What Is a Mini-Split Heat Pump?

Ah, mini-splits. They’re all the rage in the world of high-performance HVAC. But what exactly is a mini-split heat pump? Unfortunately, the terminology around this technology is confusing because it’s used so inconsistently. Let’s start at the beginning. (Well, OK, not all the way at the beginning. I’m not going to explain what a heat pump is, but here’s a primer on how they work for heating.)

The basic meaning

The term “mini-split” itself originally referred to a split system heat pump (could also be an air conditioner) with a smaller capacity than conventional systems. In that sense, a mini-split is just what its name says it is: a small split system heat pump. Where it gets confusing is in the different ways manufacturers make these lower-capacity, split-system heat pumps.

A mini-split, for example, can have a conventional fixed-capacity compressor or an inverter-driven variable capacity compressor. So, a mini-split could be a conventional heat pump that’s just smaller. Or, it could be a smaller heat pump with variable capacity. The former type is rare, though, so when you hear the term “mini-split,” you should think of the type with the inverter-driven compressor with variable capacity.

But it gets worse. This type of heating and cooling system has outgrown its name…at least the “mini” part. Yes, you can still get them down to a half ton of capacity (6,000 BTU per hour), with smaller capacities on the way. But you can also get mini-splits that have a capacity of 4 tons (48,000 BTU per hour), which is far from “mini.”

Is it a mini-split…or a multi-split?

Another confusing area is that with this type of heat pump, the outdoor unit can be connected to one indoor unit (referred to as one-to-one), or it could be connected to multiple indoor units. Some people distinguish these two types by using the term “mini-split” only for the one-to-one configuration. When you have more than one indoor unit on a single outdoor unit, that’s a multi-split heat pump, they say.

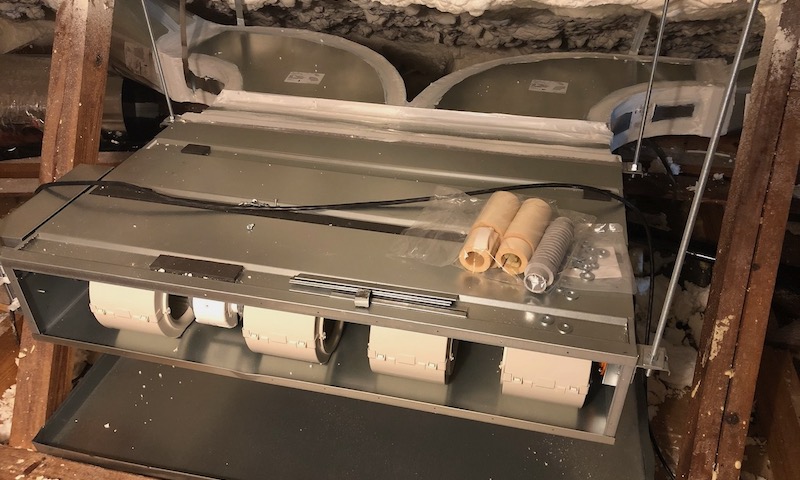

If we go with that dividing line, I have both a mini-split and a multi-split in my house. The main part of the house is heated and cooled with one outdoor unit connected to two indoor ducted air handlers. That would make it a multi-split. And I use a one-to-one ductless system for my sunroom (above).

Are all mini-splits ductless?

And then there’s the issue of the type of indoor unit. Some are ductless, and they come in different flavors: wall-mounted, ceiling cassettes, and floor-mounted. Others are ducted, and they come in horizontal ducted or multi-position types. Some people use the term “mini-split” only for ductless indoor units. Others refer to any type of split system with smaller capacity as a mini-split, no matter whether the indoor unit is ducted or ductless.

I use the term “mini-split” for all of the above. Since mini-splits with fixed-capacity compressors are rare, you don’t really need to worry about that confusion. If you’re talking to someone about mini-splits, you should be able to tell from the context how they use the term. If not, ask them to clarify.

Inverter-driven mini-split heat pumps

Inverter-driven mini-split heat pumps are the future for high-performance homes. I’ve got them in my home, and it’s what we specify in a majority of our HVAC design jobs at Energy Vanguard. Their high efficiency and variable capacity that can ramp down to very low values are perfect for superinsulated, airtight homes. And they work well in less efficient homes, too.

They give you a couple of other benefits as well. Their lower capacity means you can zone your heating and cooling with separate pieces of equipment. And using separate pieces of equipment provides resilience. If one heat pump stops working, you can still heat or cool the parts of the house that have operable equipment.

