What Is a Properly Sized Air Conditioner?

Last week at the 5th annual HVAC School Symposium in Florida, I gave a talk on undersized heating and cooling systems. You know, those systems that just can’t keep the house warm enough in winter or cool enough in summer. In this article, though, I’m going to pull out just one part of that talk: what it means to have a properly sized air conditioner. And it also applies to heat pumps in cooling mode, but I’ll mostly include both under the name of air conditioners.

Ready? Here we go.

The goal

When you’re following proper protocols for sizing an air conditioner, the idea is to have just the right amount of cooling capacity when the house is at the standard design conditions. I’ll get into the design conditions below, but first, the industry trade group Air Conditioning Contractors of America (ACCA) says very clearly what it means to have properly sized air conditioner.

That’s from the Manual S equipment selection protocol. You can find this statement in the overview section at the beginning of the book.

Now, there’s a whole lot going on in that sentence above, so let’s deconstruct it.

The sizing process

First, it’s critical to understand the two big quantities we’re dealing with here: cooling load and cooling capacity. The load tells you how much cooling a house needs. The capacity tells you how much cooling the equipment can do.

Second, with cooling, we can divide both load and capacity into two different types: sensible and latent. Sensible cooling is related to changing the temperature. Latent cooling is all about the heat carried by water vapor. It takes energy to remove both forms of heat, and that’s what an air conditioner does.

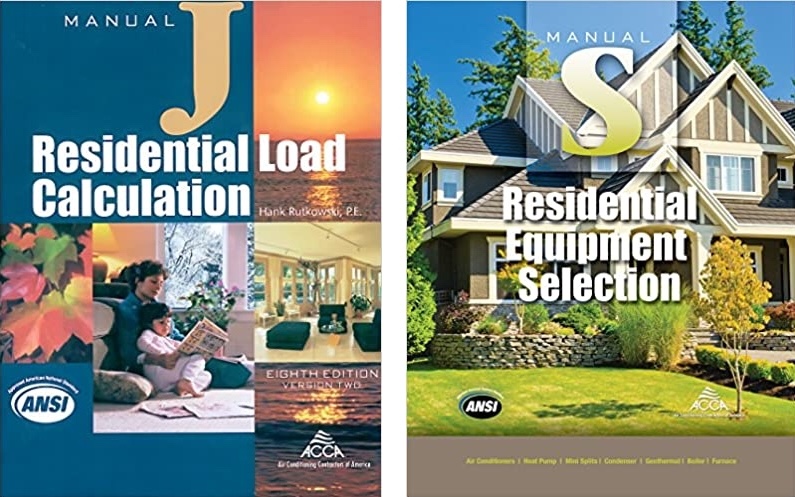

Third, ACCA has HVAC design protocols for all this. You start with a Manual J cooling load calculation. It gives you both the sensible and latent cooling loads for the house. Then you do the Manual S equipment selection to make sure the air conditioner can handle both the sensible and latent cooling loads. (If you’re looking for someone to do this for you, we can help.)

Design conditions

As I mentioned above, the HVAC designer will do the load calculation and sizing protocol for specific design conditions. The Manual J indoor conditions are the same everywhere: 70 °F in winter and 75 °F with 50 percent relative humidity in summer. The outdoor conditions depend on the location, and mostly it’s the 99 percent and 1 percent design conditions.

Basically, what the 99 percent and 1 percent refer to are the temperatures that a location is above 99 percent of the time for heating and 1 percent of the time for cooling. In other words, the temperature goes below the winter design temperature or above the summer design temperature only 88 hours per year. (There are 8,760 hours per year, so 1 percent of that is 87.6, or 88 hours rounded.)

Real conditions

But here’s the thing. What about all the other hours of the year? Our summer design temperature in Atlanta is 92 °F. So, we’re above that temperature 88 hours per year. We’re at or below it 8,672 hours per year. Obviously, we don’t need cooling all those other hours because a lot of them happen during winter.

