Building Enclosures Have Improved More Than Ducts

Yesterday I visited a home being built by a national production home building company. As you can tell from the title of this article, I have good news and bad news. The good news is that building enclosures have improved, especially the air barrier. The bad news is that ducts still don’t get the attention they deserve. Let’s take a quick look at some of the things I saw.

Building enclosures have improved…mostly

The lead photo above shows the ceiling joists going across the wall between the garage and the living space. I’ve seen some horrible jobs of blocking and sealing those joist openings above the wall. This builder got it right. They filled the openings and sealed the edges and penetrations. They even lined up the open-web trusses to have vertical members above the wall to make blocking easier. Also note the ladder T-wall that allows them to put insulation at that intersection of two walls.

Another big improvement over days of yore is that interior walls that need sheathing but didn’t used to get it now have that sheathing. The photo above shows the exterior wall beneath the stairs. They did the same thing in the fireplace chase and behind bathtubs on exterior walls. (Locating tubs on exterior walls is another matter, but I guess we need to take that up with their designers.)

And it’s all sealed up. I did see some bits of insulation around those areas, so I assume it’s insulated behind the sheathing, too. Yeah, it’s fiberglass batts, and no, it’s almost certainly not grade 1. But 20 years ago, many of those walls got nothing. (Now you know why your shower is so cold.)

But it’s not all puppies and candy. Yes, building enclosures have improved overall, but some details still need more attention. Take those attic venting baffles in the photo above. They’re bent in a way that will allow almost no insulation over the top of that exterior wall. It’s bad enough that they’re not using raised-heel trusses that allow full insulation depth there. Maybe this builder has a walk-through to fix things like that before the drywall goes up, so it could still get fixed. But not doing it right the first time is a problem.

The photo above shows what the venting baffles should look like. I took this photo at a Habitat for Humanity project in Nashville, Tennessee.

The ducts are still a mess

The design of the home still calls for a lot of ducts in an unconditioned attic. We know that’s the worst place to put them, and we have many ways of getting them into conditioned space. This house also used flex duct for everything coming off the plenums. Some of them were run high in the attic, where summer temperatures are the highest.