One final point here concerns the one-to-one configuration. If you want the highest efficiency, the best zone-to-zone control, and the most resilience, use only one indoor unit on each outdoor unit. Multi-split systems can work fine, but they’re just not as good as one-to-one setups.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and writes the Energy Vanguard Blog. He also has a book on building science coming out in the summer of 2022. You can follow him on Twitter at @EnergyVanguard.

Related Articles

My Undersized Ducted Mini-Split Heat Pump

Can You Oversize a Mini-Split Heat Pump?

Can a Heat Pump Work in Minnesota?

How the Heck Does a Heat Pump Get Heat from Cold?!

Comments are moderated. Your comment will not appear below until approved.

This Post Has 28 Comments

Comments are closed.

Adding to what you wrote… there’s the mini-split air conditioner and the mini-split heat pump. Mini-splits are by far the most common type of air conditioner in the world. A/C-only mini-splits are less common in the United States. The price difference is relatively small, so the heat pump version is a no-brainer in most U.S. locations.

Another point of confusion is the term “variable refrigerant flow” or VRF… most commonly used to refer to commercial multi-splits that can simultaneously heat and cool different zones as is often required in office buildings that have interior zones. Lighting, equipment and people can create wintertime cooling loads in zones with no exterior exposure. A VRF system recovers heat from cooling zones to offset the heat loads in zones with significant exterior exposure, thus reducing overall energy use.

David: Thanks for bringing up the VRF issue. I stayed away from that in the article, but was hoping someone would bring it up in the comments. You and I discussed this a while back, and I’m not sure I agree with you that VRF should be used only for the commercial-style systems that can do simultaneous heating and cooling. But I haven’t really researched it yet. I know some people use VRF the way I use mini-split. Maybe we’ll hear from them and others here.

Kristof? RoyC? Curt?

Well since you asked, Allison:

I would never use a ductless system in a house. Why?

1. I don’t like the looks of the indoor unit hanging on my wall or ceiling. I would much rather look at a supply register or return grill.

2. Air distribution is not as good. Your return and supply is at the same location so you need high supply velocity to prevent recirculation. With a ducted system, you can put several separate supply registers in one room. With ductless, you can’t afford to do that, so they tend to be drafty due to their higher supply velocities. High wall indoor units also tend to have more temperature stratification, especially in heating mode.

3. Having multiple indoor units, whether it be several single-splits or a multi-split system can cause more problems with managing condensate and often requires pumps and additional plumbing.

4. Multiple indoor units require more refrigerant piping and field joints, thus are more prone to leakage. Our next generation of low-GWP refrigerants are likely going to be flammable and more expensive, so this will become a bigger issue in the future.

My recommendation is to go with ducted systems. Variable-speed compressors and zoning systems are available if you want to pay for it, and it would probably still be cheaper than multiple ductless single-split systems or a multi-split system. By properly locating the supply and return registers, you will get better air distribution throughout the house. I would never install larger than a 3-ton ducted system, so if your loads require more than that, install multiple ducted systems, especially on multi-story homes.

Roy: I agree with your comments. Most of the systems we design are ducted, but sometimes architects give us plans that just don’t allow for ducts. What I was hoping you might comment on, though, was the meaning of VRF. Is that term just for commercial systems that can simultaneous heating & cooling or does it cover residential multi-splits and mini-splits?

Allison, I did not want to go there, but I guess I must. As far as I am concerned, VRF and VRV are just commercial brands and have no real meaning as acronyms. All vapor-compression cycles are variable flow and variable volume depending on indoor and outdoor conditions. I think that single-split vs. multi-split are reasonable distinctions and ducted vs. ductless are reasonable distinctions. The remaining issue with multi-splits is whether or not you can have the indoor units provide simultaneous heating and cooling in different zones. To me, this is best described as a two-pipe vs. three-pipe system. ASHRAE has a definition for VRF, but it has little to do with the actual acronym.

@Allison, I think I laid my comment that VRF implies simultaneous heateing & cooling to rest. That may have been correct at some point in the past but it’s clearly no longer true (re: City Multi S Series and other non-recovery models now being sold with VRV/VRF prominently featured in the marketing literature).

@Roy, one can apparently have a 2-pipe VRF with heat recovery / simultaneous heat & cool. It’s just a variation on the refrigerant loop topology. If you have the 2016 ASHRAE Handbook (HVAC Systems & Equipment), refer to last paragraph on page 18.6.

David, you are right that using the terminology of two-pipe vs. three-pipe to distinguish units that can provide independent heating or cooling to each zone is also not well-defined. To me, three-pipe means that each indoor unit has to have independent access through valves to the three main refrigerant line types (liquid, low-pressure gas, high-pressure gas). There are various ways of accomplishing this.

