Is Compressed Fiberglass Insulation Really So Bad?

I’ve been guilty of perpetuating a myth. Last month I wrote an article in which I said installing insulation, “cavities are filled completely with as little compression as possible.” But is compression really such a bad thing? When I posted that same article on Green Building Advisor, commenter Dana Dorsett wrote, “Compression of batts is fine (resulting in a higher R/inch due to the higher density) as long as the cavity is completely filled.”

He’s right. Compression isn’t the problem. Incompletely filled cavities are a problem. Gaps are a problem. But you can compress fiberglass insulation as much as you want. The North American Insulation Manufacturers Association (NAIMA) has a little two-page document about compressing fiberglass insulation (pdf). Here’s what they say:

When you compress fiber glass batt insulation, the R-value per inch goes up, but the overall R-value goes down because you have less inches or thickness of insulation.

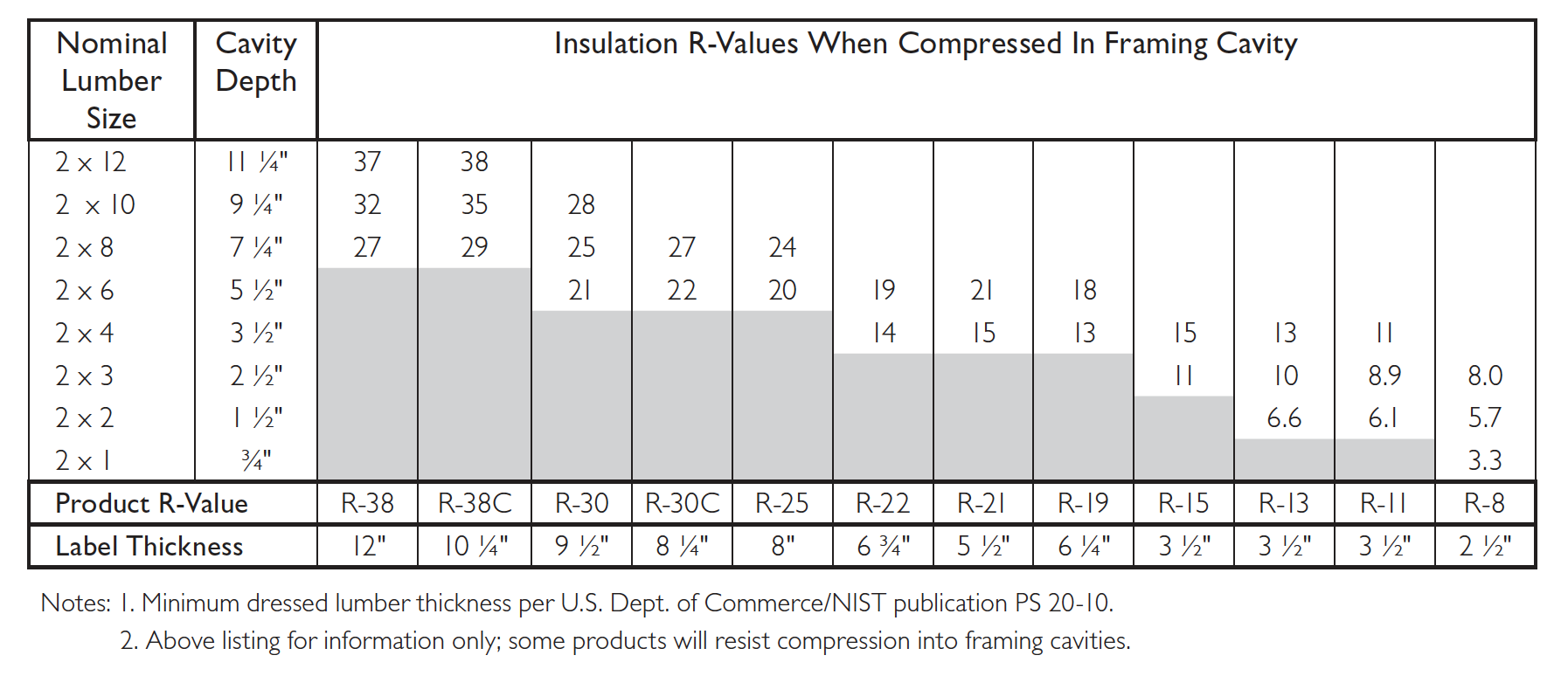

They include a general chart for how to tell what your R-value is with different levels of compression. Owens Corning also has a compression chart for R-value (pdf), and here it is:

So, you don’t get the full R-value on the label, but the insulation still works perfectly well if all you’ve done is compress it.

