Efficient Hot Water Delivery With a Simple Tool

Gary Klein, a guru of efficient hot water delivery, has been pushing for change in hot water distribution systems for a long time. In recent years, he and his colleagues have developed a great tool for quantifying the efficiency of a hot water distribution system. It’s called the hot water system rectangle, and the concept is simple.

The hot water rectangle

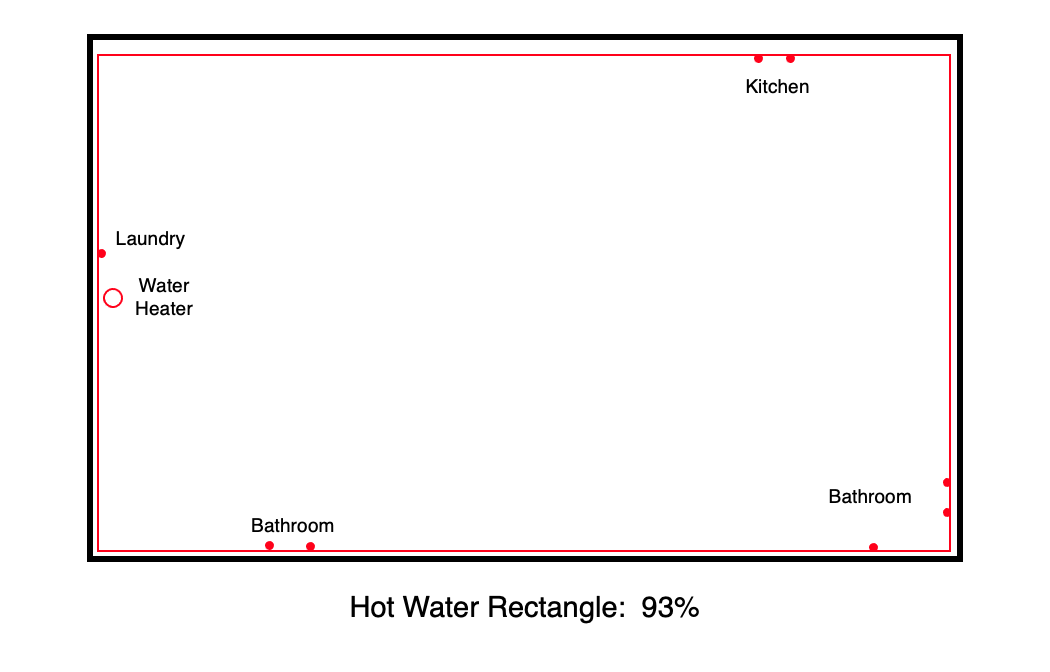

To find the hot water rectangle, you draw the smallest rectangle possible that includes the water heater and all the hot water fixtures in a house. Then you find the area of that rectangle, divide it by the conditioned floor area, and express it as a percentage. If the hot water rectangle is as big as the conditioned floor area in a one-story house, the ratio would be 100 percent.

The schematic below shows the conditioned space of a one-story house outlined in black. I’ve also shown the locations of the water heater and all of the hot water fixtures in the diagram. In this simple example, the hot water rectangle is 93%. That’s only slightly less than the conditioned floor area. And believe it or not, as bad as that sounds, it’s not as bad as it could be.

In a one-story house, the number actually can be more than 100 percent. If the water heater in the house above were in an attached garage, for example, the hot water rectangle would be greater than 100 percent. The conditioned floor area would be smaller because we’d subtract the area of the garage. But the hot water rectangle would be the same size shown above, making the ratio greater than 100%.

Multi-story houses and the hot water rectangle

When you have a two-story house, you still draw a single hot water rectangle. It has to include the water heater and all the hot water fixtures for both floors. The hypothetical maximum would be 50 percent, but that’s only if the rectangle doesn’t cross the building enclosure. For a three-story house, the hypothetical maximum would be 33 percent.

Even though we know the actual hot water rectangle can be larger than those numbers, they’re useful guides as to how efficient a house is. You want the hot water rectangle to be as small as possible and the percentage as low as possible. If you’re close to 100 percent for a single-story house, 50 percent for a two-story house, or 33 percent for a three-story house, that’s not good. If you’ve over those numbers, it’s even worse.

