My Undersized Heat Pump in an Arctic Blast

Are you afraid of heat pumps? Some people are, and it’s usually related to experiences or stories of uncomfortably cold homes. I won’t deny that there have been some horror stories about people suffering in brutally low indoor temperatures during a once-in-a-decade/century/lifetime winter storm. I’ll talk about some of the reasons for that below, but what I really want to do is to show you that heat pumps can keep you warm, even during an arctic blast. And in my case, they can do that even when undersized.

Let’s look at the example of my house. I installed an undersized inverter-driven mini-split heat pump and have been able to see how well it performs in both a heat wave last June and an arctic blast last month. In the heat wave, our indoor temperature barely strayed from our 74 °F thermostat setpoint. (See my heat wave article for details.)

So, how did we do in the recent arctic blast, when the outdoor temperature dropped into single digits Fahrenheit, to a low of about -14 °C? The answer is below.

My undersized heat pump

Before I get into how my undersized heat pump performed, however, let’s review the sizing. I did the HVAC design myself, beginning with the heating and cooling load calculation. Then I selected the heating and cooling equipment.

I went with Mitsubishi (disclosure: they’re a sponsor of this blog) because I wanted inverter-driven mini-split technology. By choosing their Hyper-Heat model, I had confidence that the heat pump would keep pumping out heat even when the temperature drops into the single digits Fahrenheit.

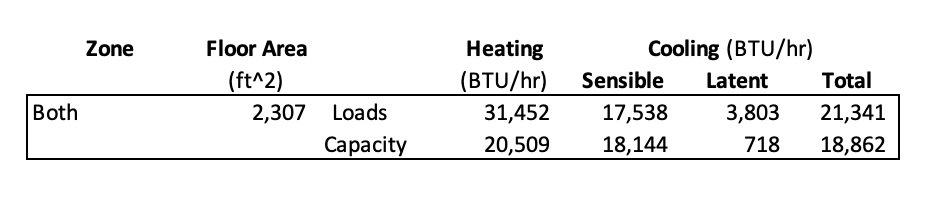

The table above shows the heating and cooling loads (first row) and the capacity of the heat pump (second row). (For the SI folks, see this conversion table for BTU/hr to kW.) As you can see, this heat pump serves ~2,300 square feet of floor area. Our heating load is 31,452 BTU per hour (9 kW). The heat pump, according to Mitsubishi’s data, can provide only 20,509 BTU per hour of heat (6 kW). The equipment I selected includes one outdoor unit, the Mitsubishi MXZ-3C24NAHZ2 with Hyper-Heat, and two horizontal ducted indoor units.

Why did I undersize it?

Yeah, that’s really how the numbers turned out. According to the table, our heat pump can provide only 65% of the heat we need. That’s seriously undersized, especially for a system with no auxiliary heat.

Why did I do it? Well, I chose this size equipment for three reasons.

- First, those loads aren’t the final answer. I’ve got more improvements to make on the house, and that’s going to reduce the loads. In short, I’m sizing more for future loads than the as-is house.

- Second, I know that Manual J heating and cooling loads are inflated. I tell people they’re generally 10 to 20 percent higher than the actual loads. The Manual J heating load, for example, doesn’t include the heat provided by lights, appliances, and people.

- And third, I didn’t fully trust the capacities I got from Mitsubishi’s software. I think the heating capacity is probably pretty close, but the latent capacity on the cooling side was suspiciously low.

One more point here: The heating load is based on the winter outdoor design temperature. For Atlanta, Georgia, that’s 23 °F (-5 °C). The idea is that you size the equipment for the design temperature, and the system will run continuously to keep the house comfortable at that outdoor temperature. When the outdoor temperature drops below the design temperature, the house may not be able to maintain the indoor temperature you designed for, which is typically 70 °F (21 °C). But we have a Mitsubishi Hyper-Heat model, which is kind of the equivalent of Nigel Tufnel’s amplifier that goes to 11.

Temperatures during the arctic blast

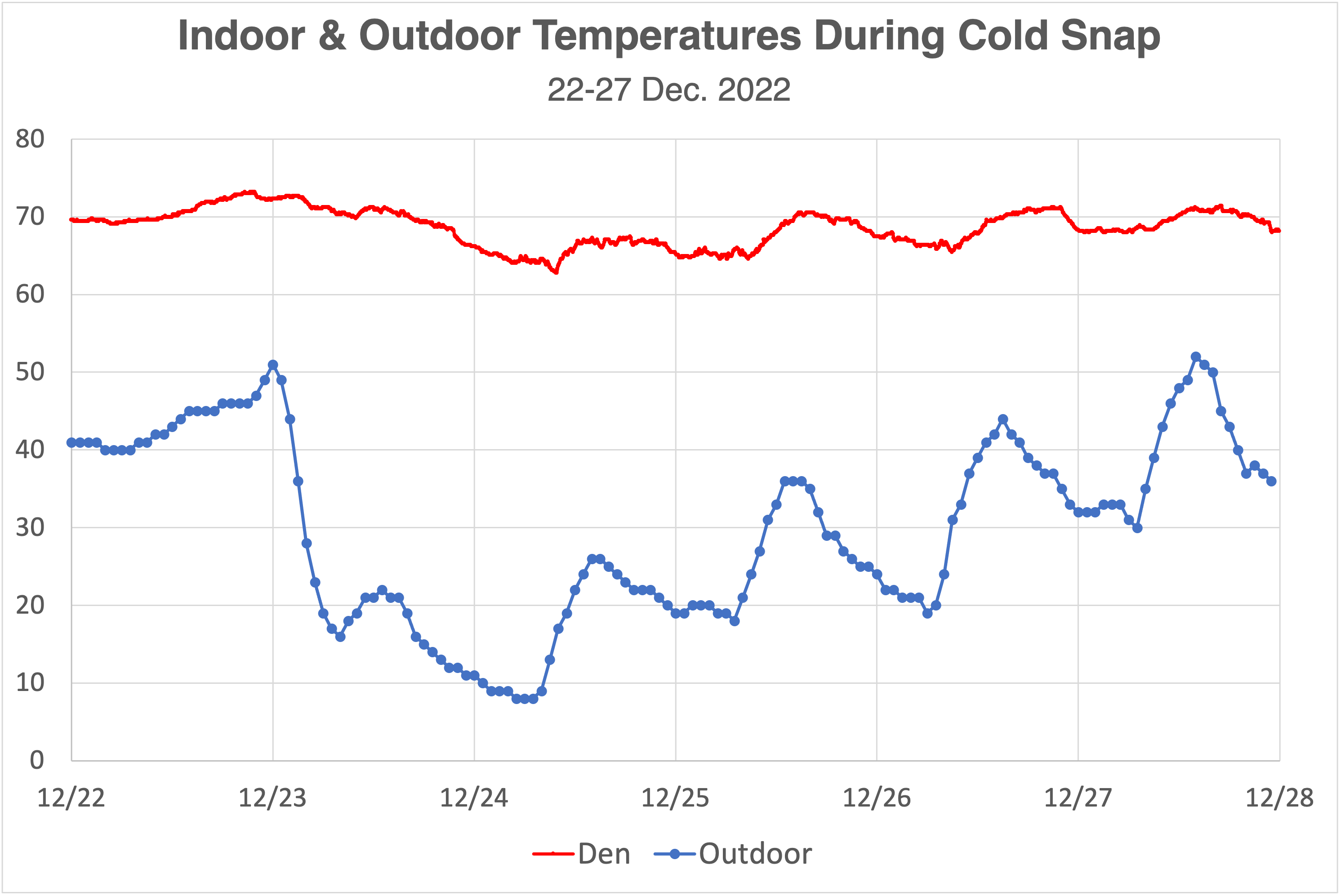

OK, let’s see the data. First up is a graph showing the indoor temperature in our den along with the outdoor temperature. As mentioned, the outdoors got down to the single digits Fahrenheit. That seems to be a once-a-decade thing here in the Atlanta area. This is my third decade here and the third time I recall that the outdoor temperature dropped this low.

The red curve in the graph shows the indoor temperature in the den. The thermostat for the common areas is in this room, and it’s where we hang out a lot in the mornings and evenings. As you can see, the den temperature did drop in that arctic blast, but the low was 63 °F (17 °C).

But I need to confess something. The den is the most protected room in the house. It’s connected to the sunroom, but it has no windows and no exterior wall area itself. (It also has a gas log fireplace, but I had the gas turned off in 2019.) Could it be that the den was fine while the rest of the house was freezing?

