Does Fiberglass Attic Insulation Really Lose R-Value?

When you get into the world of building science, it’s inevitable that you’ll hear about the study that proved fiberglass insulation loses half its R-value because of convection within the insulation. Or it could be you’re a homeowner who’s been told about this problem by an insulation contractor warning you not to put fiberglass insulation in your home. Or perhaps the article you’re reading now is the first time you’ve heard of this issue. However you came to it, though, it’s important to understand what that study showed and how much of what I said above is actually true.

The Oak Ridge study

First, let’s look at the actual research paper on this study (something that many of the people who cite it haven’t done themselves). Titled Thermal Performance of Fiberglass and Cellulose Attic Insulations, the paper describes the research done by Kenneth E. Wilkes and Phillip W Childs at Oak Ridge National Laboratory in the early 1990s. (You can download their paper along with the technical bulletins described below using the link at the bottom of this article.)

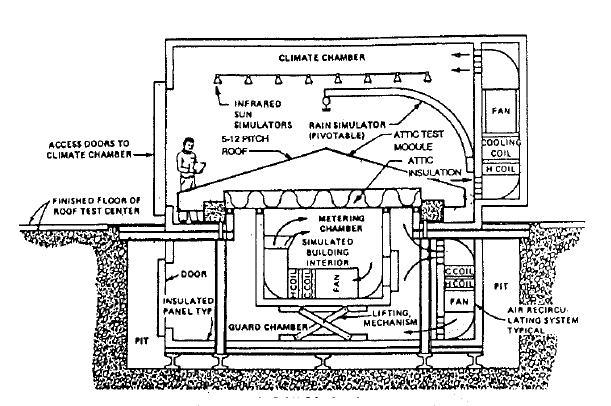

They set up an attic test module that simulated temperature differences across an insulated attic floor. You can read all the details in the paper but basically, they put a whole roof and attic assembly into big chamber (sketch from their paper shown below) and measured the R-values of three insulation types:

- Loose-fill fiberglass

- Fiberglass batts

- Loose-fill cellulose

They kept the the temperature below the ceiling drywall at 70° F and varied the “outdoor” temperature from 45° F down to -18° F. Here’s what they found:

- The fiberglass batts and loose-fill cellulose performed as expected at the whole range of temperature differences.

- The loose-fill fiberglass showed a significant reduction in R-value as the attic got colder and the temperature difference got larger.

In fact, the loose-fill fiberglass lost 35% to 50% of its resistance to heat flow at temperature differences of 70° F to 76° F. The loss of R-value started at a temperature difference of about 32° F. With the temperature below the ceiling drywall held at 70° F, the R-value started dropping when the attic temperature was reduced to 38° F and had lost 35-50% when the attic temperature got to 0° F and below.

In looking at the data, the researchers saw a pattern that led them to suspect convection within the insulation as the culprit. They did some calculations and further experimentation and concluded that was indeed the case. The further experimentation they did was to put a covering layer over the top of the loose-fill fiberglass. The two they tried were (1) a polyethylene film and fiberglass blanket combination and (2) R-19 fiberglass batts. Both eliminated the convection and the reduction in R-value.

If that were the end of the story, the lesson would be to avoid loose-fill fiberglass for attic insulation or use it with a covering layer. But that’s not the end of the story.

Questions raised by the study

If you read the paper and think about what they did and what they found, a couple questions might occur to you.

- Why would loose-fill fiberglass and fiberglass batts behave differently in an attic? They’re made with the same material and were of similar density in the Oak Ridge study.

- Is fiberglass made and installed now the same as it was back in the early 1990s when they did this research?

The answers are related so let’s see what two fiberglass manufacturers have to say.

Not all fiberglass is the same

The Oak Ridge paper doesn’t say what brand of loose-fill fiberglass insulation they used, but at least two fiberglass insulation manufacturers have written technical bulletins about their product and shown data about measured R-values under conditions similar to those used in the Oak Ridge study.

