Can a Heat Pump Water Heater Replace an Air Conditioner?

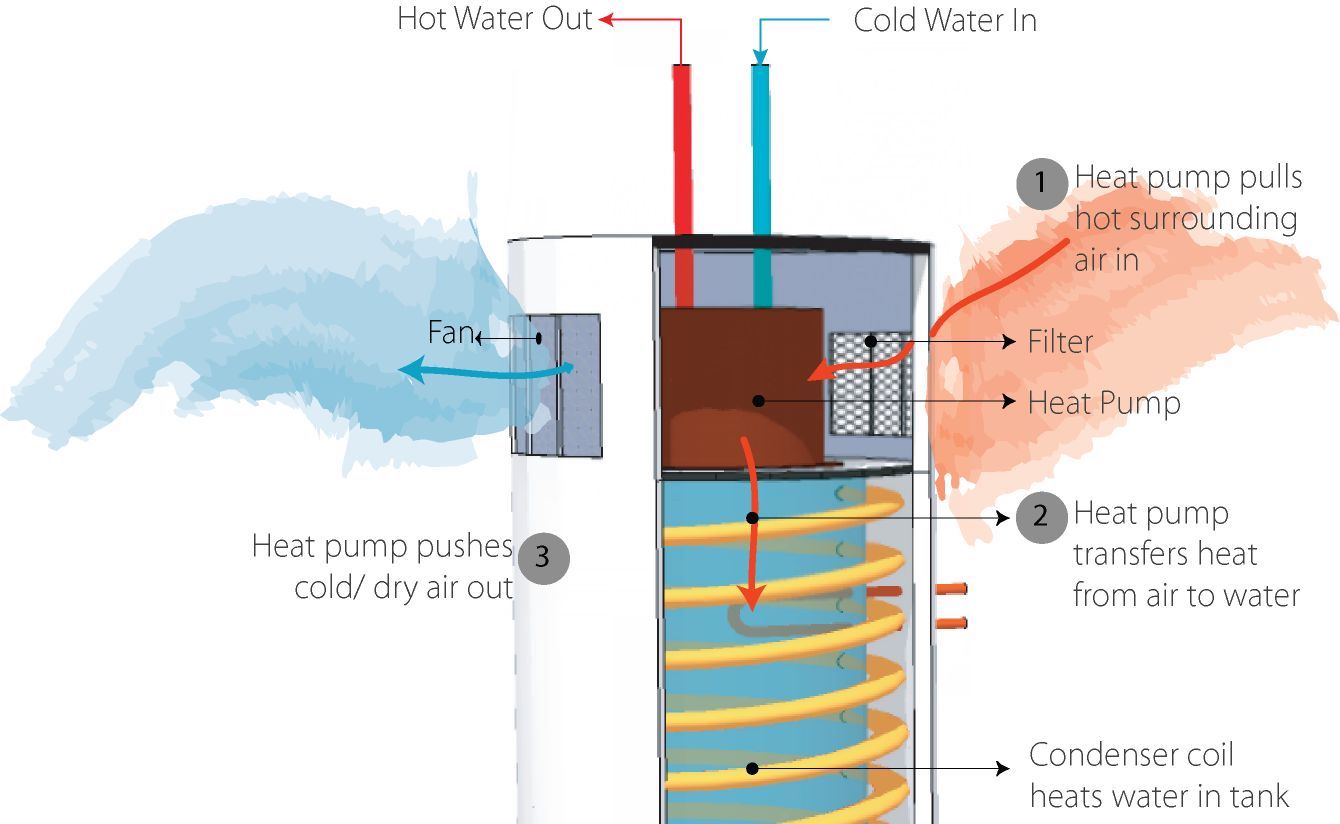

The most common type of heat pump water heater takes heat from the air and puts it into water. Of course, that’s what all heat pumps do, right? Take heat from one place and put it in another. By removing heat from the air and putting into water, though, a heat pump water heater also cools and dehumidifies the air. Which is exactly what an air conditioner does. So, can you get rid of the air conditioner and just use the heat pump water heater?

Factors to consider

The first thing we need to know is how much cooling capacity we can get from a heat pump water heater. That will depend on a number of factors, the main three being:

- Location of water heater

- Inlet water temperature

- Amount of hot water use

You won’t get any cooling in the house if the heat pump water heater isn’t located in the house. Some heat pump water heaters have the option to duct the intake or exhaust, so the water heater could be outside but sending the cool exhaust air into the house.

Temperatures can change significantly over the course of a year. The cooler the inlet water temperature is, the more heat you’ll have to extract from the air and the more cooling you’ll get. Here in Atlanta, my inlet water temperature gets up into the mid 70s Fahrenheit in summer. In a cold climate where toilet tanks sweat in summer, the water comes in colder.

Another huge factor is how much hot water you use. If you have only a couple of people in the house and do your best to conserve water, it’s probably game over right there. With several occupants in a larger house, you’ll get more cooling…but you’ll also need more cooling. (Hmmm. Where is this headed?)