Here’s something you may not know. The standard R-19 fiberglass batt is 6.25″ thick. If you put that batt in a closed 2×6 wall, it will be compressed 0.75″ because a 2×6 is 5.5″ deep. That means the batt labeled R-19 really gives you R-18 in a closed cavity.

One place where you’re pretty much always going to end up with compression is around windows. If you use backer rod in the gap around a window and then fill the remaining space with chinked fiberglass, “it’s damned near impossible to compress the fiberglass ‘too much,’ without using a hammer!” That’s what Dana Dorsett wrote in his GBA comment to me.

Another is behind electrical junction boxes. If you install fiberglass correctly, you need to cut notches in the insulation where it goes around junction boxes. You can then take that little rectangular piece of insulation and put it in the space between the junction box and the exterior sheathing. You don’t need to worry about removing some of the insulation so you can do it without compression. Just put the whole piece back there and let it be compressed.

So, compress if you need to and don’t worry about it. Just make sure the space is completely filled. That’s the real measure of a good installation.

Related Articles

How to Grade the Installation Quality of Insulation

Rare Grade I Fiberglass Batt Insulation Sighting

3 Problems with Fiberglass Batt Insulation in Floors

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 40 Comments

Comments are closed.

if it is the air, trapped

if it is the air, trapped between the fibers that provides the thermal barrier, why then would reducing that volume of air via compression not compromise its effectiveness?

Well, Paul, it does

Well, Paul, it does compromise the effectiveness by yielding a lower R-value. But it has a higher R-value per inch. A 6.25″ R-19 batt gives you only R-18 when you compress it to 5.5″. If you compress that same batt to 3.5″, you get only R-13. The R-value per inch, though, goes from 3.0 to 3.3 to 3.7.

If R-value per inch rises

If R-value per inch rises with compression, do you think it would ever make sense to compress two R-19 batts into a spot that typically would only have one?

It would cost more to install but wouldn’t you have more R in the walls?

Matt, that’s a great question

Matt, that’s a great question. I don’t think I’d put two R-19 batts in a 2×6 cavity, but you should definitely look to see what else might work for you. On my post of this article on LinkedIn, Butch Whitehouse wrote:

Ok – still confused here. I

Ok – still confused here. I aways thought insulation for the most part got it’s insulating value from the pockets of compress air it contained. If I shove an R-30 batt into a wall that we typically install one half as thick – that means I have much less air doesn’t it? How can pushing more and more air out of the available space increase overall R-Value?

Are we basically saying that fiberglass as a substance doesn’t conduct heat readily and the more glass we can fit into a space the more it starts to behave like a solid chunk of glass?

Single pane glass doesn’t seem to be a good insulator – but if it was 6 inches thick would it be much better?

So i assume this is also related to how dense you should dense-pack insulation?

When dense-packing I assume we are going as dense as we can to avoid air movement and care less about R-Value?

Thanks for making our heads hurt on this snowy (in Colorado) Friday! 🙂

Yes, insulation gets it’s

Yes, insulation gets it’s insulating value by the pockets of air. But it is not really the air that provides the insulation in and of itself, as there is more air in an empty stud bay than there is in an insulated one. The insulating value comes from stopping air movement, especially that caused by temperature changes. By increasing the density of a fiberglass batt (what we do when we compress it), we are creating more resistance to air movement, thus creating more resistance to temperature movement. We can compress insulation and increase the performance of it right up to the point where the main mode of energy transfer is through the material of the insulation itself. For “wool” types of insulation (fiberglass, mineral wool, steel, real wool, etc…), while it varies based on material, this is typically much denser than we are able to get it via compression on the job site.

I agree to an extent, Donald

I agree to an extent, Donald … but we also know that glass itself is an excellent thermal conductor and as such, wouldn’t it leave one to believe that if compressed too tightly, it would have an opposite of the intended effect??? Allison?