Density of fibrous insulation materials is certainly an important factor. But as I mentioned in the last section, the fiberglass batts and loose-fill insulation used in the Oak Ridge study were of similar density. The batts were 0.46 to 0.48 pounds per cubic foot (pcf) and the loose-fill ranged from 0.40 to 0.56 pcf. So density doesn’t explain the discrepancy.

What does explain it, according to Owens Corning and Johns Manville, is chunk size. (The industry folks call them nodules or tufts, not chunks, I guess because they don’t want to promote the image of installers blowing chunks in anyone’s attic.) Fiberglass batt or blanket insulation is one large chunk with a lot of glass fibers bonded together. In the early ’90s, Owens Corning loose-fill fiberglass was made by taking their fiberglass blanket insulation and cutting it into little cubes. This information is given in their technical bulletin titled Fiber Glass Loosefill Attic Insulation Performance in Cold Climate Conditions, which you can download from the link at the bottom of this article.

Johns Manville has a similar technical bulletin (IST09-005) titled Convection in Fibrous Attic Insulation, also included in the download link below. They don’t say how they were making loose-fill fiberglass in the early ’90s, but they do say they used the research results to “establish design specifications for all of Johns Manville’s loose-fill fiber glass attic insulations to improve winter thermal performance.” That led JM to “maintaining an appropriate nodule or tuft size, which decreased the [air] permeability of the installed insulation.”

The issue with chunk size was explained well in the OC bulletin: “The bonded cubes did not nest well, leaving voids of relatively large air spaces and allowing R-value depleting convection to occur.” That’s why the older loose-fill insulation had a problem with convective loops. And it’s why the modern loose-fill fiberglass product doesn’t. They now use smaller chunks that nest well together.

Fiberglass industry research on R-value

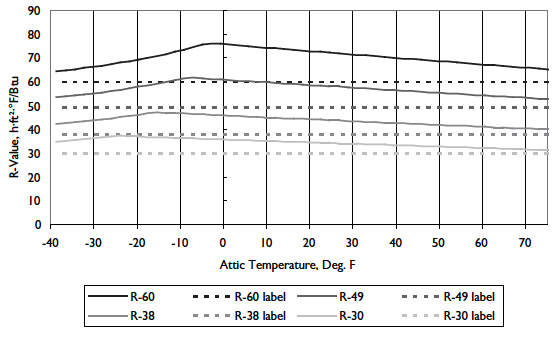

After changing their product, Owens Corning measured the R-value versus attic temperature. The graph below shows the results. The dashed lines are the claimed R-values for four different thicknesses, the solid lines are the measured R-values in their study.

As you can see, the measured R-value is above the labeled R-value for each thickness and at temperatures all the way down to -40° F. Also, note that the R-value increases as the temperature drops until you get below 0° F. For the R-30 insulation, the R-value keeps rising all the way down to -20° F.

Johns Manville has done similar research with their loose-fill fiberglass attic insulation. The two graphs below show their lower and higher density products. They present the R-value results in relation to the labeled R-value rather than just R-value but it’s essentially the same graph as the Owens Corning graph above.

For both densities, the R-value starts at 100% with an attic temperature in the low 40s Fahrenheit and rises as the temperature drops. The difference is that the low-density R-value hits a peak of nearly 125% at a temperature of about -15° F and then begins to drop, hitting about 107% at -40° F, whereas JM’s high-density (0.9 pcf) loose-fill fiberglass keeps rising all the way down to -40° F.

Where does loose-fill fiberglass attic insulation stand now?

To summarize, researchers at Oak Ridge National Lab found that loose-fill fiberglass insulation in the early 1990s had a problem. As the attic temperature dropped, so did the R-value. It happened only with the loose-fill fiberglass insulation they tested, though. Fiberglass batts and cellulose didn’t show that problem. As a result, fiberglass insulation manufacturers took a good look at their product and found that by using unbonded material in smaller chunks, the problem went away.

