The Problem of Getting Air for Atmospheric Combustion Appliances

Remember those two furnaces I showed you photos of last week? You know, the ones that had ducts placed—or taped, in one case—right in front of them to bring them combustion air. I told you it wasn’t a good way to deal with the combustion air issue, but let’s go a little further today. Let’s look at what building codes say is the right way to do it.

The need for air

The photo below shows the burners in a particular type of furnace. When you pull the cover off of this furnace, you could stick your fingers right there in the flames. (I said you could do it. I certainly don’t recommend it, though.)

What that means is that the flames are open to the air inside the furnace cabinet. Since we know combustion is the chemical reaction of a fuel (natural gas in this case) with oxygen, there’s got to be a supply of air to keep it going. The air in the furnace cabinet itself would be exhausted quickly so more air’s got to come in somewhere, right?

That’s why the furnace shown below has louvers in the cover. It pulls air from the surrounding space. This is what we call the standard efficiency furnace. If you buy a new furnace these days and want to get the cheapest one you can, this is probably what it’ll look like.

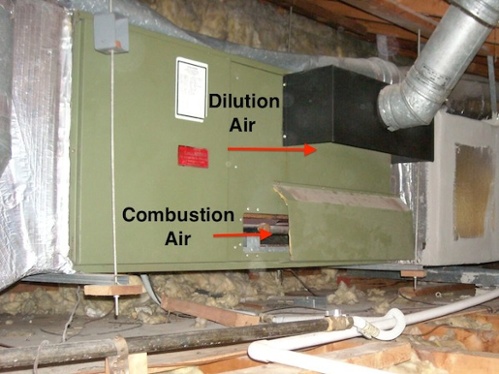

Some older homes, though, have a type of furnace that isn’t made anymore: the natural draft furnace. The photo below shows what they look like. Notice there are two places where they pull in air, and these guys pull in a lot of air. They’re also easier to backdraft, but that’s not our focus here.

Where does the air come from?

So if you’ve got any type of atmospheric combustion appliance, you need to make sure it gets air for combustion. The two options are:

- Indoor air

- Outdoor air

Let’s take a look at them separately.

Using indoor air for combustion

If you’re going to use indoor air, there’s got to be enough of it inside the house. Two building codes that address this issue are the National Fire Protection Association standard 54 (NFPA-54) and the International Residential Code (IRC).

Both say the same thing about using indoor air for combustion. The space that the atmospheric combustion air can draw from has to have at least 50 cubic feet of volume for each 1000 BTU/hour of appliance capacity.

Let’s say you bring the attic inside the building enclosure by putting spray foam insulation at the roofline (the case with the two furnaces in my previous article on this topic). Now, let’s put some numbers to it. (Yes, we’re going to do math, but it’s just simple arithmetic. I know some of you were hoping for partial differential equations, but you’ll just have to console yourself today by memorizing some more digits of Pi, I guess.)

If the attic has a floor area of 800 square feet and an average height of 4 feet, for example, the volume would be 3200 cubic feet. Divide that number by 50 to find the maximum capacity appliance you could put in the attic, and you get 64,000 BTU/hr.

That would be a medium-sized furnace. But you could put only one in this attic. Put two of them up there, and the codes say you don’t have enough air for them. And an 80k or 100k furnace, neither of which is uncommon in homes, would be right out.

One way to get more volume of indoor air for your atmospheric combustion appliances would be to connect the space they’re in to other spaces in the home. You could put a couple of grilles in the wall separating a mechanical room from the conditioned space, for example. The codes specify how you should do that and how big the openings have to be.

Another way to get more air is to count infiltration. Again, you should check the codes if you’re planning to do that.

Using outdoor air for combustion

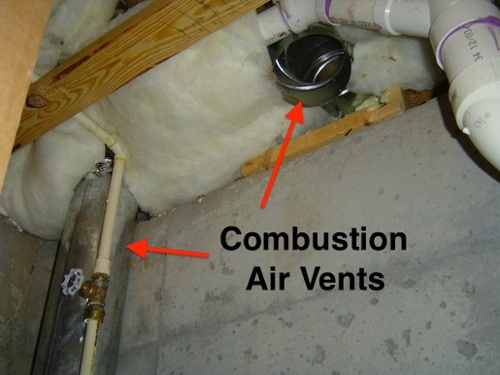

The other way to provide air for your combustion appliances is to bring it in from outdoors. The standard way to do this is with “high-low vents.” The photo below shows an example. Two ducts are open to this mechanical room in a basement. One of them terminates near the ceiling, the other near the floor.