Using the hot water rectangle

The challenge is to reduce that ratio represented by the hot water rectangle. If you’re a home builder or architect looking to improve, this is easy to do. It’s a lot cheaper to move rooms around on a computer screen than it is in a real building. Let’s go back to that one-story house above. The hot water rectangle ratio is often a high number when no one considers the efficiency of the hot water distribution system. And in this house, the ratio starts out at 93 percent, which is pretty bad.

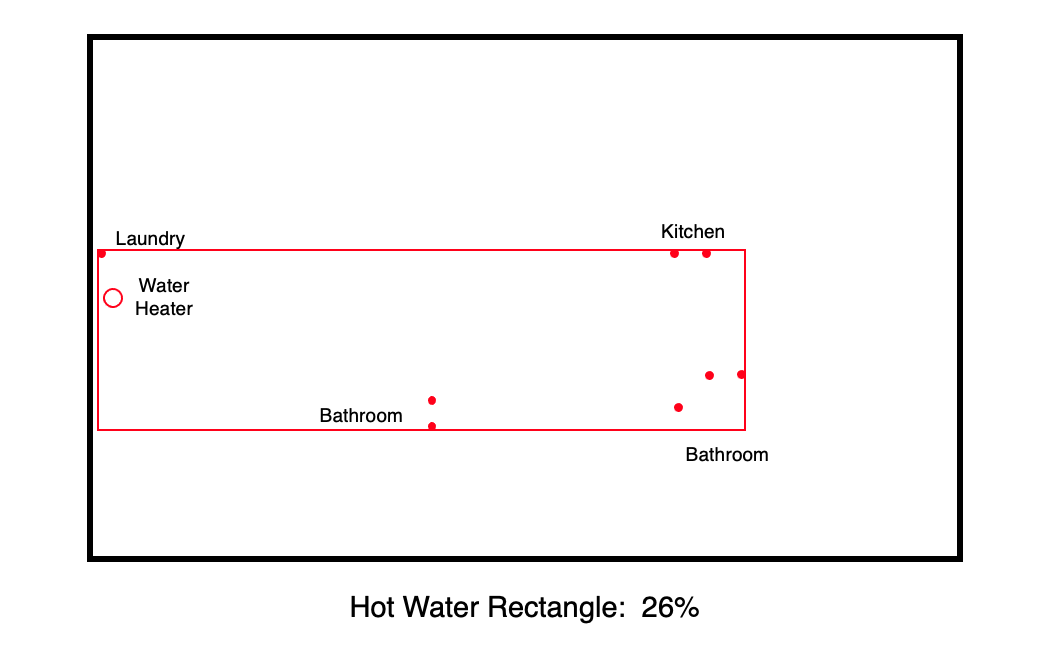

Without changing the floor plan much, we can reduce that number a lot. The second layout (just below) shows the kitchen rearranged to have the hot water fixtures near the center of the house and the two bathrooms also moved toward the center. The ratio for that configuration is 26 percent. Most of the rooms are pretty much in the same places, but we moved the kitchen plumbing to the interior and moved the bathrooms a bit.

