The Struggle to Update Georgia’s Energy Code

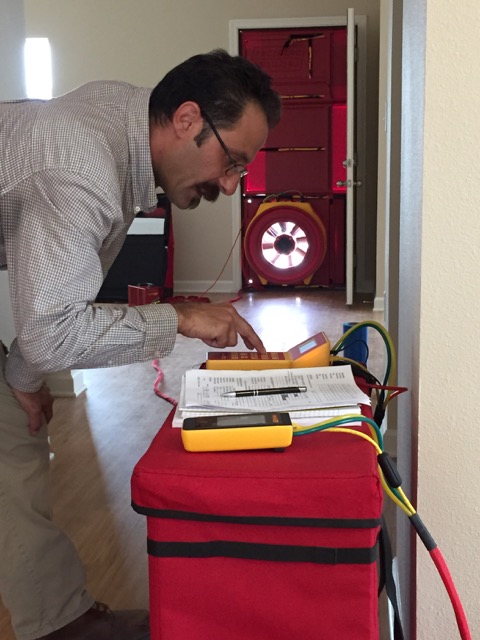

Seven years ago Georgia led the nation. Yep. We were the first state to adopt an energy code that made blower door testing mandatory. All new homes built in the state had to show through performance testing that they had an air leakage rate of less than 7 air changes per hour at 50 Pascals of pressure difference (ACH50). When I wrote about it in 2010, I called our new code “groundbreaking.” Since then, we’ve been passed many times by other states. Now we’re finally updating the energy code here, and it’s been a struggle to move that threshold from 7 ACH50 to something lower. And the reason has nothing to do with the difficulty of air sealing.

Quick overview of the I-codes in Georgia

In 2010, Georgia adopted the 2009 International Energy Conservation Code (IECC) with amendments and supplements. The 2009 IECC didn’t actually have blower door testing as a mandatory requirement. That was a Georgia thing. At that time, we also started requiring duct leakage testing and attic hatches insulated to R-5. And we banned powered attic ventilators (except solar) and electric resistance heat used as a primary heat source.

In 2014, Georgia adopted the 2012 International Residential Code (IRC). One requirement in the mechanical section is that mechanical ventilation be installed if a house comes in more airtight than 5 ACH50.

Now, in 2017, the Georgia Department of Community Affairs has been holding meetings to update to the 2015 IECC. We usually do every other code cycle, so we skipped over the 2012 version. The air leakage requirements in the 2015 IECC are in section R402.4.1.2 and stated thus:

The building or dwelling unit shall be tested and verified as having an air leakage rate not exceeding five air changes per hour in Climate Zones 1 and 2, and three air changes per hour in Climate Zones 3 through 8.

In the 2015 version, testing is now mandatory. That’s not a problem for us since we’ve been doing it since 2011 anyway. That doesn’t mean this update is easy.

The pain of an incremental improvement in airtightness

Since 2011, thousands of new homes in Georgia have passed a blower door test. One of the interesting things I observed early on was that home builders who had never had a blower door test done found that it was pretty easy to hit 7 ACH50. In fact, a lot of times they were coming in at 4 or 5 ACH50.

The proposals to update to 3 ACH50 in the northern part of the state and 5 ACH50 in south Georgia shouldn’t be too hard, right? Builders can certainly get to 5 ACH50 without a problem. Hitting 3 ACH50 will be a bit of a stretch but is definitely doable.

Before long, however, it became clear in our meetings that we weren’t going to get below 5 ACH50. And it looked like that was on track until one of the big stakeholders pushed for no change at all in the threshold. That’s right. They wanted to stay at 7 ACH50. But they might be willing to consider 6 ACH50.

At the last subcommittee meeting, we seem to have made a little progress. The current proposal is to go to 6 ACH50 for a year and then drop to 5 ACH50. Yes we have climate zone 2 in the south and 3 and 4 in the north but we’re going to simplify to one threshold for the whole state.

I’m OK with this proposal — as long as we actually do get to 5 ACH50 in a year. If that transitional year is used as a stalling tactic and we never get to 5 ACH50, that’s not good. A house that tests at 7 ACH50 is better than one at 10 or 15 ACH50, which is probably where we were before 2011 when we didn’t test, but it’s still pretty leaky. At 5 ACH50 max, we’d be doing pretty well, and not just because of airtightness.

The ventilation problem

You may have realized the problem when I wrote about Georgia adopting the 2012 IRC. In that code, a builder has to put in a mechanical ventilation system if the house tests out at 5 ACH50 or less. So currently in Georgia, a lot of builders are aiming for the sweet spot — between 5 and 7 ACH50. They want to pass the blower door test but not have to put in mechanical ventilation.

Not all builders are doing this, of course. Some will prepare for a ventilation, stubbing in the essential components and then hook it up if necessary. Builders who focus on high-performance homes install mechanical ventilation in all their homes.

