The Most Neglected Part of HVAC Design

My book (A House Needs to Breathe…Or Does It?) has three sections. The two that take up most of the book are on the building enclosure and the mechanical systems. But the one that I lead with is called Start at the End. Unfortunately, many people start with what’s right in front of them and don’t think about the results they’re trying to get.

The problem with starting at the beginning

We see it all the time in our HVAC design work at Energy Vanguard. Potential clients tell us they’re looking to get a heating and cooling load calculation so they’ll know what size system to install. But the load calculation is just the first part of the design process. The Air Conditioning Contractors of America (ACCA) has a set of manuals that lay out the whole process. The residential load calculation protocol is in Manual J.

But to determine the proper size of the system, there’s Manual S. And that’s not the end either. You can put in a perfectly sized piece of equipment to do all the heating and cooling, but how does it get distributed? For forced-air equipment, you need a duct system. That’s Manual D.

But wait! There’s more.

Ducts designed using Manual D, when applied skillfully, will move the air efficiently and quietly to the rooms where you need heating and cooling. But what if the air goes into one corner of the room and just hangs out there? Or what if you have a vent blowing the air out right on someone sitting at their desk so they’re never comfortable?

These are some of the issues that you solve by applying the most neglected part of HVAC design: selection, sizing, and placement of the inlet and outlet coverings. That’s what ACCA Manual T is for.

T is for termination (?)

Once you get the conditioned air to the room, you’ve got to put it into the room properly. But what does that mean? Well, here are a few of the things Manual T helps you with:

- Comfort – This is a result of blowing the air into the right places and not at the wrong places.

- Quiet – Sizing the registers and designing the central return are critical to keep the noise down.

- Uniformity – By choosing the right type of supply outlet, putting it in the right place, and sizing it for the right velocity, you’ll get good mixing of the conditioned air from the ducts with the air already in the room.

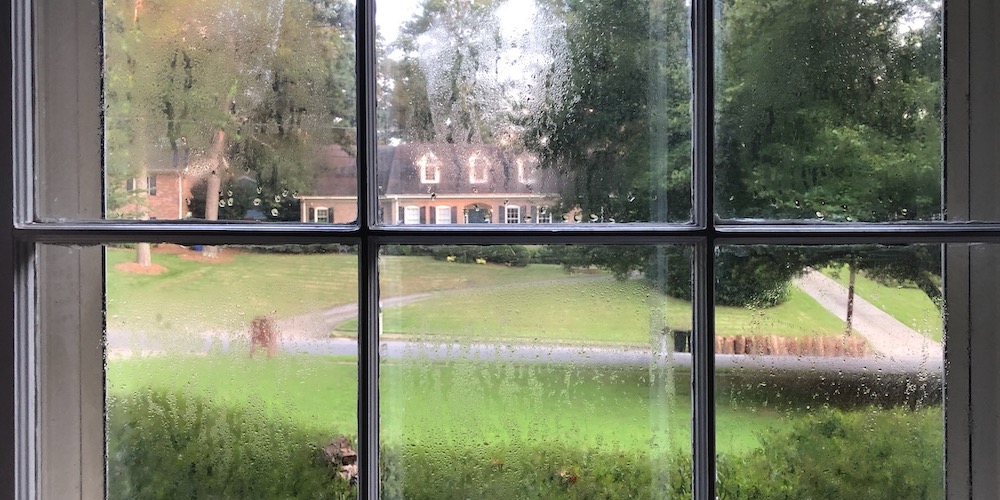

- Condensation control – Sometimes you need supply air blowing on the windows to reduce the condensation that occurs.

I don’t know if the T in Manual T really stands for termination, but it makes sense. It’s all about what you do with the end of the supply and return ducts.

- What part of the room should you put them in?

- Should they be in the ceiling, wall, or floor?

- What type should you use?

- How big should they be?

To answer those questions properly, you need to know Manual T, and you need to dig into the engineering data of the terminations (registers, diffusers, and grilles) you plan to use.

Manual T terminology

There’s a lot of great info in Manual T, and it comes with some new terminology. First, let’s talk about the special components that you put at the end of those supply and return duct runs.

