An Improved System for Even Faster Hot Water

I missed an opportunity. You may recall the retrofit I did in 2022 to get faster hot water at three of my fixtures. It made a huge improvement, but it could have been even better. But before I go there, let me give you some background information and tell you about the hot water distribution I’ve been working on for my basement renovation. And be sure to watch the video down below, too.

The most common answer isn’t always the best

If you go online and look for information about how to get faster hot water, most of what you’ll find is about recirculating pumps. Yes, they can get you fast hot water, but at a cost. If you go with a pump that keeps the hot water recirculating continuously, you’ll see a significant jump in your energy bills. It takes energy to run the pump, and it also causes the water heater to run more because of the heat loss from the pipes. You can reduce the cost by putting it on a time, but it still can be a lot.

A recirculating pump that operates only on demand is way better. (See the D’MAND pumps and controls for details.) This pump moves the hot water through the system when given the signal to operate. A switch or push button in a convenient place normally is how you make this work, but it could be triggered by a motion sensor as well. The push button type can reduce pump runtime by 98 percent and heat loss by 90 percent compared to a continuous recirculating pump.

But even with the demand type of recirculating pump, you have another mechanical system that uses energy, needs maintenance, and can break down.

The key to faster hot water

The key to faster hot water without having to add more mechanical systems is to get smart about your hot water distribution system. You can see my previous articles on this topic for more details, so I’ll cut to the chase here:

The key to faster hot water is shorter pipes with smaller diameters.

Another way to say the same thing is:

The key to faster hot water is having as little water as possible between the water heater and the tap.

That’s why I changed the hot water distribution for three fixtures in my house in 2022. And it works great! The kitchen faucet, for example, had about 80 feet of mostly 3/4 inch copper pipe It took 2 minutes and 40 seconds to get hot water. Since the retrofit, hot water arrives at the kitchen sink in about 30 seconds. That’s a huge improvement!

But I missed an opportunity because I wasn’t thinking clearly about the whole path of hot water.

