What a Load Calculation Does NOT Tell You

Here’s a little conundrum for you. To get the right amount of heating and cooling to each room in your home, you need a load calculation. Rules of thumb don’t work. But if you do a load calculation, the result isn’t the size of air conditioner, heat pump, furnace, or boiler you need. It’s only the first step to sizing your system. Do you know why? Let’s take a look.

Heating with combustion

This one’s easy. Let’s say the heating load for your home (in those annoying imperial units) is 50,000 BTU per hour. That means you have to install a furnace or boiler that can provide 50 kBTU/hr of heat to the home under design conditions. If the unit you install is 80% efficient, you need to install one that has a capacity of 62.5 kBTU/hr or higher. If you install a 96% efficient system, you need one with a capacity of 52 kBTU/hr.

This brings up the issue of input versus output capacity. HVAC pros normally talk about combustion appliances in terms of input capacity. The load calculation tells you what your output capacity needs to be.

The nice thing about sizing combustion appliances is that the capacity generally doesn’t change with changing outdoor conditions. When you burn a therm of natural gas, a gallon of oil, or a pound of coal, the amount of heat given off depends only on the fuel, not what the outdoor temperature is.

But there’s a little caveat to that rule. The output capacity of a combustion appliance does depend on elevation. If you’re burning natural gas in Aspen, Colorado at 8,000 feet of elevation, your output capacity is lower because the density of air is lower. You also need to know the BTU content of the fuel you’re using. In some areas, it can be 10 or 20% off from what the appliance was designed for.

Heating with a heat pump

If you’re going to use a heat pump for heating, things are also pretty simple. Their performance rating to the standards of the Air Conditioning, Heating, and Refrigeration Institute (AHRI) yields the heating capacity at outdoor temperatures of 47° F and 17° F. The indoor temperature for the rating is 70° F. So you can use those capacities and manufacturer’s data to find a heat pump that provides enough heat for your home in your climate.

But of course, it’s not really just that simple. If you’re using a heat pump, there’s this thing called the balance point. As the outdoor temperature goes down, the heating capacity of an air-source heat pump goes down, too. At some point, the heating capacity is just equal to the heating load. That’s the balance point. Once the outdoor temperature goes below the balance point temperature, the heat pump can’t make as much heat as the house needs. Then you need some kind of supplemental heat.

If you’re using electric resistance heat (also known as strip heat), your heating efficiency drops significantly once the strips turn on. And because it’s 2-3 times more expensive than the main heat, you generally want to minimize the use of strip heat. To do that, you have to look at your cooling needs and make some compromises. Most homes don’t have an even balance between heating and cooling loads so you’re either going to be oversized on cooling or have to use extra supplemental heat.

Cooling with a heat pump or air conditioner

It’s the cooling side of things that motivated this article. Fifteen years ago, I didn’t understand this point and ended up undersizing some equipment. Here’s why. The Manual J cooling load you calculate is how much cooling the house needs. Let’s say you need a total of two tons of cooling (24,000 BTU/hr). You don’t just go to your HVAC supply house and say, “Give me your best two-ton air conditioner.”

First, the total load isn’t the most important number. The total load is made up of two separate loads: sensible (temperature) and latent (humidity). The air conditioner you buy has to meet both separately.

A common problem here is getting an air conditioner that meets the latent load but not the sensible. Why? Because if you go by the total load only, that’s where you may end up. Here are some numbers from a job we did:

Sensible load: 14,833 BTU/hr

Latent load: 3,799 BTU/hr

Total load: 18,632 BTU/hr

If you go down to the supply house and ask for a 1.5 ton air conditioner that has a total capacity of 18,632 BTU/hr, here’s what the specs might be:

Sensible load: 13,042 BTU/hr

Latent load: 5,590 BTU/hr

Total load: 18,632 BTU/hr

This air conditioner would be fine for the latent load but it would fall short in meeting the sensible load at design conditions. The air conditioner we specified had a total load of 23,600 BTU/hr. It meets both the latent and sensible loads for this home as well as accounting for the other adjustments an HVAC designer needs to make.

What adjustments would those be? Well, as it turns out, the conditions for testing and rating equipment aren’t the same as the design conditions. For air conditioners and heat pumps in cooling mode, the different design conditions can result in significant capacity differences.

AHRI tests the outdoor condensing unit at 95° F. In Phoenix, the outdoor design temperature is 108° F, so it’s going to have a lower cooling capacity. Here in Atlanta, we get a little extra cooling capacity because our outdoor design temperature is 92° F, which is 3° F below the test temperature.

Likewise, you have to adjust for the indoor conditions. For some reason, AHRI thinks people run their homes at 80° F and 51% relative humidity. It takes more sensible and latent capacity to hit the actual design conditions of 75° F and 50% RH. All this gets taken into account in ACCA’s Manual S equipment selection protocol.

