Why Are Heat Pumps So Dumb About Frost?

Heat pumps can get frosty when they run in heating mode. It doesn’t happen all that often, but it’s a fact of life when you’re trying to extract heat from cold, outdoor air. Sometimes the outdoor coil goes below the dew point, and frost results. There’s nothing wrong with that. Every heat pump comes with a built-in defrost system so it will keep running smoothly. Unfortunately, the defrost system in most heat pumps is just plain dumb. And fortunately, I have a smart friend named Mike MacFarland who’s come up with a way to overcome that liability.

What’s so dumb about heat pump defrost systems?

Let me ask you a question. If you were to design a defrost system with sensors and controls to determine when the defrost cycle ran, how would you design it? Would your heat pump defrost system activate when it detects there’s a small chance of frost forming on the coil? Or would it instead turn on the defrost cycle when it actually measures that frost has formed?

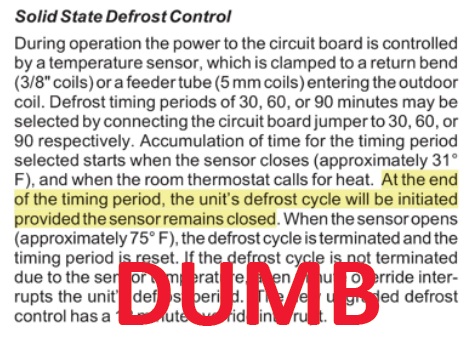

As it turns out, the defrost system on most heat pumps does the former. The image below shows the text from the product literature for a common heat pump, and it explains what happens. The outdoor coil has a temperature sensor mounted on it. When the temperature it reads hits 31° F, it starts a timer, which on this piece of equipment will be set to 30, 60, or 90 minutes. If the temperature is still 31° F or below at the end of the timer cycle, the defrost cycle begins.

Maybe there’s frost. Maybe not. This system is based only on temperature and time. Apparently, heat pump manufacturers forgot that frost forming on a surface also depends on the amount of moisture in the air and this thing called the dew point.

OK. We both know they didn’t forget that. They made a choice to reduce their manufacturing cost at the expense of the homeowner’s comfort, peace of mind, and energy costs. And the equipment may not last as long either. But hey, who’s gonna notice?

What’s wrong with a dumb defrost system?

When a heat pump goes into the defrost mode, the reversing valve activates and runs the refrigerant backwards. Instead of extracting heat from the outdoor air and dumping it into the house, it extracts heat from the house and dumps it into the cold outdoor air. That heats up the outdoor coil and melts any frost that might be on it.

What do you think happens to the indoors when the heat pump is in defrost mode? You guessed it. The heat pump, absent the effects of supplemental heat, would be cooling the house. In winter. On a very cold night.

What do you think happens to the indoors when the heat pump is in defrost mode? You guessed it. The heat pump, absent the effects of supplemental heat, would be cooling the house. In winter. On a very cold night.

For most homes with heat pumps, that’s when the supplemental heat kicks in. You can’t have the system blowing cold air inside when people want heat, right? That just wouldn’t do. So, the supplemental heat fires up, and for most people, that means electric resistance (a.k.a. strip) heat. It’s 100% efficient…but that’s only about a third as efficient as your heat pump.

If you have a dual fuel system, the back up heat is usually a furnace. There will often be a delay before it comes on, though, so you might get a blast of cold air from your heat pump running in air conditioning mode before the furnace gets going. (Did that just explain that mystery for you?)

So, either you’ll be paying for expensive strip heat for a while or you’ll get a chill in the house. Neither is ideal. If there’s no actual frost on the outdoor unit, that’s just a slap in the face.

Oh, and that defrost cycle puts a lot of extra wear and tear on the equipment. As my friend Mike MacFarland explained it, going into defrost cycle is like driving down the freeway at full speed and every once in a while suddenly having to drop it into reverse.

Another problem is noise. When the heat pump changes the direction of refrigerant flow, it’s something you’ll notice if you happen to be in earshot of the outdoor unit. If you don’t know what’s going on, you might think something is wrong and put in a service call.

Mike MacFarland makes heat pumps intelligent!

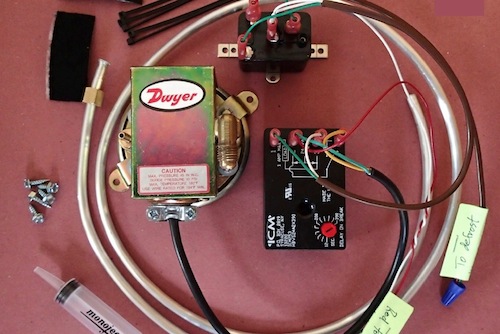

So how do you design a defrost system that operates only when the outdoor unit actually has frost on it? Well, you don’t have to because Mike MacFarland, owner of Energy Docs in Redding, California, has already done it. He calls it the Energy Docs Intelligent Defrost System (EDIDS). His system uses the temperature sensor and timer but adds another key component: a pressure sensor.

In the photo of his kit below, the pressure sensor is the part with Dwyer on the label. That gets mounted under the service panel and measures the pressure difference between the inside and outside of the unit. With a clean coil that has no frost on it, that pressure difference won’t be much. As the coil loads up with frost, the pressure difference increases.