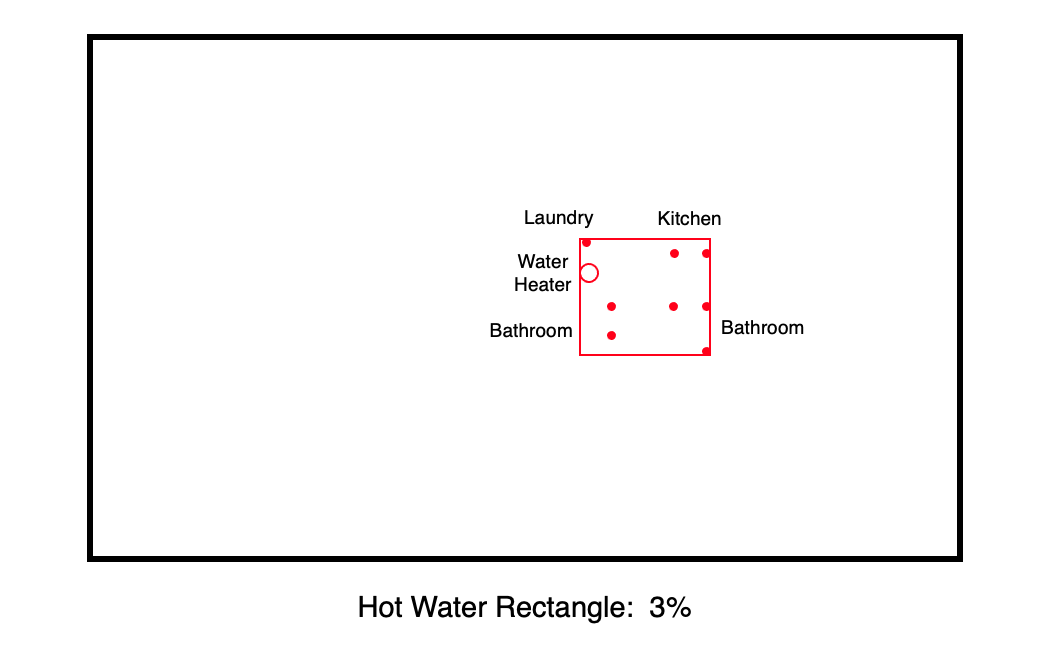

By making bigger changes to the floor plan, we can get an even bigger reduction in the hot water rectangle. In the third layout (below), the bathroom and kitchen hot water fixtures are even closer together. And the water heater and laundry room have moved to the center of the house. The result is a ratio of 3 percent. And that’s still not the best we can do.

A real-world example of extreme improvement

Klein worked with Habitat for Humanity builder George Koertzen in Stockton, California, and helped him make a dramatic improvement in efficient hot water delivery by reducing the hot water rectangle ratio for the single-story houses he built. Before learning of the importance of clustering the wet rooms, Koertzen was building a floor plan with a 79 percent ratio. Then he saw the potential and got that down to 15 percent on his first attempt. Then 4 percent…and 2.5 percent…and finally, an astounding 0.8 percent!

The way he got down to less than 1 percent was by first putting the two bathrooms on opposite sides of the same wall. Then he put the kitchen sink and dishwasher at one end and the washing machine at the other end of that wall. He installed the tankless gas water heater over the toilet in one bathroom and the home run manifold over the toilet in the other bathroom. The total length of pipe from the water heater to the farthest fixture is less than 10 feet.

What can you do?

If you’re a remodeler or homeowner trying to figure out how to get efficient hot water delivery in an existing home, you face more challenges. One option is to replace the hot water pipes (assuming they’re accessible). Without changing the floor plan, you may be able to reduce the length and also right-sizing the diameters.

Another option is to move the water heater to a more central location, if that’s possible. Then reroute and rightsize the piping at the same time. Or you could replace one large water heater with two or more smaller ones, closer to the hot water fixtures.

And the massively expensive option, of course, would be to gut the house and completely redesign the floor plan, clustering all the wet rooms in the same part of the house. My hot water rectangle ratio is currently 50% for two-story house. By switching the laundry room with the foyer and moving the kitchen to the den, I could get that down to 5% or less. But that would be an enormous renovation.

In each of those options, your goal is to reduce the size of the hot water rectangle and right-size the pipes. However, in most existing homes the least expensive option is to install a demand-activated circulation pump under a sink that is at the end of one or more of the trunk lines in the house.

A report full of great info

The hot water rectangle (also called the hot water distribution rectangle or hot water system rectangle) is explained in detail in a 2021 report from the California Energy Commission (CEC-500-2021-043). It’s similar to the wet room rectangle, which may or may not be the same numerical area or ratio.

The authors of the report (Gary Klein, Jim Lutz, Yanda Zhang, and John Koeller) have done us all a great service by doing the research and putting the information out there. And it’s got a lot more on efficient hot water delivery than just the hot water rectangle. Chapter 5 even presents “two unexpected findings.”

Download the report by clicking below:

Code Changes and Implications of Residential Low Flow Hot Water Fixtures (CEC-500-2021-043)

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and writes the Energy Vanguard Blog. He also has a book on building science coming out in the fall of 2022. You can follow him on Twitter at @EnergyVanguard.

