Are We Off Track With Combustion Safety Testing?

Burning fuels inside a house can lead to serious health and safety problems. Energy auditors do a variety of combustion safety tests to find potential hazards and recommend fixes. A couple of weeks ago at the Dry Climate Forum, I heard Vi Rapp, PhD of Lawrence Berkeley National Lab (LBNL) make an argument for changing the way we do combustion safety testing. It turns out that one of the tests we do may not be as helpful as many people think it is.†

How many people die of carbon monoxide poisoning?

You see the reports on the news, and it seems that lately there have been a bunch of them. But how many people really die of CO poisoning? According to the Center for Disease Control (CDC), 439 per year people died from unintentional, non-fire-related CO poisoning in the period from 1999 to 2004. The Consumer Products Safety Commission has a different number. They say 170 people per year “from CO produced by non-automotive consumer products.”

The small number of deaths, however, is not the only metric to look at. A report in The Journal of Emergency Medicine estimated that about 40,000 people get medical attention for CO poisoning. That’s a big number and one we should definitely be concerned with in energy audits. The BPI motto, after all, is, ‘Do no harm.’ So if you look only at deaths, it doesn’t seem that significant. If you look at CO poisoning cases, it’s something we need to understand. But do we?

What causes CO poisoning?

Energy auditors spend a lot of time testing for backdrafting, which can lead to CO entering a home. When the pressure inside the home is low enough, air can come down the flue of a combustion appliance, preventing the exhaust gases from going up the flue. The main candidate for backdrafting is a natural draft combustion appliance, like the water heater shown above or the furnace below. Other combustion appliances can backdraft, too, but it’s less likely.

If a natural draft combustion appliance is inside the conditioned space of a home, backdrafting can create serious a health and safety risk. A backdrafting appliance is more likely to create CO than one operating normally. If the exhaust gases, including CO, get into the house, people can breathe them in and get CO poisoning.

And that’s the big emphasis for energy auditors: carbon monoxide from backdrafting. But how many of those 170-439 deaths or 40,000 CO poisoning cases each year result from backdrafting? I haven’t found statistics on that, but I’d bet the majority of cases are from using unvented space heaters indoors or from running generators, and not from backdrafting.

The problems with the worst-case depressurization test

OK. So the number of deaths seems to be low, the number CO poisoning cases is significant, and the number of backdrafting events leading to CO poisoning is probably a small fraction of all the CO poisoning cases. A big part of the combustion safety testing protocols of both BPI and RESNET is the worst-case depressurization test. It’s what takes the most time, and it’s the part that Dr. Vi Rapp of LBNL took a close look at last week at the Dry Climate Forum.

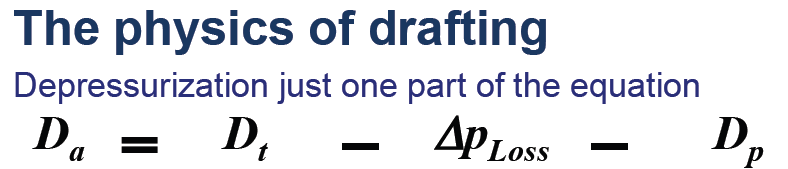

Problem #1. How well a combustion appliance drafts depends on three factors, as shown below in the equation from her presentation.

Depressurization, as you can see, is only one factor that affects whether an appliance will backdraft or not. You can have depressurization and still have good draft. The good news here is that the energy auditor measures the draft in the worst-case depressurization state, so we have some idea here about what’s going on. Sort of.

One of the factors that affects a combustion appliance’s ability to draft normally is the weather, yet that’s not included in the test protocols. An appliance may draft poorly when it’s tested in the summer but be fine when it’s operating in the winter, or vice versa.

