John Krigger: Effective Combustion Safety and Efficiency Testing

Guest post by John Krigger. Last week I wrote an article on combustion safety testing based on the Lawrence Berkeley National Lab work mentioned below and opened the article with a reference to a discussion I’d had with John last year. I revised the article to remove that reference because it was really a different topic and also didn’t represent John’s views fully. With this article, which first appeared in his blog 5 January 2014, he explains what he thinks we should do with combustion safety.

Guest post by John Krigger. Last week I wrote an article on combustion safety testing based on the Lawrence Berkeley National Lab work mentioned below and opened the article with a reference to a discussion I’d had with John last year. I revised the article to remove that reference because it was really a different topic and also didn’t represent John’s views fully. With this article, which first appeared in his blog 5 January 2014, he explains what he thinks we should do with combustion safety.

The combustion-testing paradox in our industry

The recent literature review by Lawrence Berkeley Laboratory, titled: Assessment of Literature Related to Combustion Appliance Venting Systems (pdf), asserts that worst-case depressurization testing isn’t likely a significant risk reduction strategy for CO poisoning. The Building Performance Institute (BPI) and the Residential Energy Services Network (RESNET) require these worst-case tests but don’t require a complete combustion analysis measuring CO, O2, and temperature. The heating industry’s traditional leaders, Air Conditioning Contractors of America (ACCA) and National Fire Protection Association (NFPA) don’t require any kind of combustion testing in their standards. On the BPI-RESNET side you have an unnecessary and incomplete testing methodology, and on the ACCA-NFPA side you have a general neglect of combustion analysis.

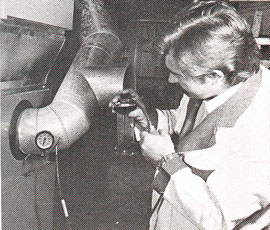

Electronic combustion analysis is easy and quick. Combustion analysis measures carbon monoxide (CO) along with oxygen and flue-gas temperature. The test is important for both safety and energy efficiency. BPI and RESNET should promote electronic combustion analysis rather than worst-case testing for combustion appliances. The combustion-analysis equipment is widely available and not expensive, considering the valuable information it gives the energy auditor or heating technician.

I don’t think you can support mandatory worst-case testing based on risk reduction. The worst-case test is too complicated, inconsistently performed, and often not followed by effective combustion-safety improvement. Worst-case testing has dominated training and certification to the neglect of standards and best practices aimed at saving energy.

In five minutes, you can know the appliances combustion efficiency and safety.

In five minutes, you can evaluate the appliance’s combustion efficiency and safety.

Here is a simpler procedure for combustion testing and hazard mitigation.

First observe

Make the following observations, and take appropriate action.

- Recognize soot anywhere near a combustion appliance as a sign that the appliance is producing CO at least some of the time.

- Recognize that rust in a chimney or vent connector may mean poor draft and spillage.

- Look for irregularities and flaws in the venting system.

- Find and seal all accessible return-duct leaks in forced-air heating systems.

- Verify that the home has a working CO alarm. If the home has no working smoke alarm in addition to no CO alarm, install a combination CO-Smoke alarm.

Then test, evaluate, and improve safety and efficiency

Test all combustion appliances with a modern flue-gas analyzer, which measures oxygen, temperature, and CO during weatherization, appliance replacement, or a heating service call.

- If measured CO is above 100 parts per million (as measured), take action to bring the reading to as low a value as possible.

- Notice the % of oxygen. For appliances with naturally drafting chimneys the value should be 5% or more to ensure adequate combustion air. If the oxygen is less than 5%, open a window and test again to see if the oxygen percent increases. If so, provide combustion air from outdoors. Avoid making a combustion air opening on a wall parallel to the winter prevailing wind. Don’t provide outdoor combustion air for appliances that operate above 5% oxygen.

- Notice the flue-gas temperature: For traditional open-combustion appliances the flue-gas temperature for gas should be above 325 degrees and for oil above 350 degrees to produce adequate natural draft.

- Operate the combustion appliances, including furnaces, at natural conditions and test for spillage. Furnaces, boilers and combustion water heaters shouldn’t spill for longer than one minute. Inspect the chimney and vent connector if the appliance spills for longer than a minute.

- Make appropriate repairs such as removing chimney obstructions, sealing leaks in the chimney and vent connector, sealing return ducts, and replacing horizontal runs of single-wall vent connector with double wall vent connector if the spillage isn’t related to depressurization.

- If you detect spillage or backdrafting and suspect that depressurization is causing it, then investigate depressurization further.

About the author. John Krigger has been a leader in the energy efficiency and home performance industry for a long time. His work has influenced and educated many who have gone through the various training classes that use the books and curricula that he has developed, including the standard, Residential Energy, now in its 6th edition. His company is Saturn Resource Management.

About the author. John Krigger has been a leader in the energy efficiency and home performance industry for a long time. His work has influenced and educated many who have gone through the various training classes that use the books and curricula that he has developed, including the standard, Residential Energy, now in its 6th edition. His company is Saturn Resource Management.

See Effective Combustion Safety and Efficiency Testing in the Saturn Resource Management blog, where you’ll find links to Krigger’s other articles on combustion safety.