Can it do enough cooling?

The photo below shows the temperature and relative humidity of the air being exhausted from my heat pump water heater. At 51° F, the exhaust air is definitely providing some cooling. We could do calculations to figure out how much cooling (in BTUs per hour or kilowatts) we’ll get. In fact, we have more than one way to approach the problem.

But let’s keep it simple here. The most electricity I’ve used to run my water heater in the summer is about 30 kilowatt-hours (kWh) in a month. The uniform energy factor (UEF) of my water heater is 3.7. That means it moves 3.7 units of heat from the air into the water for each unit of electricity that I pay for.

Here’s how to find the amount of heat moved into the water, and thus the amount of cooling provided to the space around the water heater.

E = 30 kWh in one month

Q = 30 kWh x 3.7 = 110 kWh (rounded)

Conversion factor: 1 kWh = 3,412 BTU

Q = 110 kWh x (3,412 BTU/kWh) = 375,000 BTU (rounded)

Wow! That sounds like a lot of cooling, doesn’t it?

Maybe it is. Maybe it isn’t. OK, it isn’t. Here’s why. Although it’s in the hundreds of thousands of BTUs, a BTU is a small amount of heat. Also, that’s the total for a whole month of water heater use. The main floor of my house has a cooling load of about 21,000 BTU per hour. Using my result above, I can calculate the hourly cooling rate of my heat pump water heater:

Q = 375,000 BTU ÷ (30 days x 24 hrs/day) = 520 BTU/hr (rounded)

So, my heat pump water heater doesn’t come close to being able to cool my house. It couldn’t even meet the cooling load of the basement (~9,000 BTU/hr), where it’s located. In fact, I’d have to have about four of them in my bedroom to meet the cooling load there. (But then I’d need four times the hot water use, too.)

Sum and substance

I’ve ignored some of the issues involved in doing a rigorous analysis of the cooling capacity of a heat pump water heater. The split between sensible and latent cooling will have some effect, as will the air temperature and the efficiency of the heat pump water heater. But with such a large discrepancy between water heater cooling capacity and the cooling load in my house, getting rid of the air conditioner is not a viable option.

Would it ever be possible? Well, for it to work, you’d need a low cooling load and probably a lot of hot water use. Having a low inlet water temperature would help, too. If your toilets sweat in summer, you have a low inlet water temperature. Building a passive house in a cold climate and using enough hot water might get you close.

For most houses, though, no, you’re not going to be able to cool and dehumidify your house with only a heat pump water heater. And that’s especially true in hot or mixed humid climates. But if you try the experiment, let me know how well it works.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a popular book on building science. He also writes the Energy Vanguard Blog. For more updates, you can subscribe to our newsletter and follow him on LinkedIn.

Related Articles

Living With a Heat Pump Water Heater

Will a Heat Pump Water Heater Freeze Your Basement?

Air Conditioner Sizing: Load Calculations vs Rules of Thumb

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 65 Comments

Comments are closed.

There’s one or two goofy things you’re missing about HPWH:

If you were to live in an area with such plentiful water supply that it’s almost too cheap to meter, it might actually make economic sense to replace your plumbing fixtures with ones that *waste more water* so you get extra incidental cooling.

Alternatively, someone could design a system that uses some kind of digitally controlled thermostatic mixing valves on the water heater outlet, and integrates with the home cooling system, might be able to do something neat to increase the tank target temperature to extract more heat by allowing it to go to waste when mixed down to 120°F for the supply to the rest of the house.

A recirculation pump on a timer/thermostat control and a large return loop or supplemental storage tank would significantly increase demand and produce extra cold air and keep the hot water lines “hot” up to the end points/faucets

I’d be concerned that in your circ pump / loop / tank system the extra run time and cooling effect could be partially or mostly offset by the extra heat thrown off by continuously warm pipes, loop, tank, and pump. There’s no free lunch!

When I’m doing an energy audit in a house with a HP water heater, I like to stand in front of the exhaust and let the cool air dry my sweaty face.

I want to put one in a pantry and dehumidify and cool that space to help keep food better, surely it could do some good in say, a 12’X8′ space if it is used for spare bathroom, laundry and kitchen water.

That’s exactly what we did. We ducted the outlet from our HPWH into our pantry, keeping it cooler then the other rooms. It works well except through the coldest part of the winter where it becomes a comfort issue. I have setup a rule in home assistant to turn the HPWH into electric mode once outdoor temps drop below 5F which mostly solves the issue.

I’m curious, how cold does the pantry get?

In my case, maybe 3-5*F cooler than rest of house whenever the HPWH had been running for awhile.