My basement hot water improvement

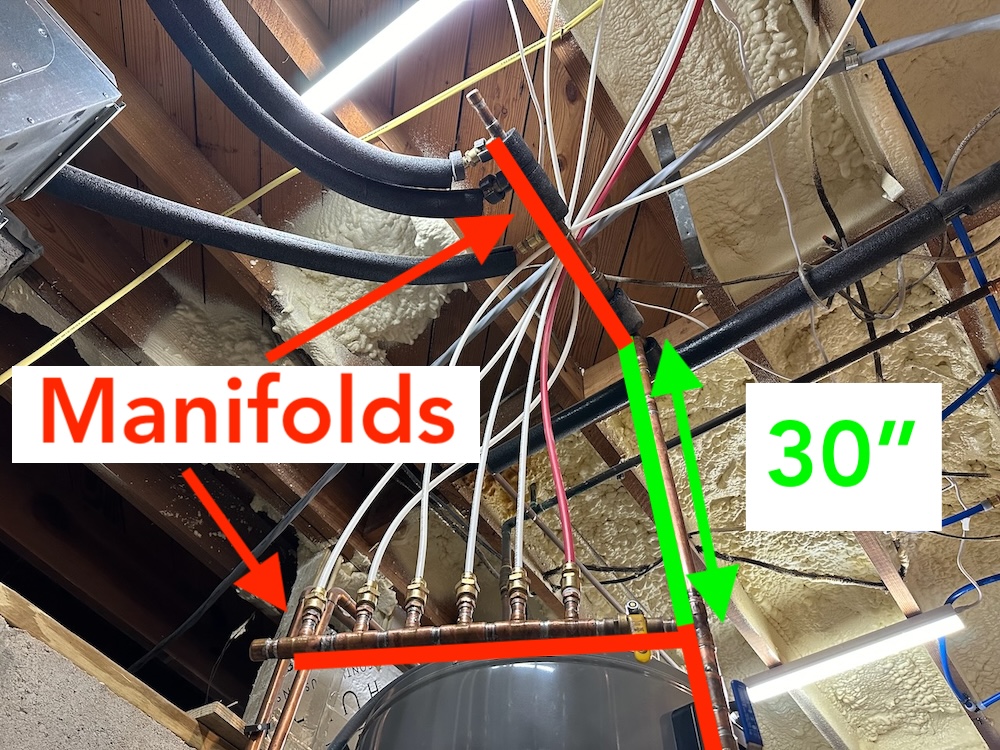

When I did my first retrofit, I made two mistakes. Yes, I did get a lot of improvement by reducing the overall length of the kitchen piping from 80 feet to about 36 feet and the diameter from mostly 3/4 inch to 3/8 inch. But my first mistake was not considering where to insert the manifold into the distribution system. I placed it up high, near the tee that sent the hot water to the other fixtures.

As you can see in the annotated photo above, that location is 30 inches above where I put the new manifold. There’s another almost 30 inches of 3/4 inch copper pipe below the new manifold. For that size pipe, that means there’s an additional cup of water in each of those 30 inch sections. In the 36 feet of 3/8 inch PEX tubing that goes to the kitchen, there’s about 3 cups of water. So I increased the amount of water I have to push out by a third by putting the manifold so high.

The other mistake I made was making the manifold so long. The new manifold is about the same length as the old one, but it has twice as many branches. By putting extra length in the old manifold, I also put extra water in there that had to be pushed through before hot water could arrive.

![Larry Weingarten likes to put the hot water manifold right at the water heater outlet [Photo courtesy of Larry Weingarten]](https://www.energyvanguard.com/wp-content/uploads/2024/10/hot-water-manifold-top-of-wh-2-med.jpg)

Here’s my video about the my hot water distribution system. It might give you a better idea of what’s going on here:

Caution: Pay attention to pressure drop

Smaller pipes or tubing means higher velocity and more pressure drop. To make this work, you have to know that the pressure drop in your new system won’t be too much. Plumbing codes generally say you need a minimum pressure at the tap of about 20 pounds per square inch (psi). If you’re starting with 40 psi and have a 25 psi drop, you’re not going to be happy with the water coming out.

The good news is that for PEX (and other plastic pipes) you can run the numbers through the Plastic Pipe Calculator to find out how much pressure drop you’ll get. In my longest 1/4″ run, the calculator says I have about a 30 psi pressure drop. Our incoming water pressure is over 100 psi and reduced to 60 psi in the house. (See my last article for more on that.) So, the 30 psi pressure at the tap is fine. And actually, I don’t even notice a difference between the hot water coming through the small tubing and the cold water coming through 3/4″ and 1/2″ copper pipes.

Quarter-inch tubing is NOT for long runs or houses with low incoming pressure. You have to have good pressure, short runs, and low flow rates. It works for single low-flow fixtures up to about 25 feet of length. That’s why for my kitchen and its 36 foot run, I used 3/8″ tubing.

But can it pass a plumbing inspection?

We just had the plumbing rough-in inspection for our basement renovation. Did the inspector approve the quarter inch PEX tubing? If you go through the prescriptive compliance path of the International Residential Code (IRC), it’s not allowed. Here’s the language in the 2021 IRC:

But in this case, our building official approved it. When he saw the white tubing, he asked, “Do you know why the plumber used 3/8″ for the hot water?”

“That’s not 3/8,” I said. “It’s quarter inch.” Then I explained briefly that it was for faster hot water, and he was satisfied with that. I was prepared to explain a lot more but didn’t need to. If that had failed, I would have gotten a letter from a licensed engineer.

There you have it. Shorter, smaller pipes are the key to faster hot water. Pay attention to ALL of the pipes, though. And if you’re going to go with 1/4 inch tubing, be prepared to support your case.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can follow Allison on LinkedIn and subscribe to Energy Vanguard’s weekly newsletter and YouTube channel.

Related Articles

Water Heating Is a System, Not Just a Water Heater

Can a Water Heater Last More Than 15 Years?

Comments are welcome and moderated. Your comment will appear below after approval.

I am 100% bought into this thought process. I’m building a custom home now, and even with an excellent builder and a great plumber… it was hard to convey why I wanted a 3/4″ manifold mounted right on top of the water heater with small, independent lines to our fixtures. It’s just such a rare thought process.