Related Articles

Why Your Hot Water Takes So Long

A Hot Water System Retrofit for an Old House

Water Heating Is a System, Not Just a Water Heater

Comments are moderated. Your comment will not appear below until approved.

This Post Has 20 Comments

Comments are closed.

The formula seems to presume rectangular floor plans.

Just looking at the L shaped house I recently designed with bathrooms at each end of the L, I’m way over 125%…

Way over 100% is certainly possible, Jason. As I pointed out in the article, if the floor plan above included an attached garage, this one would probably be more than 125%, too.

I met Gary almost 10 years ago and he shattered many of my uninformed schemas about hot water. One of the most important things he taught me was how he thinks about user experience.

If it takes hot water longer than 5 seconds to hit the tap, that’s mediocre experience, mediocre design. Longer than 10 seconds is bad experience, bad design.

I pretty much stopped recommending Tankless after meeting Gary.

Interesting. I usually do 2 (or even 3) tankless units on larger floor plans and try to spec the Rinnai’s that have the built in recirculating pump. What would be the better argument for going to tanks with the loop?

What’s the wait time on the tankless unit in that scenario?

Depends if the timer has the pump on or off. If the pump is on, you should get warm water instantly and full temp hot water in as much time as it takes to drop from the attic directly above (assuming they install the loop over each HW fixture with a minimal branch/drop straight down). With PEX its not super hard.

Theres a lot of assumptions built into that – mainly that the plumber decides to follow plans and specs and not just make it up as he goes… it would be a pretty rare house where most trades really study the plans before they start working.

Jason C, if you’re talking about a continuous recirculation system, maybe with a timer, it can add a lot to your hot water bill. Maybe $50 a month just to keep hot water in the pipes. A demand recirculation system, on the other hand, reduces the pump runtime by 98 percent and the heat loss by 90 percent, compared to a continuous recirculation system according to Gary Klein.

Those numbers for good, mediocre, and bad user experience are relative, of course. Right now it takes 2.5 minutes for me to get hot water to my kitchen sink. I’m about to do a retrofit that I think will bring it down to about 20 seconds. That would be bad according to what you said above, Ted, but compared to the 150 seconds it takes now, I’ll be happy.

While the concept described seems interesting, I am not sure how the efficiency of water delivery fits into the overall efficiency scheme. So, for example, if the cost of increasing the efficiency is $500, is that truly efficient? There must be some consideration for things such as how the cool water is handled while waiting for it to get hot, how other ‘efficiency’ options compare to this alternative, and so on. For some hot water uses such as a shower I want higher flow, while something like a dishwasher or washer might not require the same flow. Once the flow requirements vary it seems the above option may not be as efficient. I am designing a new home and am investigating various efficiency options. However, I am not prepared to modify the design for the sake of hot water efficiency.

Dennis, minimizing the hot water rectangle ratio is mainly something to do with new homes in the planning stage. It costs next to nothing to spend a little extra time moving things around on a computer screen. Regarding different flow rates, that gets taken care of in right-sizing the pipes. See this article:

Why Your Hot Water Takes So Long

If you’re bound to an inefficient design of the hot water distribution system, either because it would be too expensive to modify your existing home or because you’re attached to the floor plan you already have, the next best option is to go with a demand recirculation system. I’ll cover that in a future article.

For a long time I’ve wanted to try on-demand electric point of use water heaters at each fixture in a new construction house. High efficiency fixtures would be required, of course. I _think_ it wouldn’t be too hard to place sufficiently sized heaters at each fixture. That would eliminate standby losses, water losses from waiting for the water to get hot, and some installation costs by not having to run hot water pipes.

Has anyone tried this? Can you heat water fast enough for it to feel instant? Is it prohibitively expensive to buy that many POU heaters? What is the lifespan of those heaters? What other pitfalls haven’t I thought of?

Nathan, point-of-use electric tankless water heaters can work, but it wouldn’t be wise in a house with a lot of hot water use. The power draw can be excessive to heat water with electric resistance in a short time. Their best use is for one or two hot water fixtures far from the main water heater.

Nathan, electric POU for one shower would be a large electrical demand (10-15kw), a couple of those and you start impacting your electric service entrance size and if utility companies were to ever start demand charges on residential services then your utility bill will take a big hit too.