I have smart things and a Rheem 4th generation HPWH. I wish there was a way to control the function of the unit automatically. I don’t know if there’s a different home assistant that could do that. My condensation line runs through an exterior wall and drips into my landscape and then I’ve had a couple of times in the winter when it has frozen and backed up into the pan. I would love to set it up so that whenever the outside temperature dropped below a certain level it would switch to resistance mode. Either that or I’m going to have to run the condensate line in a way that it won’t cause this issue but there’s not a really easy way to do that

Hmmm, I think I disagree with the resulting cooling BTUs. Here’s how I’ve been thinking of it:

In your example, you’ve got the UEF of 3.7, so 30 kWh used means about 110 kWh pushed into the tank. However, 30 out of that 110 kWh came directly from the electricity burned. So you only pulled about 80 kWh out of the air.

In other words, a HPWH with a UEF of 3.7 acts as an air conditioner with a COP of about 2.7 – for every 1 kWh burned, 2.7 more kWh are taken from the air, and you get a total of 3.7 kWh pushed into the tank.

So I think in your example, you only pulled out about 273,000 BTUs from the house air.

Does that make sense? Or am I thinking about the UEF wrong?

Michael, I think you are right about the net cooling effect being reduced by the electrical energy expended.

Another consideration is that a 50-80 gallon tank full of hot water, even if well insulated, slowly releases heat back into its surroundings. That explains why the UEF ratings of electric resistance tank heaters top out around 0.93. Stated another way, about 7% of the annual energy use of a resistance tank is lost to the surrounding room. I think it works out to about 150 – 200 Btuh. That figure may be a it higher for HPWH since HPWH have more tank fittings / connections to serve as thermal bridges across the tank insulation.

Michael: Yes, all the electricity that goes into the HPWH does become heat. I wrote about that here: What Happens to Your Used Electricity?) I guess I was thinking of the heat generated by the HPWH going into the air and adding to the cooling load, but the effect is the same. The net result is in line with your numbers, and that only makes the cooling effect of a HPWH less. Thanks for catching that.

For those thinking of beneficial places inside to place a heat pump water heater, keep in mind they make noise and in the winter, they inefficiently take heat from your furnace or boiler to heat water. The ducted versions might allow more options but they normally have only allow an exhaust duct with cooler air. Which can create a pressure differential for systems installed in a garage or other unconditioned space. Not deal breakers but food for thought.

Hi, I wondered why people don’t simply install the air intake to the exterior, especially in a cold climate (me = zone 5). Otherwise you are transferring heat from your house into the water which is not saving any energy. In the summer, it would work super. I have not looked at these carefully but none of the installation videos I’ve seen show an exterior air input. Do you know what the issue would be with that? (as long as exhaust is also exterior for pressure balance)

Rudolf: Two reasons: First, heat pumps designed to pull in indoor air can’t handle the low temperatures of outdoor air. It’s like putting a fridge outside in cold weather. Second, if you’re pulling air from outdoors and exhausting it into the house, you’re creating a positive pressure in the house when the HPWH operates. That drives exfiltration.

Kelly – I once had exactly what you discussed – HPWH in a pantry / laundry. It provided useful spot cooling / dehumidification. My daughter loved it and would spend in the room reading / surfing etc – coolest room in the house. My wife, OTOH, disliked it being the coolest room in the house.

I plan our next build to site the HPWH in a closed cell foamed attic where the cool / dehu will help the attic and not annoy my dear wife who outranks our daughter!

It’s a novel idea, but it’s very hard to implement. Most of the current AS-WH’s have an incredibly small refrigeration compressor…which would make residential A/C impractical. This will seem like a contradiction, but…in the Navy, I worked on countless AS-WH’s spread all around the South Pacific. There was an abundance of year-round ambient heat to make hot water, and the “waste” cooling was used to cool a small office. Here’s the problem…the average A/C system produces too much waste heat. For that reason I’ve always admired manufacturers who’ve try to incorporate waste heat recovery.

But what about when it’s winter time (in most areas of North America…where there’s really a heating season)? Now you’d have to steal some of the heat for the house, to heat the water.

Ultimately, I think the VRF manufacturers (Samsung, LG, etc.) are best positioned to finally achieve this goal, because they could treat the water heater like a separate zone of the heat pump and the problem of transitioning between summer and winter would finally be solved.

Phil – yeah that’s what i’ve seen. When it works it great. I saw my first heat recovery chiller (30 ton) in Okinawa and recently found a use for it in a recent project, a 70 ton heat recovery chiller! Im excited, but its a client in Florida with year long cooling loads as well as a lot of hot water requirements.

I think the most realistic home approach is to combine the refrigerator and the water heater. They are the usually top 5 power users, i’d imagine their loads are more similar to each other. Plus they have the bonus of scaling with occupancy. I think the only draw back would be where to dump any excess htg/clg. The attic might be a use case for space conditioning. Its using waste heat in the winter, and helping out in the summer.

VRF are neat, but i find myself using heat pumps over heat recovery more often. I’ve only seen it used as a way to mitigate solar gain or as a replacement for hotel style ACs. Its a big cost adder to go heat recovery so you really need the right runtime in heat recovery to make it worth it. I think it need to be Samsung’s and co’s VRF side along side of their appliance division to really get heat pumps right.