- Vent – I use this term as a generic word that includes all of the more specific terms below.

- Supply outlet covering – This term includes the various types of terminations you put at the end of supply ducts.

- Return inlet covering – This is usually just a grille, but it could be one that also has space for filter. And that would be called a filter grille.

- Grille – Just a covering with fixed louvers. Used for return inlets and occasionally supply outlets.

- Register – A grille with adjustable louvers. It’s the most common type of supply outlet covering used in homes.

- Diffuser – A special type of supply outlet covering made for higher velocity air. It’s most often used in ceilings and not so often in homes.

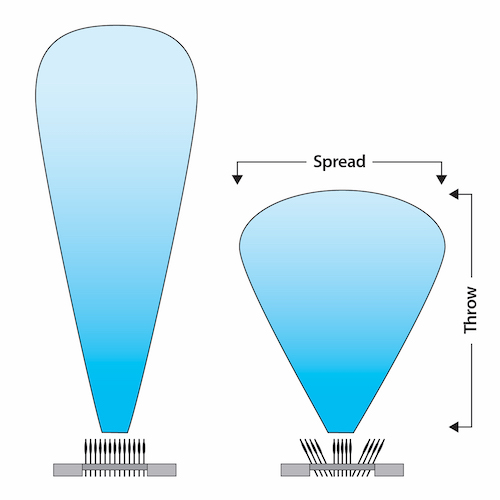

There are a bunch of other terms that Manual T throws at you (😁), many of which have to do with air flow patterns. Throw and spread are two important ones, and the diagram below makes it clear what they mean. If you have a supply vent at the end of a long narrow room, you want register that will give you good throw. If the register is aiming its air across a short wide room, you want more spread.

Some other good terms in Manual T include primary air, secondary air, entrainment, Coanda effect (also called surface effect), face velocity, and more.

Manual T has the answer to a Manual D misconception

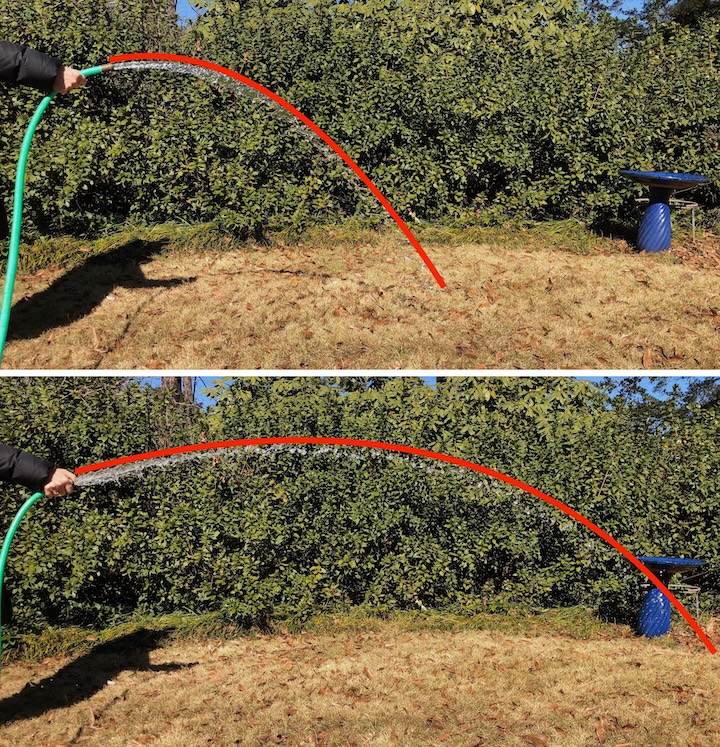

Some HVAC pros have a misunderstanding about the velocity of air moving in ducts. I’ve talked with contractors, installers, and techs who think you’ve got to keep a high air velocity in the duct so you’ll get enough throw once it enters the room. But it’s not the velocity in the duct that matters. It’s the velocity when it enters the room.

It’s the same principle you use when you’re spraying water from a garden hose and want it to go farther. You put your thumb over the end. That makes the water come out faster and travel farther. Low velocity is perfectly fine inside a duct. In fact, it’s better for air flow because it reduces the resistance felt by the air. Manual D even addresses this issue in an appendix:

There are scores of things to worry about when designing and installing a comfort system. Low velocity through a duct airway is not one of them.