This definitely got my obsessive compulsive mind cranking. As Ted & Dennis commented above, what is the cost/payoff of the efficiency? The biggest problem in our house is that the main water line comes into the house at one end, right under the master bath, travels almost 100’ to the hot water heater and then back 100’ when we turn the bathroom sink on. It can sometimes take over a minute to get hot water!

Michael, what’s the cost/payoff for hardwood floors or granite countertops? Yeah, I know, it’s apples and oranges, but reducing the length of hot water runs just makes sense. First, you get hot water faster. Second, the cost to install the plumbing is reduced because there’s less pipe to buy, install, and insulate. Third, less material and less energy use are the greenest way to go.

In existing homes like yours (and mine), it may be that the best solution is a demand recirculation system. A 100 foot long hot water line to your master bath is crazy long. I estimate my hot water pipe from the water heater to the kitchen sink is about 80 feet long. And it takes 2.5 minutes to get hot water there because the pipe is 3/4″ diameter all the way. Yours must be 1/2″, at least a good part of it.

Would it work to put an on-demand at the bath where the water comes in and let the existing water heater do the rest of the house? I ask because though I don’t have the 100 foot loop, this is my plan.

The water comes into the house at the bathrooms and that is where we replaced the original tank with a tankless but the kitchen is 40 feet away and the laundry is 10 feet beyond this so I have planned to put another water heater (maybe the heat-pump type to keep the pantry cool and dry) at the kitchen/laundry end.

I’m under the impression that we cannot use a recirculating pump because our rural water supply cuts off regularly and we get a lot of air in the line – I’ve read this kills these pumps. If there is a lot of air in the line, it is explosive!

Currently I use the (and please allow me this without ridicule) the clothes washer as a pump to pull hot water to this end of the house. I do a lot of laundry and can almost always use a few more gallons of water so it is less wasteful than sending it down the sink and faster too. The dishwasher heats the water itself. We have a gray-water system on this end of the house so this doesn’t affect the septic system.

I need to re-read the water-heating articles but while questions are being asked, I thought I’d get mine in: Will it work to put a second rectangle on this end and close off the pipe coming from the current system?

Thanks! Kelly

Kelly, yes, that can work and may be a good solution. Also, just because your kitchen is 40 feet away doesn’t mean the hot water pipe is only 40 feet. My kitchen is 40 feet from my water heater, but the hot water run to the kitchen is about 80 feet. It takes a trip around the house before it gets there.

When we started looking at hot water efficiency, the first project was a 1-story transitional design, with about 1500sqft heated, bedrooms around the perimeter of the water rectangle. We focused on two main goals: (1) reducing the volume of hot water wasted while waiting; and (2) reducing pressure drop along the delivery routes.

Don’t forget that IRC allows for 3/8″ piping to many fixture types, with limitations on pipe lengths. For that house the electric tank water heater was centrally located in a closet and we went with a central manifold in that same closet, with 3/8″ dedicated runs of pex to most fixtures (no fittings between manifold and fixture), except the washer being 1/2″, if I remember right. 3/8″ pex is a little over half the volume of 1/2″, and less than 1/3 volume of 3/4! That’s when we realized that hot water efficiency is about 3 things: user experience, heating cost, wasted water cost (while waiting).

Bathrooms in that house were laid out surrounding the WH closet. User experience was good, with wait time about 4s in bathrooms and one could not tell that those were 3/8″ runs. Kitchen sink was a bit further (maybe about 25′ of 3/8″ pex), but who doesn’t like to have a kitchen sink under a window? Again, you couldn’t tell that this was a 3/8″ pex run. Waiting on the homeowner to check the wait time for me again…

All of the above with water pressure set to 55psi in the house.

Paul, it sounds like you did a great job with that house. But there are actually four factors in hot water efficiency. The one you didn’t list was cost of the plumbing to set it up. With shorter runs, you use less material and need less time from the plumbers.

Allison, absolutely! The trick is often to convince your single-family trades to work off of plans and follow exact directions, instead of doing their typical thing.

Yes, we used up a good amount of 3/8″ pex on that house, don’t remember how much (in 2010), but I bet the savings on not having to buy and spend time crimping even a few brass pex fittings more than made up for that.