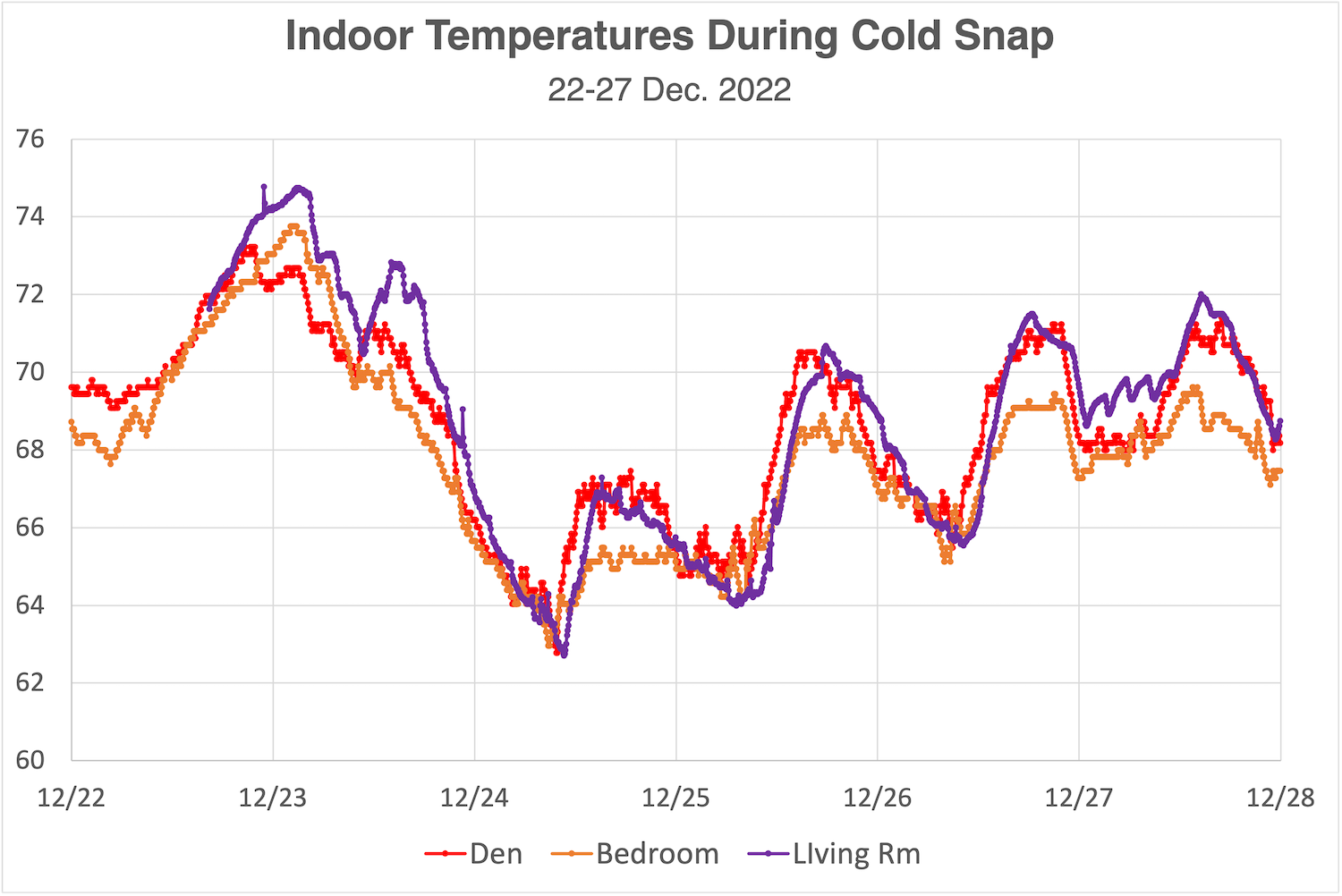

No! The graph below shows the temperatures in the den (red), primary bedroom (orange), and living room (purple). The living room actually was warmer than the den sometimes, probably because of the solar gain from the south-facing windows. The bedroom was the coolest room. It’s on the northwest corner of the house and also it’s on a separate thermostat, which we keep about 4 or 5 °F (~2.5 °C) lower than the common areas.

The graph shows that all three rooms hit their minimum of 63 °F (17 °C) at about the same time. That was a few hours after our outdoor low of ~8 °F (-14 °C). And then those rooms warmed up quickly. On the coldest day, 24 December, the den and living room got up to 67 °F (20 °C). By the next day, Christmas, we were back up to 70 °F (21 °C).

Yeah, 67 °F (20 °C) is cooler than I usually like it, but I never found it to be too cold. I had a couple of space heaters standing by and didn’t use them. OK, I did use one a couple of times while I was taking a shower. They make nice steam. (Just kidding! I shouldn’t have to say this, but don’t ever put a space heater in the shower.)

Energy use of the heat pump

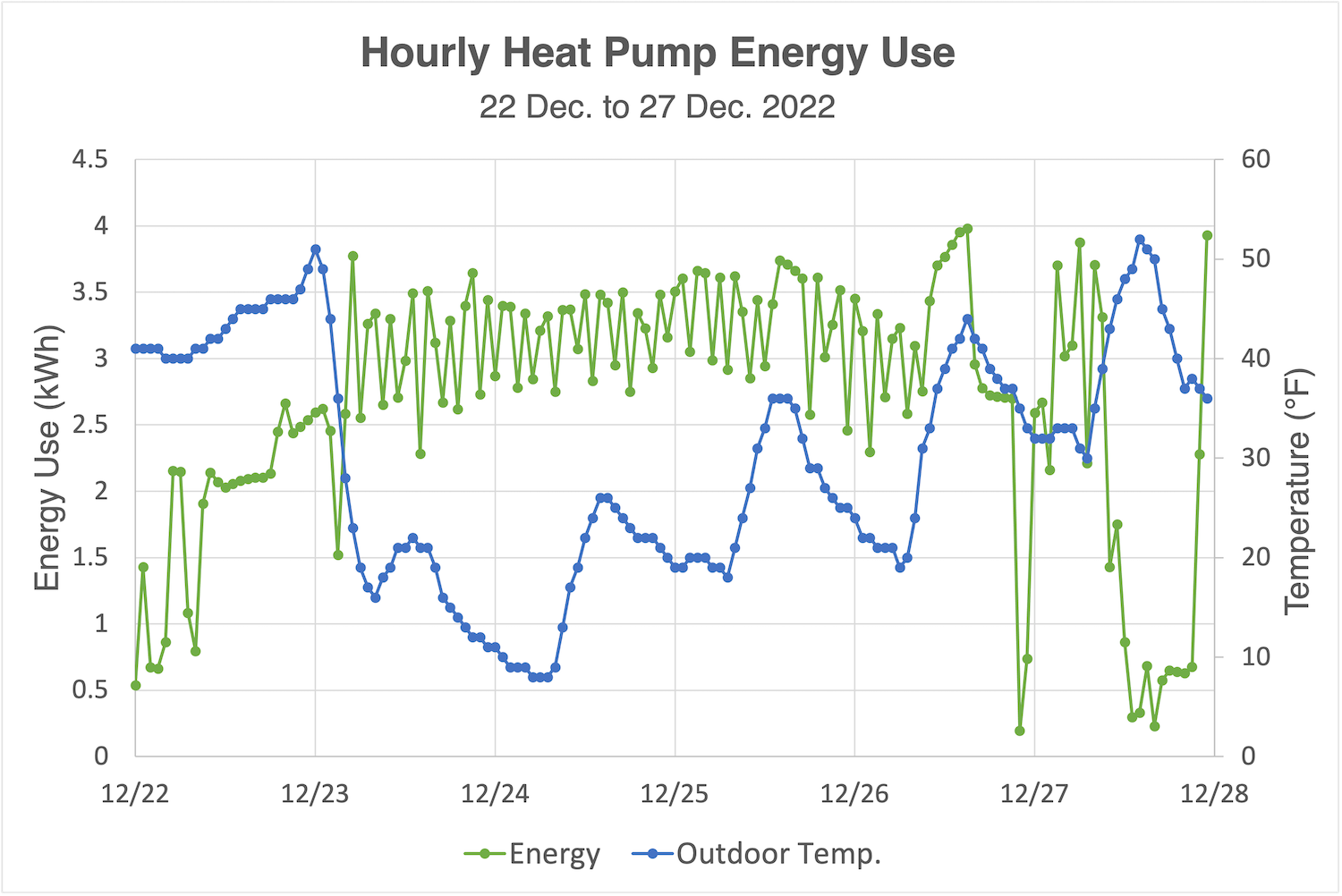

Since we’re talking about how well the heat pump performed in the blast of frigid air, you may be interested in the energy use, too. The first graph here shows the hourly energy use data (green) and the outdoor temperature (blue) for those same six days.

Even without the temperature data, you can tell when the cold snap started and when it broke by looking at the low points of the energy use curve. The cold weather arrived at about 3 am on 23 December. That’s when the heat pump cranked up to high gear and stayed there until the end of 26 December.