What happens in the real world?

Now, go into a typical home and take a look at the supply outlets. Installers often like to use a limited number of sizes. The 6″ x 10″ supply register seems to be a favorite, at least here in the Atlanta area. The problem with many supply registers is that they’re too big. A larger register means lower velocity and less throw. And that could result in reduced comfort.

You should see already that there’s quite a bit to know about air distribution after the conditioned air comes out of the supply outlets. Manual T has many of the answers. Even though it’s the oldest and thinnest of the four main HVAC design manuals, it’s just as important as the others.

Even better, ACCA did with Manual T what I did with my book: They started at the end. The first chapter is titled What Makes People Comfortable? And one of the most important things they say is that you can’t solve comfort problems with mechanical systems alone. Thermal comfort depends on much more than air temperature. And they discuss the important concept of mean radiant temperature on the second page. Unlike my take on that subject, though, Manual T does NOT include photos of naked people jumping on a bed.

3 great Manual T resources: The first, of course, is ACCA Manual T itself. The other two are from the HVAC School. The first is an article by Matt Bruner. The second is a podcast with Bryan Orr and Ed Janowiak.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can follow Allison on LinkedIn and subscribe to Energy Vanguard’s weekly newsletter and YouTube channel.

Related Articles

The Third Worst Place to Put a Duct

The Basic Principles of Duct Design, Part 1

The Best Velocity for Moving Air Through Ducts

Comments are welcome and moderated. Your comment will appear below after approval. To control spam, we close comments after one year.

Great article! And right on time because I’m in the process of replacing old ductwork and registers. I’ve read some of your previous posts on duct design that have been very helpful, and this article on terminating ducts will also be very helpful.

Do you have any thoughts on TuffBox registers? I can’t find much information on them aside from the reviews at SupplyHouse:

https://www.supplyhouse.com/AirTec-81966-MHS-Multi-Stage-Small-TuffBox-Register-Box-6-x-6

The TuffBox registers would solve a big problem for me because I don’t have much room in the attic to remove/install registers. The TuffBox design would allow me to securely install from within the living space. The installation instructions and videos state to simply install as-is, without insulation wrapped around the square portion. But wouldn’t the lack of insulation there result in condensation on the outside of the register in the attic space? Of course I could wrap it with insulation anyway, but then I wouldn’t be able to fit the register through the hole in the ceiling from within the living space. Thoughts?

Ken: It looks like a good product, but you’re right about insulation and condensation. If you’re air conditioning in a humid climate and the boot is in the attic, it would be at risk of having condensation. That it’s plastic should reduce the risk, but if you’re running cold air through it and it’s not insulated, it’ll still be below the dew point sometimes.

Thanks for confirming my suspicion. I’m curious why the manufacturer doesn’t seem to address this very important detail. Instead, they seem to really highlight that all the installer needs to do for a quick install is connect the flex duct. I might try installing a single TuffBox as a test and see if condensation is a problem.

hi Allison,

Thanks for your weekly dose of BS!!

When you talk about large ducts/registers do you consider that the size of a 6 x 10 ( 60 sq in) register is less than that because of the frame and the fins that cover the opening?

If my personal observation is correct, the size of a 6 x 10 opening is really only about half of the register ( therefore 30 sq in)

My 40 yr old house ( that I am renovating) has 5in ductwork. that’s only (about) 20 sq in. The penchant at the time was 12 x 2 floor registers. That creates an opening of about 12 sq inches( 24 / 2=12). I think that works to yes shoot air further but in reality mostly restrict air vs allow for real flow back to the intakes and back into the system.

I installed a heat-pump house heater this last summer and the fan is MUCH stronger and much more air flows through the ducts to the point that the vents vibrate. (My tip: Never get a Fujitsu ! The controller and features are pre-1950s basic.)

Thanks for your time!! Mark

Mark: Yes, the nominal dimensions of a register are one thing. The net free area, though, is what really matters and that’s often around 70 percent or less of the total area. You can look that up in the engineering data from the register manufacturer.