I have know of people putting

I have know of people putting R19 batt in a 2×4 cavity and over time the sheetrock had nail pops everywhere. But the idea of a compressed batt and filling the cavity is correct concerning R Factor and efficiency. Example is R13 batt verses a R15 batt difference the high density of the R15 batt

It is the air that insulates

It is the air that insulates in conduction mode, but the fiber is there to limit convection of that air as convection has the potential to move much more heat, higher density better limits convection. It is a case of diminishing returns however as the pure glass is more conductive than the air and convection is already quite slow in normal open cell batts.

3.5 inch r-11 has a density of around .55, r-13 is made .75 and r15 is 1.45 pounds per cubic foot. R-15 insulates like a 4.75″(136% of 3.5″) wall filled with .55 density material, but uses 260% of the material.(same mass of glass could fill 9.1 inches at .55 density which is r28, but of course that requires more wood)

(alternately closed cell foam like styrofoam has no convection as such any compression is bad)

Allison. As always, love your

Allison. As always, love your blogs. Fiberglass insulation is only as good as the fill, like you point out, but also the tightness of the cavity. Air movement only turns it into a filter. Just like a dense furnace filter.

Thomas, you’re right, of

Thomas, you’re right, of course. Air moving through fiberglass will decrease the R-value so you want it to be encapsulated in a six-sided cavity.

Somehow I liken compressed

Somehow I liken compressed fiberglass to more conduction than insulation because I was under the influence that air for age in between material allow for better insulation quality . Compressed fiberglass reminds me if I hand you a dinner glass with steamy hot water in it what do you feel ? Can you tell me if fiberglass testing is done in a vacuum chamber still ? Or if it ever was ? I think fiberglass installed with liquid nail or adhesive on the faces of the beams behind the staple tab could help what do you think ? Doctor Energy Smart Doesn’t install fiberglass – only spray foam and radiant barrier in the Attics . I am enjoying your blog thanks for great information

John, I briefly discussed the

John, I briefly discussed the how insulation is tested for R-value in this article:

Big News: The R-Value of Insulation Is Not a Constant

Also see Martin Holladay’s article:

Understanding R-Value

Back in the 1975, when I

Back in the 1975, when I started my company About Saving Heat Co., R-11 was the only choice for 2×4 walls, so we would install R19 batts into 2×4 walls, to get a packed cavity to about R-14. Now you can buy R-11,13 or R-15 for 2×4 walls. The difference is density an R15 is about 3 times as dense as R-11 (2.2lb vs. .7lb/ cu ft)

Dense packing does work smaller and tighter air space also reduces convection loops.

So it can be good to be be dense, to a point! ( Better than being pointless)

Dennis, you compressed that

Dennis, you compressed that comment as well as anyone could! That’s some high-density building science right there.

Allison thank you, I have

Allison thank you, I have great Respect (R-value) for your informative articles, so your values do matter, compressed or not!

Apparently, I’m missing

Apparently, I’m missing something. While I completely get the part about filling the cavity completely, I don’t get how you can say that compressing the fiberglass lowers the R-value, but that it isn’t a problem. If I want a space insulated to R-30 and compress the insulation so that I only get R-25, how is that “just fine”? If I’m following, then I get that in a tight space, it’s better to compress the insulation than to cut it down to fit. That makes sense where you have no choice (maybe that’s the whole point of the article?) But in an area where I do have a choice (say older insulation has been compressed by the customer setting boxes on it in the attic and is no longer bouncing back to its original thickness), then it’s no longer providing the desired R value. Correct?

Tim, I never said it’s fine

Tim, I never said it’s fine to get R-25 when you want R-30. I said compression alone isn’t a problem as long as you’re filling the cavity. Yes, you absolutely want to make sure you’re getting the R-value you need so if you need R-30, you’ve got to use something that won’t give you only R-25. I think we’re really on the same page here.

Good info that I too did not

Good info that I too did not know. What interests me is that fiberglass requires excellent air sealing on all sides as you mention but rarely gets it in real life, especially in attics and crawlspaces. Even with the paper backing stapled to the framing, air sealing is largely non-existent. The alternatives of closed cell foam, dense pack cellulose or even rock wool seem more logical except to those requiring a good short-term bottom line.

