Air Conditioner Sizing Rules of Thumb Must Die

We design a lot of heating and air conditioning systems at Energy Vanguard. When I talk to potential clients, a lot of them tell me their contractor wants to size their air conditioner using a rule of thumb. The rule is usually something like this: Install one ton of air conditioning capacity for every 500 (or 600) square feet of conditioned floor area. How far off are they? Let’s take a look

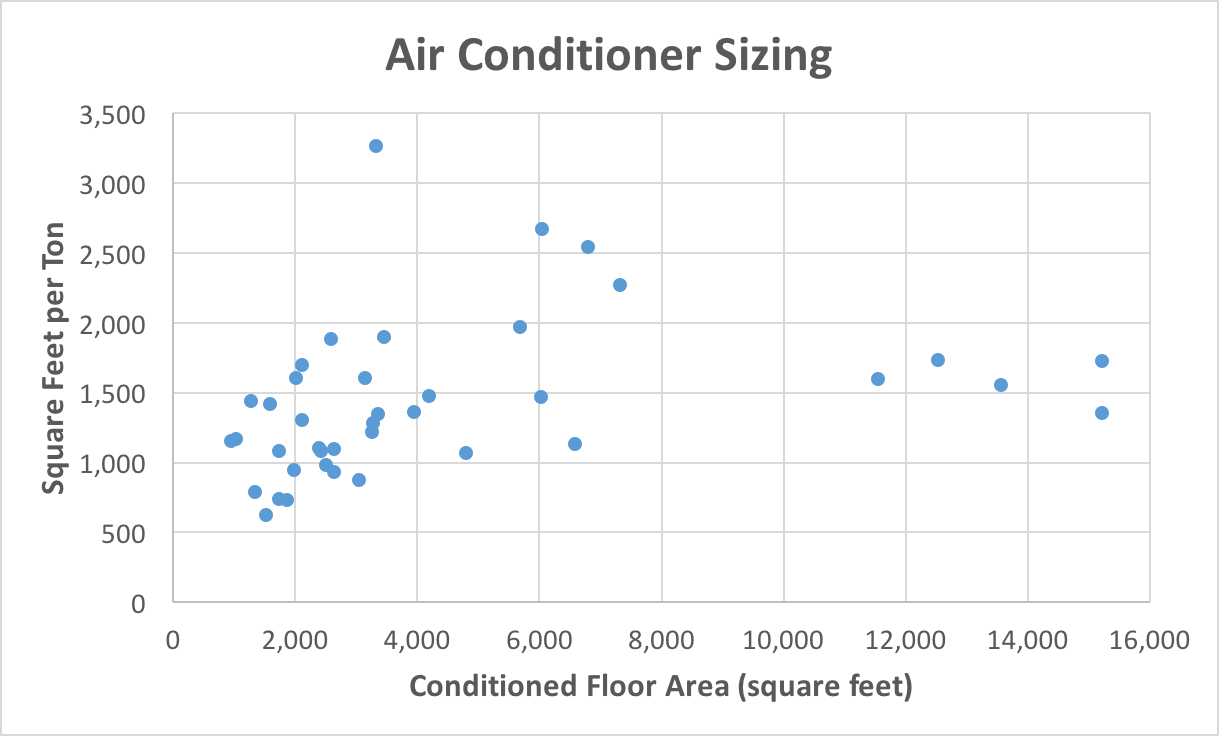

As I said, we’ve done a lot of HVAC designs, which always start with a load calculation. So we can look at the data. The graph below shows data for just a few we’ve done recently. Forty of them, to be exact.

On the horizontal axis, I plotted the conditioned floor area, in square feet. On the vertical axis, I plotted the cooling load divided by the floor area, or square feet per ton. Remember, when HVAC contractors use rules of thumb to size air conditioners, they usually pick a number between 400 and 600 square feet per ton.

Here’s what our data show.

Note that not a single one of our load calculations was as low as the high end of their range. The low number on that graph is 624 square feet per ton. The majority of the cooling loads shown here are above 1,000 sf/ton. Only eight are below 1,000 sf/ton.