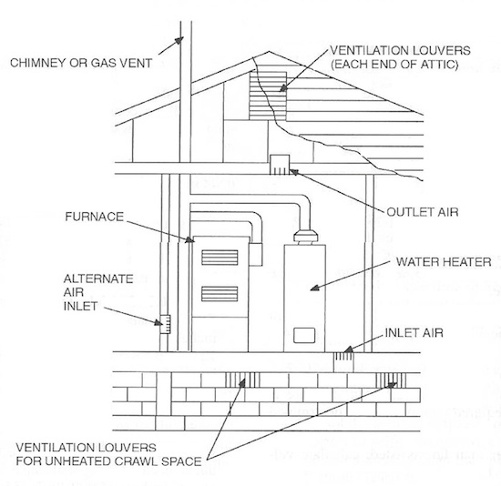

The diagrams below are from the 2012 IRC and show two ways to do the high-low vents with vertical ducts. It’s OK for the ducts to pull combustion air from the crawl space or attic as long as those spaces communicate directly with the outdoors. In the first diagram, the low vent is connected to the vented crawl space, and the high vent is connected to the attic.

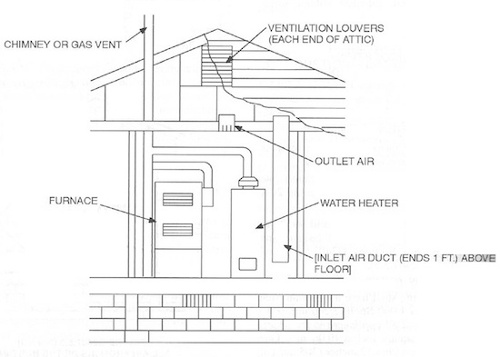

In the diagram below, both vents are shown connected to the attic.

Another method specified in the code is to use a single opening. The photo below shows a basement mechanical room attempting to satisfy the code requirement this way.

With both the high-low vents and single opening methods, the building codes specify the amount of vent area required. As with calculating volume when you use indoor air, the vent area required is based on the total capacity of the combustion appliances.

Here are the rules for the two-permanent-openings method:

- 1 square inch per 4000 BTU/hr – vertical ducts

- 1 square inch per 2000 BTU/hr – horizontal ducts

When using the one-permanent-opening method, you need:

- 1 square inch per 3000 BTU/hr – vertical or horizontal duct

But will it work?

Whether any of the methods above will work is debatable and depends on what criteria you use to gauge acceptability. Here are a few pitfalls:

- Using indoor air still means using outdoor air. Each cubic foot (or cubic meter) of indoor air that gets pulled into a combustion appliance will leave the house with the exhaust gases. When that happens, another cubic foot gets pulled in from leaks through the building enclosure.

- Air doesn’t always follow the arrows we draw on diagrams. You can put all the vents you want into a mechanical room, but whether air moves in the direction we’d like it to depends on the which way the pressure difference pushes it. Wind, stack effect, and other mechanical systems could cause air to flow the “wrong way.”

- Bringing combustion air in from outdoors can waste energy and lead to comfort problems. We know the old saw about how “a house needs to breathe” is a myth. Houses need to be able to dry out and they need good indoor air quality. They don’t need extra leaks. It’s the people who need to breathe.

- Occupants sometimes seal them up because they don’t understand why there’s a hole in their house. It happens, just like they sometimes caulk the weep holes in a brick wall.

As I’ve said before, it’s time to put atmospheric combustion appliances on the pile of obsolete technologies. Let them disappear into the dustbin of history along with steam engines, typewriters, and slide rules.