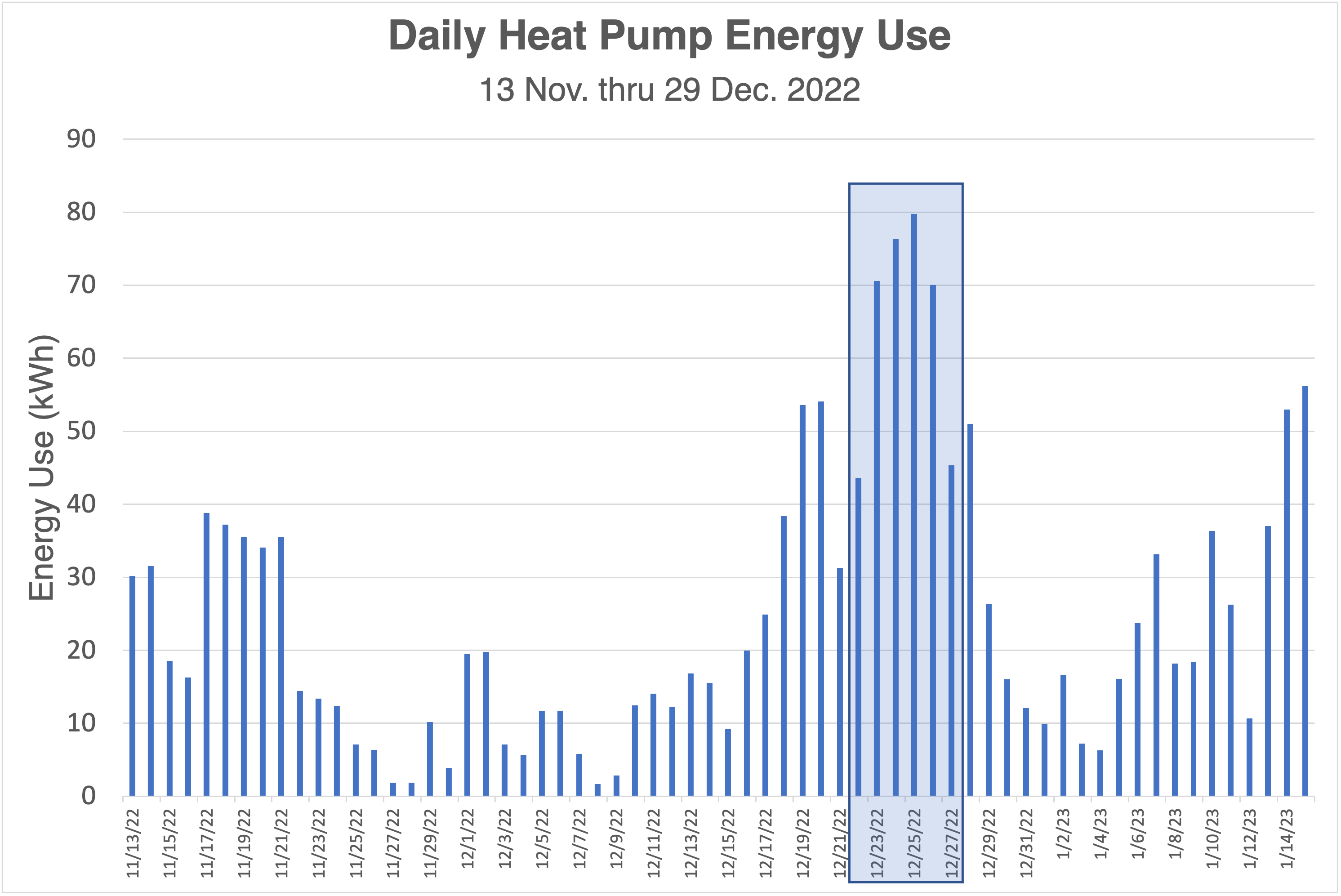

The graph below shows the daily energy use data, but over a longer period of time. I’ve highlighted the six days shown in the above graphs with the blue rectangle below. We hit a high of 80 kilowatt-hours on Christmas day. On our normal cold days, when the outdoor temperature drops into the 20s Fahrenheit (-1 to -6 °C), the heat pump uses ~55 kWh.

During the coldest part of our cold snap, the heat pump ran flat out almost continuously. The only exceptions were times when (I think) it went into defrost mode. So, 80 kWh per day is probably about as much as this unit will ever use when it’s operating properly.

Why don’t heat pumps always work?

Yes, some people have had bad experiences with heat pumps. I saw a social media post during the arctic blast from someone in the Midwest who said he had heat pumps, and the indoor temperature was in 40s Fahrenheit. Yikes!

A lot of things can cause a heat pump not to be able to keep a house warm enough in really cold weather. Of course, something could be wrong with the unit. But let’s assume the system itself is working as it should. Here are the main reasons a heat pump might not keep you warm.

- The heat pump doesn’t have a way to keep capacity up as the temperature drops. A standard heat pump loses a lot of heating capacity as the outdoor temperature drops. If this kind of heat pump wasn’t sized for its capacity at the design conditions, it may struggle.

- The house is poorly insulated and has a lot of air leakage. Even if sized correctly, a heat pump in such a house may lead to comfort problems because—this may shock some of you—air temperature is NOT the only factor that determines comfort. Mean radiant temperature of the surfaces matters a lot. (See my article on that topic.)

- The heat pump itself is fine, but the duct system is a mess. Ducts in unconditioned spaces—attic, crawl space, garage—can rob your system of a lot of heat. Best is to put the ducts in conditioned space and make sure they’re designed to move air efficiently.

A wrong answer here is that heat pumps just don’t work in cold weather or cold climates. Gary Nelson heats his house in Minneapolis with a heat pump and has done fine at temperatures well below zero Fahrenheit.

Not all heat pumps are created equal. Mitsubishi’s Hyper-Heat models are able to crank out the same amount of heat at about zero Fahrenheit as they do at 47 °F, and other manufacturers have similar models. But many models can’t keep up as the outdoor temperature drops. That’s why most heat pump systems have some kind of auxiliary heat.

The sum and substance here is that a house is a system. A heat pump has to be designed to work with the house. The house needs to work with the heat pump. Don’t run out and install an undersized heat pump just because it’s worked for me. Do your homework. Spend the extra money to get good equipment and solid professional help, both for contracting and design.

Next year, I hope to be able to report that we had some really cold weather and our indoor temperature hardly dropped at all. Because this is the year I’m going to redo my basement. It should be fully insulated and much more airtight by next winter. And have its own heating system.

Meanwhile, we had a very nice Christmas this year at my house. I hope you had a nice holiday season, too, however you celebrate it. Now, can you spot the living room data logger in the photo above?

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and writes the Energy Vanguard Blog. He also has written a book on building science. You can follow him on Twitter at @EnergyVanguard.

Related Articles

My Undersized Ducted Mini-Split Heat Pump

My Undersized Mini-Split Heat Pump in a Heat Wave

The 3 Types of Heat From Heat Pumps

Heat Pumps, Auxiliary Heat, and Resilience

Comments are moderated. Your comment will not appear below until approved.

This Post Has 93 Comments

Comments are closed.

Thank you Allison! Great read and what I would like to do for my house here in Atlanta as well. Sizing the HVAC based on load is very important. If I do lower the load even more over time by more sealing and insulating after install of the HVAC would it work even better and more efficient? Or would it then be oversized?

Eric: If you plan to lower the load after installing new equipment, make sure to get variable capacity. And pay attention to the bottom end of the heating and cooling capacity. You don’t want to end up with a system that always runs at the bottom end of its capacity range.

The little white box on the desk!?

Yep

My Mitsubishi units performed admirably during the cold snap (see my IotaWatt energy monitor results here: https://1drv.ms/u/s!AgwI-351JHY4grd3NSbkAchlMzo5Jg?e=M1bPlL). The MainAC is the unit that serves two ducted mini-splits (2 ton and 1.5 ton). The BsmtAC 1 ton serves the insulated basement. The LoftAC is a 1 ton serving two mini-split wall warts.

I did supplement with my gas logs, though that was more for ambiance than heat and I have no doubt the Mitsubishis would have done fine on their own.

Norman: What model is your outdoor unit? I’m guessing it’s either a 36 or 42 kBTU/hr since you’ve got 42k of indoor unit capacity.

36K

Great article!

I have a similar system, but live in a colder climate of Indianapolis, IN (not Minneapolis, MN)! We renovated a 1916 home to a “pretty good house” standard (before the book came out), I would tell people it was just shy of Passive House standard. We have a Mitsubishi SUZ-KA30NA2 outdoor unit with a SVZ-KP30NA indoor unit with auxiliary heat (didn’t go for the Hyper Heat).

On 12/23/22, the outdoor temperature got down to -9 deg F, and my indoor temp maxed out at 67 deg F with an indoor setpoint of 72 deg F. Since we moved in in April 2022, this is our first winter, and our first “arctic blast.” While I was nervously checking the thermostat throughout that time, but I was pleased with 67 deg F (I just convinced my wife and daughters to wear sweaters).

When I checked the contractor’s Manual J, his assumptions were for standard insulation, windows and air sealing, but I had him change to what I had designed (I am an architect), and he re-ran the calculations.