In case you’re wondering, I threw out the data for cooling loads in cold climates when I plotted this graph. We had one in Maine that was nearly 4,000 sf/ton. Most of the homes in the sample set were in the Southeastern US, including Texas, but we had a couple in California and several in the Midwest as well.

The average of the 40 shown above is 1,431 sf/ton. Yes, that’s about a thousand sf/ton higher than the common rule of thumb in use.

“But wait,” you say, “cooling load isn’t the same as air conditioner size. Didn’t you tell us that you have to adjust the air conditioner size when you do Manual S?” Why, yes. Yes, I did. Most of the time, the air conditioner size will be larger than the cooling load.

But we’re usually talking maybe 10%. So instead of 1,431 sf/ton based on the load, the actual AC size might give us 1,300 sf/ton.

That’s still a lot different from the 500 sf/ton rule of thumb. Oh, and that 10% difference is usually offset by the oversizing inherent in Manual J.

Rules of thumb must die. Start with a real load calculation.

See part 2 of this article: More on Air Conditioner Sizing Rules of Thumb

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and writes the Energy Vanguard Blog. He also has a book on building science coming out in the fall of 2022. You can follow him on Twitter at @EnergyVanguard.

Related Articles

Why Is Air Conditioner Capacity Measured in Tons?

3 Reasons Your 3 Ton Air Conditioner Isn’t Really 3 Tons

My Big Fat Oversized Air Conditioner

NOTE: Comments are closed.

This Post Has 52 Comments

Comments are closed.

Allison,

Allison,

I don’t fully believe it is completely HVAC contractors doing these things. I believe it is done by some who use the ‘bigger is better’ mentality. Because they know home owners think bigger is better, even though it’s not.

I recently went on a AC check up in which the AC unit was a 4 Ton and the square footage of the place was around 1200 sq ft. The duct work was breaking apart, insulation not very good in the attic. A real gem to say the least.

I tell the homeowner, it’s probably best that you don’t fix the duct issues, nor reinsulate because most likely they would make matters worse. I told her to buy a humidity meter and note how often the humidity in the home is higher than 60%.

This home owner is retired on a fixed budget, which is often the case.

Another visit to a home being sold, the AC was put in only a few years ago by ‘some guy’ — uncle Ned or Joe maybe take your pic. This inspection was to clean the AC to satisfy the home inspection report.

I found the sensing bulb for the TXV sticking out of the coil cabinet, hanging in the attic ‘wind’. Surprisingly I had a 18 degree temp drop across the coil. How these side show knuckle heads pull this off is beyond me.

I take sub cool and super heat readings — sub cool is around 0 degrees and superheat about 5 degrees!

No telling how much energy this 3 year old 14 SEER unit is wasting, because the homeowner tells me the pool was put in roughly the same time the AC was. Not that it would matter at this point anyway, because they are selling the home.

If anything these instances tell you ‘why’ things are more likely only to get worse.

Ray, I’m sure you’re right

Ray, I’m sure you’re right that in some cases, the homeowner forces the contractor to put in a bigger system. I think it’s the minority of cases, though.

It’s problems like these that

It’s problems like these that make me reconsider ductless mini splits. My god they’re ugly, but you don’t have to contend with inadequate duct design/install down the road.

We attempted to have our HVAC problem fixed but the misses balked at the $5k cost-to-cure. I guess I’ll just have to wait for lightning. lol. 🙂

I’ve never seen 1 ton per

I’ve never seen 1 ton per 1000 sq ft work anywhere. I’ve seen 500 square feet per ton not work on 100 degree days. I would have to see it to believe it on a hundred degree day 2000 square foot home working on 2 tons of air. You better have really great ductwork I’d have to see it. I’m in doing hbac for 33 years and when homes are not cooling it’s because lack of capacity

Ben, when you started in HVAC

Ben, when you started in HVAC 33 years ago, single-pane windows were the norm. R-11 walls and R-19 ceilings were standard in many places. Brand new houses that leaked at the rate of 10 to 20 air changes per hour at 50 Pascals (ACH50) were everywhere.

