Heat Pump Basics

Whether you’re thinking of getting a heat pump or you already have one, knowing these heat pump basics can help you get the right heat pump and operate it properly. The Inflation Reduction Act (IRA) here in the US has made some nice incentives available to help homeowners switch to heat pumps. I’ve covered a bunch of heat pump basics below, but this is just a start. Click the links here to go deeper.

One limitation in this article is that I’m covering only air-coupled heat pumps with forced air distribution systems, sometimes called air-to-air heat pumps. Now, let’s get started.

What a heat pump does

Let’s begin with the most basic of the heat pump basics. How does a heat pump get the heat it delivers to your home? It’s simply moving it. A refrigerator, which is a type of heat pump, moves heat from inside the box to outside. An air conditioner moves heat from indoors to outdoors.

A heat pump does the same thing an air conditioner does when the house needs cooling. But when it’s cold outdoors and the house needs heating, it moves heat from outdoors to indoors. Yes, this really works.

3 types to choose from

This past summer I wrote about the three basic types of heat pumps. (These types also apply to air conditioners, furnaces, and boilers.)

- The most common is fixed capacity. It’s either on or off. It’s either moving all the heat it can, or it’s not moving any heat at all.

- The second is multi-stage. It can operate at two or more heating capacities, which helps with comfort, noise, and power use because it more closely matches the capacity to the load.

- And then there’s variable capacity. It can change the heating capacity smoothly from 100 percent down to some bottom end, which could be as low as 20 percent. Mini-split heat pumps are in this category.

Heat pumps come in all three types. In our HVAC design projects, we do mostly variable capacity or multi-stage equipment because of the load-matching advantages.

Getting the right size

Here’s another one of the heat pump basics, and it’s super important. All heat pumps going into new homes should be sized according to a Manual J load calculation and then the Manual S equipment selection protocol. In existing homes, the best way to determine how much heating and cooling you need is to monitor equipment runtime and capacity. For example, if you have a 60,000 BTU/hour furnace and it runs only 30 minutes per hour at design conditions, you really need only about 30,000 BTU/hour of capacity.

Sizing a heat pump can be tricky, though. Since this piece of equipment does both heating and cooling, you have to account for both sides. Manual S says you should size for the cooling load and then make up for any lack of heating capacity with auxiliary heat (covered below).

The problem with sizing for heating shows up in homes with significant cooling loads and high outdoor humidity. If you size for heating and end up with a heat pump that’s oversized for cooling, indoor humidity levels can be too high. If you have supplemental dehumidification, you can manage the humidity, but at a higher cost. It’s best to size appropriately for cooling in mixed-humid and hot-humid climates.

And then there’s the issue of variable capacity systems. Some people think you can’t oversize them because they can ramp down and run at lower capacity. That is wrong.

Outdoor air temperature and heating capacity

With air-coupled heat pumps, the heating capacity drops as the temperature drops. Usually, the capacity drops below the load at a temperature higher than the design temperature. That point where the capacity and load are equal is called the balance point temperature. (This is a thermal balance point. We can also define an economic balance point for dual fuel heat pumps, which is where the cost to run the electric heat pump equals the cost to heat with the other fuel.)

For example, if your balance point is at 32 °F (0 °C) and your design temperature is 14 °F (-10 °C), the heat pump can’t provide enough heat for the house when the temperature is still well above the design temperature. That means one of two things:

- If the heat pump is all you have for heating, the indoor temperature will drop below your thermostat setpoint.

- If you want to keep the house at your indoor design temperature—normally 70 °F (21 °C)—you’ll need a source of supplemental heat.

Auxiliary heat

Usually the supplemental heat is supplied by an auxiliary heat system integrated into the heat pump. Often it’s an electric resistance (strip heat) element that comes on when the thermostat calls for extra heating. So one job of the auxiliary heat is to make up for that difference between capacity and load when the outdoor temperature drops below the balance point.