I don’t think Chapter 18 of Systems is clear on this at all, but what I really don’t like most about this chapter is saying that simultaneous heating and cooling operation is “heat recovery”. Heat recovery usually refers to systems that transfer heat from a hotter location to a cooler location using a pumped fluid. When VRF systems do this, they are actually operating as heat pumps that pump heat from one space to another regardless of the temperature of those spaces. This is generally more efficient than having separate systems that each exchange heat with the outdoors, but it is not what I consider to be “heat recovery”. It is internal heat pumping.

Yeah, I figured you were waiting on me 😉

Daikin trademarked the term “VRV” (variable refrigerant volume). Other manufacturers followed suit with the generic VRF (“flow” instead of “volume”, but the same thing). VRV/VRF terminology appears to be somewhat soft: even within a given manufacturer, VRV/VRV terminology isn’t used consistently. I always used VRF to refer to commercial multi-splits with heat recovery capability (i.e., simultaneous heat & cooling) but I see that’s not always the case (e.g., City Multi S-Series), so I stand corrected on that point. But I believe there is a difference between VRF/VRV and a conventional multi-splits such as Mitsubishi’s M-Series. Moreover, it’s definitely incorrect to refer to a single zone mini-split as VRF. That would imply that all variable speed A/C and heat pumps are VRF, such as Carrier’s Greenspeed and Trane’s XV18 and XV21i.

Historically, VRV/VRF has been used by manufacturers to refer to certain commercial, industrial & institutional multi-split systems. Just for grins, I dug up two DOE definitions of VRF that support this position (emphasis added):

“…variable refrigerant flow multi-split air conditioners and heat pumps (VRFs)… are a type of commercial and industrial equipment.” (ref: 84 FR 32328 Summary)

“DOE defines “variable refrigerant flow multi-split air conditioner” as a unit of commercial package air-conditioning and heating equipment that is configured as a split system air conditioner incorporating a single refrigerant circuit, with one or more outdoor units, at least one variable-speed compressor or an alternate compressor combination for varying the capacity of the system by three or more steps, and multiple indoor fan coil units, each of which is individually metered and individually controlled by an integral control device and common communications network and which can operate independently in response to multiple indoor thermostats. Variable refrigerant flow implies three or more steps of capacity control on common, inter-connecting piping. DOE defines “variable refrigerant flow multi-split heat pump” similarly, but with the addition that it uses reverse cycle refrigeration as its primary heating source and that it may include secondary supplemental heating by means of electrical resistance, steam, hot water, or gas.” (ref: 10 CFR § 431.92)

That being said, several manufacturers have introduced residential “VRV” or “VRF” systems in recent years (e.g., Daikin’s VRV Life, Fujitsu’s Airstage J-IIS). So the question is, why are these particular systems referred to as VRV/VRF and not other residential multi-splits such as Daikin’s Aurora & RMXS systems and Fujitsu’s Halcyon Hybrid Flex system? Similarly, Mitsubishi refers to City Multi as VRF but not their M-Series multi-splits. The difference I’m told refers to how the refrigerant loop is managed. I originally saw this difference described in the context of a 3-pipe heat recovery VRF system, which is why I assumed VRF implied simultaneous heat and cooling. Here’s a more recent technical explanation:

“VRF systems are similar to the multi-split systems which connect one outdoor section to several evaporators. However, multi-split systems turn OFF or ON completely in response to one master controller, whereas VRF systems continually adjust the flow of refrigerant to each indoor evaporator. The control is achieved by continually varying the flow of refrigerant through a pulse modulating valve (PMV)…” (ref: HVAC Variable Refrigerant Flow Systems, CED Engineering Course No: M03-014)

In my previous comment on VRV/VRF, I wrote: “The difference I’m told refers to how the refrigerant loop is managed.”

I called an engineer I know at Mitsubishi this morning and he said he considers the M-series multi-zone (MXZ) to be a VRF system and that there’s no inherent difference between refrigerant loop management (specifically per-zone digital metering) on their M and S series systems. Like Roy and myself, he agrees that VRF is mostly marketing jargon and inconsistent usage throughout the industry is what has led to the confusion. This discussion has definitely cleared up my own confusion on the issue!

Just wanted to provide my experience with Mitsubishi wall mounted ductless units. Mold.

The mold was there when we bought the house so I can’t say what the previous owner did or did not do. Since they were mounted high on the wall they required a ladder for access.