Related Articles

Are We Off Track With Combustion Safety Testing?

Don’t Compromise — Get a Low-Level Carbon Monoxide Monitor

A Ventless Gas Fireplace Is a Liability

This Post Has 8 Comments

Comments are closed.

Where should the CO alarm be

Where should the CO alarm be mounted in a residence? Near the floor or ceiling? Near a combustion device or near a bedroom? Should, in the case of multiple CO alarms, it be connected to other CO alarms? Should it be hard-wired or battery-powered, or both?

John, I couldn’t agree more!

John, I couldn’t agree more! ALL gas or oil fired appliances MUST have a combustion analysis done after installation and after maintenance. This is an industry standard although not in an ACCA book as you stated. I teach combustion analysis in my classes and will be including a reference to doing these tests in my presentation at ACCA in March. Best Regards, Steve

Thank you John, for an

Thank you John, for an excellent example of a different procedure we could be using for this testing.

We have almost no combustion equipment in our market so I rarely have occasion to do combustion safety testing, but I have thought a number of BPI classes which included combustion safety.

My impression as an instructor was that the standard BPI protocols, especially the CAZ testing, were sufficiently complicated and convoluted to raise serious concerns that techs would actually perform these tests correctly in the field. Especially in areas such as ours, where it wouldn’t be a daily routine.

In addition to that concern was that the testing was potentially invalidated depending on other factors (wind and temperature…).

Finally, the level of trickery involved with getting to worst-case pressurization, and then using that as a basis for taking required steps to address potential back-drafting, truly entered into the realm of the absurd at times.

I am glad to see this conversation popping up here and at the RESNET conference this week.

A couple of things that I think might be missing in the above article:

The need to check for gas leaks (extremely common).

What “natural conditions” means. OK, it means the combustion appliance is firing in the normal conditions it would be operating in on a daily basis. But this is the slippery slope into CAZ testing. If the appliance is in a room with the dryer, is the dryer on or off? Is the door to that room open or closed? And so it goes…

It’s hard to know where to draw the line that marks the transition from likely, to possible, to unlikely, to ridiculous.

I hope that we are headed for a more realistic and useful set of protocols for doing this type of testing, but it still leads me to the conclusion that I had reached when I was more involved with this world. That we REALLY need to be focusing more on switch-outs to safer designs than atmospherically vented combustion appliances. I know, easy to say, but it really is a rats nest.

We speak of it as being SO IMPORTANT, then we try to find the cheapest way of dealing with it. It reminds me of fresh air ventilation. We all say it’s SO IMPORTANT, then we talk about how we can simply connect a duct to the return…

I am confused. Isn’t part of

I am confused. Isn’t part of the purpose to have a baseline? To understand potential improvement design problems?

Personally, I feel it is my responsibility to warn my client they are at pretty good risk of needing to replace (or spend money on) that new POS water heater if we fix their house.

Isn’t the test about that? Knowing in advance that your work may take an appliance from safe to dangerous?

John – I very much like your

John – I very much like your testing protocols, but I still have issue with energy auditors performing these tests. I think they should be required by HVAC repair techs/installers and plumbers (who install the majority of the DHW systems I’ve seen). These tests are necessary – as are radon, mold, chimney flue integrity and a host of other safety checks – just not in the purview of examining a residence for comfort/cost issues related to heat/air loss. Some may say that “if energy auditors don’t do it, no one will”, but that is not a proper solution. These devices can run improperly and/or be installed incorrectly and need to be assessed during service/repair times, not when someone doesn’t like their energy bill.

John,

John,

Regarding “Make the following observations and take appropriate action” column, item 4, “Find and seal all accessible return-duct leaks in forced-air heating systems” seems to be formed around a few assumptions: 1) the central heating unit and distribution system is wholly within conditioned space. 2) the system is properly designed with sufficient return air surface area and duct sizing and 3) there aren’t any problems caused by reducing airflow on the system because it’s a furnace (alone).

Maybe it’s because I’m from California, but we rarely come across homes where any of these assumptions are true. Sealing up the pressure-relieving holes within these systems further moves them outside of the manufacturer’s limits for static pressure, and reduces airflow further below the required airflow to even verify refrigerant charge (because there is always an AC coil too). Maybe the oversized furnace somehow doesn’t hit the high temp limit after the duct sealing efforts, but the likelihood of the AC compressor being slugged is increased.

And of course tightening return side leakage on systems outside of the pressure boundary may have exactly the opposite effect as intended.

Just some food for thought from out west.

There are numerous problems

There are numerous problems with unskilled people doing combustion testing. In my State, you need a license in heating to be doing that type of testing. In an industry that barely trains just about anyone, I think combustion testing in NOT something auditors should be attempting.

Hello, I noticed that you

Hello, I noticed that you wrote that acca does not incorporate combustion analysis into their standards. However, the standard for maintenance of residential hvac system clearly states for gas fired furnace a combustion analysis is an inspection task. Correct me if I’m wrong. I have been met with so much resistance by other tech about me advocating combustion analysis and have often referenced this standard. The resistance is strong! Love this blog by the way.