The other job of the auxiliary heat is to provide emergency heat. That’s for when some part of the heat pump is out of commission but the blower can still move air through the system. It should not be confused with the need for supplemental heat. (See next section.) I’ve written an article on auxiliary heat, which will help you understand this topic better.

Heat pumps in cold climates

A revolution has occurred in heat pump technology since these things first came out decades ago. There’s a class of heat pumps that can provide a lot more heat when the temperature drops than their old-school forebears. My ducted mini-split heat pump, for example, keeps its full capacity (the amount of heat provided at 47 °F/8 °C) all the way down to 5 °F (-15 °C). Since then, the manufacturer has made further improvements so that it keeps full capacity down to -5 °F (-20 °C).

Where do you find these cold climate heat pumps? The good folks at the Northeast Energy Efficiency Partnerships (NEEP) have you covered. Just go to the NEEP cold climate heat pump page and download the product list and specifications.

But don’t feel like you can’t use them in warmer climates. I’m in Atlanta and going with the cold climate version of my heat pump has allowed me to install it without auxiliary heat. And it worked well in our extremely cold arctic blast last winter.

Using the thermostat correctly

Two things here. First, ignore the advice from some well-meaning people who don’t understand heat pumps. Please do NOT set your thermostat to emergency heat just because it gets cold outdoors. That turns off the heat pump and uses the auxiliary heat only. Aside from it being a much more expensive heat, it’s unnecessary. The auxiliary heat will kick in and supplement the heat pump when necessary. Your heat pump is generally 2 to 3 times more efficient than the electric resistance heat.

Second, be very conservative with setbacks. Heat pumps are slower than furnaces. If you turn the thermostat way back when you’re away or when you go to bed at night, it takes longer for it to catch up and bring the house back up to temperature. A big difference between the indoor temperature and the thermostat setpoint as you try to reheat the place might also cause the auxiliary heat to come on, costing you more money.

In short, keep the thermostat in “Heat” mode, and keep your setbacks close to the normal setback.

Heat pump air temperature and flow rate

Here’s one of the heat pump basics that people often miss. A significant difference between heat pumps and furnaces is the temperature of the heated air. A furnace will give you air that’s heated to 125 °F (52 °C) or higher. A heat pump heats the air to somewhere in the range of 90 °F (32 °C) to 110 °F (43 °C).

That’s a good thing! It means you don’t get blasted with short bursts of really hot air. A heat pump will provide its heat to the living space with longer runtimes or higher air flow rates or both. The result will be that the space heats more evenly, and you probably won’t notice the when it’s on or off.

For new construction, it’s easy to do a proper duct design to make everything work properly. With existing homes converting from a furnace to a heat pump, things are a bit trickier. If the furnace and ducts were sized correctly—practically impossible, but stick with me here—replacing it with a heat pump would mean the ducts are too small. Because of the lower temperature air, you’d need bigger ducts to get the same heating capacity.

The good news, though, is that furnaces are rarely sized correctly. The bad news is that neither are ducts. So you might still have a duct size problem when converting. It’s possible some duct improvements will make it doable. Usually, though, the best thing to do is replace the ducts with a properly designed system.

Ducted versus ductless distribution

Ductless units are appealing because there are so many problems with duct systems in the real world. But eliminating ducts doesn’t eliminate all problems. You still need to get the heated or cool air where it needs to go. And by going all ductless, you’re substituting moving heat via air with moving heat via refrigerant. That means more refrigerant in the system, more possibility of leaks, and more refrigerant that can escape to the atmosphere.

Here’s my quick take on this issue. What we generally do in our duct designs for someone who wants ductless units is to use them in connected common areas only and put ducted systems in bedrooms. Putting a single ductless unit in each bedroom isn’t a good idea because the smallest ductless unit usually has far more capacity than a bedroom needs.

Ductless has its place, but I like well designed ducted systems for most areas.