Now, thinking about how the conditions change all the time, we can divide the loads into three types:

- Design load

- Extreme load

- Part load

We design for the first one, but the house doesn’t spend all that much time right at the design conditions. Occasionally we have more cooling load (extreme load). And then there’s the vast majority of the time when we need some cooling but not as much as we’ve designed for (part load).

So, what’s a person to do?

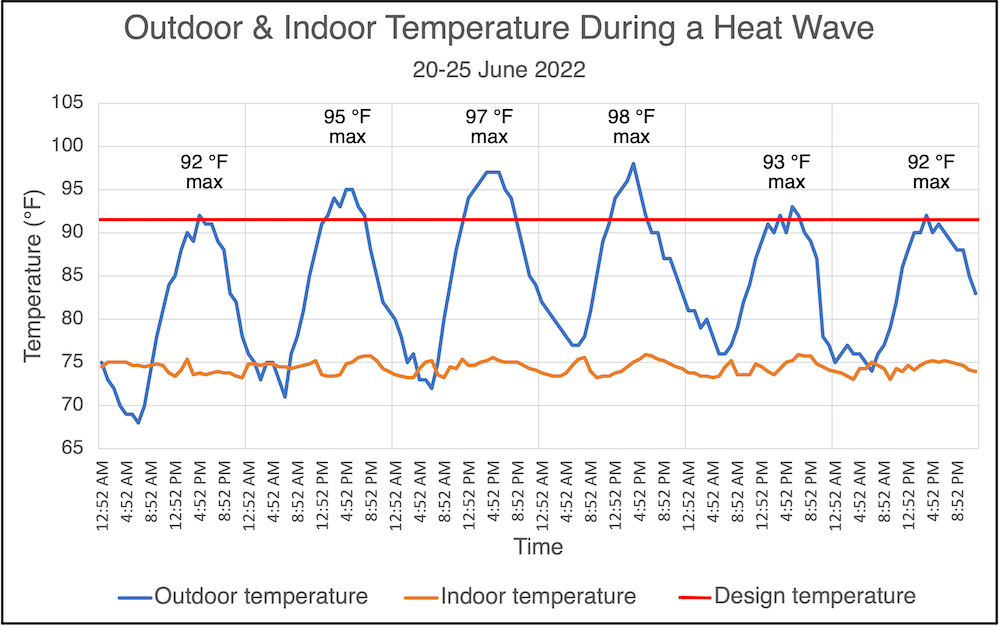

A look at design and extreme day performance

Here’s an example of a system I designed. It’s the heat pump serving most of the main floor in my house (details here). Since we’re focusing on air conditioning here, I’m going to ignore the heating side. You may recall that I wrote about how well my system did when we had a little heat wave in Atlanta a couple of years ago. Here’s the graph of indoor and outdoor temperatures over a six day period as the heat wave rolled through.

The first of those six days was a design day. Well, OK, it was really more like a design few hours. We hit our design temperature of 92 °F for an hour or so and were close for a couple more hours. And notice that the indoor temperature held at 74 °F through and after the peak.

I sized the system for the standard indoor design temperature of 75 °F but usually keep the thermostat set at 74 °F in summer. So if I designed for 75 °F and held 74 °F, that means my system is oversized, right? Based on that quote from Manual S above, I’d say yes, at least for the sensible cooling.