Unlike a regular forced air HVAC system where you can have a high efficiency filter in the return duct, these Mitsubishi units just have a thin plastic screen (which you are supposed to clean every month) that seems to have limited filter efficiency for small particles.

All three heads had significant mold growing on all surfaces (drip pan, coils, vanes, housing etc.). It took several hours to disassemble them and try to clean the mold. Some parts like the coils have limited access even after disassembling what can be disassembled. Just sprayed a lot of cleaner hoping it get to the back side. These units have several little actuators to drive the directional vanes so disassembly of these parts including the drip pan is somewhat complicated and time consuming. Of course all this has to be done on a ladder.

It seems to me these units would always be a mold problem even with regular filter cleaning.

Has anybody else had long term experience with minisplit heads and keeping them clean? Maybe with monthly cleaning which includes filter and spraying down of internal components it would be OK, but I’m guessing most people wouldn’t be doing that especially since most of the time there are multiple heads.

I agree 100% . With wall mounted minisplits, IAQ is not a consideration. You can’t even get good filtering. Have fun trying to clean then over your nice carpets and furniture. The all minisplit paradigm also leaves out closets and small baths. Variable capacity is great and is available in air handlers, ducted minisplits (sometimes acceptable) and in traditional minisplits for additions and bonus rooms. For the existing housing stock, ducted systems have better results when factors other than initial ease of installation are more important.

In mature mini-split markets, which the US isn’t really one (yet), there’s a much wider choice of form factors and something for every niche. For example, Daikin has the “Kokotasu” unit, which is rated at 800w cooling capacity (about a quarter ton for US non-metric barbarism (sorry, joke, don’t flame me!), I think I’ve got that right as we’re not used to this unit of measure here in the U.K.) https://youtu.be/Q0N4A66l1gs

This unit is designed for bathrooms (it is certified for high-humidity zones, like baths, powder rooms, kitchens etc.) as well as closets, small home offices and so on. The video gives typical use cases.

And I have to say, addressing another point, I’m sitting here with my mini-split running in “silent” fan mode (19dB sound pressure) and it’s barely audible and you can’t feel any air movement at a metre or so from the unit. I could run my hydronic heating, but in all honestly, I prefer to run the mini-split in most heating conditions compared to the rumble of the boiler and the hum of the motor in the pump — plus the occasional creaking from the radiators. I guess it all depends on what you get used to.

About the only disadvantage in the heating season of mini-splits is they don’t do radiant heat. But it has to be really cold (we have mild winters here in southern England) before I, personally, start to feel the urge to switch off the mini-splits and fire up the fossil fuel boiler.

Is this something you might be able to mitigate with a whole-house air purifier, something like a Blueair Blue Pure 211+?

I’m not sure how it applies to mini-splits, but my understanding is that central air systems, at least, are not intended to filter for air quality (mold spores, viruses, etc.), even though filters are marketed that way and most people use them that way. For one, their duty cycle depends on outdoor temperature, which really has no correlation to how frequently you should recirculate your indoor air (which is ideally constantly). I think the filter is really intended to protect the machinery itself from dust and other particulates.

While the Mitsubishi unit might still be prone to mold due to constant surface moisture, I wonder if a central air purifier might at least minimize spores in the air, and thus lead to a lower propensity for mold to grow on damp surfaces.

Craig I am one of those people who have had two different brands of mini splits over several years. Would I do it again. NO!!!! You are exactly right about the mold issues. I live in WA state and the first unit I bought to try it out was a Friedrich DIYer model for heating and cooling. It was a first of it’s kind and was only about 2k for a 24btu unit online. Installing it was a nightmare, like wrestling an anaconda with the lines. The lines would only would go 25′ from the compressor to the inside head unit. We had no idea that you had to clean these things and no mention of it with paper work etc. Plus no one wanted to touch our DIY unit since they never made a profit on the sale when the thermostat went out after five years! This sector is just big time protectionist. We figured out from watching Youtubes how to clean it. But the manufacturers do not want home owners to clean it and offer zero help on this. This is the gift that keeps giving these dealers. These things have been around for decades around the world and the manufacturers have yet to design a model that provides easy access to clean it. It was gross and moldy when we first cleaned it and pretty shocking. After it was cleaned we noticed a huge improvement in air quality but in only lasts so long. We would clean it about once every 6 months and it was a messy project. I wish there was an easier way to clean them so we could clean them more often. We previously had horrible 1970’s radiant plaster board ceiling heat and no ducting.

The problem with these units is they don’t fit over the windows so no way to dry condensation off the windows in winter . . . and if a room had windows on different walls they would not have any ducting. We have double pane newer vinyl windows too.