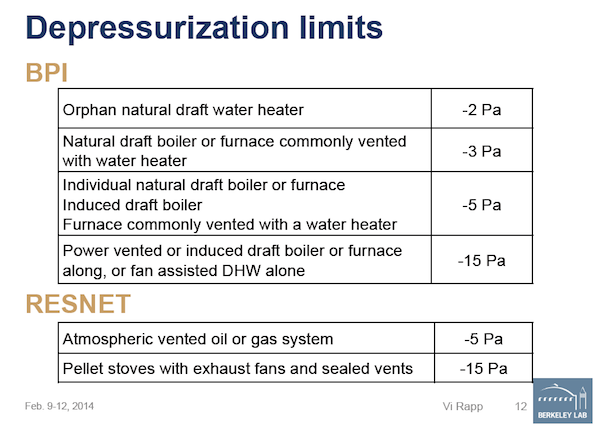

Problem #2. BPI and RESNET don’t agree on what amount of depressurization is allowable and don’t indicate what the real risk is.

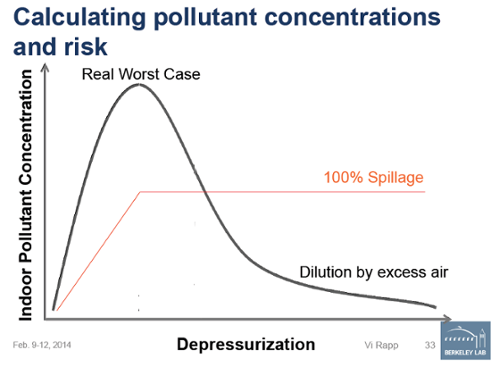

Problem #3. The big issue here is that even if there is enough depressurization to cause backdrafting, there may or may not be a problem. Dr. Rapp had a slide in her presentation showing that the risk associated with depressurization depends on three factors:

- The probability that the depressurization leads to backdrafting

- The probability that the combustion appliance is operating when the depressurization occurs

- The probability that the backdrafting leads to increased pollutants and an indoor air quality problem if 1 and 2 both occur

There’s a lot going on in problem #3. How often will worst-case depressurization actually occur in a home? Where are the appliances located? How does weather affect it? How likely is it that the backdraftable combustion appliance will be operating when the house is depressurized sufficiently to cause problems? And even if it backdrafts, might the pollutants be sucked right back out because of the depressurization?

The graph above, from Dr. Rapp’s presentation, shows that the most likely ‘real worst case’ occurs when the appliance first starts to backdraft. The pollutants enter the indoor air and build up to higher concentrations. As the depressurization level increases, more pollutants get pushed out of the house and more outdoor air gets pulled in to dilute the pollutants. So it’s not a simple matter of having bad indoor air quality and the potential for CO poisoning anytime the house exceeds the depressurization limit.

So what should we do?

Combustion safety is serious. We absolutely need to address it. Low-level CO exposure can lead to chronic health problems. Higher levels can lead to acute health problems or even death. Although I began this article with a look at the numbers of people dying and seeking medical attention, my point was not to say that those numbers don’t matter. My point was to ask that of those, how many result from backdrafting? And for those cases, what’s the best way to bring the number down?

We certainly can be smarter about how we do that. If the worst-case depressurization test doesn’t help, what should we do? Dr. Rapp concluded her talk with these recommendations:

- Remove unvented space heaters; ask above other heaters (i.e., oven)

- Check for gas leaks

- Visual inspection of appliance and venting for damage or problems

- Advise homeowner to install and/or use range hood

- Confirm range hood vents air

Just to be clear, Dr. Rapp did not say we shouldn’t do combustion safety testing. As John Proctor wrote in the comments below, she did say that testing for draft and for CO are good tests and we should still do them. What she questioned was the effectiveness of the worst-case depressurization test, especially without accounting for variability due to weather and the total risk when you factor in the three probabilities I covered in Problem #3 above.

We need to be asking hard questions and constantly evaluating the protocols we train energy auditors to use in homes. Dr. Rapp’s work at LBNL is important, and you can read more about it in her upcoming Home Energy magazine article (online only) on the myths and facts of combustion safety. Look for it on 1 March.

In the meantime, let’s all ask the hard questions about what it is we do…and what we’re aiming to do.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and writes the Energy Vanguard Blog. He is also writing a book on building science. You can follow him on Twitter at @EnergyVanguard.

Related Articles

A Ventless Gas Fireplace Is a Liability

Unvented Natural Gas Space Heaters Should Be Removed

3 Problems with Atmospheric Combustion Inside the Building Envelope

Footnote

† The original opening paragraph of this article was different. I made the mistake of mentioning a snippet of a conversation I had a year ago without giving the person mentioned, John Krigger a chance to explain his views fully. I have removed the reference to that conversation.