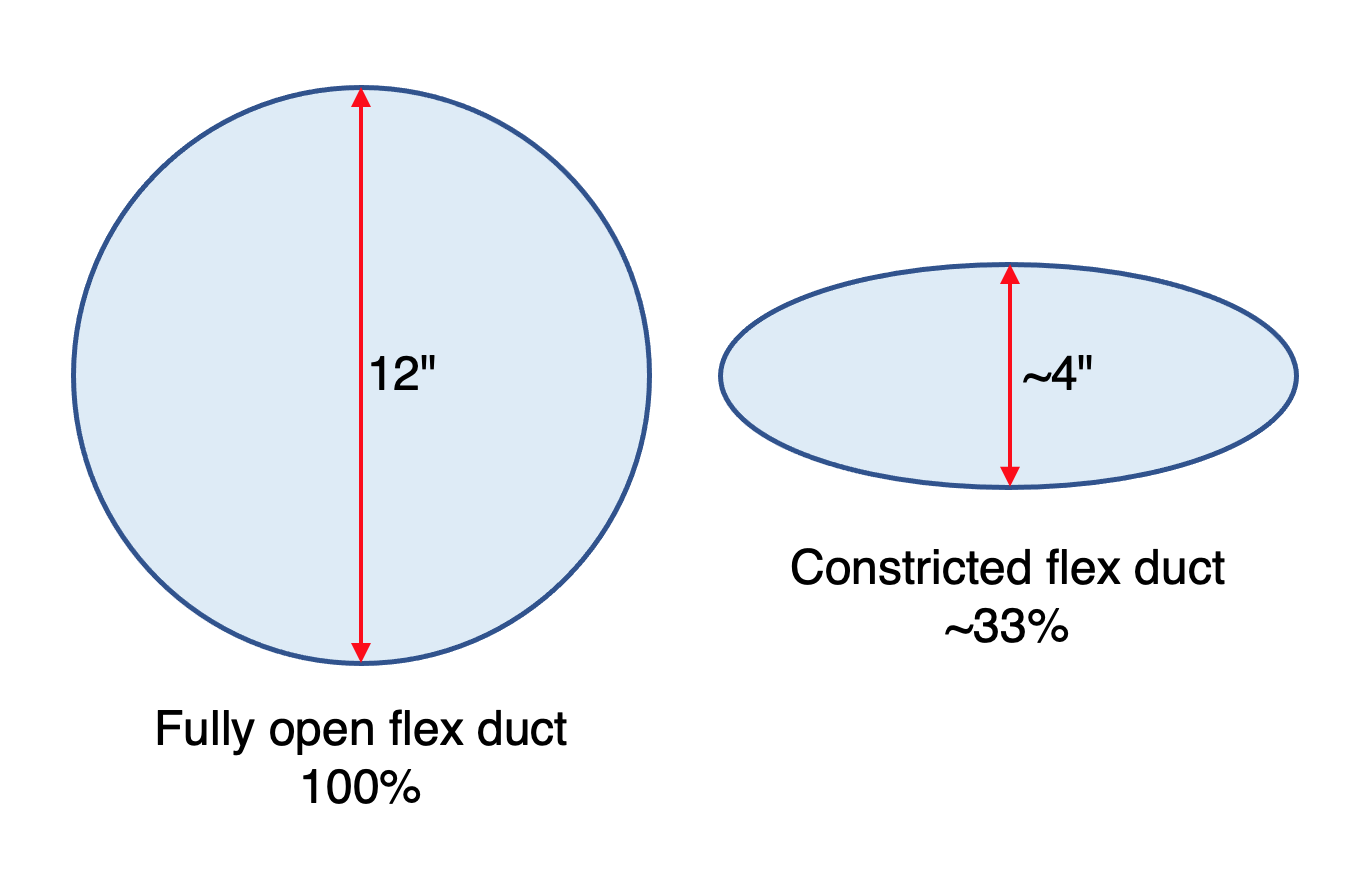

The photo above shows another problem. A 12 inch flex duct comes through the open web trusses and makes a sharp turn onto the metal boot you see here. You can’t really tell in the photo, but that sharp turn changed the shape of the duct. Instead of being a 12 inch diameter circle, it became an ellipse that was 12 inches in one dimension and about 4 inches in the other.

The diagram above shows what that does to the area available for air flow. Instead of having the full 113 square inches, the air now gets forced through the smaller 38 square inch constricted flex duct. That creates more resistance to air flow. And this is a return duct, which may well be undersized already.

And then there are the bath fans. The photo above shows one of them roughed in, with the classic 180 degree turn the duct makes immediately upon leaving the bath fan. This creates a lot of extra resistance, as does the flex duct not pulled tight. But hey, they connected to a piece of rigid sheet metal duct, so all’s good, right? Nope.

The role of building codes

The big reason that building enclosures have improved so much, especially the air barrier, is that we’ve been requiring blower door tests on all new homes for a decade now. When builders know their homes will be tested, they do the work to make sure they pass. Performance testing like this results in more improvement than visual inspections.

Duct systems for heating and cooling get tested for leakage, so that part of duct systems has improved. Most building codes do NOT require that ducts get tested for air flow and efficient delivery of heating and cooling. That’s why builders still get away with bad installations. The Air Conditioning Contractors of America (ACCA) has developed standards for quality installation and verification of HVAC systems, and using them would be a good idea.

We know how to do this stuff right. It’s just not being done because it costs money upfront, which the builder pays. Putting in sub-par mechanical systems saves the builder money, but it locks in extra costs—in money and comfort—for the homeowners for decades.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and writes the Energy Vanguard Blog. He is also writing a book on building science. You can follow him on Twitter at @EnergyVanguard.

Related Articles

How Can You Air Seal These Joists Over the Garage?

Grading an Attempt to Get Ducts Inside Conditioned Space

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 55 Comments

Comments are closed.

We CONSTANTLY battle for enough space to properly install ductwork…and sometimes I wonder if Sparky (electrical sub) deliberately aims bath vent fan exhausts 180* away from logical exterior discharge location. We try to be the ones to mount bath fans and just let Sparky wire them up.

I have refused custom new construction jobs of $50k, even $100k or more for the sole reason that ductwork appeared unconstructable to a proper standard. As a general rule, residents uncomfortable with HVAC outcome in their brand new home never ever call the framer or the structural engineer at fault for insufficient duct space!

It seems that it’s all about maximizing the amount of interior space. Townhomes are the worst in this regard.