I don’t know where you’re located, but it doesn’t matter so much. Building codes, materials, and techniques have changed all over the US. 500 square feet per ton is a rule of thumb that never really worked anyway. It doesn’t take into account the orientation, the airtightness, or pretty much anything else that matters.

Lack of capacity happens occasionally but far less frequently than you think. The duct system is most often to blame (assuming the refrigerant is properly charged and the equipment is working properly).

I’ve seen it not work on

I’ve seen it not work on double pane windows a good r factor. You’re only having five Outlets for 1000 square feet.

There are a lot of people

There are a lot of people down south who effectively shut off the AC while they are gone and want it to be at setpoint 30 minutes after they return. Additional factors include comfort issues caused by radiant heat and a lack of adequate air circulation by inadequate ceiling fans. Sometimes two speed condensers with variable speed air handlers can accommodate these needs through low speed operation 90% of the time.

My question is how to downsize a system (say 5 tons 2000 cfm on a 2500 sq ft house) to 2 tons 800 cfm after a good air sealing and insulating job while still maintaining the existing duct sizes and registers (usually out of necessity)? Are manual dampers alone adequate or is full damper based zoning needed? Or is their a better solution?

RJ, if you have a house where

RJ, if you have a house where it’s possible to go from a 5 ton to a 2 ton AC, neither dampers nor zoning is the solution. That house needs a whole new AC and ductwork. My friends in California (Mike MacFarland, Gavin Healy, & Dan Perunko) do that regularly. And it can be cost effective to do that, too.

Yes, whole new AC system, but

Yes, whole new AC system, but my question is how to make a now oversized duct system work when it must remain?

David, Thanks for the input

David, Thanks for the input on high performance retrofits as related to existing duct work. I also reviewed your excellent “Elephant in the Room” paper from your website. http://optimalbuilding.com/files/elephant_in_the_room.pdf

RJ Downsizing the AC without

RJ Downsizing the AC without reducing the surface area of ductwork in the attic will probably get you nothing. The conduction losses eat up all the cycle efficiency improvements.

While much research has been done on complicated ways to “put the ducts inside the conditioned space”, this research shows that attic ducts can perform as well as ducts truly in conditioned space when they are reconfigured. (moving the “registers” to nearer the unit, reducing surface area, and superinsulation by burial in attic insulation)

@John, there are several

@John, there are several compelling reasons to downsize from 5 tons if the load is only 2 tons. Improved efficiency is not the most important.

When the A/C is that much oversized (2-1/2 times the load in this example), the cycles will be so short, the evap coil may never get cold enough to remove moisture. Moreover, homes with grossly oversized capacity will experience wide temperature swings at the perimeter, especially at peak load. And then there’s the noise issue. And if existing system is being replaced anyway, there’s a first-cost benefit.

As you said, reducing airway velocity increases conducted heat gains, especially if ducts are in a vented attic (RJ didn’t say). That said, when an attic system short cycles, conducted losses at steady state are likely to be overwhelmed by the initial load imposed each time the system kicks on. The air conditioner not only must overcome the thermal inertia of all that hot metal, a “duct system full of hot air” gets dumped into conditioned space at the beginning of each cycle.

@John, please disregard my

@John, please disregard my last reply. I misread your comment, mistakenly thinking you were recommending against downsizing). If ducts are indeed in the attic, some reconfiguration may be warranted to mitigate conducted losses.

@RJ, I’ll drill down on this

@RJ, I’ll drill down on this cuz it comes up A LOT! As usual, the answer depends on a number of factors. First, if existing ducts are sealed tight, chances are they’re undersized for 2,000 CFM.

Second, the ideal design airflow for a 2-ton system might be ~900 CFM, depending on latent loads (which depends mostly on the building shell in a humid climate, and whether new system has advanced RH controls).

In other words, the existing ducts are likely closer to what you need than first glance.