This Post Has 26 Comments

Comments are closed.

Great post Allison! Many of

Great post Allison! Many of the assumptions that are made with combustion testing concern me. A one time CO reading and draft pressure reading that fall under acceptable guidelines DO NOT verify the safety of a piece of equipment. There is more to the story that is being taken for granted.

For additional background,

For additional background, check out Corbett Lunsford’s recent podcast with LBNL research Brett Singer: This House Sucks, But Not Very Hard

Allison, with all due respect

Allison, with all due respect to you and Vi, you both have missed the point and put emphasis on the wrong thing. The question is not how many people die each year DIRECTLY from CO poisoning. The question is how many people have serious health complications from long term exposure to less than immediately fatal exposure to CO. Another is how do we as energy and safety specialists improve or detract from the long term health of occupants of the buildings we work on. I have far too many personal experiences with health effects of CO exposure from gas appliances to say that they are insignificant, and I am only one person. Multiple people in and out of the hospital that were solved by fixing a gas appliance — with not diagnosis by the health professionals that the cause was CO. Household bird deaths from CO poisoning that sent the homo sapiens to the hospital. What is needed is a serious history lesson here. What is being implied is that combustion safety testing is a waste of time because there are not a lot of immediate deaths due to CO poisoning. That is equivalent to saying smoking is OK because very few people die immediately from smoking and that only happens when they sleep smoking and it starts a fatal fire.

To be clear Vi (at LBL) admitted that the CO test in the flue is a good idea. She also admitted that a draft test (based on a minimum draft number dependent on outside temperature) is a good idea. What she is questioning when all the hype is removed is whether the “worst case” backdraft test is worth the effort and time. Since the original Sun Power combustion safety protocols have been changed by various entities, there have been things tacked on that are probably unnecessary. The flue CO test is absolutely necessary. The draft test is absolutely necessary. A draft test (target results temperature dependent) with the largest fan that is likely to be on is where all the depressurization test stuff came from. Over the years it has been changed and expanded — for better or for worse.

Thank you Allison for this

Thank you Allison for this excellent post, I learned a lot. I’m all for better combustion safety protocols, greater emphasis on ovens, pushing for eliminating atmospheric venting appliances, etc., but you article, implies (intentionally or not) that combustion testing is a waste of time. To me, there is a big difference between advocating improved protocols and just waving our hands and not testing at all. To me, your article, Corbett Lunsford’s podcast, LBNL work, all tell me I should be spending MORE time and energy on CAZ testing, not less. Because the data tells me that the CAZ testing I’m performing really isn’t that informative, than I now know I need to go above the BPI/RESENT standards and do more because the consequences could be significant (i.e. do no harm).

As an industry, we need to adapt our language and viewpoint. First, we really are not doing “worst case” depressurization testing, but “as worse as I can make it RIGHT NOW when I run the test with current atmospheric conditions, appliance performance, etc.” depressurization testing. Depressurization is dynamic and transient, and we need to explain this to the homeowner/builder. We need to view worse case depressurization as a “point measurement” not a final assessment. That said, it is at least A DATA point, and can alert the energy auditor/contractor that more investigation might be warranted. For example, if the CAZ does fails, I can instruct the homeowner to install a CO monitor in the CAZ as a safety precaution. Even better, I can install a data logger in the room, and track it over the rest of the audit/day/week/whatever. Now, I have several data points and I can make a better assessment of the risk. Furthermore, as an energy auditor, if I’m recommending ANY upgrades to the envelope/HVAC system/appliances whatever that might affect the CAZ depressurization, then I better understand the possible consequences of the upgrades and explain to the homeowner/builder that energy efficient upgrades might result in additional costs (make-up air) or increased risk. You can’t do that without the initial CAZ testing.

Allison, as an industry we may not care about 170 people, and we may not want to set our standards to that small population, and that’s fine. But if ONE of those 170 people is my client, than I don’t sleep a sold night again the rest of my life, not to mention being out of business or worse. I can always do more than the standards, and from my limited experience, the market will eventually reward you if you have the resources to survive short term.

