InSoFast Makes Basement Insulation Easy

If you’ve seen any of the articles or videos about my basement renovation, you probably know I’m using a product called InSoFast to insulate the floors and walls. You can see it on part of the basement in the photo above. I’m not finished with the installation yet, but I’ve got enough experience with it now to be able to tell you about it.

The video below covers my reasons for choosing InSoFast. I’ve got at least two more videos on this product coming in the future: one on insulating walls with it and another on insulating floors. And in full disclosure, I should tell you they gave me a 15% discount on the panels I bought for “engineering review.” (I saved more money on the three appliances I bought at Home Depot’s Labor Day sale last weekend, though.)

Remodeling my basement

OK, let’s start at the beginning. If you’ve been reading this blog long enough, you know my wife and I bought this house in 2019. Since then, I’ve done a lot of work on it already (new heat pump, new heat pump water heater, faster hot water…). And this year it was finally time to do something about the horrid basement. Yes, I wrote a book down there, but the basement was a building science disaster area. Here’s a video about what I found after demolition in February of this year.

It was a mess. The walls were rotten, poorly framed, and uninsulated on the exterior. There was mold, asbestos, and high radon levels. The layout was depressing, as were the cabinets and other finishes.

In short, it was time to tackle this project.

InSoFast Basics

The InSoFast panels aren’t just foam board. I’ve used that before (photo below), and yes, it gets you some insulation and air sealing and maybe water management. But you still have to figure out how to get drywall and subflooring over it.

The InSoFast system, in contrast, has built-in polypropylene studs. They make it easy to attach the panels to walls and floors, and they also make it easy to attach drywall or subflooring. And they eliminate or reduce thermal bridging, too!

In addition, they have channels on the back side, making them good drainage planes that you can integrate into an interior water management system. And they have horizontal and vertical raceways on the back side for running wiring.

These panels also have great strength. In the first video above, I talked about (and linked to) an InSoFast video where they hung 280 pounds of concrete blocks on one screw driven into an InSoFast wall stud. The floor panels are likewise strong and can easily hold a bathtub full of water.

Regarding the material, the foam used in the panels is expanded polystyrene (EPS). It has an R-value of about 4 per inch, so the 2 inch panels I’m using on the floor give me about R-8, and the 2.5 inch panels on the walls are R-10. Since I bought my panels, they’ve come out with a thicker panel (3.75″) that gets you about R-16.

The embodied—or upfront—carbon in EPS is about a third that of closed-cell spray foam and close to that of blown fiberglass.

Basement building science

Basements need all the building science you can throw at them. They’re connected to the ground, which is good for helping to keep cool in summer. But that connection also means controlling water is critical. It can come through the walls and floors if they’re not watertight. And what 1961 house is watertight!?