MacFarland has configured the kit so that the defrost cycle doesn’t start until the pressure difference climbs to about 0.35 inches of water column. With frost on the unit creating that much pressure drop, he’s measured a performance drop of about 24%. He’s OK taking that much of a hit from frost, because sometimes the ambient conditions change, and there’s no need to go into defrost mode. If not, the heat pump switches into reverse, melts the frost, and then goes back into heating mode.

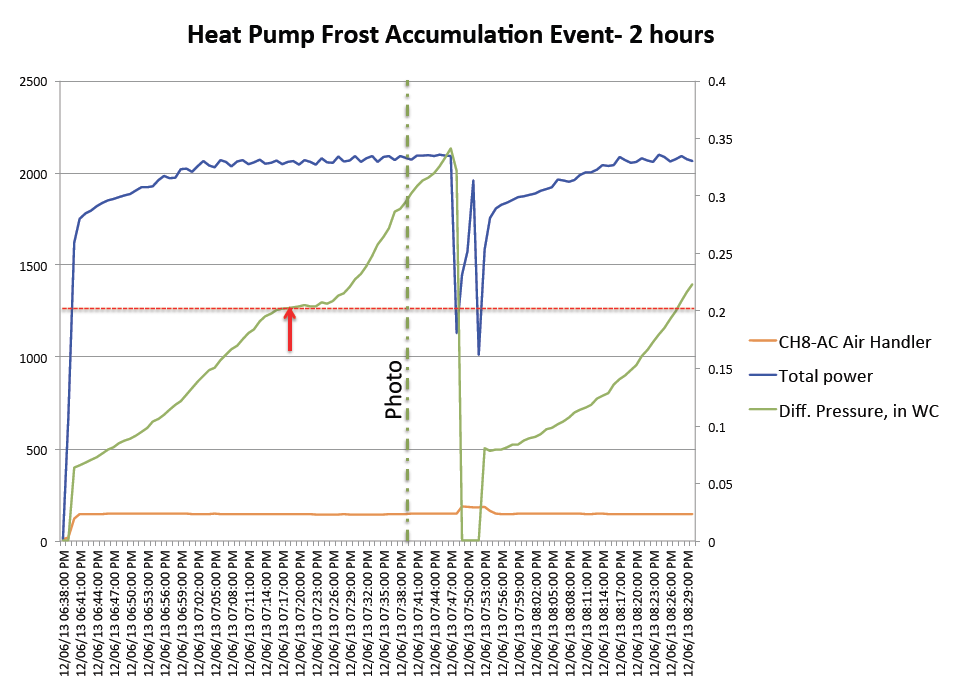

A typical heat pump will go into defrost every 30, 60, or 90 minutes if the outdoor coil temperature stays below setpoint (~31° F). MacFarland’s system goes into defrost mode only when necessary. The graph below shows how the pressure builds during a long runtime, eventually kicking off the defrost cycle when it hits 0.35 i.w.c.

The results are in

MacFarland recently put his heat pump with the Energy Docs Intelligent Defrost System to the test, logging the data of its performance over a 62 day period in December 2013 and January 2014. The graph above is one small part of what he’s learned. Here’s what’s even better:

| Actual # of defrost cycles | 27 |

| # of defrost cycles at 2 hr interval | 111 |

| # of defrost cycles at 1/2 hr interval | 443 |

| Energy saved per heating season compared to 2 hr interval | ~150 kWh |

| Energy saved per heating season compared to 1/2 hr interval | ~400 kWh |

As you can see, the EDIDS cut the number of defrost cycles way down. He got rid of 76% of the unnecessary defrost cycles that would have occurred without the EDIDS and with the timer set to the 2 hour interval and eliminated 94% of the unnecessary defrost cycles with the timer set to 1/2 hour intervals.

The energy savings aren’t huge, but as he told me recently, his primary reasons for doing this were comfort, noise, and wear-and-tear on the equipment. Also, he doesn’t have supplemental heat set up on his heat pump. If you factor in the energy used by strip heat on a typical heat pump, the savings are greater than shown above.

The takeaway here is that most heat pumps implement defrost in a really dumb way. A simple pressure sensor can make it smarter, though.

2024 Update: MacFarland is no longer making and selling the device described above.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can follow Allison on LinkedIn and subscribe to Energy Vanguard’s weekly newsletter and YouTube channel.

Related Articles

Why Does My Heat Pump Frost Over?

How the Heck Does a Heat Pump Get Heat from Cold?!

The Shocking Truth About Heat Pumps

NOTE: Comments are closed.

This Post Has 50 Comments

Comments are closed.

Kudos to Mike MacFarland’s

Kudos to Mike MacFarland’s for his elegant solution!

As everyone knows, household refrigerators of bygone days also used a simple timer to activate electric heat and defrost the freezer’s evaporator coils. Of course the system knew nothing about dew point, but mindlessly soldiered on, like clockwork, if you will ??. And many also had constant strip heat around door seals to mitigate condensation.

We’ve come a long way in regard to making controls smarter and I’m surprised to learn many heat pumps retain such primitive systems to initiate defrost, whether it’s needed or not.

Another thought Mike likely considered and discarded. A sufficiently sensitive current sensor on the outside fan should be able to detect reduced motor current as the outside coils ice up and the fan motor moves less air. The system could also be used to trigger an inside alert, in the event the outside coils became blocked by material other than ice.