Allison,

Did you consider installing a split system water heater heat pump for your house?

Jim: I did, but they’re a lot more expensive. Plus, I want to keep the cooling and dehumidification inside the house.

Interesting topic. I can’t speak to to the calculation but can provide a real world example of strategic placement of a HPWH that did allow us to eliminate a window A/C unit. Home located in NH. Hot and humid in the summer. We had been running a window A/C unit in the walk out basement mostly for humidity reduction. You could follow the pattern of condensation dripping from the cold water pipes in the summer. The window A/C unit had replaced a dehumidifyer that while removing moisture also pumped its excess heat into the basement. The HPWH was placed near our oil fired boiler that provides home heating and also hot water when its in operation. The HPWH is plumbed so that it can be in series with the boiler acting as a preheater to provide us with large amounts of hot water and reducing demand on the boiler. We are also able to shut the boiler off in the summer months and utilize just the HWHP. After the install of the HPWH we were able to remove the window A/C unit, the basement is dryer and cooler all year long and I think it’s more economical to heat our hot water. It may not be able to cool our whole house but I feel much better using the energy to heat water as opposed to a window A/C dumping all that wasted heat outdoors.

Awesome installation!

Allison got this one backwards. Instead of trying to air condition your house with a heat pump water heater, you should heat your water with the air conditioner. In the past, several companies have made air conditioners that use the hot gas leaving the compressor to heat domestic water. The market just doesn’t seem to be there yet, probably due to the cost and complexity as well as domestic water heating loads not matching cooling loads very well, especially in the winter. Thus, you need backup for the water heating which either adds cost or more complexity.

Heating domestic water with home AC is theoretically attractive and has actually been around for quite awhile – my AC company installed several 10+ years ago, but the tech was obsoleted by the onset of reliable and cost effective heat pump water heaters.

Background:

About 10% of the heat transfer capacity of a split AC system is available for heating domestic water via the process of refrigerant desuperheating. While that’s a really cool sounding process, implementing that requires a fairly intrusive break into the outdoor unit, addition of two more refrigerant lines, a heat exchanger engineered to keep a refrigerant leak from contaminating domestic water, and a separate dedicated accumulator water tank. Today’s cost to install likely approaches $5k, and the project requires space for the dedicated accumulator tank.

All that said, a domestic water heating system based on AC waste heat will not provide all required domestic hot water, especially during shoulder seasons. It will degrade heat pump heating capacity during winter and its contribution will be limited during shoulder seasons when little heating or cooling is needed. A reliable primary 24/7 source of domestic hot water will still be required. It is thus rarely feasible or cost effective.

This thread comes at an opportune time for me. I may have a good use case, but it’s pretty unique. I just returned from a remote Idaho property we share with three other families. It’s an old logging camp in the mountains of Idaho, 30 miles from a power pole. There are 12 identical cabins (416 sf) built in 1954 that we are repairing to create a field study campus for undergrad/grad students. Temps can be extreme, 105 in summer (but cool at night), -15 in winter. We are rebuilding the existing micro grid with a mix of fish-friendly micro hydro, solar and batteries. Our goal is to abandon the current use of propane for some loads and move fully to renewable electricity and burning of deadfall wood for winter heat. Each cabin has a full bathroom. I’m thinking a 50 gallon HPWH fully inside the cabin would be great for the predominate summertime use and not bad in the more occasional winter use as well. In summer, I propose limiting runtime to the afternoon through evening – the hottest hours. It really cools off overnight, even in summer. If the HPWH does not reduce the overall indoor temps much, then at least someone could stand in front of the outlet for a few minutes if they really need to cool off. The other option is wading in a very cold river. In the winter, the cabins are easily overheated by the smallest wood stove and I propose limiting the runtime to the sleeping hours when neither the cooling or some background fan noise would be a bad thing.

In any occupied cabin, ample hot water use will not be a problem as taking a long hot shower at the end of a long day (of hard fun or hard work) is something everyone gets thrilled about.

I am interested to determine whether or not the newer 110 volt units are worth consideration in this application. Each cabin will have 220 and DHW will be the largest load. Cooking in cabins will be limited to single burner induction hot plates; coffee in the morning or cocoa at night. ( there is a common mess hall) I know the 110 units will have longer runtimes than the 220 units, I’m not sure how much that matters. Minimizing peak loads is a major concern on the micro grid, so it seems staggering the start time should be considered. It will be uncommon for all 12 cabins to be occupied at the same time, but we are planning around that possibility.

Any thoughts?

