Do Airtight Houses Need Makeup Air?

When you turn on an exhaust fan, it blows air from inside the house to the outdoors. That air leaving the house will be matched by an equal amount of air coming in from outside. The more airtight the house is, though, the harder it is to get that air to come in. The result is a negative pressure and maybe reduced air flow. What’s the best way to handle this situation? Do airtight houses really need makeup air?

Pressure differences

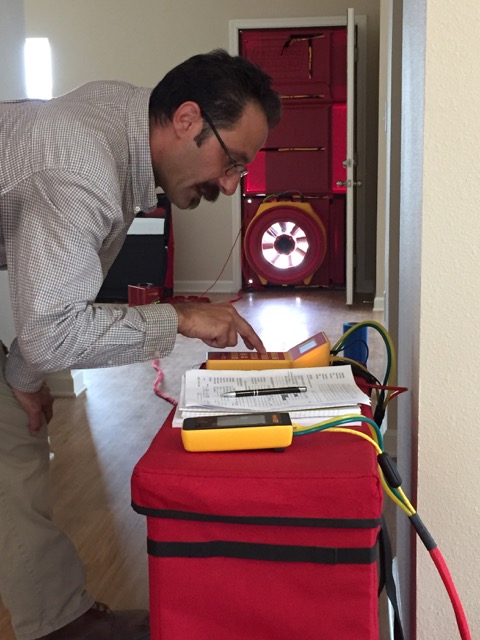

In testing for airtightness, we use a big calibrated fan called a blower door. Closing up the house and turning on the fan induces a negative pressure. The results are commonly given in terms of the amount of air flow through the fan when the pressure difference is 50 pascals (Pa). An older home might have an air flow rate of several thousand cubic feet per minute at 50 Pa (cfm50) of pressure difference. A new home might be 1,500 cfm50.

Let’s say you have a really airtight house with a blower door result of 100 cfm50. That means you get 100 cfm of air flow when the pressure difference is 50 Pa. But we can turn it around to say that an air flow rate of 100 cfm will induce a pressure difference of 50 Pa. With the house closed up, turning the range hood on low can induce that much negative pressure. Wow! That’s a big pressure difference. Is it a problem? Maybe. Maybe not.

What could happen?

Negative pressure inside the house causes it to suck air from wherever it can get it. But there are two requirements for infiltration: a pressure difference and a pathway. Air sealing results in fewer pathways. That in turn increases the resistance to air flow when there is a pressure difference.

One thing that can happen is that your exhaust fans and clothes dryer (unless it’s a condensing or heat pump dryer) may not pull in as much air when they run. Smells and humidity may linger. Clothes may take longer to dry. Using a higher speed can help with the exhaust fans, but you may need makeup air for the dryer.

![A kitchen range hood can induce a large negative pressure in an airtight house [photo by LG, CC2.0]](https://www.energyvanguard.com/wp-content/uploads/2023/04/kitchen-range-hood-full-cropped.jpg)

One thing you almost certainly don’t have to worry about, though, is the effect of these pressure differences on your body. When you drive to the mountains or fly in an airplane, your ears pop because of the pressure difference across your ear drum. That happens when you’ve got thousands of pascals of pressure difference. We’re talking maybe a hundred or two at most in an airtight house.

Makeup air is difficult

We’ve done a lot of makeup air system design for our HVAC design clients, almost always for the range hood. The first thing we try to do is convince them to put in a smaller hood so they don’t need makeup air. Occasionally that actually works. When it doesn’t, we usually figure out the best way to set them up with one the powered Fantech makeup air system. We’ve done a few passive makeup air systems as well.

Doing makeup air isn’t easy or cheap, though. You have to make a bunch of important decisions:

- Active or passive

- How to activate the makeup air system

- Where to put the makeup air

- Whether or not to condition the makeup air

You can spend days—or longer—investigating each one of those issues.

Food for thought

Don’t get too hung up on big pressure differences. It’s really the amount of air leakage that matters, and you get a lot more of that with low pressure differences in a leaky house. Randy Williams wrote a good article on makeup air in airtight houses for Green Building Advisor last year. In it, he quoted Gary Nelson of The Energy Conservatory:

But if the building is very tight, which it probably is because that’s why you’ve got the big pressures, and there aren’t any larger leaks, I wouldn’t be too concerned about intermittent pressures up to about 50 Pa. The reason for a 50 Pa limit is that at 50 Pa, it’s going to take about 10 pounds of force to open an exterior door and there are safety standards that limit the force to open a door to 10 pounds.