Still, the sticking point in our code hearings this year is ventilation. If all homes have to have it because we require 5 ACH50, builders have to pay for it and inspectors have to inspect it. What they’re saying is the state’s not ready for this because of a lack of knowledge about installing ventilation systems.

At the moment it looks like we’re going to get there, but the full committee still has to vote to approve it. The problem with not going all the way to 5 ACH50 is that having that “sweet spot” between 5 and 7 or between 6 and 7 does a couple of things. First, it means that some builders will probably cheat. Yes, I’ve heard the stories of photocopied certificates and homes that all have the same test result. It does happen.

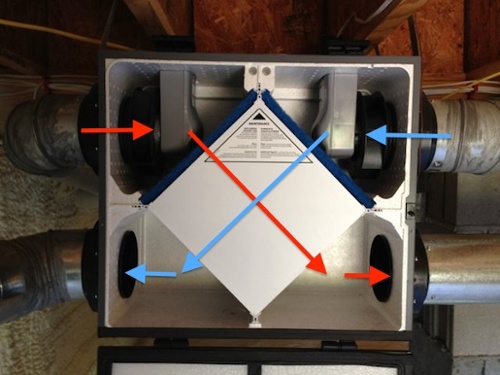

Second, it means we’re not seeing the truth about airtightness. Reducing air leakage is a good thing. Wait, no. Reducing air leakage is a great thing! It’s THE single most cost-effective measure you can take to make a house more energy efficient, more comfortable, more durable, and more healthful. But it has to be paired with mechanical, whole-house ventilation. We want to seal up the random leaks and then get outdoor air into the house in an intentional way.

Come on, Georgia. We got this.

Related Articles

The Groundbreaking New Georgia State Energy Code

4 Ways to Do Balanced Ventilation

Why Do Airtight Homes Need Mechanical Ventilation?

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 17 Comments

Comments are closed.

It’s always a struggle. My

It’s always a struggle. My experience in California with energy code development is similar — there is a lot of money at stake for builders who genuinely want to provide affordable housing and avoid liability. But I think the logic is flawed in assuming that, above 5 ACH, there is a magic non-requirement for mechanical ventilation. We’ve had the mechanical ventilation requirement here in CA for at least 10 years for all new homes, regardless of whether they were trying to meet a certain ACH target, because modern construction methods inherently make for tight building envelopes. But we have not adopted a mandatory ACH target, so kudos Georgia on that.

Can you add to your article by noting some of the common measures builders are taking to meet the 5 ACH target and even the 3 ACH target in your state? Is it with spray foam insulation typically or lots of caulk tubes?

Thanks for your comment, Nick

Thanks for your comment, Nick. I totally agree that there’s no magic that happens regarding the need for ventilation at 5 ACH50. Georgia’s not quite ready to say all new homes need mechanical ventilation, though, but we’re easing toward it.

I’ve written a lot about air sealing here in this blog over that past 7 years, but I don’t think I’ve done an article specifically on how to meet the air sealing requirements to hit thresholds like 5 or 3 ACH50. Sounds like a good topic for a future article. Look for it soon.

Meanwhile, here’s a link to the air sealing diagram created by the Southface Energy Institute for Georgia’s energy code:

http://www.dca.state.ga.us/development/constructioncodes/programs/downloads/Appendix%20A_2008GA_EnergyCode.pdf

Allison,

Allison,

Once again, you are leading the charge for air sealing! Thanks for not pulling your foot off of the gas!

You’re welcome, Bill.

You’re welcome, Bill. Airtightness is one of the most important issues.

Nearly the exact same thing

Nearly the exact same thing happened in Florida when we adopted the 2012 IECC base code. Builder lobbying kicked into high gear and it took legislative action to make changes. Currently Florida is operating with a max tightness of 7 ACH (verified with a blower door come July) and mechanical ventilation only required for homes at or below 3 ACH. Draft code with 2015 IECC was just released with the same changes carried forward.

Mike, I just heard last week

Mike, I just heard last week about your 3 ACH50 rule for requiring ventilation. I think the reason behind that is moisture because almost anytime you bring in outdoor air in Florida homes, you’re also bringing in a good amount of water vapor. Still, it’s possible to ventilate less airtight houses without having moisture problems. It might mean supplemental dehumidification, but that’s what happens in a humid climate when you kill off a lot of the sensible load.

7 ACH? I could almost leave a

7 ACH? I could almost leave a door open and get that (a window maybe?). We consistently get below 2 ACH (1.2 – 1.8) without doing anything extra. Of course we use closed cell foam under roof decking, casement windows and insulated concrete wall panels on all exterior walls. I think the challenge is continuing to build with stick framing which is inherently flawed because of all of the joints involved.

I would not say that concrete

I would not say that concrete is the way forward from stick framing in order to deal with a joint issue. That would ignore the embodied energy and all the other (very weighty) differences between the two materials. There needs to be more value placed upon the performance of a building rather than granite counter tops – and that is with both the builder and the buyer.

Other nations build better buildings using the same materials. The American domestic construction market gets away with square footage and kerbside appeal over performance and longevity.