Just thinking out loud (always risky).

Another excellent article Allison, and I’m heading over to Energy Docs to give Mike a “like”!

Would be nice to to know the

Would be nice to to know the cost of the product plus typical install. Woody

Home brew demand defrost

Home brew demand defrost system, love it !!

Does it replace the OEM defrost board or is it an add on kit? How does it handle homeowner neglect of not cleaning the coil enough so static is always over.35? Is the pressure setting adjustable for single/double row/microchannel coils?

BTW most Dual Fuel systems WILL allow the furnace to run while the heat pump is in defrost mode. No danger of kicking the high pressure switch as there would be in heating mode. There is however a delay for whatever the furnace startup time is…

Steve W.:

Steve W.: Thanks! Yeah, I remember the days of the old refrigerators with all their built-in heaters to combat frost and condensation. The one I bought in 1988 was using 150 kWh per month in the year before I replaced it in 2004.

Woody M.: Mike’s doing this on a very small scale right now and doesn’t even have this kit listed for sale on his website. I’m hoping that he’ll come in here and comment with the answers to your questions.

Bob: It’s an add-on kit. Thanks for the info about dual fuel systems. I’ve revised that part of the article.

Steve, propeller fans draw

Steve, propeller fans draw INCREASED current with increased static pressures. Control could be set-up to ‘trip’ once amp rating exceeded a certain value, but would need a bypass for startup, and be adjustable for each motor. Too complicated on the install side.

Thanks Allison.

Thanks Allison.

@Steve- Thanks for the FB like and comments. Yes, the outdoor fan current was one thought for control along the way. The units we typically install these on have ECM fan motors on the outdoor units, and it’s interesting to watch the current as the coil loads. The smooth data points become saw-toothed as loading occurs, oscillating 5-10Watts as the motor responds to being slowed down through added resistance.

@Woody- The assembled and bench-tested kit is about 125 bucks and it takes about 10 minutes to fully install. So far we’ve only sold a small amount to Home Performance contractors looking to maximize their equipment performance.

@Bob- It’s an add on kit that works in conjunction with the existing time and temperature control, adding the pressure as another condition that must be met prior to defrost initiation. Regarding the existing fouling that may cause the pressure to be high, the homeowner shouldn’t install this if they are unable to keep their coil relatively clean. It is adjustable from about 0.15″ to 0.50″ of water column using a set screw at the top. Our “clean coil” resistance is usually about 0.05″ or so on these coils, and like you mentioned, others may be quite different. I like around 0.22 to 0.25″ for the trigger point, which initiates the 30 minute timer (making it defrost around 0.35″ or so after the added loading). It can be seen in the graph above the pressure sensor closed at the red arrow location just slightly over 0.20″, then the frost loading continued (green line) up to the defrost time close to 0.35″

I haven’t studied it, but I think a PSC fan would move less air and the current would decrease as the coil loads. These ECM’s seem to be programmed to move a set amount of air and appear to use slightly more current in response to loading.

Thanks for the advice on the full defrost control replacement. I hadn’t thought of that before.

Can you identify the Heat

Can you identify the Heat Pump brands that have demand defrost?

Mike wrote: “These ECM’s

Mike wrote: “These ECM’s seem to be programmed to move a set amount of air and appear to use slightly more current in response to loading.”

Exactly. The ECM fans used in condensers have a ‘constant torque’ control that attempts to maintain torque, within limits. This creates a stepping function, which causes the power oscillation you noticed.

BTW, in the above graph, when the EDIDS tripped the 30-minute timer at 0.2 IWC, I noticed the pressure differential went flat for a few minutes. Do you know what caused this?

@Allison, I think you have the 30-min and 2-hr results reversed in the results table.

Mike M.:

Mike M.: You’re welcome, and thank you! Keep up the great work.

R. Brown: I can’t answer your question, but maybe some of the contractors will jump in and tell us.

David B.: Yes, I did. It’s fixed now. Thanks for letting me know.

@David- I don’t know what

@David- I don’t know what caused the flattening of the pressure differential curve that you observed in the data. I’m working on something now that I believe will help that effect happen, but it will trigger sooner, and not likely be quite as dramatic as that.

This was during a period of heavy, dry snowfall, where the outer louvered shell was what was clogging and not nearly as much the inner, finned heat exchanger. Maybe a portion of the outer snow layer pulled free temporarily at that pressure, creating a pocket of heat flow temporarily?

Few customers will pay to

Few customers will pay to have existing equipment modified for additional efficiency. I don’t see the kit having a reasonable payback time to a typical consumer. $120 buys about 1,200KWh of power at 10 cents per KWH. Installation costs of $80 would make total cost $200, or 2,000KWH of power. The kit would have the remaining life of the heat pump to save the additional energy. The customer that understands enough to know what demand defrost is and is willing to pay $200 to have it installed will have it OEM on their replacement system.

If the kit could serve as a replacement for a costly OEM defrost board, the customer is paying the labor and trip charge anyway. It’s just the price difference between your kit and the OEM board that has to be recovered for a decent payback time. Your kit might even be CHEAPER than some OEM boards, that is where your sales volume will come from.