David, sounds like an awesome project. I’d pay particular attention to very tight air sealing of all 6 sides of those cabins (walls, ceiling/roof, floor), thus slowing down the impact of the extremes in the winter, and daily swings in the summer, other than the obvious thermal envelope upgrades. You could schedule/stagger the 15Amp HPWH units (110V) to pre-heat to a higher set point during the day. Insulate every inch of hot water pipe in the cabin, and reduce hot water pipe sizes to 3/8″, or even 1/4″ if your local jurisdiction inspector approves (IRC allows 3/8″ for most fixtures with run length limits). Add some thermal mass into these small interiors, like block, brick, stone, etc, but away from exterior walls. Increase, if possible, the size of roof overhang on the south side. The cabin windows are probably small to begin with, when you replace, keep them small, and mostly on the south wall. Specify low U-factor, and high SHGC. Winter ventilation would be a challenge, and I have no experience with a climate like that, but my first reaction is a smallest HRV you can find (just looked at one that runs between 17 and 35cfm).

Thanks Paul,

We are phasing in shell improvements, starting with new warm roof assemblies. The original cabin structures were built similarly to the lakeside camps I am familiar with back in Maine where I grew up – No insulation anywhere. The walls are solid 2x4s!!! Eventually we will re-clad the exterior, currently 1×12 lap siding, with fire resistant material. At that time we’ll likely add exterior insulation and upgrade the windows. Since summertime use is very likely the predominant scenario, we are being cautious about how much winterizing we do at this point. The 53 acres sees A LOT of deadfall each year, so a supply of adequate firewood is not a problem for heating.

Despite being in mild-winter north Florida, I’m a huge fan of wood stove heat – If the overnight low is much below 60, I fire ours up. “First fire” typically happens sometime in November and the last one to take the edge off a cool evening maybe in early April.

I grew up in New England, and we had woodstoves beginning at the first oil embargo / price shock of the early 1970s. Rural folks often had wood lots – tracts of land owned primarily to source firewood. I remember a statistic (unsure as to accuracy, but seems reasonable) that one can sustainably (i.e. continually forever) withdraw 1-2 cords of firewood per acre per year, presumably made up of both deadfall and active management / selection…firewood is Mother Nature’s original “solar battery”

If the cabins are close enough together, could an 80 gal HPWH serve 2 or 3 cabins each? In that scenario the 4-6 cabins with their own HPWH would be first priority for occupancy with the satellite cabins occupied only during peak times. The larger tanks would be more amenable to being operated only certain hours of the day. Of course shared water lines would have to be deeply buried, OTOH, I’ve read PEX is less susceptible to freeze damage. Some sort of on-demand circ pump controlled at the satellite cabin(s) might allow sharing out to 100′ separation between cabins…I’m just spitballing here.

Look carefully at specs, but you may find that the output / recovery time in heat pump only mode may be similar. Difference between 110 and 220 Volt models is likely to be in the amount / availability of backup resistance heat – 220 Volt units can have ~4kW backup elements; dedicated 110s maybe 1.2-1.5 kW, and shared circuit 110s perhaps no backup resistance at all. I would think that to manage peak load on the micro grid electrical system you’d want very little backup resistance to have to design for.

If the cabins are tight and well-insulated, then yes, I agree finding small enough wood stoves will be difficult.

Sounds like an interesting and challenging project!

Just my $0.02

Curt,

We are definitely aiming for no use of backup resistance heat. People will have to wait for the HP to make hot water. Living at this location requires a great deal of behavior modification to align with what the weather and land provide. That’s one reason it makes for a great field study campus! I’ll review the specs between the 110 and 220 models for recovery time. I doubt we’ll go the 80 gallon semi-central route. There are already a host of issues with buried services on the property. At this point we’d like to keep each cabin as self contained as possible. That makes it easier to “open up” or “close down” one at a time as needed.

Read carefully the manuals on various models – from what I’ve read some will still operate the resistance elements under certain circumstances even when set for the operating mode which supposedly shouldn’t allow that. We users aren’t masters of our domain…merely voters able to be overidden by software.

Also read carefully what mode actually minimizes resistance use…the mode called “efficiency” may not in fact be the most efficient nor the mode that minimizes resistance use.

The software can’t turn the resistance heat on if the element is disconnected.

True, in an of itself, but the software could be configured to check for proper connection of backup resistance elements as a condition for general operation…in other words lock out the compressor if backup resistance element is not connected.

I duct my Rheem HPWH into the kitchen in the summer but it doesn’t replace my Mitsubishi mini/ multi splits it just helps lower the load. On that note why doesn’t Rheem make better attachments for the ducts?

chris: Do you have a generation 5 model? If so, it’s just a grille that you attach to. I have a gen 4 and that model (and earlier, I believe) came with a real takeoff for connecting ducts. See the photo above with the data logger on my HPWH exhaust.

Unless they are professionally cleaned every 2 or 3 years the coils get plugged and efficiency drops dramatically. That little filter has a lot of bypass. It’s like everything else it gets dirty! This is not a recipe for success.

Gary: I’ve had mine running in the basement for nearly four years now with that thin filter. I looked at the coil a few months ago, and it looked perfectly clean. At some point, I’ll duct the intake and put a high-efficiency filter on it to do a little bit of air cleaning when the HPWH runs.

Do you often see HPWHs with plugged coils and low efficiency?