In addition, it was hard to find good pre-made commercial product with 3/4″ copper that had the shut-off valves ready to go for PEX tubing. I found some options, but they were either prohibitively expensive or only for PEX-A (or both)… they would have had to custom-build a manifold.

I ended up settling for a man-a-bloc, which I believe are 1 1/4″ inside and which will be further from the heater… I’m not thrilled, but it’s good enough for occupancy. I’ll likely end up pulling it out later.

Mike: If you don’t sweat copper yourself, find someone who does and make your own manifold. It’s not that hard.

Not true. It’s a pia and stupid. Looks like hell and waste of money.

Google “copper manifold”. There are several. SupplyHouse.com has some. BlueRidgeCompany.com has some too. Sioux Chief makes some.

Taco makes the pump for the D’Mand recirculating system. Go direct with the TacoGenie. There are a few others. It is important to plumb it exactly as the instructions say. One could probably cobble together a system. Google “on demand recirculating water” to find cross over valves. Pair that with a recirculating pump with a timer. Disable the timer and put in a switch for on demand.

There is a downside to the manifold close to the tank. I once lived on the top floor of a three story apartment building. If the people in the apartment below me used the hot water while I was showering, I would lose the hot water. The plumber increased the diameter of the pipe running across the basement ceiling and didn’t change the risers. It solved my hot water problem

This might deliver the initial hot water quickly, but can it sustain it for a long hot shower?

Neil: Yes, the duration of a shower depends on how much hot water is available and the flow rate of the shower head. We have an 80 gallon heat pump water heater that has an 89 gallon first hour rating. I could shower a long time if I wanted to.

Gil, yes.

Buyer beware…The fact that this article mentions 1/4″ anything and is not immediately followed by head loss is testament to lack of understanding, well of many things. Sure, you can have hot water faster, but if you have many bit of a long run, you’ll be better off spitting on your hands to clean them. Also, consider the work required, cost of doing it, and the peanuts you’ll save at the hot water heater. Pumps are also silly, and a contractor money grab outside of large systems… Is the money you need to spend on a recirc pump and maintaining it really worth the 5-10 seconds you might have to wait for hot water? Outside of that, yes a manifold is a good idea in some scenarios. If you have two faucets on floor 2 it makes no practical sense to run 2 separate lines, from just about any standpoint, unless you want isolation at the tank.

Jesse: I did caution readers about pressure drop in the video and put a link to the Plastic Pipe Calculator that allows you to find out how much pressure drop you’ll get. Apparently I forgot to put it in the article, too, so thanks for bringing that up. I’ll add it now.

On the video you show the T&P Valve, it this piped to discharge somewhere else?

Would a Convective Heat Loop help in in the delivery of Hot water being at the source for water saving by plumbing into the DHWT drain to loop the hot water back with a check valve letting convection naturally moving thru the system?

David the natural convection method of recirculating used to work pretty well. Sometime ago water heater manufacturers were required to put a device in the hot water outlet that would prevent this. It now no longer works.

Having already laid in the 1″ supply and 3/4″ cold water delivery lines for my Pex retrofit, I started reading about biofilm buildup. I found a couple of studies that show city water treatment with chlorine doesn’t really do anything to stop it and in one study, made it worse. The best way to prevent it seems to be making sure the velocity in the pipes is high.

With very low incoming pressure (~25-30 psi at the basement floor) we use a booster pump and my strategy has been pivoting around optimizing this system with a combination of large and small diameters like Allison. Even with the pump however, the 1″ and 3/4″ won’t have a high enough velocity to scour the pipe walls except when using the tub filler. Now I’m hitting the pause button until I get a little smarter about this.

The code supply fixture units were originated a long time ago and do not account for modern low flow fixtures so the water piping sized based on code is larger than it needs to be. caution should be exercised with velocities in copper hw piping see page 11 in the copper tube handbook (you can download in online for free). I have seen firsthand the erosion in copper pipe and mix it with type M copper and you have a recipe for disaster.