Also the air is stale in the house with these. When we used the dehumidifier option in the summer it really never took the water out much. The air tends to be more humid with these ductless units. I had to resort in the winter to using dehumidifiers and well that is not energy saving at all!!!

They could have set them up to include fresh air but again they don’t bother with innovations with these units for decades. Do you know why these are so popular? This is what dealers are trying to suck people into buying because it doesn’t take actual skill to put these in much at all. They can hire kids to install them who are sloppy and make a huge profit. We bought our last one, Daiken, from one of their gold like dealers who was a real rip off with pricing. We wanted Daiken since they are the only dealer who actually offered a 12 year warranty for both LABOR and parts. They also said they would clean these units for about 200.00. The reason we wanted this warranty is due to the fact that to get these worked on it will cost more in labor than the unit is worth. Essentially these are throw away units. You could buy a new one for the cost of getting an older one fixed. Our landfills are now filling up with this throw away boxes. When we did call the dealer that installed it three years later they told us the cost of cleaning it will be 400.00!!!!! So they lied. Also they would not tear it apart but just use the spray bottle and shower curtain or garbage bag set up or pricey versions you can buy online and do it yourself with a can of HVAC coil cleaner for about 5.00.

Another problem is we had two head units installed and the smaller bedroom unit is noisy when the fins move and hit the guard. We took out he guard and it is less noisy. Also the team that installed it failed in three major ways. First the kid sliding up in the attic decided to slide on the dry wall and now we have a crack in the ceiling. That same lazy kid also did not cover the copper tubing in the attic so we found it uncovered and building up condensation! That same kid spent a lot of time in our bathrooms and I wonder if he was riffling thru out medicine cabinets. The guy who was in charge wasn’t much older and he never tested the lines so about two weeks later our air conditioning just stopped working. The gas leaked out. Not very environmentally safe now is it. They had an older electrician do that work but the crew was not that impressive and this is one of the bigger dealers in our area and I expected them to do better after interviewing other outfits that were even worse! These ductless systems do not attract the best dealers.

If I had to do it all over again and I am sure I will eventually, I would have a ducted heat pump system. I would have the vents on the floor under the windows. I would have a way to have fresh air coming in and heated. I would add on filters that would improve air quality for allergies and help with taking the moist air out. Also we have no heat or cooling in our bathroom and extra bedroom but with a ducted system I would make sure all the rooms had heating and cooling.

Friedrich only sold those DIY units for just a few years and then the family sold the company and the new owners ditched these DIY units asap. I am sure all the ductless dealers nation wide were happy about that. Maybe this was a strategy by the family to get buyers to pay their price to get these DIY units off the market? Friedrich at the time was considered the biggest air conditioning company I had read so they were a leader for sure. I recall calling all around a large metro area of millions to find a dealer who would fix our Friedrich’s thermostat on our 5 yr old ductless and also tried to get a part and no one would come out. The new owners of Friedrich would not provide us a part, only to a dealer. So we were basically screwed by this sector big time.

It makes me just want to go back to window shakers and small portable heaters you can buy on Amazon for 60.00 I am so disgusted with the way they operate with consumers today. Why is it you can buy a window shaker and you don’t need to have them pressure tested and they can plug into regular wall socket but with these poorly designed ductless units you have to have electrician, then pressure test the gas, then have a county permit, then have a county guy who knows nothing about these units come out and want to look into your bedroom even though he can see the piping stuff coming out of the attic into the wall. He has no clue if it is done right at all since after his visit we had all these issues crop up with the gas leaking and the copper pipes not covered and our ceiling cracked.

I really think there is much too much emphasis on selling these cheap versions of HVAC and I am sure the Japanese and Chinese make it extremely profitable for their dealers but it a terrible set up long run for Americans and only adding to our landfills. Also I think finding people who actually know how to duct correctly is a dying art now. I had a previous house ducted, a much larger house and he was amazing to watch. He was so good he did the house for the Costco owner. You can’t find guys like that anymore. Not only do I know what good HVAC looks like and how it operates but I now also know what horrible ductless HVAC is like too.

I would also warn against radiant heating in any form since at some point it will break down and the cost of fixing it could be staggering if you can find anyone to do it. With our ceiling radiant heat which I had never heard of before, I called our local PUD about it. The engineer out and out lied about how efficient they are and blah blah blah. Why did he lie? Well our local group owned PUD was pushing builders in this area to install them. Turns out the heat is just awful. It takes forever to heat a room and then only things heat up like coffee tables and the top of your head. It takes forever to cool things down too. It uses big time electricity and you can’t find a decent programmable thermostat (King) that won’t get fried no matter if it is a one or two pole. Then you have no cooling ability with them either. It is like buying an oven that only bakes and can’t broil, nor convection or self cleaning. It is a one trick HVAC pony.