I grew up building houses with my father who was the general contractor, the framer, and the finish carpenter. We always worked with the subcontractors to find the best way possible to integrate their work. I remember one house where the HVAC guy was heading down to the basement with a 16-pound maul. Dad asked him what he was going to do with that and he said there was some framing in the way. He was about to knock out a section of solid bridging between the floor joists so he could run his ductwork through it. Dad got his Sawzall out and cut a hole in it instead. We had many situations like that. If you want a house built right, it helps to have a general contractor who is also a carpenter and is on site most of the time.

Curt: We face the same problem of not having enough space in many of our design jobs. Or maybe there’s enough space, but they put an LVL between two parts of the house and there’s no way to get around it. And that’s before the battle of the trades that happens onsite.

I’m glad you asked the question (why the crappy quality) and answered it (because it meets code) in the same article. It just points out (again) that most builders (national or local) don’t really care about best industry practice, just what meets building codes. So the real solution is – have national (not local) building codes that reflect the most recent best industry practices for every trade. No wiggle room; no interpretations; no confusion; no grandfathering.

David: I sort of agree with that, but only if by no wiggle room or interpretations, you’re talking about the verified performance. Let designers and contractors come up with their own solutions but require testing and verification.

Always love the photos of things done wrong!

A few years ago at a WX conference I saw a demonstration where an exhaust fan with a 6″ flex loosely tied in a knot vented as well as a vented 4″ hardpipe. Of course the exhaust fan in the photo should have been oriented properly, but in your experience, does upsizing bathroom venting to a 6” flex overcome undesirable installation practices? (From the photo, was the fan flow measured and what was the fan rated?)

Randall: Sometimes upsizing from 4 to 6 inches is enough, but not always. When version 3 of the ENERGY STAR new homes program came out a decade ago, bath fans were the thing that most often seemed to cause houses not to meet the criteria. Why? Because for the first time, the program required them to be tested and to move at least 50 cfm. What people found was they had to install larger fans, bigger ducts, and keep the runs short and straight. Here’s an article I wrote about it:

This Little Hitch Snares ENERGY STAR Homes

An hvac contractor banging out a block….thats nothing I’ve seen those clowns sawzall though a triple lvl beam with flush hung joists on both sides, saying its in his way!

Its a shame that most trades people have lost the pride that came with a job done correctly. Some dont care, some just poorly trained and some just freakin clueless when it comes to common sense.

Robert: The blame doesn’t belong only to those doing the work. Yes, some people will do the minimum required and no more. Worse, an installer may want to do better work but the builder who hired them wants it done faster and cheaper. If they don’t do it half-assed, they lose the job.

So correct on the tubs on outside walls. A FLIR scan show I have no insulation on that outside wall. One day that will get fixed when I rehab the bathroom.

Danny: I’m sure you know it’s all about scheduling. That one-piece bathtub/shower unit goes in when the plumber does rough-in. The insulation comes later. It requires planning and coordination to get insulation and interior sheathing into wall before the whole house gets insulated. But now it’s required by code and it happens.

For first time in my life my wife and I are buying a new construction home. As a mechanical contractor I have been horrified to see what has been acceptable to this “national “ home builder. An 1,857 square foot home with an open crawl space, yes apparently that’s the way they still build them in NC, 2 x 4 walls, 9 foot ceilings, un insulated attached garage worked out to a 2.5 ton heat pump! All my calculations have shown a 3 ton unit which is what I originally had requested. I will give some credit to the HVAC contractor they are using R-8 flex but that’s it, it’s all flex from a 3 foot long supply plenum the entire house is flex duct including a 40 plus foot duct run to a bedroom. Oh yeah and no individual room returns not even those stupid “jumper ducts “ ! I was told the ONE central return was adequate if everyone left their bedroom doors open! This is the crap new homeowners are facing today and my industry will do nothing about it! Oh yeah and home prices aren’t getting cheaper!!

Paul: Sounds you got a ductopus. Those usually work only by sheer luck. And that 40 foot flex run has at least one butt joint, which may be just the two pieces of flex taped together with no collar.

Regarding central returns, we’re big advocates of them in our HVAC design work. But they MUST be paired with return air pathways, which it sounds like your house doesn’t have. It’s completely unacceptable for them to tell you the system will work adequately only if you leave the bedroom doors open. What they’re telling you is they gave you a faulty system that does NOT work the way it should.

It’s interesting reading these comments. I work HVAC commercial, so I’m not as familiar with home installs as I am with commercial. In commercial we always put a return in every room, whether it’s a small data closet, a small/medium sized office with/without a door, or large areas. We do this to because it better controls humidity, allows for more consistent temps with fewer variations across multiple spaces, and allows for a better air exchange when outside air minimums (10%-20% depending on the county/state) are required.