Andrew: Thanks for mentioning that. I wrote about how the evolution of plumbing fixtures from high to low flow and the effect on hot water delivery in this article:

Why Your Hot Water Takes So Long

https://www.energyvanguard.com/blog/why-your-hot-water-takes-so-long/

For those who want to download the free Copper Tube Handbook, here’s the link:

https://copper.org/applications/plumbing/cth/

And for those wondering what type M is, copper pipe for supply plumbing comes in three types: K, L, and M. Type K has the thickest walls and is typically used for underground applications. Type L has the next thickest walls and is best for indoor plumbing. Type M has the thinnest walls and its main advantage is that it’s cheaper.

I would spend a couple of bucks and insulate the copper manifold to stop heat lost.

Will: Aye, that’s going to happen soon.

Just put a temp sensor with timer with recirc pump. Only runs when temp gets below a certain temp, and doesn’t run overnight. Is it perfect? No, but definitely saves on consumption of gas and el.

Then there is always (at an obvious increased cost) the option of on demand water heaters installed at the point of use.

The wait for hot water is negligible, you don’t have a single point of failure with a single hot water heater (so with more than one bathroom you would always have one that works), and no worry of the old “flush while someone is in the shower” problem. It would decrease the amount of plumbing needed, so no heat loss along the way, fewer points to leak, and no tank problems.

Disadvantages being the increased cost, where to put the water heaters and, in my case, solar would be out of the question.

Here in Orlando, I’m keeping my solar.

I’m retrofitting a 1864 brick farmhouse house. I will have a 75ft run from the electric hybrid heat pump water heater in the unheated basement to a mother in-law suite with a full kitchen and bath with a shower. I was planning on running 3/4″ hot and cold pex-a water lines from the basement to the suite. To reduce the cold hot water issue, I was planning on adding a small electric on-demand hot water heater inside of the suite and plumb the 3/4″, 75ft hot water run from the basement into the on demand suite hot water heater. Is there an on-demand hot water heater that will kick on when unheated hot is flowing but turn off when the heated water from basement hybrid water heater finally reaches the on demand suite heater? Is the a good or bad idea? Will this pass code?

It’s my understanding that you aren’t supposed to pipe anything but cold water into an on demand water heater, but I could be wrong. I would contact the manufacturer first before hooking up any variation of that sort.

You can install a 115 volt point of use water heater and just set the thermostat a few degrees lower than the hybrid, that way it shuts off. google this for application info.

BCEE88F0-33E4-4939-B03F-117E983BDE16.pdf

Ask Stiebel-Eltron. My recollection is that I asked that question and they told me the heater would turn off when the hot water reached the on demand heater.

Thanks, Allison, for describing details on how to optimize a “home run” manifold system. I’ve read and listened to Gary Klein’s take on trunk-branch-twig vs. manifold systems. He seems to favor the former. Can you comment on why you chose a manifold approach for some of the fixtures in your house rather than a trunk-branch-twig approach? I like a lot of things about the manifold system, but Gary Klein has dissuaded me. I’d appreciate hearing another expert’s opinion. Thanks in advance.

it all depends on the situation and the goal is having hot water without waiting, at a good pressure, and without wasting energy or water to do it. if you have a big house; lots of bathrooms your plumbing will be different than a simple single bathroom cottage. The potential issue with the smaller plumbing is pressure drop resulting in insufficient flow. Allison’s place has municipal water coming in at 100psi but he regulates it down to 60psi. I don’t know if there is any water treatment (filters?) that could constain flow but I’m assuming there is not. If several runs are activated at the same time will every fixture have sufficient flow? I don’t know the homes setup, regular water needs, occassional high demand needs etc. I’d assume the performance is very good though based upon the authors knowledge. Recently I was involved with a 5000sqft house with 4 bathrooms. It’s plumbed with an 1-1/4″ trunk line that branches off. That was necessary due to being on a well (30-50psi) at the far corner of the home. Smaller plumbing would causr usage in one room from affecting water flow in another. A big home with dynamic uses from many occupants and many long runs wouldn’t work well with small plumbing. Dedicated recirculation lines are fed into a ecm grundfos pump. It has an internal thermostat to measure the returning water temp and aims to keep fixtures around 100-105F I recall. The pump is plugged into a tp link smart plug. All the room with water fixtures have tp-link motion sensing light switches. It”s easy to program the smart plug to power the recirculator when motion occurs in the bathrooms. It works very well for the way that home is used.