With all due respect to you

With all due respect to you and Li. You are missing the primary point of combustion safety testing. The primary issue is not how many people die directly and immediately from CO poisoning. A significant issue is the long term health effects of CO. Focusing on direct deaths was the gas industry’s approach to make sure this stuff was not looked at. To look only at direct and immediate death from CO is equivalent to saying smoking deaths are insignificant because very few people die from smoking and then only in bed when they fall asleep smoking and it causes a fire. The long term health effects of low level CO exposure are real and serious. Furthermore, the statistics are very poor on CO poisoning. I am only one person, but I know directly of CO deaths. I also know of people in and out of the hospital without any CO diagnosis that stopped the winter time sickness by eliminating the CO produced by their appliances. People need more history and need to focus on what is good helpful and reasonable. Even Vi from LBL admits that the CO test in the flue is a viable test. She also admits that a draft test with the target results dependent on outside temperature is a useful test. The real issue here is the “worst case” depressurization test. The original Sun Power protocols did not have that test. Over the years it was recognized that fans (often the furnace fan) can cause depressurization and combustion products into the house. The original addition was a test with only the most likely large fan on. It got elaborated upon, some think to the point of overkill (I agree). Another issue that some people miss is that a standard “clean and tune” neither checks for CO nor addresses CO if it is present. The original Sun Power protocols were based on the following: 1) We don’t want the appliance to supply CO to the house. 2) If little or no CO is produced, then even if the combustion product get into the house, they should not cause a problem. Therefore the CO test in the flue. 3) If the appliance drafts properly then even if CO is produced, it will not get into the house. Therefore the draft test (measured draft with the target dependent on outside temperature).

Later is was found that some appliances that did not produce CO under normal drafting conditions produced CO when backdrafting. At that point a depressurization test was added, but a simple one. One of the reasons this is significant is that there is such a thing as stable backdrafting that once it is established (by depressurization) continues to backdraft.

So in essence the initial problem is simple 1) don’t produce a significant amount of CO, 2) remove the combustion products from the home.

As David R points out, that may not be enough, but it beats the hell out of the standard practice of measuring nothing and ignoring the issue.

David R.:

David R.: Thanks!

David B.: Thanks!

John P.: Yes, the chronic effects of long-term exposure to low levels of CO are important. Combustion safety testing is important. I tried not to diminish that and thought that I had made it clear that the worst-case depressurization test was the main target of questioning here. I’ll revise the conclusion a bit to make that more clear.

David H.: I think you’ve misinterpreted the article. I’m not saying that 170 people aren’t important or that combustion safety testing is irrelevant. What I said is that the worst-case depressurization is under fire because it really doesn’t tell you much.

Allison, I agree that the way

Allison, I agree that the way we do Worst Case Depressurization (WCD) testing is not as telling as we’d like it to be, but it does help identify depressurization issues. But the way your article reads suggests CAZ depressurization testing is not that important when I think you meant to say it is not as informative as we’d like it to be.

I’d like to see Dr. Rapp’s rap on combustion testing. I think she has a good handle on it for the most part, but I disagree with some of her supporting arguments.

Regarding Problem #1, BPI’s Gold sheet (updated 1/2012) has a calculation for determining the acceptable draft pressure range based on outdoor temperature. That’s a weather-based testing protocol.

Regarding Problem #2, disagreement is only because each has a different acceptable tolerance of what percentage of appliances backdrafting is acceptable.

Regarding Problem #3, factor 2 should include “the probability that the combustion appliance will attempt to establish draft while depressurization is already occurring.” Factor 3 is loaded with variables, but combustion gases coming inside the house WILL increase indoor pollutants. That is undebatable. Whether the increased indoor pollutants reach an unacceptable level is the real question.

Does backdrafting or spillage happen often in many homes with no perceived ill effects? Absolutely. But what is considered acceptable risk? Do you want to live in the 2% of the homes with occasional backdraft issues? Is 2% of clients having their health further compromised an acceptable risk? Trying selling that to the 2% clients.