An undersized cooling system

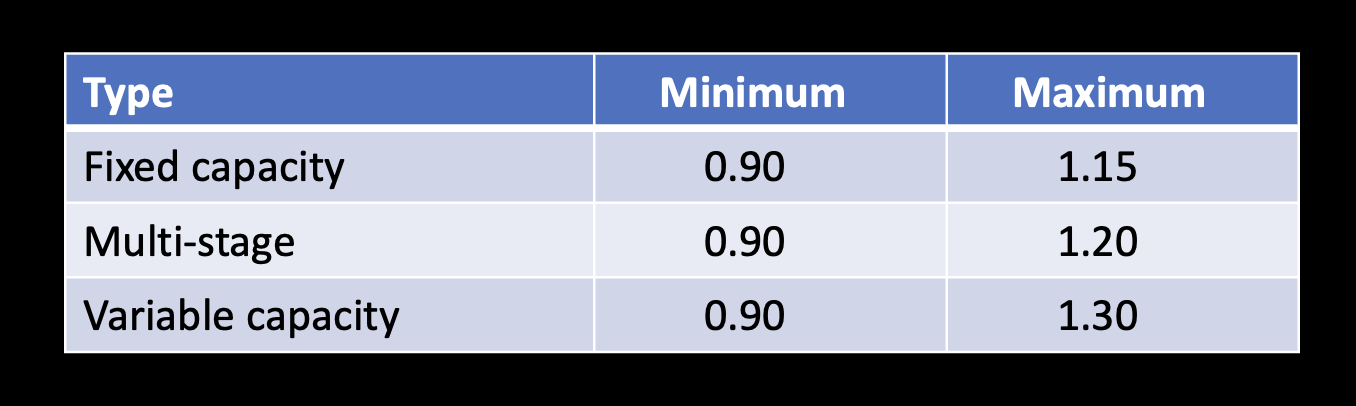

The table below shows the ACCA Manual S sizing limits for air conditioners and heat pumps in cooling mode. The numbers are the multipliers you use with the Manual J cooling load to find the range of acceptable installed total cooling capacity of the equipment. The three rows are for the different types of equipment. In my case, the system is a variable capacity heat pump.

I showed the loads, equipment model numbers, and capacities in my first article on this heat pump back in 2020. The cooling capacity is 88% (0.88) of the cooling load. Yes, I undersized it, relative to both the cooling load and the Manual S minimum. But the temperatures above show that it worked fine and even had a bit of excess sensible cooling capacity on that first design day. So I’d say I have a properly sized air conditioner.

What does this say about Manual J and manufacturer equipment data? Well, one or the other or both have some uncertainty. But let’s assume the equipment capacity is correct and that it matched the actual load on the design day. That means the Manual J cooling load (21,341 BTU/hr) is 13 percent higher than the actual load (18,862 BTU/hr).

What about humidity?

Now, the total cooling load and capacity numbers comprise two parts: the sensible and latent components. I showed above that the undersized system in my house handles the sensible load just fine. That’s because it kept 75 °F or better on that first design day. But what about the latent cooling? The indoor design condition for relative humidity is 50 percent.