Sometimes people (usually those who sell other types of insulation) will refer to the Oak Ridge study as proof that fiberglass doesn’t work at all, ever, in any circumstances. That has always been an exaggeration because the flaw was found only in loose-fill fiberglass used in horizontal installations on an attic floor and the study looked only at cold attics, not hot attics.

Now the manufacturers say they have eliminated the problem altogether by improving their product. You can choose not to believe them, of course. They do have a vested interest, after all. But I believe their claims of having changed the product and that their research proves they’ve gotten rid of the problem. If I find some independent research corroborating the OC and JM data, I’ll be sure to share it here.

I’ve taken heat for supporting rigid foam and spray foam industries and I’ve taken heat for attacking fiberglass batt installations (even getting a letter from one manufacturer’s lawyer). I’m sure I’ll get some flack now for supporting fiberglass now, but it’s important that we understand the facts. A lot of people know about the Oak Ridge study from something they heard from someone who heard it from someone else who heard it from their boss who talked to someone who learned about this at a conference in 1994.

I’ll close with the immortal words of the late US Senator Daniel Patrick Moynihan:

Everyone is entitled to his own opinion, but not to his own facts.

Download the ORNL paper and OC and JM technical bulletins (pdf)

Related Articles

Big News: The R-Value of Insulation Is Not a Constant

The Layers and Pathways of Heat Flow in Buildings

Is Compressed Fiberglass Insulation Really So Bad?

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 11 Comments

Comments are closed.

Another interesting article,

Another interesting article, thank you!

The charts show decreasing R-values as the attic temperature increases, but the charts only show attic temperatures up to 70 degrees, F. Is there information available regarding insulation performance for cooling climates with much hotter attic temperatures?

Thanks for the great article

Thanks for the great article Allison!

I a wondering not about the air falling in from the top side of the insulation, but air from the poorly installed or bypassed soffit baffle. Do you know of any research that shows a de-rate in the R-value of attic insulation when soffit air infiltrates it down low on the drywall side of the insulation?

I have always thought that the depth of the material in the attic compensates for our inability to practically enclose the top side of vented attic insulation. The depth helps ensure that attic ventilation air does not fall through all the way to the drywall of the ceiling below. But air can still migrate through fibrous air permeable insulation. So the baffle at the soffit becomes more important to ensure that air is not infiltrating into the attic insulation down low at the drywall level. What do you think of this? does it make sense or am I barking up the wrong tree? Thanks

Fiberglass is fine as long as

Fiberglass is fine as long as it’s installed at the correct density by careful installers. Finding the latter is the hard part, as what you’re looking for is someone who will do their best work in the worst environment imaginable and where nobody will be supervising them.

Oh and the building industry puts them squarely on the bottom of the pay scale, meaning most look like they’ve lived a hard life to begin with and haven’t always made the best decisions, but you’re hoping as a homeowner that today they will.

The issue with fiberglass is that it remains exactly as it’s installed, so when speed is the goal, installers tend to turn the machine on the highest blow rate and stand back and load the attic like a ski area covers runs. Rather than crawling back into the tight perimeter areas with the hose and getting the end out into each cavity and allowing the product to bubble back at them, installers tend to make it snow and ensure the area around the inspection hatch is above the rulers.

Cellulose, on the other hand, still requires good installers, but it’s density at 3x greater than fiberglass, makes it less prone to installer defects by settling to its rated r-value over time. So insulating with cellulose is inherently less risky than fiberglass, and capping a fiberglass attic (that has already been fully air sealed) with cellulose is a good practice.

I’be also found that ducts with radiant barrier jackets perform much better in summer time when they are surrounded by blown fiberglass over cellulose, and I believe the reason is the incredible r-values of radiant barriers (changes with each orientation) when there is an adjacent air space (created by pockets within the low mass fiberglass that are larger than cellulose). Deeply buried ducts in FG tested near R-30 whereas cellulose ones were about 10 less from memory.