When talking to the dealer that installed our units and then after learning they lied about cleaning charges he told us to go call another Daiken dealer. So these guys don’t worry about bad reviews since so many referrals from people who fell for the marketing and then you have PUD outfits pushing these and financing these units and they have this special list of dealers they will finance and it makes me wonder about how and why these dealers are picked by PUD. I do think this is a conflict of interest but what do I know.

I have an older 1971 ranch and ducting this will be problematic and now I doubt anyone can do it in the crawl space or wants to. I have read about using these plastic type of tube ducting with heat pumps for crawl spaces but I have also read how they really don’t work as well as the tin ducts and another half baked approach by HVAC. I want the warm air from the ducts to rise in front of the windows, not from the attic which is not optimum since heat rises. You would think by now there would be some really clear choices in effective energy efficient heating and cooling systems for us now a days for the biggest chunk of older homes today but all I have seen is how they now target us with these half baked ductless systems.

I posted on one of those online sites like reddit about the problems since someone asked about them. I thought those sites were open to people posting about their real concerns but I will not post there anymore since I learned how so many dealers are on there making sure their bottom line is not affected. So many HVAC guys attacked me and voted my comments down. One guy DM me and said wow these guys are really upset about how you are telling about your experiences and how they want to down rank my comments so no one will find them! It was that obvious. I still leave digital crumbs out there for folks so they know up front how bad these systems are. This shows you how adamant they are about squashing anyone who says anything different than what their marketing tells folks.

BTW I spent like 7,900 for that one Daiken heat pump and two heads inside units is all. I think I was taken to the cleaners compared to what I have read online about pricing since then. It took one day to install it too and they had to come back twice more to fix their mistakes. Very profitable. You mileage might vary but I doubt it.

Trillium, I tend to agree with your main points. My understanding is Carrier now makes an easy to disassemble and clean minisplit. A close to passive house house might stay cleaner, reduce humidity problems and suit the characteristics of a minisplit. Existing housing stock and most builder spec new houses are rarely good candidates for a minisplit heat pump system anywhere outside of Southern California.

Obviously sealing up the house is the preferred method to minimize operating costs but may not be reasonable in your case without a gut job remodel.

It is possible to get a good system installed well but you need to look for a company that does primarily Commercial with some Residential. You are a customer who knows the difference and may be willing to pay a premium for a complete system design. If it is not possible to keep the ductwork inside the conditioned envelope (which might require a significant remodel), consider rigid ducts in the crawlspace connected with short runs of flex for noise reduction. Your contract specifies duct testing to a standard using traditional sealing methods on all seams and gaps. You might follow up with an Aeroseal application to further reduce duct leakage.

Given the house is 1971 and undoubtedly somewhat leaky, you specify dual fuel with propane or natural gas to ensure comfort on those extremely cold wet days when any heat pump will labor a few days of the year. You make space inside the conditioned envelope for a variable capacity dual fuel heat pump from Trane, American Standard or perhaps Carrier. Multiple returns and Media filters easily accessible combine with UV to keep the air and the coil clean, often with no yearly cleaning requirement.

If necessary, add integrated forced air zoning which is quiet and efficient from the suggested vendors. Modulating dampers optimized by a variable capacity system without a bypass damper makes comfort, quiet and efficient possible.

In the end a well designed ducted heat pump system will check your boxes and provide comfort at a decent operating cost. The downside is you will pay for high quality but it is not unreasonable to expect a twenty year equipment lifespan and forty years on the ductwork.

Thanks for your response rj. We have less expensive electricity with hydro here which helps. Gas lines do not extend out where we live. Propane tank takes up a lot of room and feels like a bomb sitting in the yard. Yes you can have them in the ground but I don’t think there would be real savings with all that. I had a gas furnace before and then added a heat pump for air in my bigger home so I know how great that was. I recall getting the gas company to push out a gas line to our 400 home development decades ago. The gas company was not happy but I did all the leg work to get all the signatures for the state utility commission to push them to move the lines just a short distance to our big development. One thing that the top person mentioned to me is that gas may not be that cheap down the road either. With the way things are going right now on the world stage it is hard to say if gas will not become more expensive than it already is.

