’ll also be posting some of the videos for GBA Pro members later on, so you’ll still be able to log in and watch at least part of the sessions there.

Today I head back to Atlanta after a great week up here in New England. The Experts’ Session was well worth it, and last night I got to make a little video with the inventor of the Turbo-Thermo Encabulator Max, Dr. Joe Lstiburek. [11/16/14. Here’s the link: Interview with the Inventor of the Turbo Thermo-Encabulator Max.]

Related Articles

Highlights from Joe Lstiburek’s 2012 Experts’ Session on Spray Foam

Why Is Air Conditioner Capacity Measured in Tons?

Does a Geothermal Heat Pump Count as a Renewable Energy Source?

This Post Has 16 Comments

Comments are closed.

First I have to agree that if

First I have to agree that if you haven’t attended a John Straube session you’re missing out. Every one of his presentations I have seen over the past few years has been SRO.

I hope GBA gets the videos posted, time constraints kept me off the live feed. I wouldn’t have gotten anything done watching that!

I’m particularly interested in his take on heat pump water heaters. On the surface they look like a good fit in certain applications.

A book would be nice Professor Straube, if you’re listening. I’m working on a project with some small living units that even before air sealing and insulation are 10-15K loads. I’m anticipating that we will reduce that 20-30% at least. I need a book! Now! (OK, I can wait a bit)

Awesome Allison! Thanks!

Awesome Allison! Thanks!

Love the part about GSHP and building size! This is so obvious to an Economist. And uncertainty of efficiency (COP) of COURSE is high when there is no real incentive to track results! Throw it in and let her run. Loop size to soil type? Who cares! NYEB! (Not My Energy Bill)

I hope credit was given to Dan Holohan, he’s been talking about this stuff for over 20 years:

http://bit.ly/danholohan1992

It’s his stuff that started me questioning setback. (Hmmm, if you want fast recovery, what happens to water temperatures and condensing efficiency…)

Then Robert Bean showed me we could PROVE comfort isn’t simply air temperature.

Michael Blasnik isn’t gonna like where this ends up…

Lance: He

Lance: He said mini-splits are great for many applications, although, as we all know, some people object to what he calls “wall warts,” the ductless heads. He didn’t go into the details in comparing ducted MSHPs to conventional, but as I said in the article, we’re not going to do this cheaper because conventional systems are extremely cheap.

Bill S.: Straube said that heat pump water heaters are not a slam dunk. You have to evaluate the pros and cons for each project.

ted k.: I don’t know if he gave credit or not. When being hit full force by a tsunami, much of it washes over you. I appreciate the link to Holohan’s old articles and will read them later, perhaps on the plane back to Atlanta this afternoon. Here’s a clickable link for those who want to download this pdf:

Dan Holohan articles from 1992 (pdf)

Maybe if enough of us keep

Maybe if enough of us keep harping on this, folks will finally realize how silly it is to install a GSPH on highly efficient homes, especially those with significantly imbalanced loads.

Contractors don’t buy

Contractors don’t buy equipment that small,most don’t do heat loss calcs and if they did they still wouldn’t believe that a unit 1/3 the size they usually use will work!

Manufacturers rarely sell a

Manufacturers rarely sell a 40k furnace, why would they make anything smaller? Even though a 40K furnace would easily heat about 75% of the applications in our area, most contractors still insist on “being safe” and installing at least 75k. The only time you will see a 40k furnace installed is for an add-on, upstairs, or apartment, never as a primary heating system for a house. It doesn’t help that the wholesale cost between a 40k and 100k furnace is only $100 or so.

What were finding with the newer oversized furnaces is many are cycling on the limit switch due to poor ductwork. The newer furnaces seem to have lower settings for limit controls and therefore are less tolerant of low airflow. I can’t say I blame the manufacturers, proper airflow is the key to reducing warranty claims for cracked heat exchangers.

An excellent solution is the fan coil/water heater combo. Works well unless the hot water has run out. On a cold winter days is when both heating and entering water temperatures are creating peak load on the water heater. Don’t expect to warm the house up while you’re taking your morning shower..

The cooling side has it’s own

The cooling side has it’s own issues. Rarely if ever will you find an A/C unit over 13SEER that’s under 3 tons. The 14+ SEER units that are 1.5, 2 and 2.5 tons sit in the warehouse for years, few contractors buy them. People who are willing to pay more for an AC unit will normally upsize just about every time. When I replaced my own 3ton unit with a properly sized 2ton 14 SEER unit I found this out 1st hand. The AC was made in 2009, yes it had been in the warehouse 3 summers. The matching coil was made in 2012. The bigger is better mindset is alive and well. Some of the guys at the shop though I was nuts going 800sft/ton on my new AC since the 500sqft/ton rule of thumb had been drilled in their brains so long…

It doesn’t matter to contractors that oversizing basically kills the rated SEER, and the existing ductwork will barely support the old AC much less the new one. Don’t even get me started on all the poor installs of high end equipment we run into. Lets just say that if it isn’t a single stage AC with a single stage furnace or a simple heat pump/electric heat that something will not be right. I’ve even seen where somebody had a 15SEER heat pump with a conventional heat thermostat. Yes it worked, but ran on heat strips all winter! And crappy ductwork, I won’t even go there, there has been enough articles written on that subject.