During the 1990-91 National Weatherization Evaluation, I was part of the Northeast field crew that was conducting post audits, including Worst Case CAZ Depressurization testing with the very first digital manometers from Energy Conservatory. I was surprised to find a number of homes with chronic backdrafting issues in WCD configurations. One home had a family of four home sick with a “flu” they couldn’t shake. Obviously, the flue gases weren’t being adequately diluted by the air in the home. In another home, the CAZ went to -11 Pa. when the family dog laid down on a bedroom heat register with the door closed. The bedroom went negative and had a chase to the CAZ. No rigorous WCD test would have found this; it was purely coincidental that the dog helped me find the problem.

The EPA and the NIH are just a couple of the many resources addressing chronic low-level CO exposure. Undetected chronic low-level CO exposure is discussed in this paper at the NIH website.

In 2012, one of our auditors noted that a client had been put on oxygen by her doctor when the real problem was a clogged water heater flue. It was just another day of work for Carl, but the client recommended him for the Red Cross Unsung Hero award. While not a depressurization issue, it is just one example of a draft or CO problem being resolved and not showing up in any statistical evaluation of CAZ issues.

When LBNL conducts a study as to the number of CAZ problems discovered and resolved by the current testing procedures, or a study of chronic low-level flue gas or CO exposure, then I feel they’ll have some of the data they need to properly address the quagmire of WCD and CAZ testing protocol.

To suggest that backdrafting combustion gases get diluted and therefore aren’t a big issue flies in the face of ASHRAE ventilation standards meant to improve IAQ. (“We’re going to cycle this exhaust fan on just long enough to fill your house with flue gases, and then turn it off.”)

As of February 1st, BPI has simplified the BA CAZ testing requirements. Considering that we as an industry are becoming more effective at air-sealing, rigorous CAZ testing is more important than ever. Tight houses, exhaust only ventilation, and atmospheric draft appliances is a recipe for failure and increases contractor liability. In NY, the NYSWDA training center will continue to deliver training and strategies to reduce or eliminate CAZ depressurization and minimize the risk of backdrafting on other than the testing day. The NY weatherization 62.2 calculator includes a depressurization calculator to alert auditors to potential backdrafting risks and helps guide ventilation strategies in tight homes with atmospheric appliances.

Per the 2006 ICC Mechanical Code:

701.5 Prohibited sources.

Openings and ducts shall not connect appliance enclosures with a space in which the operation of a fan will adversely affect the flow of combustion air.

After 2006, the ICC Mechanical Code refers to NFPA 31 and International Fuel Gas Code which recommends makeup air rather than eliminating the cause of the CAZ depressurization as a first step.

Ultimately, tight houses should have sealed combustion (or no combustion) appliances and balanced ventilation. Until then, we need to train auditors and HVAC technicians to critically assess every home with atmospheric draft appliances to ensure that even occasional backdrafting doesn’t occur. I just hope we survive our efforts to apply new standards to non-standard housing stock.

I concur with Dale! One

I concur with Dale! One additional thing that I don’t recall reading in this thread; mandating low-level CO monitors is a doable measure in every living space, and should be the first thing to consider. I’m noting that the academics tend toward the charts, formulas and statistics while those of us who actually interact with the living tend to be more concerned with taking measures to keep them in that state.

I think this is a great

I think this is a great article. The programs that are in KCMO specifically use the combustion testing as a “fail area” and does not allow the customer to receive a rebate if their equipment fails “worst case”. I think the standard is a little to tight. I agree “do no harm”. But I also agree that we will have back draft issues in worst case that the home owner may never see. Installation of CO detectors per current building code standards will continue to save lives from failing equipment. Back drafting 5-10 ppm of CO for 15 -20 minutes a day in a home will not cause health problems. My previous career was in the fire department. Even OSHA standards say you can be exposed to 30-50 ppm constantly for up to 8 hrs a day. I think the equipment needs to be checked and if there are high levels back drafting should be analyzed. But failing equipment that has 10ppm and back drafts in worst case unwittingly scares homeowners and forces them to possibly purchase new equipment or make expensive changes. I had one get rid of a new gas water heater and put in an electric because the program made him. Not necessary. IMHO

Ted K.:

Ted K.: Here’s the direct link to David’s article: The Differences between Drafthoods and Draft Regulators

Dale S.: It sounds like you actually agree with at least some of what Vi is saying. The WCD test is inadequate for finding a lot of combustion safety problems, and we need to be smart (and lucky sometimes, as your story about the dog indicates) about how we go about it.