What a Manual J load calculation doesn’t tell you

My point here is simple. A Manual J load calculation doesn’t tell you what size heating or cooling system you need. It tells you how much heating and cooling your system needs to provide. It’s easy to confuse the two when you’re just learning about this, but it’s important to distinguish between load — how much heating and cooling the house needs — and capacity — how much heating and cooling the equipment provides.

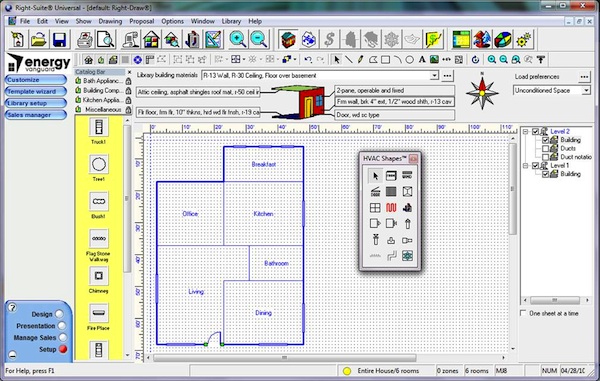

The load calculation is the first part of the HVAC design process. Then you go through the equipment selection part using the Manual S protocol from ACCA. That’s where you take into account the factors I mentioned above and more. The result is a heating and cooling system that’s likely to have a capacity higher than the loads. Taking the Manual J results as your equipment size is likely to lead to trouble.

Related Articles

3 Reasons Your 3 Ton Air Conditioner Isn’t Really 3 Tons

We Are the 99% — Design Temperatures & Oversized HVAC Systems

Finding Balance – Heat Pump Heating Load vs. Capacity

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 22 Comments

Comments are closed.

Great write-up, Allison. As

Great write-up, Allison. As almost always, the devil’s in the details. When we are interviewing an HVAC person for a new home, are there any simple question/response you might use to help screen out one contractor from another?

Great question, Charles. A

Great question, Charles. A few years ago I wrote up an article about 5 questions to ask an HVAC contractor when you’re replacing a system. It includes a link to ACCA’s homeowner page with lots of good advice as well as a download link for their score card.

Another great resource is ENERGY STAR’s Verified HVAC Installation (ESVI) program.

And this doesn’t even get

And this doesn’t even get into how many people live there or their lifestyle. If you do everything else correct (tight house, good air exchange, proper ventilation, etc.) shouldn’t you be able to balance things out with a proper commissioning of the system, adjusting the ECM motor speed, vanes in the supply lines, etc? If so, would it make more sense to commission a system AFTER a home is lived in for a while?

Bob, yes, you can overcome

Bob, yes, you can overcome some problems created by poor design with commissioning, but it depends on how bad the design was. Commissioning after the home is occupied for a while is a good idea but it should still be commissioned at the beginning, too.

@Charles, you could ask the

@Charles, you could ask the contractor for a copy of the Manual J & Manual S reports to back up the proposed system. Or better, hire a 3rd party HVAC designer like Energy Vanguard to specify your equipment. That way you can compare pricing on an apples-to-apples basis.

Nameplate size = marketing. Real systems should always be specified based on ‘expanded performance data’ at real design conditions.

BTW, I once tried to find out the genesis of the 80F indoor design assumption set forth in AHRI Standard 210/240. No one I asked knew for sure, but the most plausible reason is good ‘ole politics – let’s write the standard in such a way that a 2.7-ton A/C can be labeled as 3 tons!

I hadn’t heard that about the

I hadn’t heard that about the marketing influence on the 80° F dry bulb but it makes sense.

Not sure if it’s available in

Not sure if it’s available in residential sizes yet, but the VRF manufacturers (Mitsubishi is one) are building heat pumps that will provide full capacity down to 0F and below. We’ve installed several and they are operating surprisingly well here in the Chicago area.

Lee, yes, there a lot of

Lee, yes, there a lot of residential mini-splits that operate at full capacity down to single digits or even negative temperatures on the Fahrenheit scale.

I agree that you need to make

I agree that you need to make some adjustments to the AC ratings considering the 80 degree indoor design assumption, etc. So let’s assume you have made some adjustments and now you are looking at the AC ratings as presented,

Sensible load: 13,042 BTU/hr

Latent load: 5,590 BTU/hr

Total load: 18,632 BTU/hr

Let’s say your latent load calculation is spot on and it is the 3799 BTU/hr you stated. (I do not give the Manual J latent load numbers that much credibility, but that is another detailed post.) Your Sensible calculation is 14,833 for a total of 18,632.

Looking at your calculated S/L ratio, you have simply defined a home that is a bit drier than other homes. The above AC will probably work fine despite your belief that the unit is an example of “an air conditioner that meets the latent load but not the sensible.”