My related question is…the contractor installed a Honeywell VisionPro 8000 TSTAT (actually 2, we have an upstairs zone damper), but I don’t really like them. At my previous home, I had an ecobee TSTAT and loved it, and would like to swap out the Honeywells for the ecobees. While I was doing research if the ecobees were compatible, I came up stumped. That sent me on a research wild goose chase, and my question is: with my inverter-driven system, does it require a special inverter-driven-compatible TSTAT? Everywhere I looked, it looks like most TSTATs have 1, 2 or 3 stage heat with 1 or 2 stages of cooling, but with my (our) systems being inverter-driven, I want a TSTAT that pairs nicely and squeezes out all of the efficiency of my heat pump.

Thoughts?

Yours truly,

Hopelessly Honeywell

Ryan: Sounds look your unit’s performance was similar to mine. What was your low temperature?

The Ecobee thermostats are great, but you don’t want to use them with your Mitsubishi heat pump. If you do, you’ll lose the benefit of variable capacity, and it will behave more like a two- or three-stage system. I don’t recall the details, but unless they’ve changed something, you should stick with the Mitsubishi MHK-2.

The third-party thermostat interface that connects to the Honeywell thermostat would connect to the Ecobee and operate in much the same manner. Allison’s point regarding variable capacity is why you make sure that within the interface shell, Dipswitch 2-6 is turned “ON” regardless of the thermostat brand. This enables proprietary logic that allows variable speed operation even with an “on/off” thermostat and provides nearly the same performance as native Mitsubishi controls.

Third party thermostat interface page:

http://mylinkdrive.com/USA/Controls/PAC_US445CN_1?product&categoryName=Controls

Application note:

http://mylinkdrive.com/viewPdf?srcUrl=http://s3.amazonaws.com/enter.mehvac.com/DAMRoot/Original/10008\Application%20Note%203044%20ME%20-%20Thermostat%20Interface%20Sequence%20of%20Operations.pdf

Dana

Thanks Dana!

I will look into the links you shared. I definitely want to move away from the Honeywell, and would prefer the ecobee; but I do not want to compromise on any optimization of not using the OEM TSTATs.

I have two fujitsu two unit each compressors here in central Massachusetts. Aou18rlfzh 1.5 ton and aou24rlxfzh 2 ton units. We usually run 2 of the heads of the 2 ton compressor. Half of the house has closed cell plus fiberglass insulation in 6 inch walls and 12 inch 9ft heigh ceilings. However second half of the house has very minimum of insulation in 2×3 walls:). The house is 100% electric – heatpump water heater, induction stove, etc. With electric being very expensive in Mass we had to learn how to live with the minisplits. We usually set the bedroom to 60F when we are asleep and shut of the heat if the outside temp is above 25F. When we asleep we shut off the main living room head of if the temp is above 20F- 25F. The systems worked fine at -25F to 60F. However, the lower the temp the more electricity it uses. The defrost cycles also increase and make inside temp cooler for a few mins. The heating is also more concentrated around the head and cooler corners. The max electricity bill with all the other appliances on the coldest month was $800. The 2022 December bill with mild weather and electrical price increase was $420. The systems work, but there is a learning curve and also comfort loss. I am unsure how pushing to these systems on a federal level make sense. If your climate is like New Jersey and warmer then yes, if colder I do not see most people dedicated to lose comfort they have with gas or oil heating.

That same arctic blast hit us in Oklahoma where we even got a little colder (0 F) than you in Atlanta. I have two gas condensing furnaces and both quit working completely on the coldest day. Why? We also had high winds that caused flame roll out which tripped the safety switches. The thermostats gave me no warnings, but they did show me that the temperature was dropping below setpoint. Luckily, with 10 people staying at our house for the holidays, I figured this out and reset the switches before it got too cold. So are gas furnaces 100% reliable? Note that my fancy thermostat will warn me when the humidity is too high in the summer (>60% RH), but doesn’t tell me when it cannot maintain the temperature setpoint. Luckily, I was at home when this happened so I was able to catch it in time.

Roy: I didn’t realize flame rollout was possible with condensing furnaces. Is it one of the older condensing models doesn’t have sealed combustion? If it does have sealed combustion, where does the flame roll out?

It is only 6 years old and is definitely sealed combustion. The manual called it flame rollout, but I am guessing that the wind was bad enough that the draft inducer couldn’t supply sufficient airflow. Unfortunately for me, it is a competitor’s furnaces so I don’t have access to much more information. All I know is that if it trips a certain number of times in a certain period of time, it locks out until you reset it. When it does trip, it sounds like thunder in the attic. That sounds was haunting me until I figured it out.

Thanks for that explanation, Roy. I was with Allison on this one, thinking that flame roll-out shouldn’t be an issue with a condensing furnace.

Roll out happens in this case when the draft inducer can’t push hard enough to get enough combustion air through the burners. It should be a sealed cabinet but sometimes that extra air velocity is enough to have a flame roll out temporarily. I would venture a guess and say they either have a concentric vent or a horizontal termination kit installed.

You have some good information included in your article, but leading people to undersize 10-15% from their manual j calculation isn’t necessarily a good thing. I’m glad this all worked out for you, and 100% agree the Mitsubishi hyper heat is the way to go on mini split style heat pumps but I worry you’re talking people into being reckless. Personally, I run a 3 stage heat pump and switch to a 2 stage gas furnace when the heat pump doesn’t make enough heat. As the temperature difference between indoor and outdoor becomes enough that your home needs supplemental heat, this is why many have auxiliary heat. When your heat pump is running 100% of the time and making just enough heat to hold temperature indoors, you’re at the balance point. Many of my changeouts I see balance points at around 30 degrees. I still recommend people run their heat pump and let the thermostat (which I configure properly) to kick the auxiliary heat on as needed. Running an undersized heat pump isn’t a good thing to advertise, although you calculated correctly and understand building science in such a way that you were able to make it work.

I’m about 40 miles north of Allison. My latest house has a MXZ-5C42NAHZ condenser, a SVZ-KP30NA air handler, and a SVZ-KP12NA air handler. The house is about 3,000 square feet and has mostly R-30 fiberglass in the attic and lots of junky double-hung windows.

I keep the thermostat in the main zone around 76-78. (Yeah, pretty toasty.) In the smaller zone with the main bedroom, I drop the temperature to 73-74 most nights.

On December 24, the system really couldn’t keep up with the 8 degree weather and the indoor temp drop into the mid-60s. At that point, I decided to turn on the electric fireplace insert, which I had installed a few months earlier when transitioning the home to total electric.

I kept the fireplace on until the cold snap ended on December 27 to maintain the thermostat at subtropical levels of comfort. I could have gotten by without the fireplace but decided to prioritize comfort over energy savings.

Allison, how much would you estimate that 80kWh day would end up being if you had a similarly sized system (non hyper heat) with auxiliary heat?

Yeah, the Mitsubishi MXZ outdoor units with hyper heat really pump some serious heat out of thin air. Or should I say, really cold air. Have one in my house (well, right outside of it).

Also, I am guessing there is another reason why you are happy with it being slightly undersized in cooling mode.

Something I’ve been wondering recently – in general, does it cost more to operate an undersized unit that draws less current but runs longer versus a larger unit that doesn’t run as much but draws more current?

I’ve wondered this too, and I hope someone with more expertise can chime in here. If you’re talking fixed-output types, longer runtimes are definitely better than frequent short cycles.

With inverter units, I believe peak efficiency generally occurs around 40-50% of maximum output. However, smaller units also tend to have higher CoP figures (better overall efficiency). My guesstimate is that a smaller unit running flat out could well use less power than a larger, less efficient unit at the same output:

5 kW output / 4.6 CoP / 80% efficiency = 1359 W input (smaller, more efficient unit)

5 kW output / 3.9 CoP / 92% efficiency = 1394 W input (larger, less efficient unit)

However, I suspect I need to take into account the fact that CoP is not just a single figure, but varies with load, outdoor conditions, etc.

Very interesting graphs. So it consumed between 2.5KwH and 3.5KwH during the coldest periods. A few questions:

– why the variation; that’s variation of something like 25%? Maybe this is expected, but it seems substantial to me.

– How does that compare to the “nameplate” consumption at max capacity? Is it worth trying to estimate a CoP? Like just an upper or lower bound CoP? (e.g., assume outputting nameplate max BTUs?)

– What’s up with the consistent rise in energy use (up, up, up to 4KwH on the afternoon of the 26th (door open maybe?) Can we read that 4KwH reading as meaning that it wasn’t working at full capacity when it was reading 2.5 to 3.5KwH?

Hmmm, these are all point estimates of the hourly consumption rate (KwH) rather than the instantaneous power flow (Kw), I bet that’s part of the issue? Probably magnifies. Does your energy monitoring allow you to graph instantaneous Kw over time such that actual KwH used is the area under the curve? And there’s a better than decent chance I’m confusing something there!

–J

I’m guessing the “dives” of the green line towards the right of the figure were the defrost cycles? We find the outdoor units to be quite noisy when they shift to defrost (Thump-hiss-whiiiiiiir), so much that we had to have the outdoor unit moved to the other side of the house (away from the bedrooms).