Also, I think maybe you’re not really understanding the point of their work. They are absolutely NOT saying that combustion safety testing isn’t helpful. They are NOT saying that we shouldn’t worry about the 2%, as you put it. They are NOT saying that depressurization is OK because it’ll flush out the pollutants.

What they ARE saying is that we might actually be able to help more people if we address the inadequacies of our current testing protocols.

Here are clickable links to the resources you mentioned:

BPI’s Gold sheet (pdf)

EPA’s Indoor Air Quality page

NIH page on low-level exposure to CO

Undetected CO poisoning

Woman with CO poisoning saved by visual inspection, not worst-case depressurization test

Stan K.: If you think carefully about this, you might see that the academics are the realists and those doing tests based on charts are doing faith-based combustion safety testing. The bottom line is that we need to do all we can to reduce the amount of CO poisoning.

And yes, absolutely low-level CO monitors are the way to go, as I wrote previously: Get a Low-Level CO Monitor.

Erik H.: Thanks! One quibble, though: Maybe OSHA says you “can be exposed to 30-50 ppm constantly for up to 8 hrs a day,” but I certainly wouldn’t want to try that experiment. Also, the standard UL-rated CO detectors are useless in my opinion. As I wrote in the comment to Stan, low-level CO monitors are the way to go.

Both the title of this post

Both the title of this post and Vi’s presentation gives the impression that we might be off track on all of combustion safety testing. Both then follow up with number of direct deaths. A less heated discussion and perhaps more helpful discussion might come from a title that is about worst case depressurization, followed by a discussion of why it came into existence, what it attempts to detect, and perhaps what should be done instead.

All of us have brains that process the information we have, whether it is complete or not and reach conclusions that we often defend. Researchers that have not been in the field tend to read something that is a partial truth and think it is the whole truth. In the field doing the hard work of trying to make good things happen there is a tendency to become religious about certain things and miss nuances that are important.

Having dedicated 36 years of

Having dedicated 36 years of my career to combustion testing and csarbon monoxide there remains one things common today that existed when I started. Stupid and Naive still are abundand. According to the NFPA newsletter in January Non-fire related CO poisoning have doubled from 2003 to 2010. They show they have gone from 40,000 to over 80,000. Understand these are just the ones fire depatments respond to and the victims usually have to be transpoted to the hospital for it to count. Deaths can only be determined by autopsy and 99% of people that die are not! They die of the doctors best guess. CO related illnesses and disabilities is scary to include Alzheimers and Parkinson. Fire fighters have claimed they have a 30% higher rate of these than any other occupation. Guess what they breathe alot of?

I haven’t read all the comments yet, but to those that think doing combustion safety testing is an inconvenience, they are hiring at McDonalds.

John P.:

John P.: You wrote, “In the field doing the hard work of trying to make good things happen there is a tendency to become religious about certain things and miss nuances that are important.” That’s exactly what I’m trying to expose with this post. Yes, I probably should haven’t started it off with a discussion of the small number of deaths. Yes, the title could have been more specific. But I’m writing this for people who are open to questioning the things we do, the ones who haven’t become rigidly dogmatic, the ones who are still open to the nuances.

Jim D.: I don’t think there’s anyone here who thinks doing combustion safety testing is an inconvenience. If that’s what you took away from the article, I invite you to go back and re-read it.

Allison – First, ALL

Allison – First, ALL combustion devices are in the conditioned space unless they are in a separate structure. I have never seen a combustion zone that was isolated from the rest of the residence. [Side note – blower door tests looking to measure “natural ventilation” are also skewed by air

coming into the structure via appliance/fireplace flues which, in their “natural” condition will be exhaust only but not accounted for by current blower door protocols.]