Thanks Allison, <

Thanks Allison,

As we have discussed, Contractors “Load Calculations” on old houses are nothing more than adding guesses that give them the “loads” they want. Or as the Author says,

“they simply change some of the inputs to make the procedure spit out answer they’re comfortable with and no one questions their answers.”

Hank Rutkowski P.E. Author ACCA Manual J.

Why should we expect anything other than CYA bogus Loads from a procedure with no relationship to physical reality?

Hardly science, more like witchcraft

Thanks for your posts,

pj

This was my first trip up to

This was my first trip up to Westford, and I have to say … it was quite an eye-opener. After going to hundreds of “advanced” conferences I finally was at one where I was absolutely sure that most of the people in the room knew more about this stuff than I did. First time ever I took notes … lots of them.

Took lots of tylenol too, but that’s another story …it seems nobody up there was putting the alcohol in their gas tanks. I thought all energy geeks are boring … guess it’s just me.

I would be very interested in

I would be very interested in hearing your comments on Joe’s discussion of pellet stoves and boilers in particular.

Well, if you have ever sat in

Well, if you have ever sat in a cold house when temps uncharacteristically dip below zero for several days you will understand why people aren’t willing to undersize their boilers. When it happened to me I doubled the size of mine. You can say all you want about statistics, but three or 4 days in the cold wipes out all those energy savings for decades.

@Bob: couldn’t agree with you

@Bob: couldn’t agree with you more.

@bobspez, if boiler is sized to the 99 percentile design temperature, any deviations below that are only going to be a few hours, not for several days. During brief excursions below the design temp, the home’s mass and insulation (thermal lag) prevents indoor temps from dropping much if at all (unless house is leakly and poorly insulated). That’s the reason we design to the 1 & 99 percentile temperatures.

In any case, an additional 10% to 20% oversizing will handle pretty much anything nature can throw at a system, if home is accurately modeled. In any case, doubling your boiler capacity greatly increases its cycle losses.

Finally, your point is regarding “all those energy savings” makes no sense.

David,

David,

I’m presently in a 1200 sq ft. energy efficient one story home. Ten years ago I was in a 105 year old 1400 sq. ft, 2 story home with an open eave airflow in the attic and new windows/storm doors.

The hot air heating system we had worked fine at 20degrees F, poorly at 15degrees F and was virtually worthless at temps below zero. We had a blizzard with temps below 15 degrees during the day and reaching below zero at night for several days. We spent those days freezing despite plastic on the windows and doors and running electric heaters. After that experience I removed the hot air heating and installed an 85,000 BTU boiler and hot water baseboard heating. That boiler was about twice the capacity of the previous system and above spec for the house. We never froze again and our energy bills didn’t go up, so you are correct on that score. What I should have said was that putting in the over capacity boiler gave us the capacity we needed to cover any contingency, that the lower capacity boiler did not. For us it was well worth the $15,000 it cost us.

Allison,

Allison,

As long as you mentioned apocalypse and big picture items, it brought to mind the solar flares that hit the US in 1859 for a three day period(the Carrington Event) that melted telegraph wires in the U.S. Luckily, analysis of ice cores shows these events average about once in every 500 years. If a similar event were to happen today it would destroy all non shielded computer chips, taking down everything that uses computers … all communications, vehicles, water, gas and electric utilities, appliances, communications and finance.

Such an event would put us back into the 19th century, except we no longer have the capacity to survive in that environment.

But Homeland Security recently released a study on the problem. Hope it creates better preparedness than our “duck and cover” Atomic bomb drills did back in the 1950’s. We grammar school pundits back in the day used to say the drill was to put your head between your legs so you could kiss your rear end goodbye.

bobspez:

bobspez: Indeed, the Sun could wipe us out technologically with such an event. Did you See Martin Holladay’s 2011 halloween article?

Allison,

Allison,

I just read Martin Holiday’s article. Of all the doomsday scenarios he posed, the solar disruption of the electric grid, and therefore the financial, communication, transportation, food, water and fuel grids, seems the most likely and the the most devastating possibility. Hopefully a less than completely devastating warning event, like a Katrina or a Sandy will mobilize people to take preventative measures before “the big one” hits.