James: Excellent questions! Here’s my first take:

1. Yes, I think it’s the defrost cycles making the difference. In the minute-by-minute data from 12/24, I counted 10 big dips, and that’s about how many I see above.

2. I haven’t gone into that yet but will see what I can come up with.

3. I have no idea what’s going on there. I was wondering why it spiked there when the temperature was in the 40s at the time. The thermostat was still at the same setting (72) and no, we didn’t have the doors or windows open.

As I mentioned above, I have the minute-by-minute data but not the second-by-second data for the period of interest. My Emporia Vue has a pretty small limit on how many data it will store.

Our outdoor unit is on the same side as the bedrooms, and we haven’t heard it all when it goes into defrost mode.

Great questions, great answers.

I’m struggling to parse your max power use seen here with what the literature from Mitsubishi says.

My interest is I have a strict power budget to adhear to, being in a Townhouse complex with shared electrical feeds.

Mitsubishi support sent me a document (white paper?) explaining that the Minimum Conductor Ampacity (MCA) also represented their maximum current draw under normal operation. I realize not everyone agrees with that, but that came straight from Mitsubishi.

Looking at Submittal Data sheet for a MXZ-3C24NAHZ2, the MCA is 30.5 amps. Assuming 208V feed, that implies a max power draw of 6344 W.

But here you are, system maxed out, drawing a max of only 4000W, implying a max current draw of 19.2 Amps.

Or maybe my assumption is wrong that the highest power use condition is when the outdoor temp is coldest. Maybe it draws max power during high indoor temperature settings?

My experience is that they top out between 1,600 to 1,900 watts per ton in extreme conditions depending on the individual system and whether it is a ductless systems or has an air handler attached to the heat pump.

I try to imagine that there could be a cycle in which they exceed the level that occurs when it is flat out and super cold, but I have not seen it in years of observing my consumption data.

My concern is that with this new push to replace just gas/oil furnaces with heat pumps is going to cause more pain for a lot of people. With the government subsidies the tendency will be to just replace the gas/oil fired unit with a heat pump with no attention to the rest of the system. Poor insulation, leaky homes, leaky ducts in the attic, won’t allow a regular heat pump to perform properly at lower temperatures. Then during colder weather (~30Deg F and below) these units are not going to keep up and drop onto emergency resistance heat where electricity usage can triple. At least with a gas/oil furnace electricity only powered the blower and there was not a 2-3X surge in electricity use just because more gas/oil heat was required to combat the cold. Seems the grid capacity is already marginal during cold snaps and unless we take a systems approach that includes the entire house and power generation and distribution system we will be asking for trouble.

As the IRA subsidies come into effect, I think it’s going to be helpful to look at the progress of discussion around heat pumps vs building envelopes and subsidies.

For example here is a “builder vlogger” laying out what I expect will be a common sentiment of skepticism.

https://www.youtube.com/watch?v=GhAKMAcmJFg

I like to turn the transcript on to skim: https://www.notta.ai/en/blog/how-to-get-the-transcript-of-a-youtube-video

There is then a followup discussion from people making the case for heat pumps as part of the government subsidized program in the UK:

https://www.youtube.com/watch?v=fFpxiprcRfY

These questions have been kicked around for a long time in the US, but we should expect a renewal of the discussion along these lines as the government support increases.

https://www.bostonglobe.com/2023/02/08/science/heat-pumps-had-their-first-major-test-last-weekend-heres-how-it-went/

https://www.bangordailynews.com/2023/02/14/business/heat-pumps-cold-weather/

“We have 1,500 heat pumps in the field, and we did not get a single call of a heat pump shutting off during this event,” said heat pump installer Josh Oxley, of SolarLogix in Belfast.”

“At my personal residence, I measured 106 degrees coming out of our heat pump when it was negative 19 Fahrenheit outside,” he said.

“It was a great test case, and they came through with flying colors,” said Michael Stoddard of Efficiency Maine.

“In certain homes where we’ve been watching very closely the effects of switching the entire home to heat pumps and removing the old central heating system, we checked in with each of those homeowners individually to see how it was going,” Stoddard said. “And they all reported that the heat pumps continued to work, and kept them comfortable in the home.”

It’s hard to imagine a 125°F delta (-19°F –> 106°F) without resistance heating…

It is pretty amazing. Can’t post a picture here, but in January 2022 there was a stretch of weather in the single digits. On one of the coldest mornings January 11, 2022, I took a series of snapshots to show performance. 2F ambient outside (windchill -15F), the combined consumption of the qty (2) 1-ton FS12 systems was less than 3,100 watts at any given time. Inside house temp steady at 69F. I pointed a thermal sensor tool at the coil and read a temperature of 152.7F! I am sure the flowing air temperature out of the indoor unit was lower than that, but its pretty incredible what the hyper-heat systems can do.

Allison, something happened on 12/22. Were you trying to pre-heat the house for the dip that started on the morning of the 23rd? Outdoor temps were rising on the 22nd all the way until midnight, but so was your heat pump’s energy use.

Good eye, Paul. Yes, I knew what was coming so I set the thermostat up to about 75 °F on the 22nd.

Ah, you were riding the wave of warm outside air. It would be nice to have a heat pump system with predictive behavior doing exactly what you did based on local weather forecasting. Even nicer, if it could pump all that heat energy indoors, store it, and release it gradually later.

That is effectively the opposite of a thermostat setback, which presents an interesting counterargument to at least one of your earlier articles:

https://www.energyvanguard.com/blog/if-you-think-thermostat-setbacks-don-t-save-energy-you-re-wrong/

Ted Kidd’s guest post is conspicuously absent (so I have not read it), but during recent cold snaps such as the one profiled in this article, my experience in Maryland (~4k sq. ft. split level built in 1973) with a 5 ton ASHP (Rheem RP1560 with RH1T6024 air handler) is consistent with what Steve Allwine described in his comment on that article.

Jim: Yes, it was the opposite of a setback. In the earlier article, I said that setbacks can be tricky and may not save you much if you have right-sized equipment. Setbacks work best with poorly insulated, leaky houses with oversized equipment. They can still save energy with other houses, too, but that’s a whole other conversation.

Just some great discussion on this issue. Thank you so much, Allison, for posting your data and then being totally willing to debate each and every data point.

Jim, this particular situation was not the “opposite” of a typical setback, because the outdoor temperatures during that unique evening of 12/22 were climbing all the way until midnight (and so did the heat pump’s COP), before they dropped to 16F just 8 hours later, and I think Allison knew that.

https://www.wunderground.com/history/daily/us/ga/atlanta/KATL/date/2022-12-22

Paul, a nightly setback allows the “mean radiant temperature of the surfaces” to decrease as the outdoor temperature falls (reactively recovering at lower COP, and potentially requiring inefficient sources of supplemental heat to satisfy that subsequent demand). In this situation, a setforward? allowed the “mean radiant temperature of the surfaces” to increase as the outdoor temperature rose (proactively leveraging higher COP, reducing subsequent demand). That’s about as opposite as it gets. 😉

My family wholeheartedly agrees that “air temperature is NOT the only factor that determines comfort” and is MUCH happier with our heat pump now that all thermostats call for a consistent temperature 24/7. That constant temperature setting actually is lower than the previous cycle high temperature, and according to my logs, the difference in energy consumption is minimal (negligible, even), so life is good! 🙂

https://www.energyvanguard.com/blog/Naked-People-Need-Building-Science

Jim, if we want to dive into semantics and argue the benefits or drawbacks of a “setforward”, referring to a t-stat setting, we would assume normal nightly outside temperature behavior, i.e. falling, and call it the opposite of a setback. In this case it was an anomaly, at least for this particular geographic location.

Hi Allison,

I believe all gas furnaces (even the 95%) have flame roll outs sensors around the burners. Some are manual reset and with some you have to turn off power to reset main board.

I was looking at the spec. sheets for your Mitsubishi multi split unit and they show different capacities than what you listed- your unit is a 2 ton 24,000BTU but the cap. you listed is well below that. What gives? If you had to do it over would you opt. for a 30,000BTU unit- since it’s variable speed? Wouldn’t the energy cost be about the same (During normal parts of the heating season)?

Doug: Nominal, rated, and actual capacities are pretty much always different. Actual capacities are usually below the nominal capacity.

No, I wouldn’t go for the larger 30k unit. I want it to be able to run at the lowest capacity it can use and going larger would probably raise that bottom end. And I’ve still got load reduction to do on the house.

Allison, Great article. I have a Mitsubishi high heat 48k unit and had similar results during the below zero with 30 mph winds we had here in Michigan. My house lost a few degrees and used 123 kWhs over that 24 hour period when it probably ran 100% of the time.