I have also been in the “no combustion testing” camp for some time – but for different reasons. I have always thought that the energy auditing profession had encroached into a territory that was not their own – namely home safety. It is not that testing for combustion safety is not important, nor is it that tightening up a home’s air leakiness (possibly) will affect atmospheric venting combustion devices. It is that this work effort does not pertain to energy savings, home energy performance, weatherization or occupant comfort relating to thermal loss. I think combustion safety falls into the same work scope as radon testing, electrical panel inspection or chimney flue inspections (none of which is currently included in either BPI or RESNET protocols); all good and worthwhile efforts, but not by the energy auditor.

Paul M.:

Paul M.: Thanks. I thought that other number sounded too high but didn’t look it up.

David E.: Yes, combustion appliances are usually connected with the conditioned space even when they’re outside it. Good point. Regarding combustion safety being outside the purview of energy auditors, that’s certainly something that should be part of the discussion, for liability reasons if nothing else. As you mention, though, the hip bone’s connected to the thigh bone, so it makes some sense for energy auditors to do it themselves or have someone they can call in. Ideally, the HVAC companies would be the experts here, but many have shown a surprising lack of competence in this area.

Thanks to Allison and

Thanks to Allison and everyone for sparking a great discussion on combustion safety. I wanted to say that I agree with John that it is important to understand how combustion safety diagnostics came about. This is actually how I initially got involved in combustion safety research.

In 2012 we (LBNL) conducted a comprehensive literature review on diagnostics, research, and codes related to combustion appliances and combustion appliance venting. A copy of this literature review can be found here. The literature review provides a brief summary of research dating back to the mid-1980s and highlights gaps in knowledge.

This literature review is actually why we started questioning WCD testing. Most of the research assessing the available testing diagnostics shows that the WCD test are over-predicting the number of spillage prone appliances and may be missing some problematic appliances. I should note that most of this research was conducted by those who helped develop the original WCD test. Because the industry is using a test that is not supported by research and researchers who helped develop the WCD test, a more robust test that will correctly identify the risk from combustion appliances needs to be developed. Using the results from this literature review, we are trying to steer our future research and data collection strategies to improve combustion safety diagnostics.

We are NOT saying that combustion safety testing is a waste of time. On the contrary, we think they are very important. However, research shows that parts of the current protocols, specifically WCD testing, need to be improved in order to correctly identify and mitigate risk. A good combustion safety test should mitigate the risk, both acute and chronic, of exposure to CO and other combustion gases and keep occupants safe regardless of changes in weather or exhaust fan operation.

Allison ,

Allison , Thanks for the clarification. Part of my response is probably due to the recent simplification of BPI’s BA field testing for WCD CAZ testing.

Dr. Rapp, Thanks for your succinct response. I agree there is more we can do to ensure safe operation of atmospheric combustion appliances, and I applaud LBNL for taking this on.

I submitted a list of CAZ testing strategies to BPI in response to their draft BA standard, yet the end result was a less comprehensive CAZ test protocol.

I think between skilled field personnel and LBNL scientists, CAZ testing can be improved. There is a lot of practical knowledge being applied in the field that does not make it into any literature, but would be helpful to Dr. Rapp and others in improving our testing procedures and improving our solution strategies.

I look forward to the sequel to this blog, and the next chapter of CAZ testing.

Dale

A typical chimney cap, or top

A typical chimney cap, or top, is designed to use the Venturi effect to increase suction and pull the combustion gasses up and out when the wind is blowing. Air pressure in a building is often higher when the wind is blowing because wind typically pushes more air in through the upwind side than it sucks out of the downwind side. Both of these factors help to explain why carbon monoxide poisoning is more common when there is little, or no, wind.

I believe there needs to be

I believe there needs to be some improvement in the CAZ limits and the worst case depressurization testing procedures. Over 15+ years of doing these tests in thousands of houses I have repeatedly encountered situations where CAZ limits as per BPI protocols will be exceeded but the gas appliance(s) will pass the worst case test. In doing in-field testing for BPI candidates I have observed multiple test candidates testing the same house on the same day and having multiple sets of test results. There are variables at play here such as wind, humidity levels, and possibly even barometric pressures as weather fronts move through an area which I believe are not adequately accounted for in the test protocols. If it cannot be scientifically replicated then the test is dubitable. I do not advocate throwing out the test, but I do advocate not making the CAZ depressurization limits in themselves an actionable item UNLESS the gas appliances themselves fail to draft adequately. As to the comment about trip hazards, I look at it this way; I am in the house to help my client solve a problem without making more problems in the process, BUT I am not there to save them from every last hazard in the world. My focus is on my particular speciality. That does not include trip hazards. I am enough of a clutz some days to know that none of you cvould save me from myself!