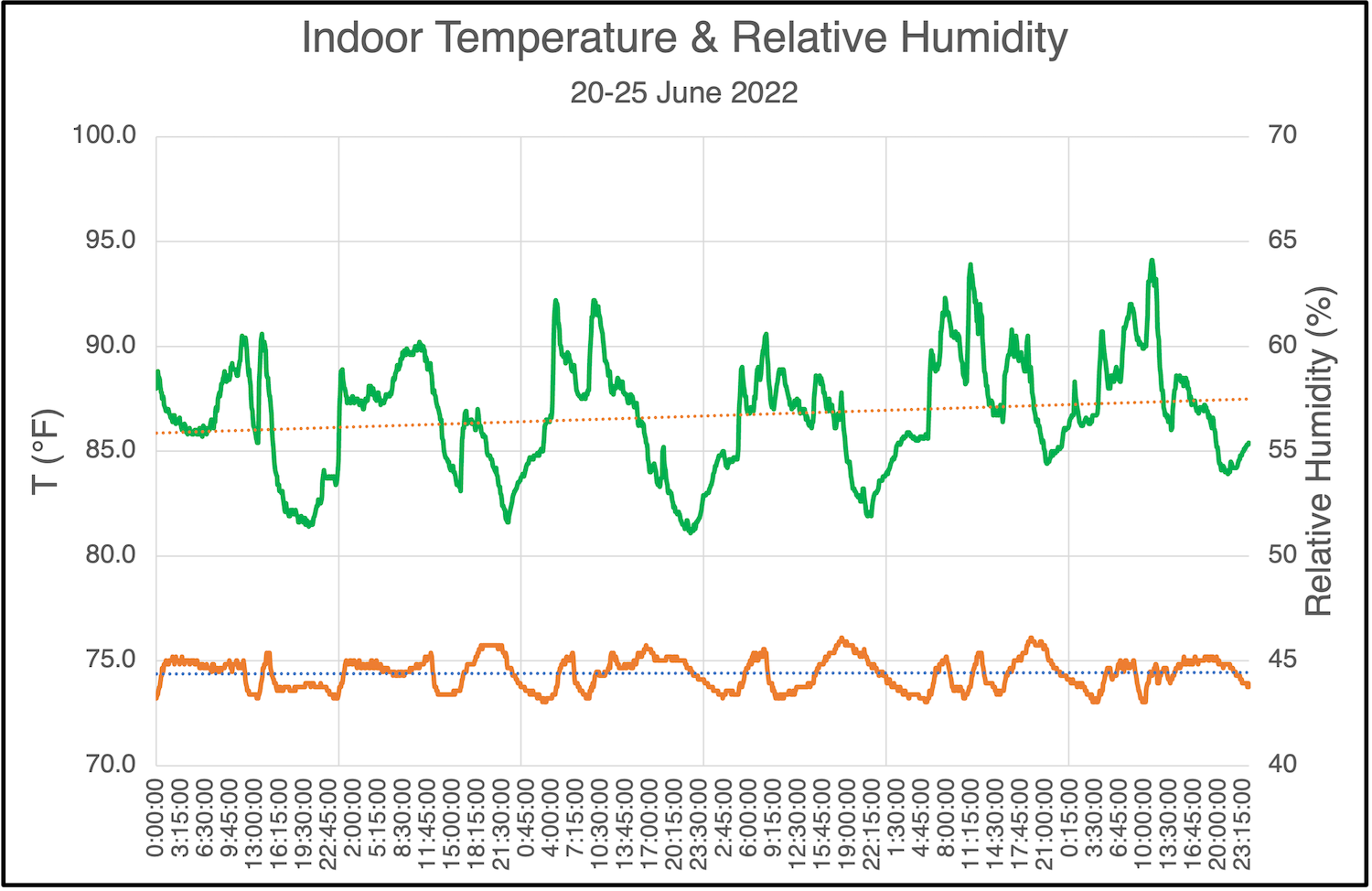

Here’s the graph of my humidity data for that six day heat wave.

No, it definitely didn’t hold at 50 percent, even on the initial design day. But remember that we want to keep relative humidity in a range of about 30 to 60 percent according to the Sterling chart. Also, modern high efficiency equipment has less latent cooling capacity. And here’s where, at least according to the manufacturer’s data for my Mitsubishi system, the system is greatly undersized.

The latent cooling load is 3,803 BTU/hr, and the latent cooling capacity is a mere 718 BTU/hr. I think the graph of humidity data above shows that Mitsubishi’s number is wrong. If I really had only 19 percent of the latent capacity I needed, the relative humidity percentage would have been much higher than the mid-to-upper 50s. I didn’t have any supplemental dehumidification going on so this system kept the humidity in check, so this system was removing moisture.

A few takeaways

The data I’ve shown here is for one heat pump from one manufacturer, so your mileage may vary with other equipment. That said, here are a few takeaways:

- A properly sized air conditioner is based on not having excess total cooling capacity.

- Manual J cooling loads and manufacturers’ equipment capacity data have some uncertainty. (As do all real-world numbers.)

- You probably don’t need to worry so much about ending up with undersized equipment that can’t handle the load.