You talk about the over sizing of Manual J and how your unit is under sized. Did you try using the sizing that is talked about in this blog?:https://www.greenbuildingadvisor.com/article/replacing-a-furnace-or-boiler. It is quick and uses actual nat gas usage as a way of determining loss. I am curious as to how that method might align with your manual J. The method does recommend that you add 30% as a safety factor which may align with manual J, but with a variable refrigerant flow unit it probably doesn’t effect efficiency. I used it on a serials of similar townhouse constructed units and found up to a 30% variation between similar units which could be due to user habits, construction differences or both.

Thanks for all that you do to spread the word on efficient design.

There is equipment that works well in certain applications. The same equipment doesn’t work in all applications unless the system (meaning envelope) is designed for said equipment.

What folks don’t get is you CANNOT take a new energy efficient heat pump and install it in an 1980s home and expect it to preform like the guy down the road house that has put some effort and energy into the science behind

Heating and cooling his home:

There are too many variables in the science behind home building for all systems to be equal. It also hard to get folks to understand that yea we can do this system however you need to air seal the basement

Maybe address some exposed knee walls and by the way we need to bring your r-value up in your attic to today’s standards for this said system to work for the money you’re shelling out. Just sign here

seriously, folks don’t have those funds for a full energy retro fit. In todays market with inflation they want you to bandaid it

But our local municipality is pushing different

Frustrating……..

Robert: My house is a 1961 ranch with an uninsulated basement, 5,200 cfm50 of air leakage, R-11 (maybe R-7) wall insulation, and single pane windows with storm windows. We do have a conditioned attic with a lot of spray foam, an encapsulated crawl space, and 99% of ducts inside the building enclosure. So it’s not as hard to do heat pumps in older homes as some people think.

The advantage of unitary equipment is that it has backup emergency heat installed to make up the difference. Can you imagine the great surprise for the Clients with standard ductless that lose most of their capacity at low outdoor ambient conditions:(

Please educate your clients on high-output models so there is no great surprise awaiting your customers.

Nice article. What was the temperature coming out the vents when it hit single digits? My Trane earth wise dual fuel doesn’t do so well below 35 degrees. Feels so good when the gas kicks on at 35 degrees. I did get in the attic and spray foamed all penetrations and wall top plates which made a huge difference in comfort in our home. I have not done anything in crawl space, nor have I added insulation in attic. Good stuff.

Ken: I wish I had measured the supply temperature, but I didn’t. Dang it! I think that thought crossed my mind ahead of time, but then I forgot all about it. I’ll do it next time.

Allison: Measured supply air temperatures would have been interesting, but to me the bigger question is whether you noticed any “cold blow” from your supply registers that affected your comfort.

Roy: Nope, no cold blow in my house. There’s only one place where we can feel the air flow, and it’s just when you walk through that area. Because it’s a variable capacity system, it does occasionally feel cooler there, but I wouldn’t say we have a “cold blow” problem.

You say in your article that you used 80 kw h per day at the lowest temperature.

Is that 80kw per hour or 80 kw for the day?

Peter: That’s 80 kWh. See my last article:

https://www.energyvanguard.com/blog/making-sense-of-energy-and-power/

I guess I’m still not clear. Are you saying you used 80kw every hour.

He is saying he used 80 kWh in a day. The kW varied throughout the day. Let’s pretend it was consistent over 24 hours hours though. That would be 80,000 watts / 24 = 3,333 or 3.3 kW drawn continuously for 3.3 kWh per hour to total 80kWh in a day.

If you want to say it was all in an hour than it would be 80,000 watts drawn for an hour to equal 80 kWh.

I have some graphs of power for heat pump and blower here:

https://community.iotawatt.com/t/device-specific-graphs/4173/6

Get yourself a killawatt or something similar to track a space heater or something. You will learn a lot.

Allison,

Thank you for the write up! Really amazed by your heat pump having a continuous capacity even as the temperatures outside drop. My heat pump is completely different. I’m in upstate NY, where my design temperate is -1 F, and my heating load is 35 MBTUh. Most years, we don’t go down to -1 F, but if we do, it’s only for a few hours. One time we had a whole week subzero, going down to – 20 F many days in a row. I think that was February 2015. We also pay around 25 cents per kWh, so 80 kWh per day would be $20 per day or $600 per month, which is crazy to spend on electricity. I tend to run my heat pump down to 35 F. Here’s my data as:

Outdoor temperature F/Integrated Capacity MBTuh/Integrated Capacity kWh/System kWh

-3 / 4.84 / 1.42 / 1/03

7 / 6.84 / 2 / 1.09

17 / 8.94 / 2.62 / 1.14

27 / 11.14 / 3.26 / 1.21

37 / 13.71 / 4.02 / 1.27

47 / 17.87 / 5.24 / 1.35

57 / 21 / 6.15 / 1.44

67 / 24.19 / 7.09 / 1.53

I agree with you and having all electric minisplit heat here comes with hefty electricity price. Massachusetts has one of the highest prices as well. I had months in previous years where my monthly electricity bill during coldest months fluctuated between $600 and $800. This is being very cautious and runing main bedroom at 60F at night and shutting off or setting to min heat(50F) others. I have electrical radiant floor heat in the kitchen and that helps a lot. Otherwise it would be a challenge. Even now wife isn’t to happy when the cold spell arrives since it is a challenge to keep constant temps through out the house.

Hyper-Heat and similar units from other manufacturers are built for low temperature operation. You state that: “Not all heat pumps are created equal. Mitsubishi’s Hyper-Heat models are able to crank out the same amount of heat at about zero Fahrenheit as they do at 47 °F, and other manufacturers have similar models”.. Please consult a submittal sheet for a Hyper-Heat model. I only checked one, but there is between a 60 to 65% drop in capacity from 47 to 17 degrees, keeping the numbers provided from the chart comparing rated capacity . (also maximum capacity)

Any air-to-air heat pump must lose capacity as the refrigerant volume drops with the temperature on the outdoor coil.

Mike, here is my hyper heat MXZ-4c36nahz series outdoor unit marketing brochure (see page 3):

https://www.mylinkdrive.com/viewPdf?srcUrl=http://s3.amazonaws.com/enter.mehvac.com/DAMRoot/Original/10007\MXZ_H2i_May2015Update_15981.pdf

And corresponding graph in the service manual (see page 22):

https://www.mylinkdrive.com/viewPdf?srcUrl=http://s3.amazonaws.com/enter.mehvac.com/DAMRoot/Original/10006\M_MXZ-4C36-5C42-8C48NA-HZ_8C60NA_PAC-MKA30-31-50-31BC_SERVICE_OCH573G_06-21.pdf

Paul,

Thank you for the response.

In his article Allison states that the unit produces the same amount of heat at 47 degrees at around zero. The manufacturer would agree that this is a misstatement. They (the manufacturer) are claiming that it will produce the rated BTU’s to zero–which is accurate. This is the nominal rating that they refer to (1.5, 2, 3 ,4 tons, etc.)

I understand that they have inverter drive compressors, and that this makes a world of difference; however the unit will transfer more heat at 47 degrees than it will at zero. The neat thing is that they can tweak the algorithm on the control board to run the compressor and fans and metering device flow to deliver the rated output given the heat exchanger sizings.

Mike: Download the submittal (link below), and you’ll see that the rated capacity at 47 °F is 25,000 BTU/hr. Look a few lines further down and you’ll see the maximmum capacity at 5 °F is also 25,000 BTU/hr. It’s true that the rated capacities at 47 and 17 °F are different, but that’s just a problem with the AHRI rating protocol for heat pumps.

https://meus1.mylinkdrive.com/USA/M_Series/R410A_Systems-1/Outdoor_Equipment/R410A_Outdoor/MXZ_3C24NAHZ2?product&categoryName=R410A_Outdoor

Allison, the only thing I am taking issue with is the statement that the unit produces the same amount of heat at 47 degrees at around zero.

The statement would be accurate as “…the unit does not slip below its rated output until the outdoor temperature reaches 5 above to zero ODT” or something similar. The rating of your unit is 24,000 btu’s . That it can produce its rated output at 5 above is impressive.

Air to air heat pumps are tied to their indoor and outdoor temperatures. The inverter compressor is light-years ahead of a standard speed compressor for heat output. There is however a great difference in the quantity of heat in ambient air at 47 f. as there is to 5 degrees f. because of this you shouldn’t state that the unit produces the same amount of heat at 47 degrees at around zero.

Mike I think you are confusing “rated output” with ” maximum output” see: https://ashp.neep.org/#!/product/57029/7/25000///0

My 48k mxz Mitsubishi will put out 48k at 5 deg. F.

I would love to know exactly what the heat pump “rated capacity” spec actually means. Clearly a heat pump is capable of greater output than the rated capacity, as the maximum capacity can be substantially higher. Is the rated capacity typically what the unit can achieve at peak efficiency, at standard test conditions? Is there a reason I shouldn’t use the maximum capacity (derated for 99% outdoor temperature) when sizing a heat pump?

Wow, Allison, what a great piece! And the discussion it engendered was even better. I love good data, and love healthy discussions of that data. Thanks for writing these articles and thanks for providing this forum for good discussions on Building Science and HVAC. Keep up the good work and all the best of luck in fighting your health issues.