Energy efficiency ratings

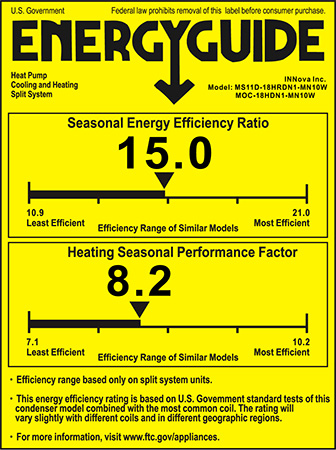

The efficiency of a heat pump is defined by the amount of heat moved divided by the amount of energy it takes to move that heat. Every heat pump manufacturer in the US has to have their equipment tested by an independent lab to get the official efficiency ratings.

Yes, ratings…plural. Since heat pumps both heat and cool, there’s an efficiency rating for each.

- SEER – the efficiency rating for cooling by a heat pump (or air conditioner). It stands for Seasonal Energy Efficiency Ratio, so it’s based on the efficiency over a whole cooling season.

- HSPF – the efficiency rating for heating by a heat pump. It stands for Heating Season Performance Factor and is likewise rated for a whole season of heating.

Both ratings are on a scale of higher numbers for more efficient equipment. As of 2023, the minimum SEER is 14 in northern states and 15 in the warmer southern states. The HSPF just rose from 8.2 to 8.8. The yellow EnergyGuide label will show the efficiency ratings.

The skinny

That’s quite of lot of heat pump basics, and I’ve really just scratched the surface with each of them. If you want a heat pump in your home, it’s important to understand how it differs from other heating systems. It’s also important to know its strengths and weaknesses. This article should have given you a good foundation in the basics. You can go much deeper by following the links spread throughout the article and in the list below.

If you have questions, criticisms, or experiences to share, please put them in the comments below.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can subscribe to Energy Vanguard’s weekly newsletter and follow him on LinkedIn.

Related Articles

Can You Oversize a Mini-Split Heat Pump?

Heat Pumps, Auxiliary Heat, and Resilience

The Easy Way to Switch to a Heat Pump

Will a Heat Pump Work in an Old House?

My Undersized Heat Pump in an Arctic Blast

Comments are welcome and moderated. Your comment will appear below after approval.

This Post Has 43 Comments

Comments are closed.

Hi Allison,

You discussed how we should size heat pumps for cooling loads in hot and mixed climates and make up any lack in capacity for the heating load with an alternate source (preferably electric). In cold climates, we are obviously sizing for the heating load, for instance, my climate runs around 9,500 HDDs with a 99% design temperature around -20°F and cooling loads around 350 CDDs. Are there other factors we should be considering when sizing for cold climates, especially in our existing housing stock? I have a bad feeling that the IRA is going to produce a lot of homes with wrong sized equipment and give ASHPs a bad name.

By the way, great post. Just when I feel I have a good handle on a topic, you supply a little more information that takes me in a new direction. Thanks for all you do!

Randy

Randy: Thanks for your comment. You reminded me that I had forgotten to mention cold climate heat pumps and the NEEP list. It’s now in there in its own section, right after the section on auxiliary heat.

Yeah, the IRA could create a lot of problems. Most HVAC contractors need to learn more about heat pumps before they jump in and start doing this. In cold climates like yours, this is critical.

For variable speed systems do you also do variable speed air handlers?

Blake: Yes, they go together. I suppose you could have a variable capacity system with a very limited range that could get away without having a variable speed blower. In general, if the capacity ramps down, so should the air flow.

Yes, absolutely. The air handler must be able to vary airflow in response to compressor speed changes (among other parameters)

A simplified balance point graph can be prepared from the Manual-J spreadsheet provided by ASHRAE. I use the Manual-J spreadsheet to evaluate an assembly against the heat-output of a mid-range Air-To-Water Heat-Pump. For Climate Zone 6 (Near Climate Zone 7) – it shows the balance point at 8F and -8F. My model also includes DWH, Hot Tub and Garage. Note that this is just a tool for the house design so it can be economically heating and ventilated.