Hi, Gary used to say he didn’t like any manifold system except mine (Larry’s). I built a vertical manifold like Allison showed, but with 3/8″ tubing for my house. The one showed has 1/4″ tube and it did get insulated. Gary likes these because they reduce the waste of water, energy, and time. In the system shown, it takes three to six seconds for hot water to arrive. It has no moving parts and was quicker and less expensive to install. Also, I have a stamped letter from an engineer saying it meets code.

Yours, Larry

I have been thinking about this for my 1974 house. WH is in the basement, but apparently nobody thought it odd that it is on the other side of the mechanical room from anything that uses hot water so an extra 12 ft of piping. I have been thinking about moving it across the room where it should be when I change to a HPWH. Manifold might also help.

Thank you Larry for weighing in. With limited user data it is always difficult to determine the best course of action. Just to add to the discussion I know you realize this but ¼ tube vs 3/8 is a huge difference as the area goes by the square of the radius. So the 3/8 should allow 2.3 times the volume of water to pass through. A major source of confusion is that PEX tubing is sized by copper tubing size (CTS), not outside diameter (OD) or inside diameter (ID) The OD of PEX is normally the same as copper, which is 1/8 more than the nominal size. But the wall thickness of pex 0.075” also takes its toll. Pex has a much thicker wall than most copper does. With the same wall thickness we can look at it another way (correct me if I am wrong)

3/8 pex has 1/2 OD and has .36 ID and holds 0.5gal/100ft

1/4 pex has 3/8 OD and has .158 ID and holds 0.2065gal /100ft

Is there any theoretical reasoning as to whether a vertical or horizontal manifold is preferable?

Lastly I do not see many reasons to hand build a manifold when a place like supply house has a dozen different choices for an 8 port copper manifold, some for $30.

Hi Ken and thanks for weighing in! I prefer to install a well insulated manifold vertically on top of the tank-type water heater. This way the manifold remains full of hot water so only the branch tube needs to be flushed when drawing hot water. About buying the manifold, I could not find any that met my spec of having the right number of ports, a 3/4″ body size and the ability to get to 1/4″ tube. I have a REMS tool, so just made my own pretty easily.

Yours, Larry

Great! Thanks for your speedy reply Larry. Looks like lower volume and nearby supply would be fine with ¼” size but larger volume and/or longer distances could move up to 3/8” or greater. The ¼” size carries only 40% the amount of water that 3/8 does. Moving from 1/2” to 1” line would effect a 600 % increase in volume.

Can I ask, do you have any preference regarding the actual brand of pipe. Plumbers and homeowners that considered everything being equal have often chosen the easiest system to install which frequently was pex B with fittings that just slide inside. Two colors seemed like a bonus. This choice may not have been the highest quality system however. Uponor recently in 2024 settled their class action lawsuit about their blue and red which is now discontinued/replaced with something “new and improved”.

I would prefer to use the expanding style to limit the constricting flow at each connection, which could mean Uponor pex A, or Zurn pex B. Apparently the Uponor “25 year Warranty” is really only 10 years. Zurn is apparently a lot stiffer but also has a much higher burst strength. Zurn pex B is used with the same expanding tools as Uponor pex A. Of course there are cheap Chinese brands that are not viable but brands like Mr. Pex, Rehau, Sioux Chief, etc also make pex. And then there is PE RT with a brand name Hyperpure Bimodal coming with a 100 year warranty. Again there are enormous differences.

Your thoughts?

Ken

Hi, I’ve used both Uponor (type A, without color) and PE RT for the 1/4″ tube. There are no expansion fittings or tools for 1/4″ that I know of, so I’ve just used the brass insert sleeve and the plastic compression ferrules. Insert fittings are probably fine, though I worry about the longevity of the O rings in some waters. About burst strength, it’s surprisingly hard to find that info online. Old pattern was that smaller diameter pipe could take more pressure than bigger pipe of the same rating, like sdr-9. Normal residential working pressures should be far below what the tube will handle. Of course, there is the problem of UV weakening the stuff, so I like to insulate it where it may have any exposure to sunlight.