FWIW, my operating experience has not included fouled coils even when I’ve procrastinated a bit as to filter maintenance. However, as with all other things HVAC in Florida, keeping condensate collection trays and drain lines flowing freely is often a PITA.

Ya I cleaned the coil last year after 3 years. Sprayed, scrubbed and hosed. Also did the condensate line. Now I just have to do my 4 Mitsubishi wall units….

Definitely stay on top of air filters, coil cleaning, and especially condensate tray / drain line management with ductless wall mount HVAC units. Those are their collective Achilles heel. While I readily acknowledge that conventional high static ducted air handlers are much less efficient than ductless systems, the ducted units are much more robust as to both high quality air filtration and condensate management in my experience (Florida HVAC contractor since 2009)

I have a generation 4 . The intake takeoff seemed better than the exhaust. I modified it but , maybe it’s me, I thought it could protrude a little more to make it easier. I also swap my ducting depending on the season so I guess I notice it more. The same circular central air type register that I have mounted in an open cabinet that’s above my refrigerator is the intake in winter and the exhaust in summer. The HPWH is in an unheated storage room that’s attached to the house but with its own exterior door. The exhaust is warm enough to prevent pipes freezing in winter. I also installed a rectangular HVAC register in the same wall that I open in winter (closed in summer) which passively transfers additional heat and balances pressure…..phew

on LinkedIn, I posted a picture & comments of symbiotic use of hydronic standby losses for HPWH. PV so only cost is water and anode rod someday. If water is expensive, harvest the condensate.

In my experience, it takes several days to accumulate a gallon of condensate from an HPWH, although Your Mileage Will Vary.

OTOH, the condensate accumulation from my central heat pump easily tops 10-15 gallons per day, and I sometimes catch and repurpose that for watering plants. At least one of my HVAC customers includes central heat pump condensate in their rain barrel system. We configured their condensate drain line to help them do that – easy if air handler is in attic or 2nd floor closet.

1 KW hour we’ll heat about 5 gallons of water. The average household uses 40 gallons of hot water a day so that’s 8 kilowatt hours or 27,000 BTUs. Let’s say an air conditioner removes three units of energy for every one unit of electricity then for every three units of cooling you good four units of hot water so $27,000* 3 / 4 =20,000 Btu cooling per day. So, in theory,

a 5000 Btu/hr ac run for 4 hours would provide the average household a day’s worth of hot water.

Well, as a matter of fact, in round numbers, a heat pump water heater is in many ways similar to a 5,000 Btuh air conditioner that typically runs several hours per day. An HPWH pulls in room air, cools and dehumidifies the room air, and transfers the extracted heat into an insulated tank of hot water.

As a practical matter, adopting a conventional AC system to heat domestic water is quite complicated and costly; I outlined what’s needed elsewhere in this thread.

Am planning on changing our fossil fuel (“natural” gas) water heater to a heat pump. We’re in central Texas and can get our air for the HPWH from outdoors OR indoors (the attic). Similarly, we can exhaust the cooler/dryer resulting air back outdoors OR back to the attic. The attic is foamed under the roof (meaning it’s sealed and the air is about the same temp as – and shared with – the living space).

When it’s 100º out, and the attic is being constantly heated by the sun, it could be great to take the warmer attic air, heat the water, and return the cooler air to the attic. But, when it’s 35º out (in January) we don’t want to cool the air in the attic (and thus the house).

It’d be fairly simple to automatically control where the intake air is coming from and where the exhaust air is going to. Logically there are four possible modes (from attic to attic, from outside to outside, from attic to outside and from out to in). Of course, if the air goes from outside (through the HPWH) into the attic, that same amount of attic air then needs to be vented outside, and similarly if the air goes the other way. Thus it might be easier to say there’s just two modes: attic air in and back to the attic, and outside air in and back to outside.

The questions are: which of those two (or three or four!) modes make sense, and when? What inputs (e.g. attic temp, outside temp, HPWH air out temp, HVAC mode) to use to control where the intake air should come from and where the exhaust air should go to? And what’s the simplest logic to say when to have each ‘switch’ (for intake source and output destination) in each state? Anyone up for a relevant brain teaser?

This sounds familiar. I originally ran the air from my attic in the summer and dumped it into the storage room where I had the HPWH because the air in the Attic was so hot it was obviously a lot more efficient. And the storage room is part of the house but it’s not part of the heating and cooling envelope, it shares a sealed wall with my kitchen. The storage room also has an exterior door with a vent built into it from when I had my oil boiler out there. In the winter I switched it to pull heat from behind my refrigerator and dump it into the storage room because I’m outside Philadelphia and the exhaust was warm enough to keep the unheated storage room from freezing and I sealed the vent in the exterior door. I also added a passive central air register in the wall to equalize pressure. Now in my summer mode as I call it I pull the heat from behind my refrigerator and dump it back into the kitchen through a central air register that I have mounted in an open cabinet above the fridge. Have it tastefully hidden with some pictures and whatnot… and I close and seal the central air register. Having said that the HPWH is less efficient this way but I’m getting “free” cooling in the kitchen and since my Mitsubishi wall unit for the living room/ kitchen is in the LR it’s helpful. I don’t have the Kwh comparison but my HPWH electricity cost in the summer went from approximately $8 to $10 to $12.