A good HVAC designer can help assess whether it makes sense to mod the existing ducts (versus full replacement) and if so, what mods are recommended. If ducts are in good shape, it may not be as bad as you think. Here are some general guidelines…

The return side can’t be too large, especially the filter surface area. It’s the supply side you may need to worry about.

Low velocity in an airway is NOT an issue (confirmed in Manual D). The issue is terminal velocity as it affects the throw distance. In-line dampers or OBD’s don’t preserve terminal velocity so you’d be wasting your money there. At worst, you may need to switch out some supply boots and diffusers. That’s a lot easier than a full duct replacement and works just as well.

Full zone control is a solution for a different problem.

In well-insulated, tight homes with good windows, terminal velocity becomes *much* less important — even irrelevant if the shell is efficient enough. The key when working with these low CFM/ft2 homes is to get the air to the room (interior walls are fine) and make sure the system is air-balanced. In-line dampers and/or OBD’s are good for that. Throws and supply placement are the least concern.

The duct system for my home (now rented out) was originally designed for a 5-ton condenser, but ended up with a 4-ton (long story). When I bought the home I replaced with a 3-ton system and it worked just fine, hooked to that huge duct system. I had considered replacing the diffusers but it turned out to not be necessary.

One last thought… when specifying heat pumps, I often bump the size by one size to reduce or eliminate supplemental heat. In your example, 2.5 tons or 1,100 CFM on a duct system that may be ideal for, say, a 1,500 CFm system ain’t that far off. (sorry for so many words 😉

You can’t put any AC system

You can’t put any AC system to any duct work. If you have grossly oversized supply duct for the CFM you’re trying to push you lose your velocity and you won’t have very poor airflow. The returns of course the bigger the better you cannot oversized the return and the bigger the return the quieter the system will be. I’ve never seen in 1000 square feet per ton work I’d have to see it to believe it it would be a hell of an r factor in that house. In a lot of homes you are not going to be able to change out ductwork because it’s all buried you have to cut the house to pieces to do it

Benjamin, there’s nothing

Benjamin, there’s nothing inherently wrong with low velocity in supply ducts. Yes, it’s not a good idea for ducts that run through an unconditioned attic because of the temperature rise in summer and temperature drop in winter of the supply air coming out of the vents. But actually, larger ducts are great for air flow because the resistance is a lot lower. And fittings, which dominate the total effective length, are rated for a velocity of 900 feet per minute. When you cut the velocity in half, you reduce the equivalent length of fittings to a quarter of what’s published in Manual D.

And if you’ve never seen 1,000 sf/ton work, you must be working on uninsulated, super leaky houses. We often design for houses that come in at 2,000 sf or more per ton.

Allison,

Allison,

Thanks much for the info – when I read your post last night I was thinking about 2,000 sqft /ton. I realize its hopeful, but there are some very big – yet very simple problems to scrutinize closer. I recently completed a high performance home design here in MA. Three HVAC contractors calculated the heating load between 48kbtu – 65kbtu. The home is about 1200 sq ft. The Homeowner initially wasn’t pleased his HP Home was such an “energy pig”. I had my energy guy run the house – 16.5kbtu. There’ a big disconnect even when the right input info is provided. As for the cooling side specifically. I was in Texas last week. My good friend is in commercial office construction. I must say it was actually disturbing to me as to the allowed construction assemblies in a location where 100 deg can be a typ day.Windows, R-Values, non-existent air sealing. I told my friend “your construction is like an Eskimo telling me a lean-to is an appropriate technology for their climate” Even with some simple minor scrutinies/changes we can do soooo much better.

Thanks again for the info….

Steve

You’re welcome, Steve! I’m

You’re welcome, Steve! I’m glad you got a chance to see what things are like in Texas. It’s pretty much the same across the Southeast.

This is why God gave Texas

This is why God gave Texas Matt Risinger.