RJ, you’re absolutely right.

RJ, you’re absolutely right. Without tight control over the installation quality, you’ll end up with insulation that underperforms. But that’s also true for every other type of insulation. My most popular article of all time is 4 Pitfalls of Spray Foam Insulation, which describes some of the common problems with that one.

I sipped on the Kool-Aid, but

I sipped on the Kool-Aid, but then decided to do the math before drinking the full glass. If I were the batt industry and I had been beat up for years about poor performance of poorly installed insulation, then I too would develop a chart or formula that shows little to no performance issues when the product was not perfectly installed. And they are correct, to a point.

One comment above was perfect. ‘’…it can be good to be dense, to a point!”

The formula is given at the NAIMA link. So I applied the formula to an R19 batt. Guess what? I have discovered the world’s best insulation product in the world coming in at an R40 per inch! All you have to do is get that R19 batt into a ¼ inch space.

Here is what happens when you apply the formula to an R19 product installed into a 6.25 to .25 inch space. (Chart Image)

(Chart image would not send, but at 1/4 inch, the R value is still 10 which makes the R per inch = 40)

Now I know it’s not our intention to cram this product into a small space with a hammer and screwdriver. But the chart above leads me to believe the formula may only apply to a little bit of compression. Then I am curious if the curve falls off to the point that spun glass starts to act like glass? The R40 per inch is not likely so I contend that we still do not want to compress at will.

Allison I agree with most of what you are saying but I would say it with a few more boundaries. I think it is important to qualify that a small amount of compression is not too bad and we should not point and shame when we see some normal, slight compression going on. But I would not say, “…compress if you need to and don’t worry about it. Just make sure the space is completely filled.”

Excellent point, Dan. Yes,

Excellent point, Dan. Yes, there are limits to simple formulas like the one NAIMA gave in their paper. When you’ve reduced a 6.25″ batt down to 0.25″, you’ve gone well beyond the ability of that formula to give you an accurate number. I don’t know what the bounds are on that relation, but I’m sure it’s for relatively modest compression. 96% compression, as in your example, is too far, I’m certain. Compressing to 50% may be OK.

Here’s the graph you tried to post:

[[{“fid”:”2206″,”view_mode”:”default”,”fields”:{“format”:”default”,”field_file_image_alt_text[und][0][value]”:”R-value compression chart from Dan Welkin”,”field_file_image_title_text[und][0][value]”:”R-value compression chart from Dan Welkin”},”type”:”media”,”field_deltas”:{“1”:{“format”:”default”,”field_file_image_alt_text[und][0][value]”:”R-value compression chart from Dan Welkin”,”field_file_image_title_text[und][0][value]”:”R-value compression chart from Dan Welkin”}},”link_text”:null,”attributes”:{“alt”:”R-value compression chart from Dan Welkin”,”title”:”R-value compression chart from Dan Welkin”,”height”:”449″,”width”:”771″,”style”:”display: block; margin-left: auto; margin-right: auto;”,”class”:”panopoly-image-original image-style-panopoly-image-original media-element file-default”,”data-delta”:”1″}}]]

Fair enough on the advice, Dan. I think maybe I just needed to put in some kind of context. I mentioned two examples of where compression is OK: around windows (assuming you already have an air barrier material there) and behind junction boxes. Last year when I wrote about my bathroom remodel, I showed another one. I insulated the exterior wall with 0.5″ XPS first and then put an R-13 batt in the 3″ of space left in the cavity. As a result, the batt performs at about R-12 instead of R-13. (Edited to add: That’s a photo of the wall at the top of this article.)

Thanks for the great comment and for keeping me in bounds!

Seen this post on insulation.

Seen this post on insulation. Dont know a lot about it. My friend hastorn of all the old paneling of the walls of her old trailer and i think the studs are like maybe 2×2 and practically no insulation can she use regular builders house insulation. I’ve been told u can’t compres it. But it has to be better than nothing? Any help would be appreciated. Tks

Dan,

Dan,

IMO insulation is designed to entrap air so the more it’s compressed the less air it contains and you end up relying on the conductivity of the material (fiberglass) itself.