And oh yeah, thanks for introducing me to Spinal Tap’s guitarist Nigel Tufnel who demonstrates the importance of always having and eleven on your one-to-ten dials, no matter what it is they’re controlling. Feeling cold? Just tune that knob “up to eleven.”

Thanks again, Allison. This was a great article.

What was the COP for the unit during the cold snap, that is what I am most interested in.

Ditto. 🙂 Here in New Zealand these models are marketed as HyperCore, and seem to be a pretty good match for our winter climate (often just a few degrees above freezing with very high RH and therefore outdoor unit condensation and icing issues). Heat pumps seem happier at both higher and lower outdoor temperatures! I would expect the CoP to drop considerably when the built-in supplementary heating kicks in.

Hi,

Rookie question here for you.

How were you able te to get exact kWh usage for your unit?

All I’m able to determine is my daily household usage by reading my outsude electric meter each morning..

Thanks,

Great article. I recently installed a mitsu hyper heat as well. The installer insisted I needed a massive 20kw aux heater I refused and went with a 10kw. I live in Ottawa Canada, it gets very cold here. But designing for a maximum heat load is ridiculous, it gets to -25C regularly but it doesn’t sustain, it will warm up during the day and get cold again at night. My aux hear has never turned on and I’m saving about $1500 a year vs propane heating I had before. My house is warmer and more evenly heated because the heat pump is always maintaining instead of blasting then shutting down. Thanks for trying to inform more ppl there is a lot of miss information out there!

I have a 150,000 BTUh steam boiler and a separate hot water 73,000 BTUH boiler for all the new extensions in the house. I’m married and I don’t want to hear “it”. Get a steam boiler. (I have installed several very large commercial variable refrigerant heat pumps primarily Mitsubishi and probably know more than anyone in this space. However women….)

I actually thought some more about your costs and energy usage, and I’m not impressed with heat pumps in cold temperatures.

At a rate of 80kWh per day, peak 4 kWh per hour, you’re using, converted to BTU, 273k BTU worth of electricity per day, and a peak of 14k BTU per hour, to produce, at most, 480 BTU of heat. If the capacity of your heat pump is 20k BTU, then your efficiency is 20k/14k = 143%, which is not great, considering that natural gas is so much cheaper.

One Therm of gas is around 29 kWh. If you produced ~ 450k BTU that day, that would have been around 4.5 Therms, and cost around $5. Instead, 80 kWh is around $20. Where is the savings relative to natural gas? NY state recently banned the installation of new heat gas appliances and is mandating heat pumps after a certain year. Their claim is that it will save customers money, but looking at your data, I’m not seeing it.

Leo: I think you’ve missed an important point. The 80 kWh consumption in one day was in extreme weather, when the low temperature was ~16 °F below our design temperature and the high for the day was only ~3 °F above the design temperature. If the COP of 1.4 (your 143% efficiency) you estimated is correct, that’s pretty darn good for such weather. On a more typical winter day here in Atlanta, with a low of ~30 °F and the high ~45 °F, the COP probably will be 3 to 4 (300 to 400 percent efficiency). As you can see from the graph, our normal daily heat pump energy use is ~10 to 50 kWh.

Leo, NY will not allow installation of new fossil fuel heating systems starting in 2030, and by 2025 for new homes.

Main motivation is “Buildings are the largest source of emissions in our state, accounting for a third of our greenhouse gas output,” said the NY governor.

ICE cars would be several $1000’s cheaper if they didn’t have emissions controls and measures. They would be cheaper to operate as well.

Leo:

I think that NY state has a large population that uses fuel oil, electric resistance, or propane for heating. All of those will definitely save money. Those using natural gas will have to wait until natural gas prices rise more. Predicting that is a bit difficult if you look at its price over the last 20 years its been somewhat erratic and given climate disruption and world conflicts, it is bound to be in the future .

Just my 2 cents

So replying to three different posts.

1. Only 1/3 of electricity generated in NY comes from renewables, so using a 98% furnace might be cleaner than using electricity generated by burning fossil fuels. https://www.eia.gov/state/analysis.php?sid=NY#:~:text=Natural%20gas%2C%20nuclear%20energy%2C%20and,electricity%20net%20generation%20since%202012.

2. Upstate NY averages over 6000 heating degree days per year vs around 3500 for the Atlanta area. Upstate NY record low by the capital is – 28F while Atlanta GA is -8F, so twenty degree difference. 100% agree that anyone in agricultural zone 6 or warmer should have a heat pump!

3. Even if the average use of a heat pump is 40 kWh in NY, that’s ~1,200kWh per month, or around $300. By comparison, assuming an average COP of 2, the cost of 2,400 kWh of natural gas would be around $80.

4. I can run my furnace off my little generator, but I would not be able to run a heat pump that would use up to 80 kWhs in a single day! Even going with decent sized battery backups, and backup resistant heating, you would be screwed if you had a bad storm that knocked out power for a few days and had a few cold days behind it.

Leo, interesting discussion, and one that prompted me to compute a worst case comparison of my ASHP vs. my (now rarely used but certainly nice to have) oil-fired hydronic baseboard system. At just under 20°F ambient here in Maryland, my Rheem RP1560 with RH1T6024 air handler runs flat-out to maintain the 65°F winter set temperature in my ~4k sq. ft. split level built in 1973. Cooler air blows during short defrost cycles without heat strips, but published capacity is for marginally lower ambient, so I’ll consider it a wash and use that for load / demand (empirical assumption vs. ACCA Manual J estimation).

electricity in my area costs ~$.07 / kWh

17°F heating capacity is 35,600 BTU/h or 10.4 kWh output with 2.66 COP = 3.9 kw/h input

active energy monitoring confirms that my heat pump consumes ~4.0 kw once stabilized

4.0 kw * $.07 / kWh = $.28 per hour when heat pump runs at max capacity

heating oil in my area costs ~$5 / gallon

1 gallon heating oil contains 138,500 BTU

my Bryant BW4 boiler is 86% efficient

138,500 BTU * 86% = 119,110 BTU / gallon

35,600 BTU / 119,110 BTU = 0.3 gallons

.3 gallons * $5 / gallon = $1.50 per hour to match heat pump at max capacity

So, even at very low temperatures near its max capacity, my ASHP costs about 20% as much to run as my boiler (ignoring my grid-tied solar array with net metering). If my electricity in MD cost as much as yours in upstate NY ($20 / 80 kWh = $.25 / kWh – yikes), then it would cost about 67% as much to run as my boiler.

Jim,

Your rate of $0.07/kWh sounds too good to be true! I did a quick Google search, and average for Maryland is $0.1586, still less than mine, but more than twice yours! Electric rates have two components, potentially on two separate pages of your bill. If you don’t mind me asking, what is your supply cost and delivery cost? I’m currently paying 18 cents supply and 7 cents delivery.

Leo, our rates do seem to be relatively low!

https://www.firstenergycorp.com/customer_choice/maryland/standard_offer_price.html

My grid-tied solar array overproduces enough in the summer months to cover underproduction in the winter months, so my bill typically looks like this:

Customer Distribution Charge 5.70

Electric Universal Service Fee 0.32

Current Consumption Bill Charges 6.02

Each bill also provides Generation, Transmission & Energy Cost Adjustment Price Comparison Information:

– The current price for Standard Offer Service (SOS) electricity is 6.537 cents/kWh, effective through May 31, 2023.

– The weighted average price of SOS electricity will be 6.921 cents/kWh through May 31, 2023.

– The price for SOS from June 1, 2023, through May 31, 2024, will be set in January 2023.

With net metering, each kWh that I generate for the grid is worth the same as each kWh that I consume from the grid.

*** I found an old bill showing more consumption than generation which shows the following:

Generation Charge 42.70

Transmission Charge 2.76

Customer Distribution Charge 5.70

Distribution Charge 12.18

Electric Universal Service Fee 0.32

Energy Cost Adjustment 1.97

Administrative Credit -1.27

Electric Distribution Investment Surcharge 0.47

Cogeneration PURPA Surcharge 5.03

Franchise Tax 0.43

EmPower MD Surcharge 4.31

MD Environmental Surcharge 0.10

Current Consumption Bill Charges 74.70

Jim, glad to see a fellow PV array owner having overproduction “issues”. Maryland summer, 5ton heat pump, overproduction: hm, you either have some gas appliances (WH?), or your array is well over 10kW nominal.

With our all-electric, 5400sqft, 3-ton HP, HP water heater, 4.2kW array, in a typical year will have overproduction during 2-3 months, and overall average of 0.99 kWh/sqft per year.

Paul, a 9.69 kW array on the house feeds a 7.6 kW inverter (supply side connection at the meter) while a 9.12 kW array on the barn feeds another 7.6 kW inverter (load side connection at the panel). Both face 190° (but at an inclination of ~25°, which is less than ideal during winter months at our latitude). According to PVOutput, annual production averages ~15 MWh, so ~3.75 kWh/sqft.