You use a lot of inside lingo that I tried to follow. The idea of using a main trunk to push the air to all parts of the house is what I have watched being done before. There is an art to getting the air to distribute well to all rooms is what I learned from watching my old house being ducted by someone who knew what he was doing. I think he put in round pieces tilted that would push some of the air flow out to the branches from the main trunk. It was a bigger house. This one is nearly 1/3 of that size at 1200sf one level ranch. So having a commercial type of design seems a bit over kill in my opinion in this situation. There is only one direction it can go and one area it can be installed in the garage. I also use Blueair 210 and 310 air cleaners which helps with air quality but not optimum and again I am not sure having to use these is energy efficient and the filters are pricey and I change out every six months. They take up floor space and noisy and my grandson likes to mess with them and not optimum at all. It does help with keeping the awful ductless heads a bit cleaner. I got them because the wildfires in CA and Oregon have been blowing our way the past two years and we even had to stay inside due to the worst air quality ratings we had for a whole week. Being able to shut down fresh air from outside is now a necessity. But I still want to have fresh air ability with a ducted heat pump system, that would be optimum. As far as a passive house I like the idea of putting the insulation on the outside covering all the studs etc but not sure this little house is worth investing so much money into all that yet. I am already putting on a new roof this year out of necessity. I really think there should be a sweet spot in the middle with all this. On one end are the cheapo crappy ductless heat pump units along, cadet wall heaters, baseboard heaters and radiant ceiling heat. On the other end high tech designed ducted heat pump system with commercial prices from the sounds of it. Most folks cannot afford a complete huge remodel. I just paid off my house and not willing to go into debt right now with so many uncertainties in the world right now. I will live with this crummy unit until that warranty expires and maybe I will move by then. But I wanted folks to know how bad the options are right now for the middle of the road applications and not to get fooled by all the marketing hype of ductless or radiant or wall heaters. One thing you can count on with the newest energy saving thing, chances are there is a real bad down side to them that these fly by night HVAC installers won’t reveal. They are on online trying to silence those who try to make it known. Right now so many trades are having glory days with the hot housing market, getting good help with remodeling is very problematic now. But these come in cycles and not a great time to see much reasonable pricing with any of it now. If possible, I would wait for the price gouging to recede in the building sector before getting a better ducted HVAC system. I like the idea of UV air cleaning and keeping cleaning costs down is a better approach and keeps the filters out of the landfills. I do think having zonal control of a ducted HVAC system would be amazing at affordable prices is probably not there. The sector is not concerned about what is best it is more concerned about how to make the most money with the least training and effort with manufacturers who also operate the same way. Reminds me of my dentist who retired. He teaches too and spends a lot of time volunteering to help those with dental issues who can’t afford the high costs today. He says it is impossible to talk to the younger dentists in doing the right thing and all. They don’t worry about your bite and they don’t get paid from insurance company to make bite adjustments so that is why it took me 60 years before I found him to fix my bite when I had countless dentists make it worse. These younger guys want the easy fast money and not willing to do the right thing. It is this mindset that is prevalent in so many sectors right now. If any of my dentists would have said you need these adjustments I would have paid out of pocket but they just don’t give a rip anymore nor do they have the skill to do it anymore. It is not surprising this same mindset lives in the HVAC sector as well. My grandfather was in the trades he would make great custom work and he didn’t charge a fortune for it either. But he lived within his means and that is a big problem with so many of these guys who don’t know how to manage a business let alone actually do the work well.

My main points were you pick a contractor who also does commercial. You then have someone who knows how to do it right. You don’t have a passive house and should not have to remodel the older house to get comfort. A high end residential system from Trane or Carrier will make you glad you spent the extra $5k. 1200 sqft likely does not need zoning but you have great options once you get the right system .

And Invisalign is a superb method to straighten your bite. The hmo dentist with $1000 worth of insurance to work worth won’t do it.

I’m with several other respondents – the quiet operation and superb efficiency of minisplits are superficially attractive BUT:

1) Most of my clientele aren’t real big on plastic wallwarts

2) All of our conventional systems get 5″ media filter bays – ain’t happening on Minis

3) Minis (of all descriptions) seem last robust and more finicky than conventional splits – less durable, need meticulous cleaning and prone to condensate fails.

4) We much prefer zoned variable capacity conventional systems – Trane XV20i is our standby / go-to

5) There are some limited use cases for ductless – single open rooms inaccessible to ductwork, such as sunrooms, bonus / FROG rooms, tiny houses. There is a 1 ton Mits single zone ductless that turns down 8:1 – 1500 – 12,000 Btuh that’s pretty much our goto for all such apps.

