The Thermal Bridge To Nowhere

Let’s play a little game today. Take a look at that photo above. See anything that bothers you? No? Well, pretend that you’re the heat in the house once everything is finished and people are living in it. Does that help? If your answer is still no, let me give you a little help. Here are the approximate R-values of wood and the standard insulation you might find in a wall (fiberglass, cellulose, open-cell spray foam):

Let’s play a little game today. Take a look at that photo above. See anything that bothers you? No? Well, pretend that you’re the heat in the house once everything is finished and people are living in it. Does that help? If your answer is still no, let me give you a little help. Here are the approximate R-values of wood and the standard insulation you might find in a wall (fiberglass, cellulose, open-cell spray foam):

Insulation: R-3.7 per inch

Wood: R-1.1 per inch

When the heat inside the house passes through wood when it’s cold outside, it does so more than three times as easily as when it passes through insulation. In other words, the wood forms a thermal bridge, allowing the heat to escape more easily. In the summer, the heat moves from outside to inside, but it’s still a thermal bridge.

The problem in the photo above is that there’s too much wood. The ideal way to eliminate the thermal bridging would be to put all the insulation on the outside and create what Joe Lstiburek calls the ‘Perfect Wall.’ In that type of building, you’d get continuous insulation, which can perform better overall even with less R-value.

Let’s look at the trouble spots.

Trouble Spot #1

The first trouble spot is where the rafters come down onto the double top plate and even hit the header. Either the designer or the framer made the bad decision to lower the roof here, and that puts a lot of excess wood into the building enclosure. If there was a nice big space above the exterior wall, they could blow the attic insulation deep enough there and not have to worry about filling the space between the rafters. The rafters would be higher and not nearly as much a part of the building enclosure as they are here.

As it is, you’ve got ceiling joists and rafters nailed together in a way that will make insulating very difficult. And that constuction on the right side of this closeup has a gap that may well not have gotten any insulation at all. Air has a much lower R-value than wood, so if indeed that gap didn’t get insulated, that’s a serious thermal bridge. If this were a bathroom, it could create a cold spot in winter that collects moisture and starts a biology experiment.

Trouble Spot #2

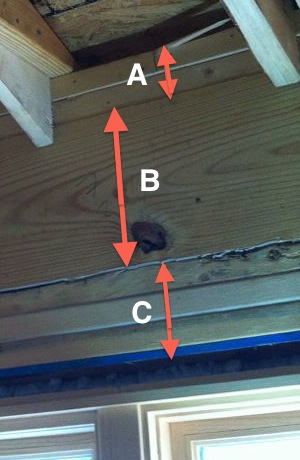

The second area with a lot of thermal bridging is the solid wall of wood above the window. Section A in the photo is the double top plate, a standard part of most stick-built homes. It’s possible to use advanced framing and build with single top plates, but most builders don’t.

Section B is the structural header. That’s fine. With a window below, you’ve got to have a way to transfer the load downward without going through the window. This is made of two 2x10s with a 1/2″ gap that’s normally filled with wood (OSB) spacers. (This home is in IECC climate zone 3, where 2×4 walls are the standard.) You can double the R-value here, and reduce thermal bridging, by putting a 1/2″ piece of foamboard between the 2x10s.

Section C is the most avoidable problem with this part. To fill the gap below the header, someone made the decision to just add more wood, so they stacked three 2x4s on top of a 1/2″ piece of OSB. That’s an extra 5″ of solid wood in this wall. That may not sound like much, but underinsulated areas in the building enclosure can have a huge effect on heat loss and heat gain.

The upshot of all this is that not paying attention to thermal bridging can hurt performance. That room might not only waste energy; it also could create comfort and moisture problems. Somehow, the team that designed and built this house did not include a Building Enclosure Control Freak.

Tip of the hat to our former HERS rater student and current HERS rater Jonathan Goodman of Envirofoam for the expression, ‘thermal bridge to nowhere.’

Related Articles

Combobulating the Perfect Wall – The Basics of Control Layers

Flat or Lumpy – How Would You Like Your Insulation?

Attic Stairs – A Mind-Blowing Hole in Your Building Envelope

Be a Controlling Building Enclosure Control Freak with Control Layers

This Post Has 8 Comments

Comments are closed.

Someone should have informed

Someone should have informed that framer that rafter bird’s mouths typically go on the exterior side of the top plate, not the interior side (if they even did that…going by the gap between the doubled rafters…maybe not). As it is, the entire way this was framed at the featured location in the article appears structurally weak, aside from the thermal bridging concerns raised. There just does not seem to be much beef up there between the top plate and the roof deck.

By the looks of things, when the drywall goes in, it will need to be sloped over the window to accommodate this odd framing technique. And that would raise another thermal boundary weakness…how to ensure adequate insulation gets into the cavity over that slope, and that any provided ventilation from the sofft does not wind-wash or even blow the insulation out?

Yes, this is the problem with

Yes, this is the problem with stick frame construction – even if done very well you are looking at 25-27% of building envelope (according to US DOE) to be stick frame. When you add in another 20-25% for windows & doors you are at 50% of the home that has an R value of about 4 or 5 no matter what kind of insulation is installed between the studs. Coupled with all of the air leaks that wood framing inherently provides, it’s a wonder this dinosaur still lives. People sweat buckets figuring out how to pay for the kitchen cabinets, and hence they build their homes out of the cheapest methods allowed by law…..

Not that I have an opinion on this or anything…. 🙂

Great article describing a

Great article describing a way-too prevalent problem. Also, a great headline that made me want to read the article even though I guessed (correctly) what it was going to be about.

Sorry but forget the thermal

Sorry but forget the thermal bridging, that thing is so far out of code compliance it isn’t even funny. If they can’t get the basics right, they are the last ones I would mention single top plates to for fear of being involved in a game of pick-up sticks when someone walked in.

All very good points and not

All very good points and not necessarily easy to solve. I found that the easiest way to eliminate all of them is to build with double wall construction with insulation between the plates/headers/etc. I also have a similar method to deal with the sloped ceiling shown in the example.

In Louisiana we build the

In Louisiana we build the chicken coop better than this, but not like energy efficient is a necessity but at least save $$$ on the structure!

This is crap, i have ever

This is crap, i have ever seen as architecture like this.

THERMAL BRIDGING IS

THERMAL BRIDGING IS LEAST OF THE ISSUES HERE!!!!

This is the most dangerous framing I have ever seen. Allison you need to turn this construction in before someone is killed. Not being able to see this in the image you posted really makes me doubt your credibility in any construction advise. Hope you were wearing a hard hat when taking the image. I could not image imagine what the rest of the structure looks like.