The COP. vs. temperature graph provided by some equipment manufacturer’s is also a useful graph. NG would become more economical when the COP drops below 4.

Bill: Here’s a simplified method I wrote about a while back:

A Simple Way to Calculate Heat Pump Balance Point

Thanks – Being the retired engineer in Zone 6 and who skis in Zone 7 I like to see what happens in the 8F to -22F range. Our low point is -29F – the day the boiler died….

My neighbor installed a Carrier 38MUR variable speed heat pump. They are supposed to be dead quiet but both of it’s fans are aimed right at my side wall 9 feet away and of course the low frequency sounds just go thru normal walls like they don’t exist. And every cycle this design runs in reverse at it’ highest speed to clear of the coils of debis. Oh and since the installer installed an Ecobee thermostat, it’s no longer a variable speed heat pump. No one I’ve talked to is willing to do anything of course…my problem. I’ve measured the dB level to be way beyond the advertised levels at 76 dB during these constant high speed runs. Talk about a neighbore unfriendly design. And I recommended this company because I love how quiet the 5 stage Carrier AC they installed for me is. But like all installers locally they oversize everything. The heat pump is huge at 5 tons for a 2450 sq ft house with good insulation and windows. I offered to do a manual J for them and recommended they have it done but the installers here ignore the data and use the rule of thumb. Luckily with a 5 stage AC I can overcome some of that oversizing and the proof is that it’s never gone beyond 3 stages in 7 years for my 2100 sq ft house with a 4 ton. Variable speed pulse modulated 98% furnace too limited to about 1100 cfm in heating mode as well.

Thank you for the interesting points regarding heat pumps in colder climates. I would like to understand the heat pump ducting issues more in terms of why the changeover would likely make previously adequate ducting insufficient. Would fan CFM requirements be higher with the heat pumps than with the gas furnace? Would one have to consider relocating the heat exchange to the ducting to a more optimal location for a spread out ranch home?

Thanks for the update. We replaced or A/C system starting in late November of 2022 and finished up in January 2023. I’ve been reading your articles on heat pumps and home design for a number of years so we did quite a few things that you recommended and it turned into quite an experience.

tl:dr

Are 6 year old Amana acted up in June of 2022, we had it serviced and the repair man wanted to just replace the expansion unit in the attic.

The blower was originally installed in 1980 as was still running. We had a whole home dehumidifier installed a few years before that was a disaster, the installer was unable to get the humidity below 60-65% even with the A/C running and ended up just putting a dump discharge vent in the living room that blew 95 degree air in the middle of the hot Houston summers.

I hired 2 different A/C designers to compare the results. The one in Florida insisted that they had conditions that were close enough to Katy Tx to be able to do the correct design. He was mistaken. We also had the house inspected by an excellent home energy inspector. We then put the design and the inspection out to bid to replace the entire system, the duct work that had been installed in 2005 had apparently not been installed correctly and had been trampled quite a bit by service personnel in the interim, the results were not what we expected.

We got bids from $9,000 to over $45,000 all to replace the system. The $9,000 bid was by a company that insisted that all we needed was to replace the expansion coils and blower, that would entail cutting a large hole in our hallway that would sever several rafters and we would have to find someone to repair the hole after he was finished, not a option.

The rest of the bids were in the $25,000-$35,000 range except for 2 bids, not including the 2 highly rated companies that declined to bid, one because they were upset that I had put the job out for bids at all and the other because I had had the audacity to hire a PhD system designer instead of trusting their calculations.

The bids were very different in the equipment specs and materials and warranty’s. The closest to what I had put in the specs proposed to install a Bosch 4 ton external unit and a carrier attic system along with new ductwork but disabling the 3 year old dehumidifier and using a electric backup heat instead of the natural gas furnace that we desired. The rest of the bid except one were all $30,000 or higher and we’re using ruud single stage heat pumps.