I’ve addressed only the issue of exhaust fans inducing negative pressure here. You shouldn’t have any kind of atmospheric combustion in the house other than perhaps a gas cooktop or range. Airtight houses and atmospheric combustion don’t go well together.

So, do airtight houses need makeup air? Well, when you need any at all, you probably just need to open a window enough to provide a little bit of makeup air when necessary.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a popular book on building science. He also writes the Energy Vanguard Blog. You can follow him on Twitter at @EnergyVanguard.

Related Articles

Is Negative Pressure Causing a Problem in Your Home?

A Continuous Air Barrier Between Garage and House

7 Tips & Tricks for Blower Door and Duct Leakage Testing

Photo of range hood by LG from flickr.com, used under a Creative Commons license.

Comments are moderated. Your comment will not appear below until approved.

This Post Has 35 Comments

Comments are closed.

“The first thing we try to do is convince them to put in a smaller hood so they don’t need makeup air.”

I think the first thing is to convince clients NOT to use gas stoves/ranges so they don’t have to install big exhaust hoods that requires to install MAUs.

I’m gradually transitioning away from gas, but I’d note that depending on the type of cooking you are doing, the need for the hood is less about the heat source and more about what you are vaporizing on the pan. When I do gyoza, for instance, PM2.5 spikes to massive levels in my home unless I have the hood on (and even at 600+CFM I still measure a rise in PM2.5). Those same levels aren’t seen if I’m just boiling water (though I do see the rise in CO2 and NO unless the hood is running), so gyoza on an induction range will be just as bad.

I think that even with induction ranges, the greater recent focus on air quality is going to push people to more powerful extraction hoods unless their cooking is predominately boiling in nature. That does make the makeup air question harder, though I usually just go for “crack a window”.

Allison said: “You shouldn’t have any kind of atmospheric combustion in the house other than perhaps a gas cooktop or range.”

What about a fireplace weather it be wood burning or a gas log? Do they require make-up air?

We install a direct vent gas log fireplace, no make up required. At 27mbh (though I don’t know the efficiency), it’s great for a quick family room heat up when the heat pump is slowly warming in the morning after night setback.

I meant “whether”, not “weather”.

By code the makeup air is required for a 400cfm exhaust hood for either gas or electric. We avoided the makeup by using a system with just under 400cfm and normally don’t run it full speed anyway. I’m curious on the make air systems if they are switched in tandem with the exhaust fan?

Lee: That’s an approximate reading of the code. The IRC says this:

“Where one or more gas, liquid or solid fuel-burning appliance that is neither direct-vent nor uses a mechanical draft venting system is located within a dwelling unit’s air barrier, each exhaust system capable of exhausting in excess of 400 cubic feet per minute (0.19 m3/s) shall be mechanically or passively provided with makeup air at a rate approximately equal to the exhaust air rate.”

So in an all-electric home or a house with sealed combustion, the code doesn’t actually require makeup air even if you put in a 1,000 cfm range hood.

Thanks for the clarification. Our inspector/plan reviewer posed the question whether the hood was over 400cfm. It’s likely he either did not see the induction cooktop or didn’t know the code. Either way we installed a downdraft unit that nicely pulls steam/smoke right off the top of the pans. The exhaust duct is routed down through the basement and exits out the band joist, one less hole in the ceiling and roof.

Opening a window is tough when it’s zero degrees out.

At the same time, even with my <1 ACH50 house, a fantech makeup air system (with filter and pre-heater), for a dryer or a 400 cfm hood for an induction cooktop seems like overkill, especially when spread over 3800 sf and with an ERV.

Could you talk more about passive systems? We've been wondering if that would be enough. The air could be tempered a little by going across the conditioned crawlspace on the way to the kitchen and laundry room.

I’ve always wondered why make up air was required for a stove exhaust >400 CFMs but not for a dryer, which is typically ~600 CFMs. In existing homes (moderately leaky ones, at that) it is not unusual for us to be able to induce combustion vent failure (spillage) from natural draft appliances inside the building enclosure with large stove exhausts turned above ‘low’, where make up air isn’t present or is not functional. Next time we have one of these I’ll try turning on the dryer.

Where did you get 600 cfm for a dryer? Every venting person I talked to said they were about 125-150.

Hi, Cindi – you are of course right, as LeeH noted below. I’ll just call it a BS Urban Legend – lots of those about! The reason I love these conversations is when assumptions are challenged and corrected.

Folks with very large homes tend to have very large gas ranges, with red knobs, just because that what its in style, even though most of them don’t cook.

