How Is a Blower Door Like a Hydraulic Jack? Pascal Knows!

Remember the first time you ran a blower door? OK, maybe that’s not the best way to get where I’m going because most first-timers turn the pressure up like they’re practicing tai chi on Jupiter. After you’ve done a few tests, though, you learn to crank it up to 50 Pascals of pressure difference in just a few seconds. And that’s where you may have discovered the mystery that Blaise Pascal solved nearly 4 centuries ago when he invented the hydraulic press.

When you run a blower door and move air from indoors to outdoors, you’re decreasing the air pressure inside the house. At least you know that’s true right by the fan because that’s where you set up the manometer to measure the pressure difference. If you’ve done any blower door testing, you may have wondered if the pressure is really the same in other parts of the house and how long it takes for the pressure in the farthest reaches of the house to drop to the same level.

Of course, you could always do the experiment. Set up your blower door as usual on one side of the house. Set up a second manometer on the far side of the house with a way to see the results right there at the blower door. You could even use data loggers to record the blow-by-blow if you were so inclined. The solution lies in understanding how a hydraulic jack works.

How a hydraulic jack works

If you’ve ever raised your car with a hydraulic jack, you probably noticed how easy it was to lift a lot of weight. That’s because the jack multiplies your force. The diagram below illustrates how it works. You push down on Piston A and it moves a relatively large distance with a relatively small force. The physics of fluids allows you to trade off those two quantities.

On the other side, Piston B rises only a small distance but does so with great force. The amount of work done, force times distance, is the same on each side, though. It works just like a lever, but with a fluid instead of a stick.

Pascal’s Principle and blower doors

This is where our friend Monsieur Pascal comes in. He discovered what is now called Pascal’s Principle:

This is where our friend Monsieur Pascal comes in. He discovered what is now called Pascal’s Principle:

A change in pressure at any point in an enclosed fluid at rest is transmitted undiminished to all points in the fluid.

The hydraulic jack works because when you press down on Piston A, you increase the pressure in the fluid under the piston. That pressure is then transmitted right across to Piston B. And it happens right away because that pressure wave transmits to the other side at the speed of sound. It is a sound wave, in a sense, since both are pressure waves.

So when you turn on the blower door, Pascal’s Principle guarantees† that the pressure you measure at the blower door will be the same as the pressure on the other side of the house. And it happens almost immediately…unless you have an unusually long house. If your house were, say, a mile long, it would take about 5 seconds for the pressure to equilibrate.

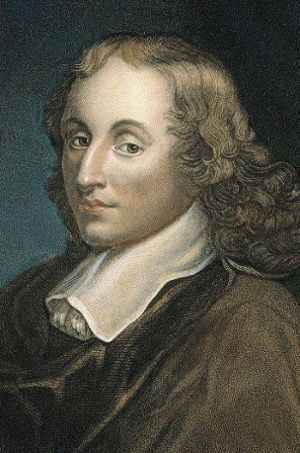

Happy Birthday, Blaise Pascal!

Pascal’s birthday was last week, on 19 June. Although he didn’t make it even to 40 years old, he accomplished a lot in his short time here. In addition to discovering Pascal’s Principle, he invented the hydraulic press and the syringe. He was one of the few who rejected the Aristotelian notion that a vacuum couldn’t exist, contradicting luminaries like René Descartes. He also helped advance the development of the scientific method by writing that falsifiability is a distinguishing feature of scientific theories. And then there’s every high school algebra student’s favorite Pascalism: Pascal’s Triangle.

Happy (belated) Birthday, Blaise Pascal!

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a popular book on building science. He also writes the Energy Vanguard Blog. You can follow him on Twitter at @EnergyVanguard.

Related Articles

What Is Pressure? – Understanding Air Leakage

Rats to You, Daniel Bernoulli! – Understanding Air Pressure

A Blower Door Can’t Tell You How Much Mechanical Ventilation You Need

Footnote

† OK, “guarantees” is a strong word. Strictly speaking, Pascal’s Principle applies to incompressible fluids that are completely enclosed. Air is compressible, but the pressures we’re working with in a blower door test don’t do much compressing. Also, houses aren’t airtight, so the leakier they are, the more pressure variation you’ll find, especially when you’re close to the leaks.

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 6 Comments

Comments are closed.

Another caveat worth

Another caveat worth mentioning is the impact of restrictive orifices within the house. For example, a small scuttle to an encapsulated attic, or taken to the extreme, the gap beneath a closed door (that should have been opened) will impede equalization in areas beyond the so called orifice.

In a theoretical air tight house, this would manifest merely as a delay in reaching equalization, but in a leaky home, areas past the orifice will never reach the test pressure, thus understating leakage in those areas.

Pascal’s contributions to

Pascal’s contributions to science and mathematics would be remarkable under any circumstance. All the more so when you consider that he did almost all of his scientific work by the age of 31. The last eight years of his short life were mostly devoted to philosophy and religion.

Reading his philosophical writings with a modern perspective could leave you unimpressed. When you consider it in relation to the work of the time, however, it stand out for it’s clarity. It served as the basis for many writers who came after him.

Nice analogy, Allison. But

Nice analogy, Allison. But given the leakiness of so many homes, it is more likely one will observe a pressure gradient as you move further away from the blower door. This is more easily observed in a leaky old colonial house with multiple additions on additions. The last room farthest may be only -45 Pascals while the room with blower door reads -50 Pascals. As David pointed out, flow restrictions of doorways (orifices) combined with leaks to the outside (more orifices) to create this condition. Try jacking up your car with a hydraulic leak on your jack. Of course, once the worst of the leaks are sealed, the house pressure is essentially equalized. A perfectly sealed house would only need a giant extraction syringe in the doorway to reach -50, not a blower door fan. Can you tell us what size syringe?

Hi Allison,

Hi Allison,

Certainly a smart guy like Mr. Pascal would agree requiring a blower door test on every home in every sub division is silly, a complete waste of time and money, and kind of like repeating the same thing over and over and expecting a different result. This Blower door test is in reality nothing more than a dog and pony show that proves repeatedly that houses are leaky.

Treating Home Performance like a science project has prevented any real energy conservation from happening on any real scale, and relegated those involved to a boutique club that only exists as long as they can beg for money to subsidize their excessive time and cost from rate payers or force the issue through codes. It’s ironic that those who claim to be efficiency experts are probably the least efficient group of folks around, have shown little business savvy, and simply an “industry” that evaporates 15 minutes after their subsidies end.

Thanks and, Keep on posting,

Pj

Interesting comparison, but

Interesting comparison, but you left out a small detail; air is compressible, while hydraulic fluid is not. When I used to work on large (long) compressed air systems, it was not unusual to a couple of psi difference from one end to another; especially when dumping it for repair. As mentioned above, internal restrictions and the degree of “leakiness” of the house could make a difference. I really enjoy your articles, keep them coming.

Ed

I agree with PJ that programs

I agree with PJ that programs distort solving client problems,but disagree that measuring the problem before to determine importance of fixing, during to determine if fixing is happening, and after to prove (and learn) quality fixing occurred is unimportant.

There is plenty of evidence that when you measure results and provide feedback to all involved, results and skills continuously improve. There are also plentiful examples of where forging blindly ahead leads to disappointing results and terrible consequences.

Its the difference between quick and good, like guessing if your refrigerant charge is correct vs measuring and verifying.

Certainly the quick approach is best for the contractor. But its also the approach that leads to HVAC contractors being perceived as lower on the integrity scale than attorney’s and used car salesmen.

If you sell air sealing without measuring and verifying, what are you selling? What kind of person are you?