That’s pretty awesome! I owe

That’s pretty awesome! I owe you one! Matt

Thanks for this article,

Thanks for this article, Allison – I often send out your HVAC sizing articles to clients of ours and we generally note to people that even a Manual calculated load should be looked at with general suspicion when using our system. We encourage them to talk to clients of ours and try to impress upon them that there are alternatives to traditional HVAC systems for smaller homes. I would love to see you do an article on that someday. It is continuously frustrating to me that HVAC companies don’t make units smaller than 1.5 or 2.0 ton in size (“they cost the same so why NOT get the bigger one” people say to me) – is this simply mechanically impossible or an issue of “bigger is better” mentality? Dropping down to a mini-split – that many builders are unfamiliar with or clients think are ugly – is sometimes too far a step for many of our builders and clients.

I agree, Charles.

I agree, Charles. Manufacturers don’t give us small enough units. Maybe that’ll change some day, but we’re not there yet.

Have you looked at the

Have you looked at the offerings of Dettson? They offer modulating heat pumps from 3/4 ton to 3 tons. They also offer modulating gas furnaces from 15-120 Kbtu/hr.

Yes, I love what Dettson is

Yes, I love what Dettson is doing with equipment size. We need more like this.

Are you referring to ductless

Are you referring to ductless or ducted mini-splits that are deemed ugly. For low load areas, we use ducted mini-splits with satisfactory results. With the ducted mini-splits, the interior of the home looks no different than a typical split system install.

This is the perfect start to

This is the perfect start to properly sizing air conditioners, but I hope the ending (Part 2?) will include the ways to know if your scientific WAG was correct, something referred to as “truing up your model”. No discussion of modeling IMO should conclude without mention of planning your data points and processes to gather feedback post-installation and apply that learning toward becoming an AC expert within your climate. I say this because when you do high quality enclosure and insulation work, it is a foreign concept to the software calculation engine (it was trued up to “normal” jobs) and you’ll find what we do: Even with our most aggressive modeling efforts to tell the program to downsize as much as possible, our cooling loads are still 20-40% higher than we measure/calc with data. So you could still be wildly oversizing on every project despite having pride in doing a great Manual J load calculation, leaving opportunity on the table without realizing it. Just a suggestion for those who want to dig deeper and up their performance game dramatically. Thanks for the good info and great chart, Allison.

You’re absolutely right, Mike

You’re absolutely right, Mike. And yes, I will be following up this article with more information about the whole process. My point here was to say that load calculations show that we should be installing much smaller equipment than is usually installed. The next one will make exactly your point that the load calculations still result in bigger equipment than required. Take my condo, for example. With a 2 ton AC, I get runtimes of about 30 minutes per hour on design days. So we might need only a 1 ton AC. I recently redid the Manuals J and S for our home. The result: It says we need a 1.75 ton AC. We’ve gone through the inputs multiple times and can’t find any more ways to get it lower. So that’s a 75% oversizing in this case.

This is great feedback

This is great feedback Allison. How long would you like to see your AC run if beyond the current 30 minutes? We often talk about “low and slow” and we know cycling is a bad thing, but how long of a cycle does it start to become acceptable? And how many square feet do you have?

Charles, the idea, as I

Charles, the idea, as I understand it, behind Manual J is that the AC should run continuously on a design day once the load hits the inside. There’s a lag in heat transfer from outdoors to indoors, so the longest runtimes usually occur after it starts cooling down outside.

This year, our indoor humidity is much better. Part of that is because there’s more sensible load this year because it’s hotter. Another is that my condo is tighter now because of my bathroom remodel and the new spray foam beneath the floor and the dehumidifier in the newly sealed up basement. I’ve even seen the indoor percent RH drop into the 40s occasionally.

Too much to say here!

Too much to say here!

First, Manual J overestimates the sensible load. http://www.proctoreng.com/dnld/97501B.pdf

“This study found that the most widely accepted sensible

heat gain calculation, applied without “safety” factors, overestimated the sensible heat gain for these homes by approximately 50%.”