What I’ve been able to do is recommend my clients to use an induction range/top + a two gas burner, and always adding a MAU. I’ve also managed to convince a few clients to install the gas units on an outdoor kitchen only.

Wondering if an ERV/HRV that’s running continuously can be sufficient for makeup air when using dryer, the gas cooktop in our house and hood vent?

I’ve always wondered why make up air was required for a stove exhaust >400 CFMs but not for a dryer, which is typically ~600 CFMs. In existing homes (moderately leaky ones, at that) it is not unusual for us to be able to induce combustion area zone failure (and spillage) from natural draft appliances inside the building enclosure with a large stove exhaust turned above ‘low’, where make up air isn’t present or isn’t functional. Next time we have one of these I’ll try turning on the dryer. I’m also quite concerned about the typical-around-here home with a large Great Room with an unvented fireplace at one end, a gas stove with a giant exhaust at the other, and, if we’re lucky, an outdoor air supply directly dumped into the return.

M Rokicki, I can’t find anything online to support that a typical residential dryer’s exhaust is 600cfm through their 4″ duct. That’s almost 7000fpm (80mph). Pretty sure the number is closer to 100-200cfm, still a pretty high velocity in a 4″ duct. The rest of your post is right on.

Thanks, Lee! I think I was told that way back when and I stand corrected. I’ll still try it with the CAZ test, just for grins.

Thanks for the timely article, Allison. I was just looking at range hoods today. I like the new linear microwave combos but not the 400cfm number. I haven’t typically had an outside exhaust hood anyways so was contemplating foregoing one all together and just let the HRV replace the air with a boost. This is for an air tight new build. I’ve never really used bathroom fans either… I guess we’re just not that stinky or damp in our household behaviours.

Going all electric means I am putting in an EPA rated wood stove, however, because our area is very rural and the power goes out. Designed the windows so that the one behind the stove is an awning one for makeup air. We’ll probably want it open anyways for the heat buildup since it’s difficult to get a small enough stove.

Always interesting to read your articles.

You recently shared an article on the diminshing returns of additional insulation and I wonder if you have thoughts about a similar comparison of purchasing mechanical makeup air methods vs. opening a window.

As Cindy noted, opening a window might not be the most energy efficient or comfort-focused option for those of us in cooler zones.

I currently have an article coming out in JLC on this topic. A lot going on in this area. I define three forms of makeup air to consider: 1) general air exhaust from bath fans, dryers, etc. 2) replacement of high volume exhaust to remove the concentration of pollutants from cooking. 3) dilution of air contaminated from human occupancy like CO2, TVOLS and particulates in general. These three can require different solutions. For numbers 1 and 3 I use a QFAM 6″ makeup fan that can be programmed up 130 CFM and with limitations for temperature and humidity. I bring this air into the conditioned attic space to be acclimated prior to entry into the living space. For number 2, I tie a makeup vent the same size as the hood vent that is opened with a pneumatic switch in the exhaust duct so that fresh air is brought in directly above the hood and pushes contaminated air around and up the hood vent. I also provide my owners the Awair monitor, that Allison suggested, so they know if their air quality is in trouble.

Can you explain how you bring makeup air in above the exhaust vent? Most people talk about bringing it in below and through the toekick of the neighboring cabinet so the air has a path to help carry the cooking fumes.

Fair enough article and generalized. Should have talked about radon in a tight home running exhaust fans as a safety concern.

What is the effect of this pressurized situation on mechanical ventilation?

We have a makeup air damper switch by our range hood so that we can open the damper when we run the exhaust fan. It was not expensive, maybe a couple hundred dollars for the damper, ductwork and wiring during construction. I believe Allison has written in the past that passive makeup air is not a big deal in well air-sealed houses because the makeup air will only come in when required (buy creating a pressure differential).

Where is your makeup air coming from?

Back in the day…I frequently used the HRV or ERV for make up air by disabling the ventilators exhaust fan through a relay with the kitchen exhaust. The ventilators were selected to match the hood exhaust capacity. Because of the project sizes, kitchen exhaust requirements and my approach to ventilation for lifetime housing rarely did sizing become a problem. The only real challenge I had was finding a good control contractor to marry the variable speed to variable or multi- speed and vice- versa between the hood and ventilator fans. Alas the proprietary blackbox was born. FanTech hope your reading this[;@) Background: my clients were building retirement homes mostly in Canada and in mostly cold to very cold climates. The projects were of very high quality. Our ventilation rates were based on active and inactive lifestyles to deal with potentially decreasing building and personal hygiene due to aging or illness and always the clients planned to die at home. Few designers consider the consequences of underventilated tight homes occupied by elderly or infirm who have reducing capacity to maintain good hygiene in all aspects – it’s a thing. Thus the ASHRAE/CSA rates were acknowledged as minimums only….our bathroom rates were variable with high capacity to rapidly vacate odours and moisture. Due to our clients climate zone the MUA needed tempering from appx -40C/F to 22C/72F. This was done usually with glycol coils…sometimes electric…

Just a few thoughts to consider from a retired practitioner.