Actual Latent capacity (or “Latent tax”) of an AC is a function of the indoor air moisture content. It’s a moving target, not a locked quantity. In really humid indoor conditions, your sensible capacity could actually be cut in half! But in drier indoor conditions, the light latent load allows most of the cooling to be sensible. So you could think of it as Sensible capacity = Total capacity, unless you have some condensation occurring on the coil that robs the unit of sensible capacity. Light latent loads result in higher than rated sensible capacities.

The more interesting topic on which we could spend some time, is when sensible loads are very low in less-than-design conditions (think low AC run times), but latent loads are substantial and completely independent of the sensible loads. Again, that is another post.)

All good points, Dan. I

All good points, Dan. I expected someone to look at my example and bring up the issue of excess latent capacity being used for sensible cooling, so you get the prize for that! Yes, the AC I described in that example would probably work fine most of the time. I wouldn’t specify one that just met those loads, though, because of the times when it wouldn’t meet the sensible load. And with the climate changing the way it is, those times are increasing.

You wrote: “Looking at your calculated S/L ratio, you have simply defined a home that is a bit drier than other homes.” We didn’t define the home. This is how the loads came out. And it’s not really that dry. The SHR for the load is 0.8. We often see homes that are at 0.9, even in the humid southeastern US.

Your last point about the low sensible/high latent days happens more and more now because of more energy efficient homes. And it’s actually pretty simple to solve. You need supplemental dehumidification. We’re getting to the point where air conditioners don’t give you enough control over the latent loads.

Thanks for the great comment, Dan!

You and I agree 100%. So this

Allison, you and I agree 100%. So this might be a good time to ask your opinion (and other’s opinions) on the following thought. (I would love to stir up summer camp with this proposal/contention, but I would have to get invited first.)

If – homes have such low sensible loads that we cannot expect the AC to cover the latent loads

And if – we ventilate these energy efficient homes and add to our latent loads even more

And if – we agree that the ventilation designer is now responsible for adequate dehumidification

And if – we recognize the design latent load in a load calculation is simply a snapshot at design time and has little to do with total seasonal latent loads

And if – in appreciation of the above we treat supplemental dehumidification as a necessity

Then… how critical is the perfectly sized AC since it is now primarily the sensible heat solution? Is it time to bifurcate sensible and latent into two separate HVAC services?

Of course, there is still a proper size for the AC and a properly matched duct system for the new home and proper commissioning, but I propose the following:

A properly and perfectly sized AC is no longer the solution for proper dehumidification. Therefore, logic might allow that a one size bigger AC is no longer the culprit for moisture problems.

We hear it frequently. Got moisture problems? Your slacker dude must have messed up his heat gain calcs, did no calcs at all, chose the wrong AC, did not bring in enough fresh air and other set-in-stone claims. I have fun getting contractors thinking once I offer a more complete story on moisture loads.

@Dan, you are correct that

@Dan, you are correct that both the conditions in the home and the sensible split are moving targets. But it would be incorrect to assume 100% S/T (or even close) for sizing purposes. Let’s say your sensible load is 15k and the system has a total capacity of 17k at your design conditions (note that total capacity also depends on indoor conditions). If your latent load is, say, 4k @ design conditions, then the system can never remove enough moisture to match the sensible load. Not only are the conditions moving targets, but they’re interrelated. The Manual S procedure accounts for this.

@Dan, the idea that low load

@Dan, the idea that low load homes necessarily require supplemental ventilation is nonsense.

The key to humidity control is a tight envelope, an enthalpy hx to minimize the additional latent load, and equally important, avoid over-ventilation. I consider anything beyond that to be a design and/or installation flaw.

If you keep the moisture out to begin with, a properly sized AC can handle the load. Source control always trumps remediation. During those occasional periods when there’s no sensible load and outdoor dew point is above, say, 60F, you always have the option to shut down the ventilation system. But as long as RH stays under about 60%, the building and occupants should remain happy.

I should add… To the extent

I should add… To the extent that you’re talking about existing homes, I would agree that many homes are defective beyond reasonable repair (leaky envelope in particular) and thus may need supplemental dehumidification. But I would also argue that a lot of these homes don’t need to be ventilated in the first place, other than spot ventilation.

Also, controls can be added to to enhance an air conditioner’s latent capacity on demand.

My main point is to refute the premise (that I often hear) that low load homes necessarily need dehumidifiers. In my opinion, mechanical DH in most cases is a band-aid.

My dad used to say that band

My dad used to say that band-aids were for sissies. So I’m not one to promote any band-aids if they are not needed. But in this case, the band-aid solution might not even be enough if it is a low-cost $250 portable dehumidifier. If you have a gusher of a load, like ventilating in a humid climate, you will probably need to go to the ER for stitches for better control of the excessive flow. When the doctor/designer feels this is needed, that would be a whole house dehumidifier.