I tried to be as accurate as possible in the load calculation for my house, adding no extra load as a “safety factor.” I undersized the system. And everything worked perfectly for cooling.

In my house, the cooling loads turned out to be about 1,300 square feet of conditioned floor area per ton of load. (See how this compares to others.) The equipment capacity was even better. And this is a 1961 house.

As I said in my talk at the HVAC School Symposium last week, I’m willing to risk my marriage for the good of the HVAC industry and homeowners. The good news is that my marriage is intact. My wife and I just celebrated our 15th anniversary this week.

More info: You can download my slides (pdf) by clicking a few words back. You can watch all the presentations from the HVAC Symposium by paying a mere $26 for a virtual ticket. Click that next link and scroll down for the list of speakers and their presentations.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can subscribe to Energy Vanguard’s weekly newsletter and follow him on LinkedIn.

Related Articles

Air Conditioner Sizing: Load Calculations vs Rules of Thumb

The 3 Types of Heating and Cooling Loads

5 Tips for Sizing an Air Conditioner

My Undersized Mini-Split Heat Pump in a Heat Wave

Comments are welcome and moderated. Your comment will appear below after approval.

This Post Has 5 Comments

Comments are closed.

Hydronic systems also benefit from being undersized. You want to always have water circulating through the heat sources (in-floor or panel-rads) to create a balanced energy exchange. Things are more comfortable when the system is just able to keep up (or being slightly undersized). If you keep the water temperature below 9F5 for heating or above 48F for cooling- you can achieve COP of your heat-pumps in the 4-5 range.

We followed your guidelines when we installed our new heat pump a year ago. It did have a bit of an issue with the humidity control at first, we set it for 50% humidity as the Lennox system has a dehumidification mode and allows you to setup the limits of over cooling to get the humidity where you want it. Then we replaced our 40 year old sliding glass door and dog door.

It keeps it within a couple percent of 50 without a problem now.

Your news letter comment struck home as well. Because of health issues we wanted better than a merv 13 filter which I had been running for at least a decade. During the design I requested a merv 16 filter which Lennox and Traine both offer. The engineer properly sized the new ducts and blower for this. It’s a 4” filter and box. The pressure drop across this is still very low and according to the particle counters I have in my house the air has never been cleaner. This combination along with a fresh air duct has made significant improvements it the air quality that’s important to me as I was born with chronic lung issues. As this design was right in the middle of the big Covid lock down we also had UV-C led systems put in the return and supply’s ( in metal work as the uv-c will degrade the standard piping). The difference in comfort, air cleanliness and energy usage couldn’t be more different. In a record setting Houston summer heat our utility bill never exceeded $125. It’s cool, comfortable, dry. The unexpected surprises were bread now takes weeks to mold rather than days and the house stays much cleaner. This with the rising cost of electricity has made it a very worthwhile investment. Thanks for all you do.

David

Would you have better humidity control with another brand of heat pumps such as the Carrier Greenspeed that claims to do better?

Allison, congratulations on your anniversary! There is no manual J or S for that!

The daily swings in indoor relative humidity from low 50%’s to low 60%’s were maybe a bit high. But that depends on the building envelope (including the basement underbelly), human activity, and outside conditions. I can see that your indoor de-humidification effect on average started between 8-10am. Was your system cooling that early in the day?

The problem of oversized heat pumps could be a non issue if thermostats had a turn on and turn off temperature settings. Usually they have a swing/differential/deadband/delta fixed setting of 0.5 to 1 degree which can be very energy inefficient with wear and tear of your heat pump. There are a few thermostats on the market that let you set the turn on temperature and the turn off temperature. For instance, I would prefer setting the AC to activate at 78 degrees, cool down the house to 72 degrees, then turn off and stay off until the temperature rises to 78 degrees again.

The inverter heat pump seems to avoid this problem by adjusting its speed to the needs of the house and runs much quieter as it idles and gradually speeds up or slows down.