Every little bit helps. It should like you’re taking advantage of everything you can. Waste nothing.

With the ducting it will be easy to pull the hottest air from the highest point of a triangular attic. I just need to figure out how to build in some hysteresis loop so it’s not constantly switching back and forth (between cycling the air inside only versus outside only). If the HVAC is in heating mode it’s easy, it’s just outside only. If in cooling mode, if it’s not too warm out maybe the HPHW could cool the attic/house more than we’d like.

Maybe I should just install it, with the switchover manual, and see if this is even an issue (the “getting too cold” problem).

I ended up docking the cool air into my kitchen in the summer because the storage room got pretty cold and I figured might as well make use of it. The storage room does have closed cell spray foam and all of the exterior walls and the ceiling with the other side being the attic. All the work I did was pretty cheap because I just used materials from home Depot and did it myself. I have thought though if something were to happen to me, God forbid, my wife would never really get a grasp of it. She’s just simply not interested which is probably more logical but less fun. Basically my setup is I’m pulling from the house and exhausting into the house in the summer and pulling from the house and exhausting into the storage room, which is connected to the house threw an open vent so indirectly exhausting into the house, in the winter. I just didn’t want to exhaust the cold air directly into my kitchen in the winter. I haven’t noticed it getting too cold in the summer.

“ I have thought though if something were to happen to me, God forbid, my wife would never really get a grasp of it.”

Laugh, yes. My wife tells everyone that when I die she has to move, as she could never know how to manage/maintain all the home automation equipment.

Nope, IMO you are way overthinking this given the likely low actual daily airflow and heat transfer of an HPWH. If feasible and cost effective, duct the HPWH to pull from and push into the foamed attic volume 24/7/365.

Don’t invest in a complex seasonal control scheme which would be difficult, costly and almost certainly introduce other problems (inadvertent air leaks, thermal bridges, and the like). Instead invest in blower door testing and any other relevant quality control to make sure that the attic foam is actually substantially airtight so as to ensure the attic volume is well within the home’s pressure and temperature envelopes…That will ensure your home will actually benefit from the HPWH’s positive influences upon the attic above’s air temperature and humidity.

Agree 100% assuming the unit has supply and return ducting options,

Well I know mine I sort of overthought it but it’s not expensive. I just did all the work myself using some duct work from home depot. I thought about both pulling and exhausting into the Attic but since my attic is fully vented both the soffit and a ridge vent I couldn’t do that in the winter here. And I can’t exhaust into the living envelope from the attic because then I’ll just have a big hole between the house and the Attic. And when I have a negative pressure situation like a bad fan, range hood, dryer etc I’ll be sucking air in from the attic.

“ And when I have a negative pressure situation like a bad fan, range hood, dryer etc I’ll be sucking air in from the attic.”

Having been an owner of various homes since 1981, I’m shocked how much “replacement air” was overlooked. I guess we just had drafty houses and cheap(er) heating and cooling energy costs.

Ding, ding, ding. I think we have a winner.

“ If feasible and cost effective, duct the HPWH to pull from and push into the foamed attic volume 24/7/365.”

In a typical year we have the HVAC in cool mode for most of (or more often all of) the 12 months. I think this answer is the starting point (with full time measurements to get a feel of whether there should be a chapter 2 to this story). By the way I love the Govee H5051 for doing temp/humidity data logging. WiFi accessible and nice graph tools.

Thanks to everyone for chiming in.

You’re welcome, I don’t know if I was any help but you know another perspective always helps. My attic is fully vented so that’s not an option 365 here. It gets way too cold in the winter. If it was sealed and insulated I would probably go that route if I was somewhere like Southern Florida I would probably just have the intake and the exhaust in the living envelope.

One installation of a heat pump water heater we did was in the lower level of an extremely well insulated home. The bathroom/laundry room was where their old, leaking, electric water heater resided and the new heat pump water heater was to be installed. His father-in-law was living in the lower level, which had just two rooms. When I cautioned my customer about the 9,000-Btuh cooling the HPWH would deliver, he was delighted saying he hoped his father-in-law would be incentified to move out! He was and did, making our customer very happy.

Laugh, that’s great. The cooling was noticeable. Chasing off in-laws. That’s funny.