So it boils down to how much load. David, you are right, “If you keep the moisture out to begin with, a properly sized AC can handle the load”. If you could really do that.

But some type and amount of ventilation and infiltration is more realistic. Now do some dew point weather analysis and quantify the seasonal latent loads. Now compare that to the run times of your perfectly sized, sensible load activated AC in an energy efficient home. You’ll be needing several Steri-Strips on that gusher, son.

With the non-sense comment,

With the non-sense comment, it seems the point that Dan was making wasn’t grasped. I believe what he is saying is that in a home below BAS require mechanical ventilation so with passive (or more passive/Energy Star) houses you are still required to hit 70% BAS, so you can’t avoid the mechanical ventilation; therefore, you can’t avoid bringing in the moisture from outside even if you can avoid bringing in the sensible heat. Furthermore, if your house is cooling and shaded the moisture content from the warmer air outside produces a higher RH in your shaded, naturally cool house.

Dan is right on point, the

Dan is right on point, the evaporator coil will actually shift from greater latent removal to greater sensible removal depending on the humidity of the conditioned space.

The main problem I currently

The main problem I currently experience is that the latent load in a climate like Houston is incredibly dependent on infiltration and ventilation. Using standard stick framing and relying on the drywall for a lot of air sealing, we cannot do a blower door test prior to sizing and installing the HVAC system, so the Manual J has to be based on either the Tight, Semi-Tight values or estimated CFM50 numbers of what the blower door results will hopefully be. I have tried a bunch of different possible scenarios (Tight vs Semi-tight vs 3ACH50 vs 5ACH50 (yup that’s still the worst case scenario in Houston) and the latent load varies from 3,000 to 8,000 BTUs for a 3300 sf house here in Houston just by playing with those infiltration rates.

In addition based on all of Allison’s articles I read about ACHnat and how the blower door only tells us about the size of the holes but not about the real-life daily pressure differentials (due to outside conditions like wind but also variations caused by hood ranges, bath exhaust fans, etc.), it appears that modeling the infiltration rate correctly in Manual J is close to impossible even if we had the possibility to base it on blower door results.

Therefore, when choosing equipment without a blower door test how do you guys deal with these latent load swings? Just select “Tight” and go with whatever the outcome is? (this particular project is a stick frame, ZIP home with BIBS insulation + plugging all the “big holes” and the top plates sealed to drywall)

Thanks for the insight

Thanks for the insight

After reading a lot of the

After reading a lot of the debate on proper sizing I haven’t ever seen any mention of the factor additional heat from electrical equipment (tvs, lights, etc.) being taken into account. Currently I’m dealing with the issue of freezing in the bedrooms but noticeably hotter in the livingroom. I wonder if these additional heat sources should not affect the cooling like they do. Any suggestions?

Jessica, you’re right. I

Jessica, you’re right. I just looked back at the most recent article I wrote about load calculations (How to Read Manual J Load Calculation Reports) and saw that I didn’t mention appliance loads there at all. To address your concern, though, yes, we do factor in the internal loads from lights and appliances. ACCA’s Manual J uses 1,200 BTU/hour as the default load for kitchens, 500 BTU/hr for laundry rooms, and 900 BTU/hr for living rooms. When we’re doing load calculations here at Energy Vanguard, we’ll tweak things when necessary. On Passive House projects, for example, we’ll go a little lower because they usually use more efficient appliances. And on the other side, I added some extra load to a laundry room recently because the plans showed a freezer in addition to the washer and dryer.

In your case, I don’t know what is the reason behind the nonuniform cooling in your house. It could be failing to factor in appliance loads, as you wonder, or it could be a duct problem. Was the system designed using the ACCA protocols? My guess is they didn’t, instead using the old rules of thumb that result in the kind of problems you describe.

Hi Jessica, long time no hear

Hi Jessica, long time no hear! I would be surprised if internal loads are causing your living room problem. As Allison said, today’s electronics (especially TV’s) produce much less heat than when the MJ internal loads.

What you describe sounds like an air balance problem. As you know, very few residential contractors do air balancing. You can adjust your bedroom diffusers to push more air to the living room, but you need to monitor the impact on the static pressure at the air handler to make sure you have adequate airflow across the coil (I know you have the tools and know-how to do this, but feel free to contact off-line if you want to discuss). Depending on duct layout, it may be necessary to add another supply the the living room, e.g., if living room supply duct is undersized or compromised. To the extent that your living room windows have direct sun exposure, be sure to use window coverings to block direct sun into the room.

(As an aside… Jessica trained me on REM/Rate back in 2006. She was our lead HERS Rater/QA designee.)