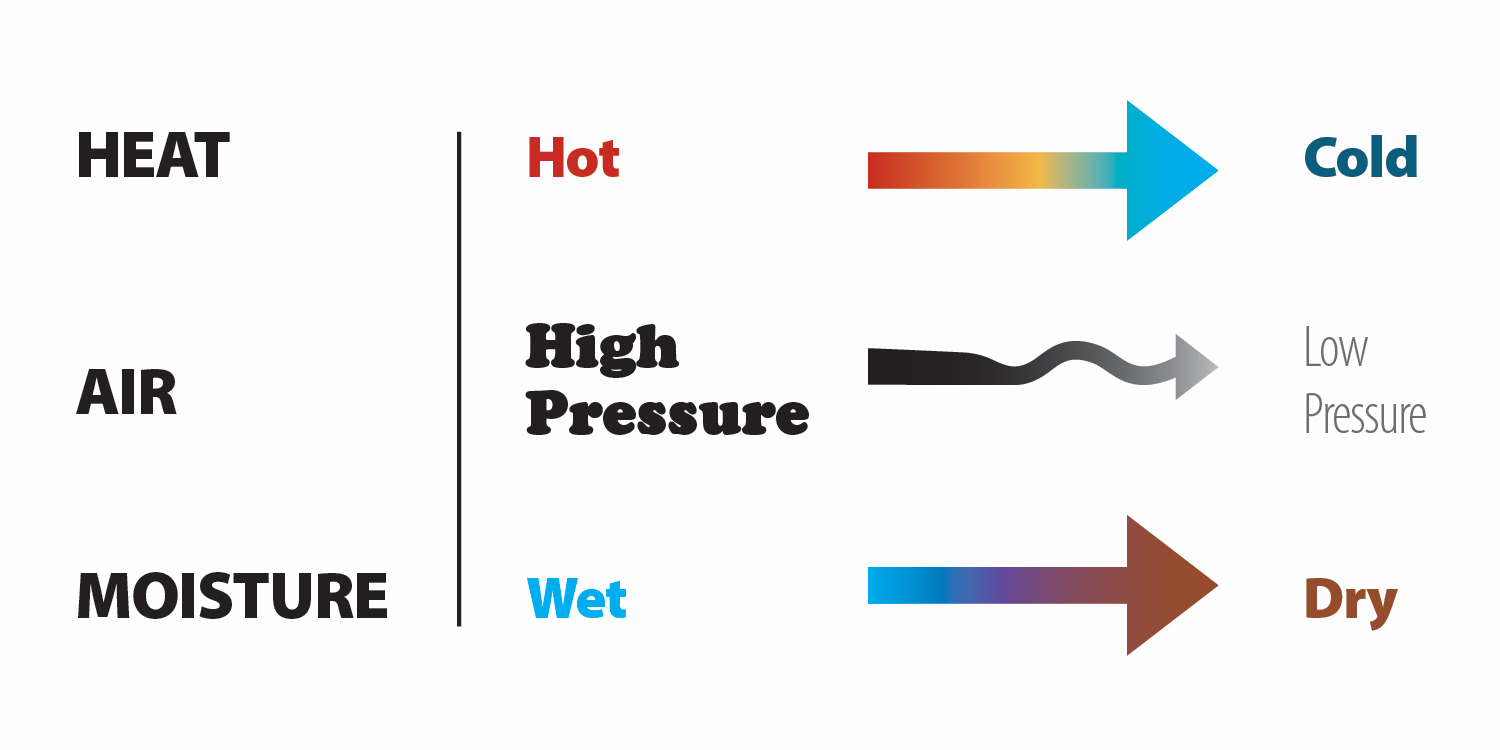

So, we need insulation, yes, but we also need a good air barrier. That’s not only to help with heating and cooling but also to keep soil gases like radon, water vapor, and methane out of the house.

The heat control layer is the insulation in the InSoFast panel. That’s where most people start their thinking, but in terms of the building science needs, it’s the least important.

Options for insulating basements

When insulating a basement, you have some choices.

- Fiberglass blanket on walls — I’ve seen them in Atlanta basements, but they’re more common in colder climates. You still have to figure out how to cover them with something if you want to finish the basement.

- Framed 2×4 wall with fiberglass batt insulation — This is probably the most common way they’re done. Sometimes the builder puts plastic sheeting on the wall in an uninformed attempt to control moisture. This method typically has a lot of problems.

- Closed-cell spray foam —High upfront carbon, but it does insulate, air seal, and control moisture. You still have to do something to cover it if you want a finished basement.

- Rigid foam board — This is what I talked about in the InSoFast basics section above.

I didn’t mention exterior insulation, but that’s more a possibility for new construction. There is a method for putting closed-cell spray foam on the exterior of existing homes without having to dig up everything, though.

Why I chose InSoFast

From what I’ve written above, you no doubt know my reasons by now. But let me summarize them here:

- InSoFast handles all the building science needs of controlling heat, air, and moisture.

- The built-in studs make attaching the panels to walls and floors easy. They also make it easy to attach drywall or subflooring on the other side.

- The built-in wiring chases make doing the electrical work easy.

- They’re very strong!

The InSoFast system is cleverly designed and easy to install. I’ve been very happy with my choice.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can subscribe to Energy Vanguard’s weekly newsletter and follow him on LinkedIn.

Related Articles

Basement Renovation in a 1961 Home

Radon Reduction From Basement Sealing – Preliminary

The Problem With Too Many Basement Walls

Comments are welcome and moderated. Your comment will appear below after approval.

Hi Allison –

Great article!

You report that the carbon footprint of EPS is about 1/3 that of closed-cell SPF. Is this based on comparing the CO2 contribution of a ‘functional unit’ of both products or the CO2 generated per weight, thickness or R-value of the product? A functional unit of insulation is the amount of insulation to provide RSI=1 over an area of 1 m2 per the US Insulation Product Category Rule.

Additionally, did you reference closed-cell SPF containing HFC or HFO blowing agents? The carbon footprint (global warming potential) of the new HFO foams is about 12-15% of that for HFC-based closed-cell foams. I should note the EPA will no longer allow manufacturing of HFC-based ispray foam insulation in the US beginning January 1, 2025.

Insofast sounds like a great solution.

I am building a steel barn clad in steel sheets. I will be using rolls of vinyl reinforced-faced fiberglass to insulate walks and roof. Vinyl facing is on the conditioned side of the structure. The rolls are laid over steel gurts and purlins taped together and steel sheets over that, screwed down. If I added a wrb/arb between the steel sheets and the fiberglass am I creating a moisture problem between the insulation and wrb? I would like to add some measure of air control, thus an air-water barrier.

This structure is a workshop whose interior will be heated and cooled (dehumidified) but moderately, so as to be comfortable enough to work in, not live. Location is SW Tennessee.

Interesting product. I just completed a lower level walk out finishing project on our 2019 constructed home. Over 50% of exterior walls were reinforced concrete (exterior finished with a drainage system but without insulation). Foundation walls on the walkout side are 2×6” flash & bat insulated. When I started the finishing project, all concrete walls were faced with 2” EPS board with seams sealed. The floor was covered with Platon moisture barrier topped with OSB and then engineered wood flooring. All in, the end product is very good. My question with your ‘engineering test’ of InSoFast is about permit inspection sequencing. How can you run wiring in channels on the back side and get rough in inspection before other electric components can be installed? I did not get to electric rough in until all exterior walls & subfloor phases were completed.

This is like ICF’s without the “C”!

Very nice presentation. I think i like this product and final installed design.

I’d like to see more about the flooring portion of this remodel – the “damp” concrete slab covered by the foam boards (insofast) – where does the vapor go – does it achieve a balance in those small channel spaces?

Are there end of wall and corner studs available to install, for when the foam is trimmed between the poly studs, to provide added strength and stability?

One of those products that’s going to solve a lot of problems for people.

Can these panels be applied under an existing subfloor in a shallow dirt crawlspace? If so, do they need to be covered?

Thanks.

Can you still use these panels if the CMU walls are painted?