In my own home (2,000 sf), I had a central return with flex duct. Humidity was terrible, even with longer run times. After using Manual J (which should be required for every install), I went to metal duct and returns in every space. The Humidity issue immediately went away, even with the addition of an OA duct on the return set for 10% OA, which is now required for all new construction installs in WA.

In older buildings with humidity and temperature variation issues, we add returns to fix the issues. We often run into issues of improper sizing for spaces because original contractors failed to use proper sizing. Comfort and health are the driving forces leading to the changes. With all this said, why are you a proponent of Central returns?

Thayer: It’s not a matter of how the air gets back to the air handler. You can do that with dedicated returns in each room that can be closed off or with a central return and return air pathways. The problem with many homes that have central returns is that they didn’t put in the return air pathways. When a builder tells you you have to keep the bedroom doors open for the system to work right, as in Paul’s case, they didn’t design the return air pathways properly.

Some advantages of central returns are:

* less ductwork

* less chance of duct leakage

* less conductive loss for ducts in unconditioned space

* easier to use filter grilles

Here’s an article on return air pathways:

An Easy Retrofit for Return Air From Bedrooms

And here’s an article on duct systems:

17 Steps to Better Duct Systems

@Thayer, in addition to what Allison said, I try to specify ductless returns whenever possible, especially in homes with a finished basement.

The typical basement setup has the AHU mounted on a site-fabricated box with filters on front and one side (allows for larger filter surface area), with a louvered door for the mechanical room. This not only saves the cost of return ducts & grilles, but reduces blower energy and makes it easier to run supplies through floor trusses (no interference from return ducts).

But the big advantage of having the central return in a finished basement is that it ensures good (and more persistent) air change between the basement and other levels. Otherwise, basements tend to be musty, especially if they’re shut off from the main level. If designed properly, putting the central return in a basement eliminates that problem!

I’ve had more than a few HVAC contractors object: “That’s not going to work!” but I have plenty of clients that say otherwise. The missing piece in most homes that have a central return is a plan to provide for (and verify) low static return pathways. There are several low-cost ways to achieve this depending on the situation, and it only takes a few minutes for the blower door technician to do site verification.

Very helpful article. My ERV installation used all flex duct, and never worked properly. My contractor was a great guy who did very good work overall, but he trusted an HVAC guy to do the ERV. I don’t think my contractor ever read the directions himself, even when I noted the system didn’t work. Between reading the installation directions myself and this article years after install, it’s clear that the pleasing to the eye strapping of the flex duct to about a quarter of the duct diameter in spots, the 60-80 degree bends of flex duct, probably not pulled tight, and the 30 foot supply run length fated the installation for failure. I think standards have to be applied, and manufacturers should help lead the way. You don’t get repeat sales or word of mouth recommendations from ventilation failures .

Linda: Yeah, energy recovery ventilators (ERVs) require an installer who knows more than the typical contractor. I’ve seen many bad installations of ducts on ERVs, too.

I was fortunate to install most of the ductwork in our current house (built in 1986) – then go and fix some of that ductwork back in 2016 during a remodel of the second floor. My dad taught me back in 1986 to always design a house for the installation of mechanicals – and then install things in a specific order: vent work; hydronics; plumbing, electrical and audio. Sounds like some builders need to go back and learn some lessons.

Entertaining photos, as always. That bathroom exhaust duct should be insulated, shouldn’t it?

The least expensive upgrades in the total built-price of a home have been detailed framing plans, building envelope, and HVAC design and execution, and so we stuck with them as defaults. No worries about meeting code in any of the areas, because we can usually beat the code by a factor of 2.

I do realize we’re in minority, and for the vast numbers of builders who learn quickly how to keep inspectors happy, the only path is to improve codes to go well beyond minimums, as well as to provide mechanisms that would enable the AHJ’s to make their framing/insulation/HVAC inspections to be more complete. For example, installing $5 air pressure test ports in selected duct runs?

Last, an extreme, out-of-this-world thought: tie house pricing in MLS systems to the ever so flawed HERS number. For example, a HERS of 25 gets the 1.0 price factor, a 40 gets a 0.95 and so on.

Paul: Yes, bath fan ducts should be insulated. In winter, they can get condensation on the inside. With dips in the duct, water can pool and turn nasty fast. Worse, dips deep enough to form a trap can completely block air flow if they fill with condensation.