Customers resist paying $800 to have heat pump installed vs. strip heat, 75% of all electric homes in our area use strip heat!!! R22 Dry unit AC Condenser swaps while leaving the 1986 air handler are the norm.

My mother’s HVAC had an issue

My mother’s HVAC had an issue just a few weeks ago(when it was SOOO cold in South GA). Our A/C contractor explained the exact defrost issues in the Post. I wondered why it was “Going to the defrost cycle…” when there was NO frost? It made me say, Hummm? I knew there had to be a better way. Thanks for the advice and direction of thought. I have been converting Old Methods and Old Thinkers for a few years now to the smarter methods of the whole house approach and other thoughts of building science applications in residential structures. In some cases, I’ve had to inform the local inspectors that Ga is no longer on 2006 code(Jan 14, True story) Its nice to see and have some support. Thanks!

FYI, Differential pressure

FYI, Differential pressure switches for defrost initiation are nothing new, there were similar systems on heat pumps back in the late 70’s and early ’80’s. The industry moved to electromechanical timers and then circuit boards…..As far as reliability goes I would prefer the more modern systems over the pressure switches and relays. To each his own.

I DO agree that the defrost logic (or lack thereof) could stand to be improved upon, just not sure a differential pressure switch is the way to go.

Lennox actually used a device

Lennox actually used a device similar to this on some old heat pumps, I guess it’s cheaper to manufacture without it.

Sounds great and all, but

Sounds great and all, but what about a clogged coil, wouldn’t that deceive it into thinking there is always frost?

I was just pondering this

I was just pondering this approach as I listen to my heat pump defrost without any sign of frost on it. It seems to me that a very simple setup using a pressure switch could be done with existing hardware by having the pressure switch “alter” the coil temp sensor input to fake a higher non-freezing temp when air flow is good. The temp sensor is switched into the circuit normally only when air flow is below the threshold of the pressure switch.

@Joe, how does your proposal

@Joe, how does your proposal differs from MacFarland’s solution?

One thing that hasn’t been mentioned is that all heat pump defrost controllers are not alike. The more recent designs are much smarter. For example, my Lennox 14HPX (2009 vintage) has a “demand defrost control” that looks at two temperatures (ambient and refrigerant). Although it will initiate based on ambient temperature and time, the cycle will terminate in less than 20 seconds if there’s no frost (just long enough to get a good read on the liquid line after the cycle reverses).

A pressure-based control will prevent unnecessary cycles from initiating, but may not be worth the cost on systems with more sophisticated defrost controls.

@David, well I’m not sure how

@David, well I’m not sure how it differs since we don’t have any technical details of how the MacFarland solution works. I’m still working on the design, but basically the coil temp sensor (switch types only) is taken out of the circuit by a relay. The relay is latched by the pressure switch tripping, which puts the temp sensor back in the circuit. The latching setup is needed because when the HP stops the fan to do defrost the pressure switch will un-trip, but you don’t want the temp sensor to drop out of the circuit again until the defrost temp is reached. Obviously, this needs a lot of testing before it can be safely used. It would only work for coil temp sensors that are switches. I’ll be trying to test this on a Goodman heat pump.

I set up a similar system on

I set up a similar system on my 3 ton Lennox 21 years ago to lock out the defrost control until there was sufficient DP across the coil and measured with an hour meter that 19 out of 20 defrost cycles were unnecessary, especially during cold dry weather. The above figures underestimate the real savings, which are closer to 1500 KWHRs per season. No to mention the increased comfort and reduced shock to the system of reversing the cycle. It allowed my heat pump to last over 21 years without any service calls. BTW, coupling a heat pump to an oil furnace after the heat pump is a really bad idea due to mutually exclusive operation and caused my previous heat pump to fail due to excessive pressure build up from residual heat in the furnace.

Yep… Dumb… <

Yep… Dumb…

I’m sitting here, its 25 degrees outside (-5 degree dew point) and needless to say my heat pump is defrosting every timing cycle without any signs of frost… DUMB…

I’ve sent an email to Mike MacFarland at Energy Doc – what’s the price and how do I order?

Maybe someone can explain

Maybe someone can explain this to me: I installed a 1 ton Mitsubishi “Mr. Slim” mini-split heat pump on my house in 1996. When it went into a defrost cycle, the indoor air flow stopped (otherwise it always ran), the outdoor fan stopped and the compressor ran for a few minutes and then stopped. It sat there for a few more minutes (with the coil dripping) and then the reversing valved changed over (with a big whoosh!!), the indoor air flow started up again with nice warm air from the start. There were no heating coils in the unit at all and it worked fine when I sold the home last year. How does the outdoor coil defrost? The only thing I can think of is the “heat of compression” generated by the compressor squeezing the refrigerant – why don’t American units work like this – it was a wonderful unit!

@Bill, I did some research on

@Bill, I did some research on MITSUBISHI’s Heat Pumps with their H2i technology and found a Brochure (MXZH2iRO) which indicates the outdoor unit comes with a, “Factory installed base heater” (which) “Prevents ice buildup in extreme environments” (only) “Active during defrost cycle”. So, these units do use electric heat to defrost. Now, I’m guessing, since the unit isn’t heating the whole house and since the compressor would be under low load during defrost that the electrical requirements does not exceed that of a typical heat pump (i.e. no additional requirement for a 15 Kw heater).