I suspect the context of the NAIMA calculation is that it pertains to common and customary building practices so I wouldn’t attempt to extrapolate their findings to anything other than what they’ve chosen to show. I suspect the actual curve is a downward sloping and parabolic that ends at R-0.

JC,

JC,

Exactly! My intention was to discredit the straight line relationship. I think we are all smart enough to absorb a real curve and I was hinting that that is what we should see before we start claiming that higher densities are better. This curve should come from a manufacturer. In reading the opinions and insulation applications from some of those in this blog, I am concerned that many are still looking at the straight line (since that is all we have) and stuffing the wrong product into the cavity. I do not know what this curve looks like, but I would like to know, accurately, even for low compression percentages. Fun stuff!

What about friability? As a

What about friability? As a DOE weatherization inspector, I’ve seen many attics, walls, and framed-floor cavities that contain fiberglass batts that have become friable, in as early as 20 yrs. If a batt can lose its elasticity in such a short period of time, then it’s possible that the R-value decreases too because the size of air-pocket within the batt would be increasing. This leaves me questioning the wisdom of using any batt, whether it’s high-density fiberglass or even roxul because unless there’s a magic formula out there, the overall R-value will drop enough to encourage installers to use other insulation materials.

What do you think?

most recently 20 year old batts that were pretty

We are currently insulating

We are currently insulating our attic space (finished room). The slant ceilings will only have about 4″ of room after placing the foam barriers. Of course we want as much insulation as possible but can’t fit R-30 so R-13 seemed to make the most sense. However, after going to Home Depot to check out other options, I noticed an R-21 which is 5.5″. From the charts I read, it appears even with compression we’ll probably get about R-17/R-18. So in this case, would it be best to go with the R-21 and compress or stick with R-13? Will we have any issues? We will be sheetrocking over this area. Thank you!

Cosette, I would use R-19

Cosette, I would use R-19 about same thickness as R-21, but less expensive than the denser R-21, but you will be doing the compression (my impression). The most important part is to fill all 6 sides of the cavity, to reduce the convection loop around your R- value (like a down parker with an open zipper!) The batting is straight and square, but the framing is often is not, but “knot” wood, “would” still move a little as temperature and humidity changes. Therefore stuff all gaps with extra insulation and make sure your drywall compresses it too! Do not leave the convective loop, heat is like most humans; takes the path of least resistance!

Close those zippers’

For the sloped ceiling areas,

For the sloped ceiling areas, install rigid board insulation under the drywall. I went with 1″ XPS. Just remember to buy longer drywall screws.

When we install an apartment

When we install an apartment house sized cast iron boiler, we hare horrified at the large gaps between the fiberglass-lined sheet metal jacket and the unevenly shaped cast iron of the boiler. Over the years obscene amounts of air will flow into those gaps through the holes cut in the jacket for pipes to pass through, then through those gaps, then out another hole, taking huge amounts of heat with it. We usually go to the nearest lumber yard and buy a roll of fiberglass insulation and stuff it in those voids. No, the R-value of the roll we buy goes to hell, especially in the areas where the gap is small, yes we save the owner a ton of energy over the years by greatly reducing airflow through those gaps and by having insulation in what would otherwise be a wide open space.

One observation you didnt

One observation you didnt make is that the r15 and r21 batts are HIGHER DENSITY batts. They are simply compressed batts and much more expensive than r13 and r19 batts respectively, certainly more than proportionate $/in of insulation indicating the extra material used is not proportionate. I dont know specifically but i believe essentially the r15 is simply 2 r13 batts and the r21 is two r19 batts. If you have never worked with them they are both considerably denser than the counterparts for the same cavity depth they’re recommended for (2×4 and 2×6). Tho looking at the chart the r21 compressed into a 2×4 cavity yields r15 but the r15 product sold is NOT simply the r21 compressed it is some other density

Another observation, somewhat

Another observation, somewhat disturbing… does the software use for determining compliance for requirements like California’s Title 24 take into account that the r-value for a product reflects an insulting value for a deeper cabity than which it is used in? Seems they should all be derated in the software but aren’t

The R-value from fiberglass

The R-value from fiberglass insulation represents the resistance to heat transfer through the material by all three heat transfer modes: conduction, convection, and radiation. Please note that the R-value on the label is measured with no airflow through the insulation — though there can be micro convection within the air spaces or pores. To Allison’s point how it is installed will impact the convection within and around the batt, and to a limited extent the air flow through it. If it is compressed enough it does become less air permeable.