Yours, Larry

Thanks again Larry for your vital information. It always seems difficult to find actual factual data these days. Our information age seems to spread marketing hype and inaccurate data more easily than pure facts. Google AI seems to get things wrong more often than right. I only found 1 source for comparing ID of pex A vs pex B **fittings**. It said:

½ pex nominal tubing ID : 0.475″

Uponor Pex A fitting ID: 0.378″

Standard PEX B fitting ID: 0.350″

So there is a 74% VS 80% choke point in either one. I must have read 100 times how pex A was so much less restrictive than pex B. Not much difference if you ask me. I see why you and Allison are using compression fittings. I am also glad to hear you are on board with PE RT.

Allison you haven’t mentioned the rest of your house plumbing. The picture shows the ¾ copper disappearing into the rafters?

I just measured a scrap piece of Uponor 1/2″ PEX A pipe ID with a caliper. It measures .47″. My copper (brass?) 1/2 PEX A Elbow ID measures .397″. l never rely solely on printed standards because they are generally inaccurate. So yes, there is a larger reduction in the Fitting ID verses the Pipe ID then what the marketing hype would lead one to believe with PEX A.

Thanks Bret! Confirms my suspicions.

Hi, I think I wasn’t very clear on what I said before about insert fittings. I said “Insert fittings are probably fine” and should have said push fittings are probably fine… at least they should have minimal impact on flow, as nothing is being inserted into the tube. Gary Klein has done a fair amount of work actually measuring flow through all different sorts of fittings. The expansion type fittings are noticeably less restrictive.

Yours, Larry

https://lh3.googleusercontent.com/proxy/PywmbaWWZzo3Q15_zrbb7QEyymph4KEffd35Z-b_jZRi–dyg8dzY-5UNbGcpC3pjO_jHETvRhMzMSFm5A5BekEFUJM

https://www.sharkbite.com/sites/default/files/styles/max_1600/public/images/U008RLF-2-diagram.jpeg?itok=f0GFF5G5

https://media.bunnings.com.au/api/public/content/3604372d26b944bea65c740def1ed45f?v=8073880b&t=w500dpr1

https://image.made-in-china.com/226f3j00KjVWlTiyLUkA/SAE-Standard-Brass-Compression-Tube-Nut-Brass-Compression-Fitting-Pneumatic.webp

https://legendvalve.com/media/images/productlines/smartclick/legend-installation.jpg

Larry, I appreciate your continued vigilance in this discussion. I hope the links I posted come up as pictures.

The insert necessary for ¼ pex compression is indeed quite small but it does interrupt laminar flow and I have not found any info in all of the Gary Klein data so far as to how much it will affect flow. Unless using copper tubing “A compression fitting needs a brass insert when connecting to plastic pipes like PEX or PE-RT, as the insert helps maintain the shape of the plastic tubing within the fitting”. I would guess the impact on flow as you suggest is minimal.

I have so far not found any of Gary Klein’s data comparing pex expansion type fittings v crimp fittings (often incorrectly called Pex A v Pex B). Bret E Kline comment above confirmed my suspicions of considerable choking of the size even with Pex A (Uponor). The wall thickness has to be a minimum thickness. This would explain why there is no such thing as crimp fittings for ¼ tubing. There would be little room left if the wall thickness takes up most of the diameter. This does not matter much in larger fittings as the wall thickness is the same but less of a percentage overall.

Push to connect type fittings (sharkbite style) do also have a small insert when used on plastic pex PE RT etc. Again probable minimal impact. Of course we also do not know how long the O-rings will last as they have not been in wide use more than 25 years.

I was hopeful Legend “Smart—click” fittings would solve the problem but as easy and positive and high quality are the connections to use they also use an internal thick walled “choking” mechanism.

If you have any particular link to the specific information I am discussing please let me in on it. I have gone through the building science 179 page ” Architectural Compactness and Hot Water Systems: Good Design Lowers Cost:” with no results so far.