Our 50 gallon Rheem hybrid electric heat pump water heater is super efficient, and I’ve trained the other three family members to hang clothes outside to dry, so the primary energy offenders are pretty well mitigated!

Even if gas were available (well, propane is…), I prefer oil from a safety perspective (it sits outside in a tank and can’t detonate my house). Regardless, it’s better to use power generated on-site rather than to burn fossil fuels we can’t renew, so replacing our 1980’s era central A/C with an ASHP made 5 tons of sense.

Jim, awesome PV! Sorry, I was wrong, the 0.99kWh/sqft was our total energy billing. Total usage (PV+grid) comes out to 2.11kWh/sqft, so about 53% of energy provided by PV.

Jim, you did mention a current oil boiler, is that part of your total energy picture?

The heat pump based house heat and water heater made it possible for our PV to make sense (speaking from ROI point of view). Sawnee EMC is paying us $0.0281/kWh for overproduction, so I wanted to use as much as possible on site.

This was only one of the reasons for not hooking up natural gas to the house (available along the street).

Paul, I have not paid for consumption in the past twelve months and received only a tiny annual reimbursement for over-production last spring so sit pretty much right at 100% (until we start charging BEVs, anyway!). Efficiency upgrades to my 50-year-old house go only so far, and many loads are difficult to shed (pond aeration, stock tank de-icing, pool filtration, hot tub heating, radon extraction, etc.), but we are diligent about seizing feasible opportunities to conserve within reason. As Maryland is fortunate to have net metering with price parity (for now, anyway), I don’t need to worry about scheduling consumption to correspond with production or investing in expensive storage solutions. Monthly SRECs also help offset the PV cost.

Yes, my Honeywell HZ432 zone panel in dual fuel mode is configured to engage the oil-fired hydronic baseboard system below our thermal balance point of 20°F ambient or when the heat pump calls for assistance, whichever comes first. So far this season, the former condition has occurred only during the frigid event profiled in this article (when it was most welcome!), while the latter condition I have not detected since abandoning thermostat setbacks and maintaining a consistent temperature.

Here are the average rates in Georgia. We have a lot of providers.

https://psc.ga.gov/utilities/electric/residential-rate-survey/

I have Sawnee with solar net metering (each provider has its own rules on that too) and pay about $.10 kWh and monthly base fee is $26.85

Sawnee has a 3 tiered structure by kWh usage and also a wholesale charge per kWh and tax. Simple bill.

It would be annoying to pay a base fee for both electric and gas so luckily my house is electric only. Total annual usage is about 29 MWh

We have 2 heat pumps and a hot water heat pump in the garage in series with a regular electric in the basement. Plenty of hot water and backup if one has issues. Learned that lesson a couple times. Happy wife, happy life.

Leo, replying to (1.), in 2021, 54% of NY energy was from renewables+nuclear:

https://www.eia.gov/state/?sid=NY

Is the energy production portfolio getting cleaner? Yes:

https://www.nyserda.ny.gov/About/Publications/Energy-Analysis-Technical-Reports-and-Studies/Patterns-and-Trends (see page 27, table 3-1a).

Looking forward to seeing the article about primary energy vs. on-site and their impacts on emissions, which Allison promised earlier this year, if I remember right.

For now, I’ll take 1 natural gas power plant over 100,000 homes with 1 gas furnace, 1 gas WH, 1 gas dryer, and 1 gas stove each. Power plants can and are scrubbing their exhaust stacks, some better than others. Combustion emissions in home appliances are uncontrolled.

I’ve been wondering about the off-grid or emergency backup situation with a conversion to all-electric as well.

Setting aside a wood stove for emergency heating through a grid failure (or some wonderful superinsulated resilient house that stays survivable for days just by breathing or some such) seems like the option would be to run a propane generator to provide sufficient power?

Very, very quick googling suggests that would be something in the realm of 5-10 gallons of propane a day, to output something like 80KwH. I think one would want a battery and inverter in the mix to ensure clean enough power (I bet variable refrigerant flow is very sensitive to power quality and generators are notorious).

That seems high, but perhaps not ruinous, as long as it was a very rare occurrence. Sure, might seem “the long way around” to burn propane to create power rather than burning it directly to create heat, but with the higher CoP of heat pumps perhaps it’s even more efficient than burning the propane directly. If anyone has resources/tests on that idea would love to see them.

Just as a fun exercise:

A few years ago, the high voltage line running underground from the pole at the street to the transformer at my house failed in several places (the shorts were located by a “thumper truck”). As that line had been direct-buried (without conduit) for nearly 50 years, the utility wisely opted to replace it rather than repair it, and the outage lasted three days (a temporary line eventually was run above ground until a directional boring machine became available to “bury” the replacement). My tractor with 15 kW PTO generator ran continuously during that time, but sadly I failed to track fuel consumption and energy usage. Since diesel fuel and heating oil contain about the same energy content, I tweaked the numbers in my earlier comment to see what it would cost to run my heat pump on oil if my boiler generated electricity as efficiently as it boils water (more than a stretch for my tractor, but…):

heating oil costs $5 / gallon

1 gallon heating oil contains 138,500 BTU

my Bryant BW4 boiler is 86% efficient

138,500 BTU * 86% = 119,110 BTU / gallon

119,110 BTU / 3,412 BTU/kWh = 35 kWh

$5 / 35 kWh = $.14 / kWh

4.0 kw * $.14 / kWh = $.56 per hour to power heat pump at max capacity

Incidentally, that outage occurred before installation of our ASHP and HPWH, but both refrigerators operated without incident!

The heat pump in cold climates conversation is getting more traction in the media, as this recent article in the Colorado Sun attests.

https://coloradosun.com/2023/01/26/heat-pumps-work-colorado/?utm_source=The%20Colorado%20Sun%20Newsletters&utm_campaign=SUNRISER_20230126&utm_medium=email

I could have used this post perhaps 4 months ago while planning my HVAC system. I had just purchased my new (old – 1938) home. This freestanding masonry home has no insulation in the walls and very little in the attic. It was heated with gas fired hot water radiators and no central AC. The main two floors are 1500 sf with a 600 sf finished basement and a 320 sf finished attic. I’m a builder, not and HVAC pro, but having paid for several designs from pro’s based off my ideas, I decided to wing this one and designed and installed it myself with the help of a technician, after demo’ing the old heating system.

Last week it was 13* here outside of Baltimore, MD basically the design cold temp. My system is a Mitsubishi three zone with a ducted 30000 BTU air handler for the main two floors and two mini heads for the finished attic and basement respectively. It’s all managed through a branch box and a powered by a single 42,000 btu hyperheat outside unit.

I woke up to 65* the day it was 13* and it took 3 hours to reach 69* set point, then it idled the rest of the day. So I’d say i could have gone smaller.

Love your blog!

Allison,

I read your blogs occasionally and know how you feel about blower-door tests. In the last 4 years I’ve been involved in purchasing high efficiency ACs and heat pumps for myself and family members. When I bring up the question of a blower door test I’m always told that that is old school and that their method of determining heating or cooling requirements gives the same results. I don’t believe that, but in my most recent experience, in small town Minnesota, there was no one in small town, or probably within 100 miles or more that would do a blower door test. The other problem is that if you want a particular brand, there might be only one authorize dealer for that brand within 50 miles and the one 50 miles away won’t travel 50 miles to do an install. In other words, you run out of options. The only answer to this dilemma seems to do the blower door test myself which I have not attempted yet. This was with a GreenSpeed system for a fairly large home. What’s your advice? Thanks.

If it an existing home with a year or two of energy bills those can be used to size a ASHP system(see size an HVAC system in 15 minutes on the web). You can add a resistance backup to give additional assurance it the system will do the job. On a new house, code requires a blower door test and a manual J in most cases although not all munis require it.

I have looked at the specs on the Mitsubishi that I have and with the variable refrigerant flow systems there is not much of a difference between minimum and maximum flow COPs at the temperatures they list so “undersizing” probably doesn’t effect efficiency and so I would just right size it.

Check out my heat pump experience at -30F!

https://mindmuser.wordpress.com/2022/12/29/the-heat-pump-torture-test/?fbclid=IwAR2Z1TOQaNsyy1TN2uYoXdEapINmFbIKdMX9efXcA0OAQYhNc99T3gdVyus

That’s some heavy basement insulation. Here in Maryland, code is no insulation under the slab if the slab is below frost (30″) and R-11 for basement walls.

Yes, it is. We built the home with SIPs and in order for the basement walls to withstand the pressure of backfill, we needed a 9 1/2″ thick wall, which happens to be R-40. We aren’t required to put insulation under the slab here either unless the slab is hydronically heated but I can confirm it makes the lower level so much more comfortable!

Even though we live in the Sunny South (Greenville, SC), we elected to put insulation at our slab perimeter and two feet into the slab from the edge. This has made our basement very comfortable, too, while providing a thermal store under the slab which limits large temp swings.