The Brochure also states

— 19.1 – 17.0 SEER, 11.3 – 9.8 HSPF, INVERTER-driven compressor.

— Quiet outdoor unit operation as low as 49 dB(A).

— Hyper-heating performance down to minus 13 degrees F outdoor ambient.

— 100% heating capacity at 5 degrees F outdoor ambient.

Now, I’m not gullible enough to believe all that I read – But, those are some impressive statements. Note: I also read that EPA penalized MITSUBISHI’s declared COP values by 1 to 11%, based on EPA’s test data for various outdoor environments (still impressive and deserves further investigation).

@Bill, you raise a good point

@Bill, you raise a good point. There’s not much information out there about defrost cycle operational details for mini-splits.

The reason your indoor fan “stopped” is because there’s no internal supplemental heat source to warm the air. Since the heat pump is operating in A/C mode during defrost, the indoor coil gets rather cold, I’m not certain, but I think your indoor fan continues to run at a low speed (perhaps lower than you can achieve with the blower controls), in order to transfer some heat to the refrigerant. I don’t think the heat of compression is enough.

So why don’t conventional heat pumps work like this? For one thing, most don’t have variable speed air handlers. But more importantly, it’s because they don’t need to, precisely because they have a built-in reheat coil. Keep in mind that the efficiency rating test procedure doesn’t differentiate among smarter defrost control strategies, so there’s no incentive to innovate here.

Since I haven’t tested a mini-split defrost system, I wonder if there’s a trade-off in defrost performance, or if the average defrost cycle is longer to make up for a lower heat transfer rate.

BTW, killing the outdoor fan in defrost mode is standard procedure with all heat pumps. The goal is to transfer heat from the house to the outdoor coil, not to reject it into the air. But one thing that puzzles me is why your compressor turns off for “a few minutes” before resuming the heat cycle. I don’t understand how this could add to defrost performance.

Oops… That is a pan heater

Oops… That is a pan heater to keep the drain from freezing. Must rely on crankcase heaters for a heat source.

@Gerard, as you noted, that

@Gerard, as you noted, that pan heater is just to prevent ice buildup in the drain pan at bottom of unit.

Crankcase heaters are standard (or an option) in all heat pumps, but that has nothing to do with defrost operation. When the system is off, refrigerant will naturally migrate to the coldest part of the system. The can cause problems if the refrigerant mixes with the oil in the bottom of the crankcase. The heater will switch on at about 50F to prevent this from happening. That’s why it’s important to wait a few hours before starting a heat pump in cold weather after the breaker has been off for any length of time. Although I don’t know the specs for Mitsubishi’s crankcase heaters, wattage is relatively small. My Lennox 3-ton heater is 35W.

BTW, the reason the new MXZ-C series has such impressive heat output (as is the case with most inverter heat pumps, including models from US mfrs) is because the compressor (and coil) is larger than the nameplate rating would suggest. Cooling output is limited to nameplate in order to to get the AHRI rating (that’s strictly a marketing consideration), but in heating mode, the compressor ramps up to maintain output at lower temps. The hi-heat models have larger compressors than standard models.

In areas without significant sensible (or latent) cooling loads, you can accomplish the same thing for less $ by installing a larger non-inverter heat pump, and not give up anything in efficiency.

The MXZ-C series is is the first multi-split hi-heat model from Mitsubishi, but you can get a much higher efficiency rating by going with a small single zone mini.

my carrier 4ton all electric

my carrier 4ton all electric hp/airhandler system produces a strong stale dry ice type odor upon defrost cycle. i think it’s from the a-frame evap coil condensate that blows off the aluminum fins into my rooms when system at attic-end is acting like ac. i had a sr. tech here and he never had this issue w/customers b4. really? it’s definitely NOT dirty sock syndrome. any diagnoses and solution for stale ice, freezer burn type odors thru vents when hp defrosts???

@Wendy, unlikely enough

@Wendy, unlikely enough moisture in winter to form condensate during defrost cycles. In any case, the evap coil is on upstream (return) end of all Carrier air handlers (the opposite of a furnace), so if airflow is high enough to suck moisture off the coil (not a good thing), it’s not likely to make it past the blower compartment. Also, this issue would be worse in summer. Any resulting odor would be from mold growth, and that’s the ‘dirty sock syndrome’ you say you don’t have. Also, once you have mold in the air handler or ducts, the odor would be continuous when the blower is operating.

I can’t relate to the “stale dry ice” odor you described, but electric heat elements will emit a strong odor the first couple of cycles each winter, as accumulated dust burns off. If the odor persists, you should have a tech inspect the electric heat module and surrounding area.

Thank you David for

Thank you David for responding to my quandary;

I failed to say my unit is brand new (04/14) and working its first winter. I doubt there is much dust on the heat strip but I know what that smells like, and my present case is not that odor. I did run the system on aux. heat by itself to test that theory and there was no odor from it. Also, I have had this dry ice type odor issue the entire winter season so initial dust burn off is not the issue.

I have wondered why my unit did not stink while in summer AC mode knowing that the evap coil worked the same way as it does in heat/defrost mode. So, I have one other theory; the aluminum fins on the evap coil are off-gassing when they go through their RAPID temperature change during the defrost cycle.