Lots to think about with real people installing products. Thanks for another good article and reopening “the great debate”. 🙂

Is there any R-value

Is there any R-value information regarding HOT attic performance? That’s of interest in the cooling-dominated south.

I have a hunch that the convection issue doesn’t apply, since relatively cooler air in immediate proximity to the topside of the ceiling beneath the insulation is denser, so should remain in position.

However, I wonder about radiant effects. Asphalt shingles and the sheathing immediately under them routinely exceed 150*F, especially with dark colored shingles. What happens to the heat that radiates downward onto the top of the fiberglass?

Great article, Allison. You

Great article, Allison. You continue to hit all the right buttons. Again.

I have wondered about why fiberglass batt insulation seems to collapse over time. When you go in an old attic like the one I have pictured, the insulation seems to have settled to a mere hint of what it might have originally been. Years ago I was told that the insulation is held together by an adhesive binder of sorts and as moisture moves through the insulation via the convective flows the moisture breaks down the binder and the fiberglass fibers gradually settle. This is a wonderful way to further emphasize how important the air sealing is.

I did ask someone in authority at OC a number of years ago and he said that was not the case, but it would be an interesting thing to be studying as well. Time impact as well as temperature. Do you know if there is any truth in the binder story?

Very good article Allison.

Very good article Allison.

However, if I might make an observation or two, don’t you find it interesting that they only change the make up of their products when other people point out their faults. Are we really to believe they were unaware of these inadequacies! Now we are supposed to believe everything is OK and their products are up to specifications and will perform properly? Aren’t many of these manufacturers the same ones that told us for over 100 years that asbestos was safe and we had nothing to worry about! I can assure you (based on my own personal experiences) any testing that they provide should be thoroughly scrutinized, even down to how the test chamber was prepared. In closing let me say this, I find it appalling that they would have their attorney send you a letter reprimanding you for anything considering their past history!

I’d like to see third party

I’d like to see third party testing on the performance of these materials. Anyone that can find any sources — please let me know.

Have you all seen these? “Fiberglass BattsLabeled vs. Installed Performance”

https://www.demilec.ca/documents/Tech-Library/Building-Science/Actual-performance-of-fiberglass.pdf

https://web.ornl.gov/sci/buildings/conf-archive/1998%20B7%20papers/032_Christian.pdf

These papers contradict the performance metrics suggested by the fiberglass batt product manufacturers.

Note that all of the

Note that all of the references Jose listed are 18+ years old.

Note: fiberglass as an

Note: fiberglass as an insulation technology is well over 100 years old and fiberglass Batt hasn’t changed except for the elimination of VOC causing additives, ex. formaldehyde. It’s still very much the same product. Alison (Energy Vanguard) has provided me with updates regarding the changes with their blow in product.

The only recent studies coming out are mostly directly from the manufacturers. My concern is that there are no longetivify studies being performed by third parties, or being followed up on. If my data is so outdated, can you please provide me with updates since no one else can?

Additionally, I recently found out that the OSHA toxicology definition which encompasses fiberglass was changed in the last two decades to not include the Insulating fiberglass fibers… hmm

Wondering, in a hot climate

Wondering, in a hot climate and, there when I purchased, a black roof, the best way to insulate attic.

The foil looking stuff between or across rafters? Fiberglass bats between rafters? Or…?? All done allowing eave vent breathing, of course.

Previous owner has shot in some fluffy, white whatever that prevents storage use of floored attic. And I’d wanted to have a whole house fan installed.

Please help.

How much or what thickness of

How much or what thickness of closed cell foam do we need combat convective insulation problems. I am using 12″ fiberglass for conduction and thin aluminum for radiant. But need help with the convection question!! I am in a Denver climate….cold and dry.

Thanks

just jim