Second, ACCA and the Manufacturers know it oversizes

http://www.proctoreng.com/dnld/ACCA.pdf

Trane: “While the Manual J 8th edition may be procedurally acceptable, the quantitative results are not consistent with established operating systems and accepted load calculation

practices. The load estimates produced by the 8th edition result in considerable equipment sizing increases and result in driving up the costs of the equipment and the installed system.”

Third, You can get any load you want out of Manual J.

Fourth, Even when utilities pay contractors to size to Manual J, they still oversize.

http://www.proctoreng.com/dnld/HVACInstallationsLongIslandServiceTerritory.pdf

“On average, the units receiving an incentive for sizing to

Manual J exceeded Manual J by 67%.”

All good points, John! Thanks

All good points, John! Thanks for posting the links. But we’ve got to win the battle over sizing to rules of thumb first.

Mike’s exactly right. Many of

Mike’s exactly right. Many of us need to do more monitoring of these systems (self-funded, if needed) in order to learn. Case in point – I currently have an energy monitor on a client’s ducted mini-split heat pump that serves the 1st floor and basement. My aggressive, by-the-book Manual J shows a total cooling load of 12,000Btu/hr at 91F for this part of the house. The 1-ton (nominal) equipment that I spec’d should (theoretically) require in the ballpark of 940W power input to output this capacity. Yesterday’s high was 92F…peak 1-hour power input to the heat pump during the afternoon was only 310W…about 1/3 the “expected” power input.

A couple of weeks ago, on a 96F day (5F above our 1% design temperature), the system peaked at a “whopping” 480W power input.

Allison, This is a excellent

Allison, This is a excellent and useful article. HVAC continues to be the wild west, but hopefully the work being done by you and others will change the industry. Energy Star is trying to help that process along with our verified installer certification –

https://www.energystar.gov/index.cfm?c=hvac_install.hvac_install_index

Thanks, Danny. Yes, when the

Thanks, Danny. Yes, when the ENERGY STAR new homes program went to version 3, the HVAC requirements mandated good design and installation. The verified installer certification you mention is another step toward moving the HVAC industry in the right direction, too.

So do we distinguish between

So do we distinguish between new and retrofit, because it seems Allison wrote to new and the discussion moved to retrofit.

These seem like birds of such different feathers that lumping them together does neither justice.

These are both problems of very broken processes, but the parts that are broken for new build are not at all the same as the parts broken in retrofit.

In retrofit I think the biggest problem is not enough time spent understanding the homeowner, asking questions, developing and coming together around objectives.

In retrofit it needs to stop being about “saving energy” first and foremost. It needs to be about fixing broken houses – do that and the energy savings naturally follows along.

My contractor was so

My contractor was so skeptical of the small capacity (2 ton) of my specified system for 2800 SF house in Massachusetts. But, it’s perfect!

He would have put in one for the upstairs and another for the downstairs, with ductwork for the upstairs in the attic. Yuk!

The situation of people

The situation of people leaving their AC off can be overcome by selling them one of many Internet capable thermostats for about $100 so they can turn the system ON before they get home. They will arrive with their house already at a comfortable temperature AND they’ll have to put up with lower air flow velocities and noise from their oversized system to say nothing of the other technical problems we all know.

Friends who have these thermostats, love them.

Hot topic for sure – pun

Hot topic for sure – pun intended. After sitting through way to many presentations on right sizing equipment I have to throw my 2 cents in.

I agree with John Proctor, you can make a Manual J say whatever you want once you get familiar with it. On that same note it easy to miss an input in Manual J and get wrong answers too. As equipment gets smarter, to combat the typical industry accepted installations, sizing might not be as big of a concern as it once was. Perhaps with wide range, variable capacity equipment we could get real results, too bad they don’t make them small enough…yet.

The real issue here is quality, until the industry steps up and stops accepting sub-par, cost based HVAC installations as the norm we will have issues. We need to find a way to support the few individuals that are taking the time to do the job right and reward them. Testimonials, some form of recognition, and let’s make sure they are making lots of money too, then perhaps others will follow and the industry can transform as a whole. If you have any idea on how to do that I am all ears.