Allison, comment about

Allison, comment about combustion testing was in reference to John Krigger who has said this more than once and should know better.

The majority of CO poisoning and deaths occur from appliances that aren’t venting correctly, not necessarily backdrafting. As said before and I think BPI agreed “Worst case testing is not Worst case”.

If CO is spilling into the space so is CO2. CO2 will be in the 10,000ppm range. CO2 displaces O2 rapidly, so if you are spilling, backdrafting etc. COppm will accelerate.

My students find thousands of CO problems every year that go unreported. Worst case depressuriztion is rarely the problem. To the credit of the Home Performance people, they are probably doing more CO testing than HVAC contractors. Our industry still doesn’t require it most of the time.

I will be glad some day when checking the pressure of the flue during worst case (as is case) gets implemented. That is the only pressure that is important. Any interference there is unacceptable.

Low level CO detectors were available before the UL2034 was written. But because of the nuisance they caased fire departments and utilties the detectors sold in stores were raised to higher levels to assure people were poisoned before they went off. I just hope the ones that are currently available don’t cause the same problem.

I don’t advocate and never

I don’t advocate and never have advocated neglecting CO testing. I only question whether worst-case depressurization testing is effective in reducing the risk of CO poisoning. I have stated that opinion many times. I have never advocated neglecting or reducing the importance of CO testing. My last blog post on the importance of effective combustion testing was on 1/5/14. The post recommended simplifying the procedure and relying more on observations and a complete electronic combustion analysis. You can read about what I consider effective combustion safety testing by following this link:

Did everyone forget why the

Did everyone forget why the test was developed in the first place and the massive study that followed? CEE demonstrated the very high number of homes that were back drafting before any energy improvements had been made to the home. We’ve since documented thousands of homes with combustion spillage and occupants who had potentially related health issues.

We need to take a do no harm approach to homes, and rather than quibble over deaths and levels, focus on removing atmospheric venting and open combustion appliances from our homes.

John, the original comment

John, the original comment above seems to say that but that doesn’t matter because it has created a good conversation.

Depressurization testing is necessary but it is not really done correctly, and is misinterpreted as what appliances can withstand. I read lots of useless theories that seem to think things behave in a fixed manner.

Another problem I see is that we say you have a problem. What problem? You failed the depressurization test. How do I fix it? You fix the problem. What problem? The problem that caused the depressurization test to fail. What cause it to fail? The problem. What problem? The problem you need to fix. Fix what? The problem. I could go on forever with this but I think we might get the point.

It might not be you John but I do hear many others make the comment that safety testing is too time consuming and may even cost us work.

Having just sat through two

Having just sat through two sessions at the RESNET conference with the folks from LBNL (whose work I deeply appreciate) I think the problem is that their conclusions are getting lost in all of their wonderful data. What I gathered is this, do the tests and understand the problems, but stop worrying as much about getting a combustion air inlet to a water heater when it probably won’t solve the depressurization issue anyhow and start making sure the range hood gets ducted outside and actually used. In others words lets spend more time addressing the things that are actually causing problems and less time meticulously testing things that are not. We auditors have a limited amount of time with our customers, LBNL wants to make sure we use it to do the most good.

Regarding CO monitors/alarms:

Regarding CO monitors/alarms: where should they be located? Low, near the floor, or high, near the ceiling? Should they be located near a combustion devise, or near bedrooms? Should they be battery-powered or hard-wired or both? If using multiple monitors/alarms, should they be interconnected?

A lot of information to be

A lot of information to be sure. thanks to all.

If the CAZ test is too involved, not involved enough just go in and

A: recommend a CO monitor

B: All sealed combustion appliances

C: Electric water heater

Save the angst of the CAZ test and apply the savings to the selected remediation.