I did read one other long web-thread about some people who have experienced the same odor issue as mine when their unit was in winter defrost cycle, but none has had success with what causes it or how to remedy it.

I did have a Sr. tech from the company that installed the unit out here; he never experienced this particular odor issue before and was not able to produce it when he put the system into forced defrost. Not too soon after he left, of course, the system ran its defrost cycle and there was the stinky dry ice type odor (smells like an old freezer that needs manual defrosting). The odor has continued since then and seems to only happen during cold days, below 50ish. It’s been warming up here in south Dallas so I will need to wait until it gets cold again before I call another tech out.

I purchased some ‘Frost King’ AC-coil spray cleaner and am thinking of cleaning the evap coil myself, but I’m afraid I will then create a worse and longer lasting odor and ruin my warranty. I would install a new coil myself if I had the tools and know how as to draining the system of Freon and then recharging it, but I don’t.

Hopefully someone else will read this and know just what is happening with my system and will post here.

Oh, I just had another idea. Since the defrost cycle on my heatpump is on a timer, whether the unit actually needs to defrost or not, then perhaps while having this FORCED defrost cycle something is causing an abnormality to occur with the evap coil. ???

Can the timer be disconnected so that the hp only goes into defrost when it needs to?

Any thoughts on my 2 theories here? (aluminum fins on e-coil off-gassing, or forced defrost causing abnormality at e-coil thus resulting in odor release.) Hmmm; I’m getting sleepy 🙂

Sincerely;

Wendy

First you probably have a

First you probably have a timed defrost. Usually you can move the jumper to either 30,60,90. If it not on 90( min), you might try that and keep an eye on it to make sure it is defrosting often enough. They have a demand type defrost board that only defrosts when it is necessary but not a DIY project. Next there was a brand that had trouble with stinky coils, but I can’t remember the brand. Their fix was replace coil. The coil was covered under warranty but not sure about labor? You might do a google search on recalled coils because of smell. Also in a/c mode the blower usually shuts off with the condenser but in heating the coil gets warm again with moisture on it. If it was satisfied and ready to cycle off, then it may have a delay for blower to shut off. This means that the blower would still be blowing air across a wet coil for awhile which may cause a slight smell. Just ideas for you.

@Wendy, do you happen to have

@Wendy, do you happen to have a Trane or American Standard system? The relatively new Hyperion line of air handlers (model numbers beginning with GAM or TAM) has the blower on the return end and the evap coil *after* the blower (blow-through, as opposed to draw thru). This design has some advantages and, to my knowledge, Trane/AmStd is the only company that builds AHU’s this way. This may be significant because it puts the coil in direct line-of-sight of the heat strips (always at AHU outlet). Normally the blower compartment is between coil and strips.

My thought is that the strips could be heating the backside of the coil during defrost (through radiant heat transfer), causing some sort of off-gassing. Just a theory, but if this were the cause, then it seems like the odor would also occur when strips come on in Aux mode, not just defrost. If you switch the system to EM(ergency) mode (strips only), is there an odor?

Another way to try to isolate the source would be to disable the strips during defrost. However, the details of how to do this vary by system. Some AHU’s have a separate breaker for the strips. Otherwise, it would require interrupting the strip heat control wire between the outdoor unit and the AHU. I can’t be specific without a model number. In any case, I can’t advise a homeowner to remove the service panels, at least not in a forum like this.

A google search turned up a number of complaints about smelly coils in defrost mode, mostly related to Trane equipment, supporting what John said. Aluminum coils have become more common in recent years. It’s possible a chemical used in the manufacturing process (which can vary by coil supplier) is the source of the odor.

Hi Dave; my heat-pump defrost

Hi Dave; my heat-pump defrost timer is set for 60 min; I’m changing it to 90 this weekend. Yes, I definitely thought of the blower delay and it blowing across a moist e-coil. The moist coil thing was, and still is, where I believe the trouble is, along with the aluminum fins.

Concerning the aluminum material used in mfg of the coil, I did read somewhere that many fins are made of recycled aluminum which is impure as opposed to virgin aluminum, for cost sake. This particular article stated that the recycled aluminum has more nooks and crannies that bacteria can live in, hence the common dirty sock syndrome. Many of the DDS coils have been sent to a company in Florida called Bronz-Glow, to be coated with a bacteria inhibitor that has proven well.

I did want to mention that my e-coil has copper for the coil and aluminum for the fins. I think people use these terms interchangeably?

I mentioned I have a Carrier HP & AHU:

Air Handler: Carrier

Mfg Date: Jan 2014; Installed April 2014

Product #: FX4DNF049T00ABAA

Model #: FX4DNF049 4ton unit

Serial #: 0514A86710

Refrigerant 410A; 450psi

Motor: 3/4 HP

Heat Pump: Carrier

Model #: CH14NA048-A

Serial #: 1014X60297

I contacted Carrier twice but they keep passing me off to the HVAC dealer.

My blower is in-between the e-coil & heat strips. There is no odor when I switch my unit to emergency heat mode. I do have two power toggles at the AHU; I know that one is to shut-off the entire system; not sure about the other. All I noticed is the tech shut them both off before he opened the door panel to the e-coil. I will check this weekend, and perhaps try your idea upon colder weather when the unit calls for defrost. (It’s been warm here this week.) When the system starts its defrost thing I know how long it takes before the next cycle; about 2-3 hrs, hence the timer.