Gerry Whelan wrote:

Gerry Whelan wrote:

Hear, hear! That’s what I’ve been preaching here for a long time.

Well, that’s a bit of an

Well, that’s a bit of an exaggeration, Thomas, but you’re right that 7 ACH50 isn’t a place to stay. It’s a starting point. It’s the training wheels for air sealing. We’ve been there for six years now; it’s time to move on. Spray foam and concrete wall panels are one way to get there. Taped sheathing and fluid-applied membranes also work, as do many other techniques. I built a house out of structural insulated panels and hit 1.7 ACH50 — before I’d ever done or even seen a blower door test.

2 Questions.

2 Questions.

#1 Is it possible to hit 5 ACH by only taping housewrap or would builders have to resort to taping the OSB/Nailbase (i.e. ZIP-R) instead?

#2 What about exterior insulation? Doesn’t the 2015 code require either 2×6 cavity only or 2×4 cavity + R5 exterior foam?

JC, here are my answers:

JC, here are my answers:

1. Yes, you absolutely can hit 5 ACH50 with house wrap. See this article with test results from a project I worked on in 2011:

Does Your Air Barrier Work in Both Directions?

http://energyvanguard.com/blog-building-science-HERS-BPI/bid/59648/Does-Your-Air-Barrier-Work-in-Both-Directions

It’s rare to see house wrap installed well, however, so while possible, it doesn’t happen often.

2. Yes, the 2015 IECC does require better insulated walls in climate zones 3 and 4, either 2×6 with R-20 cavity insulation or 2×4 with R-13 cavity insulation + R-5 continuous insulation. Climate zone 2 is still allowed to have R-13. Unfortunately, this was one of the things that’s not going to make into our Georgia code. It’ll remain R-13 statewide. You gotta pick your battles and that was one we decided to let go.

Heh I feel your pain, we are

Heh I feel your pain, we are locked into 5 up here even though many are siting at 3 or better

Curious about duct testing; I figured that would be a bigger sticking point going from a tiered system to a flat 3 or 4% whether rough or final

Has Georgia considered a HERS

Has Georgia considered a HERS rating alternative, using a performance path, rather than a strictly prescriptive path?

For example, as an alternative, a builder may choose a lower efficiency heating/cooling system but offset that with better insulation and windows, etc. Or a builder may use minimal insulation, and have 6 or 7 or 8 ACH50, but have low duct leakage to outside with the ducts in conditioned space, etc, and put in a heat pump water heater as offset?

I am not arguing against lower ACH50, necessarily, but setting up certain ventilation systems in Georgia tend to FORCE the need for additional dehumidification with both requiring increases in energy usage. Seen it too many times in my work. I am still not sure what a good, low cost (to run and/or install) ventilation/dehumidification system is for a fairly large house in a 9 month high humidity climate. I am very open to suggestions–as are my clients.

I keep hearing about how

I keep hearing about how Georgia has required blower door tests, but as far as I know, Gwinnett has not been doing them for a while. My house permit got approved January this year and I don’t think it will have the test (i did notice the foamy ?air seal? spray between lots of joints).

https://www.gwinnettcounty.com/static/departments/planning%20/News_and_Notices/Notice_bldg_inspections_insulation_inspection_201612.pdf

As an inspector I see these

As an inspector I see these homes getting below 5 pretty easily. sealing up frame joints and caulking around drywall penetrations. I think the bigger part is the cost of a mechanical ventilation system. I see most of these guys will take a duct and run it from the return to the soffit and draw air in that way. Wrong or right almost all of the production builders do this. Their counter is …. its mechanical and we put a damper on it to only open when needed.

*deer in headlights stare*

I think they would be more receptive of it if some one came out and said here this is what you need and this is what it adds on the bottom line. They think it will add thousands and thousands and the house wont sell. When in reality … it wont cost nearly half of what they think. the house will still sell and the buyer will sing their praise for how cheap it is to heat and cool their home and how wonderful the air feels.

They block good things for no real reason because even if a house costs 5,000 dollars more …. no one is gonna care. But that can significantly change their heating cooling and comfort in the home which ultimately helps everyone with power consumption. Mr builder don’t you want to say “I’m the best because your gonna love not paying so much to heat/cool your home. And in our perfectly designed HVAC system your going to breathe better and live better.” That 5,000 uptick in cost….. nothing. Oh wait, you made more money because more people bought your homes, I’M sorry.

Its a shame they don’t use their heads for more than a hat-rack.

Allison, I’m hoping you can

Allison, I’m hoping you can help me understand something about the history of the Georgia energy codes. I am trying to understand how Georgia houses would have been built in the 2014-2019 timeframe. If I understand correctly during that time Georgia was using IRC 2012 which required mechanical ventilation but was referencing IECC 2009 for Residential Energy Efficiency and had amended it to require envelope air sealing to less than 7 ACH. If a house tested at 6.9 ACH and was still required to have mechanical ventilation that would be too much outside air. Am I missing something?