This was a total of 16 different contractors, the $45,000+ high bid was one of the three Traine dealers that bothered to respond, the sales person never went into the attic or outside to look at the existing unit but just sat at the kitchen table and entered figures that I gave him into a software package and handed me a bid that was not a fixed cost but did include the variable speed unit that we desired (we had only paid $58,000 for the house).

The last company was picked because they met several of the designers specifications for a good company, family owed with 3 generations of work, good recommendations of residential and commercial customers, experience with many vendors. They were one of the few companies that the inspector highly recommended.

Their bid was $17,000 for a Lennox variable speed system. The second lowest bid and $10,000 less than the other company that was bidding a mix and match variable speed system.

One problem was the terrible online reviews of the Lennox system do to a history of cooling coil failures and a lack of spare parts available for their units. The owner spent quite some time assuring us that it wouldn’t be an issue and even put us in contact with the distributor he used and his supplier contact at Lennox.

We went ahead with his installation.

Things progressed smoothly, we had delayed the install until November until the Attic temperature would be more reasonable for the technicians but November 2022 was one of the hottest ever recorded, we went ahead with the installation because of the 20% price increases that were going to go into effect on January 1 2023.

The units and duct work came out cleanly, the 40+ year old metal work was in terrible condition, it had been crushed but service people using it as a shortcut to reach the raised ceiling area and had several of the ducts partially disconnected or destroyed over the years, the ducts had all been replaced in 2004 for my in-laws who would be moving into the home , the metal work was all full of mold and was rusted badly.

They replaced all the ducts, installed the new system then spent a couple of weeks trying to get the dehumidifier to function correctly with this new equipment.

One of the conditions was I had a 10% hold back until the inspector reinspected the home and system and preformed a duct blaster and door blower test.The home had been able to be measured the during the first inspection as it was so leaky that it was beyond the resolution of the test equipment. The ducts were leaking more than 45%.

Before the test, they had to come out and seal all the registers, something that’s not done except for new builds, we did pay an extra $700 for that as it had not been included in th initial bid or the spec sheets.

The house passed but had some structural issues that we would address later.

So 8 months, 2 PhD’s 16 bids and 2 full home energy audits at $750 each, all to find one honest reputable company that did a very good to excellent install with the second from top of the line 4ton Lennox system, the old Amana system had been a 5 ton unit.

Normal people should not have to go through this.

The results have been spectacular so far.

With the record setting heat of 2023 our highest utility bill was $120 dollars, $60 of which are non-bypassable sur charges by the distribution company caused by the State of Texas handling of the URI snow storm and the billions of dollars that were incurred when the TPUC nailed the price to the $9,000 system cap and went home before all quitting a week later.

The humidity consistently stayed below 60% until we replaced the original sliding glass patio door and some other door seals and now stays right at the 50% set point with out the dehumidifier being powered up and with the fresh air system running almost continuously.

We also installed 2 uv led systems one in the return and one in the supply and are running a merv 16 4” filter that were included int the price of $17,500.

Truly an eye opener, we would have never been so insistent on the specifics if it hadn’t been for your articles and book to show us the way ( I supplied copy’s of your book to the technicians and the owner of the company, they all got autographed copies).

Thanks for all you do.

If you happen to be in the Houston area please call G.K Mechanical for you A/C needs and SQ One testing services for your energy audit. We also need to put a plug in for Susan Quave with SQ one as we would have never found GK without her and for the enormous amount of help she provided throughout this process.

Regards,

David & Debbie Power

“Normal people should not go through this”

Those are very wise and reasonable words.

What this blog draws attention to is the lack a defined problem relating to AC in residential applications. As the saying goes “to a man with a hammer, everything looks like a nail”. It is important to review the existing building envelope, historical and forward leaning design conditions, human activity factor in the space…. It shouldn’t be this complicated for an industry valued at billions of dollars… Dr. Bailes is speaking, is the industry actually interested in listening and changing?