Question:

Are all defrost timers set to activate when the temp gets to 31*F? If so, is that the outside air temp or the temp at the sensor due to Freon cooling down the system? Because I notice my HP goes into defrost when the outside air temp is well above freezing; like I mentioned before – up to 50*F outside. If the timer activates at 31*F can this number be programmed differently?

What do you think about me spraying the e-coil with the Frost-King cleaner? Does this stuff stink too? I read a site that one person used Pine-Sol (8.7% pine); I thought that would smell great but then I read that it was flammable; Hmmm. Also, I would think that the ‘oil’ in this solution would inhibit heat transfer over the fins?

I’ll google the complaints you mention.

Thanx; Wendy

@Wendy, if microbial growth

@Wendy, if microbial growth were causing the odor, I would think it cause the dirty socks smell you said you don’t have. I’m still thinking a chemical used during manufacturing, although I’m puzzled as to why it wouldn’t happen in heat or cool mode. Your theory about rapid temperature change doesn’t make sense to me, but I’m no expert in materials properties.

I see now that you indicated Carrier in your initial comment. Sorry I missed that and went on about Trane. Since your AHU has blower between coil and strips, and since you don’t get the odor in EM mode, it must be coming from the coil, and not related to the strips. So no point in disabling strips to further test.

One more thing you can try during milder weather is to operate the unit in heat mode, then switch the thermostat to cool mode and reduce the setpoint to turn on the AC. If this creates the odor, at least it gives you a way to demostrate the smell to the technician. Note: do not operate your AC below 55F outside. Also, wait a couple of minutes between heat and cool mode to allow the high and low side refrigerant pressures to stabilize. Some systems enforce a minimum off time in the controls.

As for your question about defrost operation… Different model series manage defrost control in different ways. Most look at ambient (outdoor) temperature and liquid line (entering coil) temperature. For example, a typical time-temperature control will start the defrost timer when ambient drops below a certain point, say 45F. Since the outdoor coil gets a lot colder than ambient (by design), you can get frost when it’s above 40F outside. Sounds like yours is set to 50F, which is a bit high (it’s not adjustable). The defrost cycle ends when the liquid refrigerant entering the coil climbs above a given temperature, say 70F. On some units, this setting is adjustable. A “demand defrost control” may also look at differential temperatures. I can’t be more specific without reviewing the installation manual for your unit, which I can’t locate online. I believe the CH14NA is a special builder series as it’s not listed on Carrier’s website.

Sorry, I can’t advise on coil cleaners, but if the odor is caused by a chemical from the manufacturing process as I suspect, I don’t think there’s anything that can be done other than to replace the coil.

Thanks Dave; <

Thanks Dave;

Something interesting happened this morning. First, it’s pouring rain outside and 44*F. I keep my heat on 69*F at night. I got up and set the thermostat to 70, the system came on and within a minute I was smelling the odor. I’m doubting a coincidence that the defrost timer was ready to cycle just at that exact time. During the odor time, I notice the blower then slows down, and within a minute or two the odor dissipates. Any thoughts?

Can I open the AHU access panel to the e-coil while the system is running, or remove the panel while the system is off and then turn the system on? I want to look and smell in there when the system goes into defrost. I know how to force a defrost cycle; I’ll have my husband short out the pins while I’m in the attic… (any other procedure tips here would be great).

Also, is there a non-aluminum fin type e-coil on the market? Or a company that has on its shelves e-coils that have already been coated so I can do a quick swap and not have to wait for mine to be sent out somewhere and be out of heat in the meantime? Can you recommend anything?

Wendy

Wendy:

Wendy: Unless you are a trained HVAC professional, you should NOT open the AHU and short out any pins. This site is here to provide information about the science and technology of homes and not a training site for pros.

I understand. There were

I understand. There were other questions though that did not regard disassembling the unit etc…

I can’t stress how important it is for someone else who has the same HVAC odor occurring and they google the problem and this thread shows up allowing them to get a lot of details that will hopefully help them solve their problem. I have purposely detailed my posts for the ‘next’ guy. It has been very frustrating for me to find anything on-line concerning my unit’s issues, getting Carrier to help me, and getting a professional out here to ‘witness’ the odor so I can move on with this quandary. Thank you for all the info help you have provided. Sincerely; Wendy

Two things, I made another

Two things, I made another post earlier but it wasn’t posted probably cause I left out name and email. Next I haven’t read all the posts so I apologize if this has been said. Trane and maybe others have had DSS(dirty sock syndrome). You could probably google your model and serial and find out? They have supplied coated coils and in some cases labor. Don’t bank on it though. The theory is that bacteria grows on these coils and when the coil get warm again it gives a smell. Trane offers a spray for this and Johnstone does also. Johnston is a lot cheaper. You most likely would have to use it at least once every heating season. Temporary fix. Your a/c guy should be able to find out if it is warrantied. Good luck

Wendy wrote: “I got up

Wendy wrote: “I got up and set the thermostat to 70, the system came on and within a minute I was smelling the odor. I’m doubting a coincidence that the defrost timer was ready to cycle just at that exact time.”

Did you verify the unit was actually in defrost mode? If so, the timer may have expired between cycles, in which case the unit will enter defrost mode the next time there’s a heat call. On the other hand, if your heat pump was already running when you raised the setpoint, then it may have been a coincidence.