But back to the issue at hand, as you compress the fiberglass the conduction between glass fibers goes up, the radiation goes down, and the convection goes down. Therefore a higher R-value per inch of material. The ASHRAE Handbook of Fundamentals covers this very well. There is a great figure that shows the conductivity as a function of fiber diameter and density. You will see that at some point the density gets great enough the conduction increase will offsets the radiation and convection gains and the R-value/inch will once begin to decrease. If you think about it — if you compress it until it is a solid (ie. window) it is all conduction and you know what the R-value for an inch of glass isn’t that good.

A second table in ASHRAE will show you how conductivity changes with density for other material as well.

See ASHRAE HoF (2013) Chapter

See ASHRAE HoF (2013) Chapter 26. Figures 1 and 2. Chapter 25 does a nice job on fundamentals including air spaces that can come in handy, too.

Is this the same with normal

Is this the same with normal ‘fluffy’ insulation rolls? I am currently insulating my loft and have used RWA45 100mm bats (I got for free) for the lower layer, and 100mm standard rolls for the 2nd layer as I have 200mm to insulate before the loft boards.

The roof is low pitch, so I didn’t want to go to 270mm.

I have lots of the insulation roll left over which I can’t return.

Would I be better adding more insulation into the gaps to pack it tighter and compress it down? I’m not fussed about wasting insulation as I can no longer return it, but presumably that would give me an overall better R Value. Everything else I’ve read so far says no, but this article says yes from my understanding.

Good to know. I want to stand

Good to know. I want to stand off a facade from basement foundation and now I know I can oversize the insulation so it fills in behind the studs and cuts drafts and thermal breaks. I just have to make sure I don’t get condensation! I have seen a lot of unfaced bats that are not very regular and it’s good to know to err on the side of putting a little more in.

I’m fighting a really weird

I’m fighting a really weird old house situation.

The 6″ deep rafters were left completely uninsulated, with the long roofing nails uncut on the inside. When the attic was turned into a living space, they put the old thick, real wood beadboard over them. Now I’m trying to figure a way to squeeze insulation into that space. No one does poured foam in my area… and the cost is prohibitive in general right now.

If I could find a way to wrap fiberglass batts in something and vacuum them down flat, them slide them into the space, and let the air back in, would they decompress and fill the space around the nails and give me at least 6″ worth of insulation behind the beadboard? Would blown in cellulose go around the nails to fill it up?

NEED ADVICE ANYONE? I

NEED ADVICE ANYONE? I contract a company that makes trailers for me. The walls have only 1 inch space for me to work with. I want to make sure my customers I sell to that are from the colder regions like MN or MI are comfortable. I want at least R-13 (at least that’s what someone told me). So what would you (anybody) recommend I do? Thanks for any input.

Hi,

Hi,

Thanks so much for this article. I have a question for you regarding what you wrote: “you can compress fiberglass insulation as much as you want.” I am trying to make a shower niche on a 2×6 exterior wall, in which fiberglass insulation already exists. I believe it is R-19. To make a niche, I want to compress the insulation quite a bit, down to only 1.5 or 1.75 inches. What R value or R value per inch would this give? Is it ok to compress it this much, assuming it will fill the cavity completely? Or, will it be better to remove the fiberglass insulation and replace it with 1.5 inch polystyrene insulation board with the R value of 7.5? By the way, behind the fiberglass on my exterior wall, I see some type of form board (don’t know how thick it is). So, I don’t know if it’s a good idea to put a 1.5 inch form board on top of another form board. Any comments from you would be greatly appreciated!!!

I currently have a space

I currently have a space approximately 4.5” deep that I am looking to fill with R-19 and also have a space 4” deep that I am looking to fill with R-15. There may be a small gap in the 4” area that I am looking to fill with R-15 with need for increased compression on the wall with the 4.5” space (compression of approximately 1.5”). Is this the best plan of action or are there any suggestions in the types of insulation (R-15/R-19) I am looking to use?