Thank you for sharing your experience and specifics on what success looks like…

A lot to read through. Seems you did your home work. It’s tough to get a good contractor. You do not need a phd to do this type of work. Basic education and havoc school is fine. Many people over think hvac it’s not rocket science.

Great article, Allison. Lots of good info.

How much condensate should you expect a correctly installed 3 heat unit VRF compressor to have when set to 60F and outside temps are in the 30’s dipping to 10-20 at night? Does it make sense that we’d been getting gallons of condensate per night, or does that indicate an install problem? Does the amount of condensate really go up a lot the colder it is?

That should say “3 head unit”

A very good way to explain how a heat pump can pull heat from cold outdoor air is to refer to your every day deep freeze appliance. The inside of the freezer can be colder than minus 30 degrees F and yet the exhaust air or the freezer casing (both designed to get rid of heat) are dumping heat removed from the inside of the freezer. So transferring heat from minus 20 degree outdoor air? Same deal, we have been doing this for more than a hundred years, we are just changing the hardware and its intended use. We are refrigerating the outdoors and dumping the heat into the living space.

This comment probably belongs to the Allison’s article on decarbonizing, but isn’t that outdoor cooling a bit of a benefit in the warming climate, if ever so small?

Nay, nay. Laws of thermodynamics aside, the heat you bring inside will eventually go back outside along with the heat generated by your compressor and fans. Entropy is a b..ch!

Roy, thank you, please see my reply to the other Roy below. I landed on his comment first.

Yes heat does not change .Heat just moves to a new location. From where you don’t want it to a new location where you want it.

Paul, the net effect of a heat pump when heating a house in the winter is to still add heat to the outdoor environment. The heat that the outdoor unit removes from the outdoor air ends up back outdoors when it leaks through the home’s envelop (conduction and infiltration). The net effect of a heat pump is that the power consumption of the compressor and fans ends up in the outdoor environment as additional warming. I am not saying that this heating effect is significant in terms of global warming, but it does exist with heat pumps.

Roy, can I remove my previous comment, please? Energy cannot be created or destroyed, and you are much more consistently conscious of that than I am. Next time, Paul, think first, then write.

One only needs to take a glimpse at the rejected energy (heat) portion on the LNLL graph to realize what’s really cooking.

Paul, I knew that you knew better, but I had to keep you honest 😉

“keep your setbacks close to the normal setback.” I think you meant keep your setbacks close to the normal temperature. 65F for our AWHP. Even if traveling for 2 weeks I would keep 65F constant. This now makes a programable thermostat something I discourage, especially if paying extra ($175/head for Mits Kumo). With heat only AWHP, it’s better to have analog tstat and avoid changing batteries. 3 window A/C with inverters provide cooling.

Also, the tank temp is adjusted based on Outdoor Ambient so 25F OA = 122F tank but 45F OA = 90F tank. This is where the new setback equivalent happens. The additional benefit being radically higher COP (4 instead of 3). I wish I could measure/log SCOP.

Allison, in the main photo above (two outdoor units within a tight alcove), the window in the background, as well as possibly other windows above will be subject to some additional intermittent cooling (in heating season), or warming (in cooling season). Am I chasing diminishing returns? (I often do)

I ALWAYS cringe when I see one or more outdoor heat pump units potentially tucked into an alcove…but not for reasons of nearby windows. Air leaves the top of a heat pump in kind of a swirling funnel motion, and adjacent walls, heat pumps, and, in particular roofs / overhangs increase risk the unit will ‘rebreathe’ some or all of its exhaust air causing losses of efficiency, capacity and performance compared to a single heat pump installed so as to be essentially unrestricted on top and all sides.