And finally, join Efficiency First, we are on your side and doing what we can to make this happen.

Charley Cormany – Executive Director – Efficiency First California

@Charley Cormany

@Charley Cormany

Get the film industry involved and start making 2 annual films on doing HVAC the right way and the wrong way.

A few titles for the wrong way:

‘3:10 to Disappointment’

‘No Way Out’

‘No Where To Hide’

‘Predator: Comfort Gone Wrong’ – starring Ductopus

“I would like to accept this award from the Academy of hard compressor knocks and phosgene gas…”

This a great article.

This a great article. Something else I have seen contractors do is recommend that a homeowner get a system of the identical size that they have had in the past. that should go along with rules of thumb. I never trust guesswork

Good stuff indeed. Like Emre

Good stuff indeed. Like Emre, I just had a contractor specify a replacement 14 SEER 5 ton package unit to replace a 10 SEER 5 ton package unit. No accounting at all for the increased efficiency of the new system. I also got the argument that to get adequate heating capacity we needed to get the 5 ton AC capacity in the package system. The salesman also offered that “he’d be surprised” if Drees (our home’s builder, in 2005) didn’t do a proper load calculation during the design of the house. Frankly, I’d be shocked if they applied any quantitative analysis to HVAC during design or construction back in 2005.

Might I suggest you address sizing split upstairs/downstairs systems? Figuring out how to size a downstairs and an upstairs system is a challenge. Two separate systems, thermostats, and duct runs, but air space connected via the building envelope.

Brian just to be clear, a 5

Brian just to be clear, a 5 ton unit will have the same capacity regardless of its efficiency rating. So that should not effect sizing. ( Not that the original 5 ton unit was not too large also.) How long does it run on the hottest days at a fixed thermostat setting?

That makes sense. If I

That makes sense. If I understand correctly, 5 tons of capacity is 5 tons regardless of the SEER number and the efficiency only answers how many kW it takes to cool that volume of air. Higher SEER = fewer kW used per unit of cooling, right?

Last night I timed our AC cycle and it cooled for 15 minutes around 9:30pm CDT in Nashville. My outdoor thermometer reported it was 81 degrees at that time. I didn’t time the off cycle to see how long my house kept temperature. I haven’t noticed the indoor temperature overshooting the set point much. RH is in the ~51% range. I believe my thermostat is set for 3 cycles per hour. So, based on this we aren’t horribly over-sized. We do have a lot of volume to condition (5k SqFt, 50,000 cubic feet of volume) with moderate air sealing and good duct sealing (done by a good local vendor). We do have LOTS of window area with over 800 sq ft of fair quality double glazed glass.

John, thanks for helping me clarify my understanding of this.

@Brian: cycling timing should

@Brian: cycling timing should be done on a design day.

Time at least two complete cycles when house is at peak load (typically a couple of hours after the daily high), noting total on-time vs total time. For example, 20 minutes on, 10 minutes off, 19 minutes on 8 minutes off = 39/57 = 68%. This would indicate load is roughly 2/3rds of the existing system’s capacity at those conditions.

BTW, the thermostat cycle rate setting only effects system operation at low-load conditions.

It would seem to be very easy

It would seem to be very easy to use small data logger, like a Hobo, to collect this information. We have 8 tons of cooling In 3724 sq foot home in Houston. Run time is not hard to measure, even with the timer in your phone. Doing this I find I can turn off, or least set to 80 degrees, the upstairs AC unit ( 3 ton) and let the 5 T handle the whole load. Even when outside design conditions are exceeded the AC only runs 60% of the time.

It is important to add that since I installed a 90 pint per day whole house dehumidifier set to 50% I had to set the inside temp up to 77 to keep from being cold. We used to set it to 75.

The whole house stays at 50% humidity +/-2% and the temperature likewise stays at set point +/-2 degrees even during worst case conditions. The monthly bill in the summer averages about $220.