“During the odor time, I notice the blower then slows down..”

The FX4D air handler is not variable speed, but has 5 discrete speed taps, one of which is for electric heat mode. The fact that the speed changed suggests it transitioned from Aux or defrost mode after you noticed the odor.

John wrote: “The theory is that bacteria grows on these coils and when the coil get warm again it gives a smell.”

That’s something else entirely. In other discussions I’ve seen on defrost-cycle related odors, some people describe the smell as more chemical than fungal (dirty socks). In any case, Wendy says the smell only occurs in defrost mode, so the coil will be cold, not warm.

I have to throw hot water on

I have to throw hot water on my unit for it to run after it freezes up what is wrong it want defrost some times

@Todd, your problem might be

@Todd, your problem might be resolved by something as simple as changing the timer from 90 to 30 minutes, or perhaps a sensor has gone bad. Or a defective defrost control. In the meantime, it may be easier to remove frost buildup with a garden hose than shuttling pots of hot water.

If ice forms on TOP of the unit (as opposed to coil surfaces), that’s a different problem. See my comment @ Allison’s previous article on defrost, “Why does my heat pump frost over?” (linked above)

Talked to copeland compressor

Talked to copeland compressor training analyst about demand defrost and they seem to think that a demand defrost could show up as a potential problem for compressors. The rheem demand defrost can go as long as 6 hours of run time without a defrost. They are concurn about running extemely cold outdoor coil for extended periods of time and thus not getting proper oil return. Defrost help with oil return from the evaporator(which is the outside coil) in the winter.

howdy; if i understand this

howdy; if i understand this article correctly my heatpump won’t defrost until my timer tells it too, whether it needs it or not? correct? i ask because i presently have lots of frost on my heatpump and have no clue when the timer kicked in and when the defrost mode will actually occur. my timer is set at 90 min. i’m afraid to let the system run again for fear of damage if the wait for defrost is too long, so i ‘shut the system down’ and put the thermostat on aux heat strip only. is my heatpump designed to override the timer if a defrost is actually needed? did i do the right thing by shutting down?

thanx; wendy

I don’t see a compressor

I don’t see a compressor running for 6 hours straight and it not being cold enough to go into defrost at least once during that time.

hi william; are you

hi william; are you commenting to wendy or todd?

wendy has a 4ton carrier unit.

will the unit’s defrost cycle override the timer if a defrost is actually needed?

what is wrong with putting

what is wrong with putting your HP on cool and turn the thermo down for an emergency defrost for a little bit until the defrost issue is fixed rather than hot water?

hi stan; (the hot water

hi stan; (the hot water solution is todd’s, not mine.) interesting thought on ac use; however, i read somewhere it’s not recommended the ac portion of the unit be operated when outside temps are below 60’s; and since i’m still under install warranty, i don’t want to be burning anything up that will come back as my fault. anyhow, i can just short out the 2 pins that are near my timer selector which are located under the hp panel, but it’s a pain to remove the cover when it’s pouring rain out. this short will throw the system into defrost.

so, anyone have an answer to my original question? will the unit’s defrost cycle OVERRIDE the timer if a defrost is actually needed?

@Bob & Wendy, I think

@Bob & Wendy, I think William was addressing a *potential* side effect of the after-market control described in the article.

Keep in mind that the colder it gets, the less likely there will be enough moisture in the air to form frost. So a pressure-based control that locks out defrost in the absence of frost will necessarily eliminate defrost during the coldest weather. That’s a good thing from an efficiency standpoint but if oil migration away from the compressor is truly a problem, then such a control would need to have additional logic to protect against this.

@Mike, do you know anything about this?

It’s well known that oil will migrate away from the compressor during cold weather during extended off periods, which is why most HP’s have crankcase heaters, and why it’s important to turn off the heat at the t’stat during an extended power outage and leave it off for several hours after power is restored so the crankcase heater can draw the oil back to the compressor sump.

However, I’ve not heard of oil migration being a problem during normal operation without defrost. I would be interested to know if anyone has published a paper on this.

@Wendy, your heat pump will

@Wendy, your heat pump will not go into defrost until the timer tells it to. Depending on the control design, there’s typically a sensor that disables defrost above a certain outdoor temp, and another sensor that ends the defrost cycle. But cycles are always initiated by the timer.

If frost is building up on your outdoor coil, you should change the timer to 60 or 30 minutes, as may be necessary when outside temp hovers for long periods between 30 and 35 during wet weather. Running in EMergency mode is silly as it’s only going to double or triple your heating bills.

@Stan, do not run your system

@Stan, do not run your system in cooling mode in cold weather unless it has a low ambient kit, as this can damage the system. keep in mind that the outdoor fan is turned off in defrost mode. That makes a BIG difference.

thanx dave, bunches. i’ll put

thanx dave, bunches. i’ll put the timer back to 60min. it’s been rainy and cold here for a week now and i have run the emergency heat twice at night only; the extra money spent is worth a good night’s sleep for me anyway. i don’t want to be calling an hvac co. at 3am because something failed during the night.

Does anybody have the p-h

Does anybody have the p-h diagram for the H2i Mitsubishi Heat Pump System? Or explain how it works?