The photo with the constricted 12″ flex actually does illustrate how improving codes works, at least partially, in the face of ever-complaining NAHB and local AHB’s: the hot water pex line is insulated. If it was only optional, good-practice type of thing, on many homes it would not happen.

Could the floor trusses be deeper instead? For a moment envision a 3k sq/ft 3-story townhome with floor trusses that are 1 ft tall. Now imagine having to snake duct work through this space while avoiding electrical and plumbing.

Hello, all.

I’m the MM at an apt complex and have been dealing with an on-going issue no one can answer… I’m reading some intelligent comments here, I hope y’all can help!

A year ago, they built two new buildings on the property. Since day 1, I’ve had a half dozen units complaining about excess condensation forming in their front load dryers (all same dryers, all same floor plan). I’ve seen 3~4 tablespoons of standing water in a couple drums, the doors sweat, and a few complain of extended drying times.

We’ve brushed the ducts, used a bore scope to look for damaged ducting, had the GC and HVAC contractor back out, inquired with GE about known issues with the dryer, bought a new dryer to swap (no change), reviewed the prints (this floor plan actually has the best looking design of all the floor plans- minimal bends and straight shot!), hours of conference and zoom calls… And hours on the internet, reading stuff like this!

I’ve considered booster fans but then we’ll have issues brushing the ducts in the future and it becomes a new maintenance item. I’ve considered installing a small vent behind the dryer to let the wall breathe, but I’m not sure the overall impact that will make (and again, no one I’ve talked to seems to know, either…).

Oh, and this is in Houston. Effected units are on the E, S, and W walls…

Sorry for the wordy post but I do appreciate your time.

EB

Eric: The problem is the ducts. You may not have found problems when you looked with the borescope, but everything you describe indicates low air flow through the ducts. If the ducts aren’t blocked anywhere, then it’s a matter of too much resistance because of an effective length that’s too high. Some possible reasons are:

.

To fix the problem, you can:

Allison, would it be possible that the apartments are actually tight enough to make the dryer ducts the paths of least resistance for “make up” air when people turn on bath fans and kitchen exhaust hoods?

Yes, Paul, that could happen, but I wouldn’t expect the bath fans to beat out the dryer. But the low air flow could be caused by the apartments being very airtight and not being able to pull enough air through. If it’s a small apartment with a blower door result of 200 cfm50, a dryer running at 200 cfm would create a 50 Pascal negative pressure. Fans having to fight against big pressure differences have a tough time moving the amount of air they’re supposed to move. I could see that being the problem.

Eric, do you know anything about the airtightness of the apartments? Do you have blower door test results?

Its not that the dryer ‘beats’ anything. It’s the fact heavy air sinks through the ducts when not in use. I suspect his dampeners on the building exterior are the static type and not self-closing. The dampeners should slow that backflow to a trickle. You can also add inline backdraft blockers, too, to keep infiltrating air at a minimum.

Matt, backdraft blocking is a good idea, except I would not put any on a dryer vent. This whole thread should remind us how we are still hanging on to a relatively primitive method of drying cloths.

Paul,

I’m replying here because it wouldn’t show reply to your post.

Inline backdraft dampers are available in several flavors. I most certainly would use them in the positive airflow environment of a dryer vent. They close themselves when you have negative gradients. No different than damper vents on the exterior walls. The commercial dryer vents shouldn’t have all the fibers going through them like on residential, so less prone to clogging. Besides that, you always put them in a place where you can service them if they do stop functioning.

MattM, I understand your point, but stubbornly remain in the position that today’s dryers are (most of them) yesteryear’s technology, like internal combustion engines.

And so we keep trying to find excuses for their existence, such as venting. And the hickups with venting, and lint, etc. etc.

OK, coming back to earth now, from the building science perspective I understandably agree with you. However, my builder’s instincts tell me that lint will find a way to accumulate given an opportunity such as an inline damper.

Eric: The problem you describe sounds like an issue that used to be prevalent here. In apartment buildings with shared dryer exhaust, the dryers would have the same issues. When too few dryers were running, there wasn’t enough air to prevent air below the dewpoint in the duct from returning down dryer duct (insulated or not, rigid or flex). Dampers couldn’t fix the issue. To overcome this, a small powered exhaust fan would be installed on the roof, pulling enough air to keep the OA from entering the duct. I’m wondering if that’s your problem.