Cheers.

Unfortunately the cheapest system with a damper, pre-heater and air filter is several thousand dollars. It’s kind of insane since we already spent $30k on an ERV system. Why it can’t just adjust it’s other flow for the few minutes the hood is on is beyond me.

Mr Bean, I didn’t know you cooked. I thought you ate raw salmon pulled directly out of a Canadian stream.

When one has to engage in hand to paw combat with the bears over fishing spots… there’s no time for cooking…beat the bear, steal his catch, eat the fish…before the cougar show up… its much easier than it sounds unless the wolves arrive then its game over [;@)

While researching an issue that I have, I stumbled upon this site, which more or less covers what I think is going on. I have a fairly new house with a constant exhaust fan. The HVAC system that was installed by the builder is whatever the minimum requirements were for it to be an HVAC system. They didn’t even add a return air vent on the second floor. All the houses in my development are like this, and this builder actually said it isn’t required because there are so many supply vents. This meant the master bedroom (upstairs) was always a good 8-10 degrees warmer. I didn’t want to run my AC at 65 at night so the first floor can be an ice box and the second floor can be a sweat box. I considered a portable AC, but felt they were too inefficient and the HOA would likely not like the window kit. I had a contractor install a Mitsubishi Mini-Split. It was a ceiling mount unit, so no unit hanging on the wall. This was supposed to be the cleanest look possible. Their install was less than satisfactory. The next day the smells from the attic permeated my bedroom. They assured me it was contained and sealed, but I could remove a panel and blown-in insulation would fall out and I could stick my hand into the attic. They came out and “sealed” it (duct tape), which did nothing. Eventually they stopped returning my calls. I went up there and used loctite and foam panels to build an air tight box around it. It obviously isn’t that air tight because I can still detect the attic smell, just not as strong. If I crack a window upstairs the smell is gone. I think the constant exhaust fan is creating negative pressure which is sucking the attic smell through whatever gaps still exist in my enclosure. Any suggestions on how I might address this? Once the temps start pushing 100 outside, I’m reluctant to leave a window open, even just a crack. Perhaps adding a fan to exhaust the box the mini-split resides in?

I can’t directly answer your question (although yes, you need to seal that into your thermal envelope). But I would be very concerned about an attic that smells. You need to figure out what is causing that because it is likely something unhealthy.

I have read about the constant exhaust fan code for New England states. It is about the dumbest thing possible to do. Making a house go negative on purpose opens up a can of worms for air infiltration. Your house is desperately looking for a “nose” to breathe in. I design the “nose” into every house I build using a QFAMD unit from AirKing. It pulls in outdoor air at a selected CFM with programmable limitations for temperature and humidity levels outside. It uses a 6″ duct cut into a grill in the soffit or wall. My attics are all unvented so I simply bring fresh air into that space. With a vented attic, you would need to bring it into the HVAC trunking or into some part of the living space.

In Florida open cell sprayfoam insulation is getting a lot more popular, especially in these air tight houses that custom builders like to show off to homeowners. A company I worked for always brought in make-up air (outdoor air) to make sure the sprayfoam off-gassing didn’t erode the evap coil. Was a real lifesaver.

They do it out here in the Mountain West as well. Every home I’ve had in the last decade or more has had this type of constant exhaust fan. Never really gave it a second thought until getting this mini-split installed and having attic air leaking in. I already have an air intake for the furnace, so I wonder if I could split that and pull air in into the AC system with something like the unit you mentioned. So far it seems like just cracking a window upstairs solves the issue, providing the nose, but once our temps are 100*F, that’s going to be a less desirable solution.

Ditch the dryer vents and go with ventless. Makeup air is now only needed for the oven hood. I love a high CFM hood that has a varied speed. No smoke, no odors after cooking. It’s a dream. Less energy efficient, but comfort comes first.

Most people say anything but the smallest house can handle the 120’ish cfm of a dryer without make-up air. I guess I will know soon when I move into mine with ACH<1.