6) We also occasionally apply ducted minis (Mits SUZ / SEZ) to small detached homes and cottages whose compact attics are suitable for short low resistance duct systems and whose total load is <= 1.25 tons

Addressing resilience ……….. Suppose you live in a VERY cold climate where going w/o heat in even part of the house can be a big problem. Why not set up (for example) 2 multi-split systems with one ducted to heat/cool multiple ares in 1/2 (call it portion (A)) of the house and the other portion (B). But add to (A) and (B’s) ductwork some (normally closed-off) ducts that go to the opposite area ((A) to (B) and (B) to (A)). Then if one of the multi-splits fails (say it (A)) just open the (normally closed) (B) area duct run to provide heat/cooling to area (A). The 2 extra extra duct run shouldn’t add materially to the overall cost.

Wow – great conversation going on here and I am learning a bunch of things I wanted to look at with heat pumps. Thanks Allison for triggering (once again) a constructive discussion.

I am involved in a long-term (personal) study of district heating and cooling. ‘twould be great to hear what our participants think about Air Source Heat Pumps (what the heck, throw in other Geo-exchange as well) used as a source for warm and chilled water to hydronic distribution systems. My personal belief (until proven otherwise) is that with smaller and smaller loads, and efficient variable air and fluid flow distribution using ECM fan and pump motors – we can wring out every watt of energy in both heating/cooling production as well as distribution. Too much of a diversion for this particular post, but I welcome any reasoned opinion.

@Roy, I think you’re referring to air-to-water heat pumps (AKA reverse-cycle chillers)? If so, take a look at this discussion at Green Building Advisor.

As you alluded to, hydronic distribution doesn’t necessarily imply radiant. Some of the mfrs mentioned in the article and comments sell hydronic fans coils. Forced-air versus radiant distribution in super low-load homes is a whole other debate. Here’s an in-depth discussion on that topic.

Homeowner here. Another factor in duct vs ductless is maintenance costs for the non DIY homeowner. I’m lucky enough that one of my two indoor ductless units is mounted below a window so that I can easily reach and clean the filters. The other is an easy enough ladder reach job for now, but when I get older it may not be so easy. The cost issue comes from probable mold I noticed for the first time after several years so I now must pay a professional to clean the system. I’ll note that when first installed, the installer didn’t even mention any maintenance at all, but I had enough experience to know that dusty screens aren’t efficient. Looking for mold didn’t occur to me until I started researching ERVs last year, which led me to all sorts of building science issues to learn about. Now I can research more on the ducted options, seems like it might be worth doing if I can find a contractor to do it right.

Can you elaborate on why one-to-one configurations provide better zoning control and efficiency? My understanding was that a multi-split configuration could be more efficient because supplying multiple zones could give the outdoor unit more opportunity for continuous operation i.e. less cycling.

Adding to what Curt said… All else being equal, smaller capacity heat pumps and air conditioners will have higher efficiency ratings than the larger sizes within same model line. And that’s not just a mini-split thing.

Single head units have wider turndown ratio – the ability to reduce capacity. If for example a 3 ton outdoor unit supports four 3/4 ton heads, if just one of those heads calls it will get full flow even if it does not need full capacity because the 3 ton outdoor unit can go any lower than 3/4 ton in the case of a 4:1 turndown ratio, which is fairly typical.

OTOH if individual indoor heads are matched to individual outdoor units they can individually and collectively turn themselves much lower during mild weather.

Hope this helps

Dave’s right.

Some of that effect arises from manufacturers reducing SKUs (Stock Keeping Units…in other words, inventory) by marketing identical hardware as several different model combinations via software modifications.

For example, a given pair of indoor and outdoor minisplit heat pump and air handling units can be (and is) sold as 1/2 ton, 3/4 ton and 1 ton systems. Identical hardware is programmed via software / firmware to hit the three different capacity performance points. AHRI efficiency ratings for the lower capacity variants will be higher since a 1 ton system limited to 3/4 or 1/2 ton output will always be loafing along at slower more efficient fan, blower and compressor speeds. Manufacturers price the hobbled lowered capacity variants at slightly lower prices; willing to accept lower margins to hit more capacity points with less inventory.

@Curt, great description of how inverter driven compressors are marketed! My 1-ton Carrier 18VS has same compressor, coil, fan, cabinet & circuit board as the 2-ton model, just different firmware.

What I said is also true of single-stage equipment where each size has a different compressor: the smaller sizes will have higher efficiency ratings than larger sizes within same model line.

My experience with psc compressor models was the 3.5 ton splits that still had single row condensers had the highest seer. Normally they had ecm blowers, scroll unloaders and txvs.