The ideas of restricted vent ducting or negative pressures in the units makes sense in terms of increased drying times, but I can’t think of any psychrometrics that would explain “condensate” in the dryers.

Good point, Roy. I was thinking maybe the condensation happened after the dryer went off.

But it’s also Houston, where condensation is on everything all the time. ;~) (OK, not really, but it sure feels like that sometimes in the city of my birth.)

Also, he said the doors sweat, which could be caused by an air conditioned laundry room and a leaky dryer duct. The 3-4 tablespoons of water inside the dryer is a mystery, though.

Yea, the doors sweating sounds like hot humid air is being sucked back into the house through the vent, probably during the off cycle. I wonder if the people leave the dryer door open when it is off. Closing it might help the condensation problem. But the long drying times do indicate that the negative pressures could be significantly reducing the airflow when it is running too.

Well, the dryer is designed to suck with the doors closed, and I am assuming it can happen in the opposite direction, unless there is a damper on the intake side. Maybe there is enough condensation on the inside of the door to drip down to the drum… Haven’t looked at a dryer with a metal door in a while, but older dryers used to have metal doors that were part of the air intake path.

Yea, Paul, that is a good point. It would backdraft through the dryer with or without an open door during an off cycle if there is negative pressure in the unit. There should be a backdraft damper on the exhaust termination, but many of those are nearly worthless. At my house in Oklahoma, that damper would rattle like crazy on windy days. I finally solved that problem by putting weather strip around the edges so that there would be no metal-on-metal contact.

But if the problem is due to negative pressurize in the unit, that should probably be corrected first to ensure the dryer has enough exhaust airflow when it is running.

I was thinking on both fronts, tight enough for dryers to have trouble pulling, and tight enough for dryer ducts to become make ducts when something else is pulling, not necessarily at the same time as the dryer.

If blower door results come back tight, Eric could enlist a couple willing dwellers and ask them to always crack open a window (just a couple inches) whenever they 1. use a dryer, 2. use any other exhaust fan. Just tape a reminder note to the dryer. Run this experiment for a couple weeks. If it confirms, maybe find a way to install small make up air inlets in an exterior wall somewhere?

This is a timely topic for ASHRAE Standard 62.2. There is currently a proposal to not allow exhaust-only whole-unit ventilation systems in multi-family units because with these types of systems, you don’t know where the make-up air is coming from . Many people are concerned that it is coming from adjacent units, but it sounds like it could be coming from dryer vents too.

I wonder if any of the dryers share a common exhaust path and in that case super high dewpoint air from an operating dryer could be back flowing into inactive dryers. That is the only explanation I can come up with for water in drums.

Eric,

Would it be possible to substitute a condensing dryer for one of the “problem children” as an experiment? If this dryer solves your problems then it may be more economical long run to replace problematic dryers with condensing units and remove the labor of vent cleaning/problem searching while increasing customer satisfaction.

Wow! Y’all are awesome! Thank you very much for all the responses.

I’ll go thru all the posts, make my notes, and get with project manager. I’ll follow up periodically so you know how things progress.

A couple quick notes:

-I have already teamed up with a couple residents for experiments. Keeping the doors closed is where we started. Leaving them open for 15-30 min after use helps but doesn’t resolve completely. This was also GE’s “official” answer- leave the doors open after use. Yeah… I’m not comfortable telling residents of brand new, premium apartments that that’s the final answer…

-the laundry rooms are not conditioned but do have a large vent above the doors

-I’ve messed around with the fresh air system settings for another issue and haven’t seen any impact on the dryer issue

The other issue- many of the new units run constantly high humidity levels, 65% and up, have seen it as high as 72%. They’re supposed to be “super-sealed”; guess a blower door test should confirm. I’ve messed with the FAS with some success, but still getting 60%+ readings (electronic t-stats). I get it’s Houston, but my old units aren’t like this. The cooler temps lately have helped.

I shall follow up!

Thank you!!

It is common for brand new construction to exhibit higher humidity for the first 6-12 months…it takes that long for construction materials (wood, concrete, grout, etc) to fully dry / cure.

😮

I’ve never heard that before! Thanks!

If it were my job to investigate I would also evaluate the Man J / system sizing with a gimlet eye. If the units are super tight then HVAC equipment may be oversized and short cycling. Also consider internal latent gains and managing those better – bath fan timers, or motion sensors. Ensure fan vent ducts actual terminate outdoors and air actually flows through them when the fans run. A $7 termination fitting stuck or painted shut renders a bath fan useless. Are range hoods vented to the exterior or do they recirculate, returning air right back into the kitchen?