“Rebreathe” all of the turbulent air? Not likely. Some of it, maybe, depending on overhang height and geometry. But let’s say there are two 3’x5′ windows in that alcove above, so that’s 30sqft of glass receiving doses of air that’s a few degrees below ambient, and it’s moving fast, increasing the convective heat transfer coefficient for the glass and wall surfaces inside the alcove. If, let’s say, the coefficient rises from 10 (somewhat still air) to 35 W/(m^2 K) (about 10m/s air), the heat flow increase through the glass/walls might be significant for the affected area.

Noise is another good reason to not put outdoor units near windows, especially bedroom windows.

Re: Noise, especially in alcoves! Home design is like setting up and solving systems of multi-variable equations…

Yes I can speak to that because like many trac homes, I am about 10 feet from my neighbor. They replaced a very noisy single stage AC with a Carrier Heat pump. It’s the syle with two large horizontal fans. Their lot is about 4 feet below mine so most of the fan exhaust is into a 4 foot tall cement retaining wall. There’s also a 5 foot vinyl fence on my lot that does little to block noise. All of the ground around this HP is cement and sits on a prefab slam with just a bunch of stacked rubber washers meant to shim it level and maybe issolate it a bit. Lots of noise paths and echos. But they are really not issolation dampers at all. This model, 38MUR is reported to be quiet, 60 dB or so. But it is not really that quiet and it runs in reverse at the highest speed after each cycle to “clean the condenser”. This has been confirmed by Carrier. I’ve measured about 76 dB in this mode aimed directly at the side of the my living room wall. I had another owner of this model contact me to tell that his unit wakes him up at night evertime it ends it’s cycle with this high speed cleaning run!

I’ve also determined that the offending frequencies that get thru my wall are around 41 hz and 125 hz. Virtually nothing I can do short of rebuilding my entire dining and living room will address and block low frequency. I can hear their HP 30 feet across my house in my family room while eating or watching TV when it’s running max rpms. And it’s ecobee thermostat insures that it is no longer variable speed.

Mass loaded vinyl in the walls might help but I would need to do all of them or a another layer of dry wall sanwithching acoustic green glue. I would then also have to convert all the double pane windows to triple pane or acoustic glass. I did build a 5.5′ X 7′ cinder block wall filled with sand against the vinyl fence that only reduced the sound level in my house by about 4 dB and didn’t do much about the low frequency sound. And I knew this was not going to help with all the reflections but hoped the sand would help some with the low frequency, which it did but not enough. I even thought about extending that 4 foot retaining wall by a couple of feet but low frequency passes very easily thru concrete and in this case around as well. My Carrier 5 stage AC exhausting upward is a dream compared to this monstrosity and is only about 53 dB most of the time and never approaches much above 60 dB even running all 5 stages! I love the concept of a HP but not one placed like this one is and designed to transmit noise horizontally to nearby neighbors. Carrier and the installer say it’s not their problem and my neighbor is a bit too laid back to complain on my behalf. It’s on the other side of his laundry room so not a bother. It could have been installed about 10 feet further towards the street exhausting into my front yard and probably would have been a lot less offensive although maybe my large dining room front windows might have transmitting more of the sound.

Most contractors don’t consider location of heat pump.A lot of times they put the heat pump is a place that gets direct sun for most of the day. They leave the job and the customer pays a elevated bill going forward.

That’s apparently what happened with mine. They didn’t follow the specs for distance from wall and ceiling, and now the units stop running way before the set temp because we are recirculating the cold air from the units back into the coils. Moral of the story is do not trust people who say they understand the system they are installing unless you talk to other people who have the same system installed by them in the same climate and configuration.

Good advice. Some people in hvac are not well trained,especially in the south .

Thanks Allison. I always enjoy and learn from your posts.

You mention using a modest setback for the temperature at night during the heating season. How much would this be?