Okay, here’s a question for all of you big brains…I live on Maui and our condo building does not allow A/C. It never gets cold enough here to need heat, and I’m fine most of the year with our Tradewinds and fans. But it would be nice to have a little cool air circulating in the condo. Especially in the late afternoon when the sun is setting and Aug-Oct. My condo is small, 770sq ft, and the current water heater is in the middle of the condo, directly across from the electric dryer, which vents into the condo. (I know. That’s problem for another section). Would there be a way to pull hot air from the dryer vent? or from the air in the condo, and then vent the cool air out into the living room and bedroom? Would that provide me with some cool air? I know it wouldn’t be like having an a/c, but it would be better than nothing. How loud are these heat pump water heaters? The climate here is an average of 80 degrees all year round during the day and 70s at night. High & lows don’t vary much. 80/63 in January and 88/71 August. Humidity varies but it averages around 71%. I’m a single person, but I rent out my condo to tourists 6 months out of the year, and there are usually 4 people staying here then. I don’t know if this matters, but we have solar panels and we all share the electricity. So I also like that these heat pump water heaters are energy efficient. What do y’all think? Would this help me keep my condo a little cooler?

If the HPWH is ducted theoretically you could conduct the dryer right to the intake but I would worry about a couple of things. First of all I would worry about lint clogging the filter on the water heater up frequently and also probably clogging up the coil and when the dryer wasn’t running if the dryer door is closed it’s going to basically turn into a vacuum situation. I would, if it’s in an open space, just let it cool air in from the room and exhaust it out to cool it down. I don’t know about other models but the Rheem model I have can also be run in regular resistive mode using the electric rods. That way if it got too cool you can switch it to that mode or if people were renting it out and you just wanted to get too cold for them. It’s a lot less efficient in that mode but it’ll work fine. And yes they are efficient and when it’s running it will help lower the humidity level

They do make noise which would be noticeable in a quiet environment. If it is not heating water you don’t get any cool air. So it might be equivalent to a small window unit that only comes on for 90 minutes after someone takes a long shower. Not at night when it is really humid. Probably would cost $2000-$3000 more than a straight electric water heater and requires an ac tech to fix instead of a trip to a hardware store to fix. Also are taller and require a drain nearby. Most are slow to recover when the hot water is used up, eg when your renters all return at once. The solution to that is additional straight resistance heat in the water heater which recovers quicker but without cooling. A 12,000 btu dual hose portable heat pump from Midea for under $500 that runs on 120v would be a better solution without a visible condenser outside.

Huh? $2000 to $3000 more? I bought mine for $1200 in 2019 and got a $300 rebate from the electric company. Today the newer version of the same one is $1699. With the rebates and credits available now it’s almost free. Plus I’ve been paying approximately $10 a month for hot water. Knock on wood I’ve had no issues with it. If the heat pump part of it breaks you can just switch it over to regular electric resistive as it’s a hybrid unit. Yes it does require a drain line. For the condensate. The same company sold a $600 electric resistive water heater in the same size. After the rebate mine was $300 more. I saved that amount in the first year.

Huh? $2000 to $3000 more? I bought mine for $1200 in 2019 and got a $300 rebate from the electric company. Today the newer version of the same one is $1699. With the rebates and credits available now it’s almost free. Plus I’ve been paying approximately $10 a month for hot water. Knock on wood I’ve had no issues with it. If the heat pump part of it breaks you can just switch it over to regular electric resistive as it’s a hybrid unit. Yes it does require a drain line. For the condensate. The same company sold a $600 electric resistive water heater in the same size. After the rebate mine was $300 more. I saved that amount in the first year. Even if it broke today and I decided to just replace it over the last 3 years since I made my money back it’s more than paid for itself. I put it in resisted mode and the electrical usage went up by 300 to 400%.

You MIGHT be able to make a perceptible difference for a few hours per day ducting the HPWH exhaust into one otherwise closed room, such as a bedroom, but you’d have to time the HPWH recovery operation to coincide with optimal time to cool the bedroom…perhaps beginning an hour or so before going to bed and extending for 2-3 hours after that. You’d probably want a big HPWH, 80 gallon, to max the potential ability to confine its recovery to certain times of day while also guaranteeing adequate hot water the rest of the day.

HPWH noise varies widely – pay close attention to decibels ratings and user / owner reports online. One major manufacturer unfortunately chose to let their most recent generation of HPWH be much louder than the previous generation, resulting in a boatload of backlash, especially since their being a typical large corporation, they figured it was cheaper to bob, weave, and gaslight their loyal users rather than own and fix the problem. Your mileage may vary.

Fuhgedabout doing anything with the clothes dryer exhaust…the lint and humidity load make that airstream problematic for anything other than exhausting outdoors – sorry to hear yours doesn’t go outside…for shame on whoever came up with that!

Short answer is there’s no way a HWHP hot water provides any real sustained cooling to your house. First, the hot water heater is not on long enough to provide much cooling. Secondly, the output in BTUs from the water heater when it is on is minimal. I had one in my 2-car garage in Florida and it might drop the temperature 1 deg but that’s because the garage gets hot. But even in your house it’s still going to provide woefully insufficient cooling. It might cool a large closet, but other than that it’s not on long enough and not of high enough BTU value to really help you much. The good news is they cost only about 45% as much to run for a full year compared to an electric hot water heater and they are on par with natural gas water heaters for cost to operate. Initial cost to purchase is more than a pure electric or a natural gas hot water heater but in the long run, they’re much cheaper to operate than electric.