Eric, you mentioned “the fresh air system”. Can you describe it? This might change our conversation somewhat, but not necessarily make it any easier.

Paul, sorry for the delay.

As explained to me, the fresh air system is ducted directly outside. There’s a controller that turns on the blower- whether havc is on or not- and draws-in fresh air based on the controller settings, and controls one damper. It seems to be strictly time-activated, unless it ties into the t-stat humidity readings; I haven’t seen any additional sensors. There’s a manual damper and an activated damper.

Dealing with the high humidity issue, I’ve experimented with the timer, dampers, turning it off entirely. My argument is we’re drawing HOUSTON AIR- you know, the super humid stuff?! Minimizing the FAS did help lower the humidity levels a few points. I don’t know what the long-term effects of this will be… I guess it’s there for a reason : /

@Eric, that’s a timer-based ‘central fan integrated supply’ ventilation (CFIS). Those are notorious for not being properly commissioned, and therefore often improperly sized for the attached blower. And even if installed perfectly, can lead to excess indoor RH, especially in Houston. On top of that, off-cycle operation of the HVAC blower can consume copious amounts of energy if the blower is not ECM and properly configured to operate on lowest speed during off-cycle calls. Here’s Allison’s article on CFIS.

Eric, David lays it out for us about CFIS. And I know little to nothing about multi-family fresh air strategies, but I’d think it’s more difficult to do than single-family. Smaller volumes of living spaces, just as many people breathing, cooking, washing etc. Would ERV’s be feasible at this point? Are they even allowed to be installed on a one-per-many units basis? Commissioning those would also be crucial in order to get the correct flow rates, and I am sure the right section in ASHRAE deals with those. Curt also had a point with new construction materials drying out.

Would CO2 sensors (to control FAS) in each unit be feasible?

At this point in the conversation about your high RH readings, I’d arrange the contributing factors discussed here in the following order of influence:

1. FAS

2. Backdrafting through dryer ducts

3. Others, including new-construction materials drying out.

My kids move to Georgia a couple of years ago and purchased a new semi custom home in Barrow County. While I see attempts being made at air sealing, the builders there have along way to go with water management with regards to WRB and properly installing windows. I see poorly installed house wrap leaving oriented strand board sheeting left exposed under brick. Given all the rain you get in Georgia, I just cringe at the lack of the basic understanding of building science. I live in Arizona and production builders do a much better job with sealing the building envelope with respects to water management.

Hello Allison, I’m hoping you can point me in the right direction. I live in Denver, CO in a single family detached house, built around 1900 on a city lot. Exterior walls are 2 wythes of brick @ first Flr, brick for about 4 ft then transition to stick built for upper ext walls, then roof. Full basement, rhyolite walls on flagstone footers, about 750 sf per flr. I want to do an addition off rear (kitchen and flex space, primary bedroom and bath above, finished walkout basement below) and would really like to incorporate renewables for as much energy as possible. Because house was a somewhat neglected 3 apt. rental from the 1930’s to 1990’s, it has had very limited renovations (still knob and tube, for instance), so now is the time to upgrade all systems. I’m an interior designer so can handle most of the general design but definitely would like to hire someone (with no products to sell) to analyze and specify the best renewable HVAC system or combination of systems for this residential project, including all relevant mechanical, insulation, solar/heat pump, etc. equipment. Are there mechanical engineers specializing in residential who also have expertise in renewables, good knowledge of building science, along with experience in retrofitting older buildings? How would I go about locating such professionals? Research doesn’t scare me, but incompetency does, thus my inquiry. Thank you in advance!

If only they were correctly enforcing M1506.2 Duct Length that bath fan would have a better chance.

They’re 1/2 way with the 4 inch duct, but need to read note ‘c.’ I see a deduction of 45 + feet – 30 for the 180 and 15 for the little jog – that duct is “too long.”

Good point, Andy. That table in the code (M1504.2 in the 2018 IRC) uses a set 15 feet deduction for each elbow. That 180 degree turn would take two elbows, as you say, but I’d guess the actual effect probably would be worth more than a 15 foot deduction because they didn’t make the turn gradually enough. The other problem here is that the flex isn’t pulled tight, which the IRC doesn’t address.