In my case, I have a heatpump with gas unit in NE Kansas. I set back from 68 in the day to 62 degrees at night, but when the temperature is around 35-40 degrees, with the switch over at 35 degrees it just takes too long for the heat pump to make the house comfortable. I’ve had to change the setting to run the gas furnace from 40 degrees and colder. As I have solar panels I’d prefer to use electric as much as possible, but I guess that until this unit fails and I get a new heatpump for the house, I’ll burn more gas.

Comfort really is king, and as much as I tried to make the heatpump/furnace work for every room at all times, I’ve slowely learned that there are conditions where cental heating in a 122-year old house just isn’t perfect. I rebuilt and enlarged an enclosed rear entry porch and added radiant electric panels on the ceiling (working great so far), in my den that sits on the north side of the house and has almost 3 exterior walls, I have to use a space heater on cold evenings to supplement the heat. I made a huge effort to airseal and also insulated my joist cavaties and did other improvements, but at a certain point had to accept what is going to be the best outcome my system will deliver. I now see I was rather stubborn (or dimwitted) in thinking I could do otherwise.

68 to 62 is, IMO, not a modest setback…recovering a full six degrees during early morning when outdoor temps are at their lowest is a tall order for a properly sized heat pump. Consider reducing setback to no more than 2-3 degrees, and let sleeping comfort rather than supposed energy savings drive the setpoint.

Thank you Curt. I appreciated having your input on what is a “modest setback” and will turn it up higher for the night setting and see what the results are.

Great article with lots of great information; however, the opening photo made me cringe. I’m in my 51st year in the industry, having worked as HVAC contractor, code official, adjunct faculty, and currently involved as a consultant, and an HVAC/mechanical and energy code instructor. One of the most common installation errors impacting unit performance and efficiency is the lack of required clearance around a condensing unit or a heat pump. The Frigidaire installation instructions require 18″ between two units, one side can be no closer than 6″ to a wall/building, 24″ on the service access side, and 12″ on other sides. This installation fails to meet the manufacturer’s installation requirements. We constantly rightly talk about indoor airflow, but often fail to recognize its importance at the outdoor unit.

Just an observation about setbacks. I have found that employing a smart thermostat, in this case an Emerson Sensi, which modulates start of recovery as a function of actual deviation from target temperature, will permit fairly significant setback settings. I setback to 58° with morning target of 68° with no problem. Of course, when it’s really cold the system may start recovery at 3:00 AM . But still I’ve realized savings compared to no setback. My system is 2 stage compressor with auxiliary resistance heat. I disable auxiliary heat above 15° ( rarely needed)

I do not even understand how I ended up here, but I assumed this publish used to be great

Came back here as I’ve been trying to find good information on where to set my heat pump lock out point at its most economical setting. I’d love a link to a simple calculator that would help me figure this out. My HVAC installer seems to be a “rule of thumb” kind of thumb thinker. I found the lock out set point at 45 degree’s and reset it to 25. I’m pretty sure my equipment is sized to the heat load as we had a professional manual j done to size out the equipment (thank Allison). My calculations show that my cost per therm of heat is 2x when we use our oil fired boiler to provide auxillary heat given the current cost of oil vs electricity but I’m not positive that my cost per therm with the heat pump is calculated accurately.

I’ve also started monitoring the temp of the conditioned attic all the utilities are located in and have found it about 15 degree higher than the living space below. I have not seen any article on regulating temps in conditioned attics an am curious what others experience……. Thinking about installing winter time “return ducts” in the attic space but need to do more research. Rafters are insulated to roof peak, no insulation installed in ceiling of the living space (may have been a mistake?)

https://gegcalculators.com/heat-pump-lockout-temperature-calculator/

Those 2 condensors in the photo are quite close together. Is that only okay because you’re in a warm climate? My 2 in a cold climate are wall mounted but not operating right because they are too close together.

Also the last post mentioned a hot attic… We realized the top of our 10′ ceilings are about 15 degrees warmer than the bottom. Do reversing ceiling fans really help that problem?