Charlie, Yes, there’s a Hobo

Charlie, Yes, there’s a Hobo datalogger that measures runtime. See this article I wrote two years ago for details:

My Big Fat Oversized Air Conditioner

http://energyvanguard.com/blog-building-science-HERS-BPI/bid/76640/My-Big-Fat-Oversized-Air-Conditioner

Anyone who is using energy

Anyone who is using energy Vanguard is probably building a mansion and really does need a load calculation Lol A person who has put in loads of systems can usually rule of thumb a small 1500 square-foot home better than any computer ever thought of doing or load calculation !!!!!

Justin, Be sure to take a

Justin, Be sure to take a look at the graph above. You’ll see there that most of the homes included in this sample were in the 2,000 square foot range, far lower than mansion size. You’ll also see that when you use 500 sf/ton, you may get lucky and be only a little oversized. More likely, though, you’ll be installing an air conditioner that’s 2 or 3 times as large as it should be.

If a contractor said they

If a contractor said they usually size them 500 to 600 ft per ton they probably live in a hot area like me in south ga . That’s what works best on MOST homes here not ALL homes in the area . Most contractors know what works best for their climate that they live in and work in and have worked in for decades . You cannot take the rule of thumb from south Georgia and take it to anywhere else in the United States and expect it to be accurate such as Maine !!!! Lol !! Most contractors can look at a structure and it’s environment and know when they can use rule of thumb in the when they cannot .

Justin wrote: “you cannot

Justin wrote: “you cannot take the rule of thumb from south Georgia and take it to anywhere else in the United States and expect it to be accurate such as Maine”

Your comment implies that sizing rules of thumb are appropriate within a geographical area. Nothing could be further from the truth.

I just finished the design on a new home in Savannah. The design cooling load came out to about 1.6 tons for 2,000 ft2, or 1250 ft2 per ton. That’s not that unusual for a verified code-built home.

Contractors who rely on what’s “worked for decades” are the ones doing stupid things now, as today’s code-built homes require far less capacity than homes build decades, or even a single decade ago.

Typical load calcs don’t

Typical load calcs don’t include measured leakage.

If the calc without leakage ranges between 600 SF/ton and 2000 SF/ton, what are you going to lean towards?

Our process is delivered by HVAC contractors and offers a blower door based load calc.

1000 SF/ton not so frightening when you narrow in on load with measured leakage.

I would like to make some

I would like to make some points that i think my father-in-law (my boss and owner of the company i hope to buy) would make if i were to present this to him and try to change the way he “designs systems”. I’d like to hear responses from you folks who are much more knowledgeable on this subject.

1) I think this would be his primary point: 1000’s of satisfied customers and a successful business would disagree that 500 sf/ton is a bad idea. I don’t remember the last customer that complained that their new system left their house uncomfortable. (We are in Northern California, btw). To be clear, i am not claiming that 500 sf/ft ends up with the same result as a proper load calc would, i am claiming saying it doesn’t lead to an uncomfortable house around here.

2) I think every article i have read on the topic of the problems with oversizing gives an example in the southeast US where humidity is a huge factor, which makes me think that it’s just not a big deal around here.

3)If you install a smaller system than what the customer had and it has any issues on hot days (days above design temp or just doesn’t cool as quick as the customer feels like it should) even though we say it is working properly, you will have angry customer. If you install what they had or bigger, you can just blame it on abnormally hot days and the customer will be fine with it.

4) I suppose the solution to this is to properly “sell” the system by explaining the concepts in articles like this one; but i think that is exactly what he and many, many small hvac owners are trying to avoid. They don’t want to be salesmen. When you have enough business and can pick between customer who use your time by asking about every little thing (that they could easily find on google) and you know will be picky or customers who just want their a/c to cool off the house, you will go with the latter.

I guess that turned into me thinking out loud. To be clear, I want it to be necessary to take the more advanced steps like this. If you just just grab anyone off the street and teach them how to design and install a proper system in a day, then how can i ask for any more money than a handy man or a new employee? Thanks for any help on this topic!