Related Articles

How NOT to Retrofit a Furnace in a Spray Foam Insulated Attic

The #1 Question to Ask before Putting Spray Foam in Your Attic

3 Problems with Atmospheric Combustion Inside the Building Envelope

Photos by Energy Vanguard. Line drawings from the 2012 International Residential Code from the International Code Council, included under the Fair Use exemption.

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 22 Comments

Comments are closed.

Allison, can you explain the

Allison, can you explain the necessity for two vents (high and low) when providing outside combustion air?

Precisely why we only use

Precisely why we only use naturally aspirated gas-fired appliances for those whom cannot afford high efficiency with PVC or PP vents.

Don’t forget about sources of

Don’t forget about sources of air for other non-traditional items in your very-tight home. A dryer can process 200cuft of air per minute, and some of the newer ones have a separate vent for air intake. A kitchen range hood – required for healthy indoor air – will not function well in a very tight home also without dedicated replacement air.

"The space that the

"The space that the atmospheric combustion air can draw from has to have at least 50 cubic feet of volume for each 1000 BTU/hour of appliance capacity." <br />That part of the code always bugged me. It assumes that a certain volume of space will have adequate leakiness of the enclosure of that space. An air sealing specialist with OCD could choke off a 40 kBtu furnace in a 5,000 cu. ft. space. <br />High-low vents in CZ 5+ can lead to frozen pipes in the mechanical room due to stack effect. Sealed combustion (or no combustion) reduces liability risks for the installer while saving money for the owner. Less math involved, too.

The ones I love have a

The ones I love have a combustion closet in the garage – outside the conditioned space. High/low vents and a warm air supply from the HVAC system to keep the pipes from freezing. Too many things going on in that closet!

Allison, can you explain the

Allison, can you explain the necessity for two vents (high and low) when providing outside combustion air?

We’re finding the Known Air

We’re finding the Known Air Infiltration Rate Method (KAIR) which addresses buildings with low air infiltration can be used when the ACHn is available (from the blower door test) when the structure has less than .4 ACHn. Sometimes, this method ends up requiring less combustion air. Is anyone else using this KAIR method?

Precisely why we only use

Precisely why we only use naturally aspirated gas-fired appliances for those whom cannot afford high efficiency with PVC or PP vents.

Don’t forget about sources of

Don’t forget about sources of air for other non-traditional items in your very-tight home. A dryer can process 200cuft of air per minute, and some of the newer ones have a separate vent for air intake. A kitchen range hood – required for healthy indoor air – will not function well in a very tight home also without dedicated replacement air.

We will be including a blower

We will be including a blower door test in all of our remodels by year’s end.

“The space that the

“The space that the atmospheric combustion air can draw from has to have at least 50 cubic feet of volume for each 1000 BTU/hour of appliance capacity.”

That part of the code always bugged me. It assumes that a certain volume of space will have adequate leakiness of the enclosure of that space. An air sealing specialist with OCD could choke off a 40 kBtu furnace in a 5,000 cu. ft. space.

High-low vents in CZ 5+ can lead to frozen pipes in the mechanical room due to stack effect. Sealed combustion (or no combustion) reduces liability risks for the installer while saving money for the owner. Less math involved, too.

The ones I love have a

The ones I love have a combustion closet in the garage – outside the conditioned space. High/low vents and a warm air supply from the HVAC system to keep the pipes from freezing. Too many things going on in that closet!

We’re finding the Known Air

We’re finding the Known Air Infiltration Rate Method (KAIR) which addresses buildings with low air infiltration can be used when the ACHn is available (from the blower door test) when the structure has less than .4 ACHn. Sometimes, this method ends up requiring less combustion air. Is anyone else using this KAIR method?

We will be including a blower

We will be including a blower door test in all of our remodels by year’s end.

@Tamasin, I installed an

@Tamasin, I installed an atmospheric water heater in my previous home, which I built in 1999. Because the inspector knew I was air sealing the shell (although not to today’s standards), he required me to put the prescribed outside air vent in my mechanical room, even though it connected via a louvered door to an adjacent room that exceeded the volume requirement. It was a judgement call on his part. As I recall, the code at the time included a vague comment about "tight" construction with no definition as to what that meant. If the KAIR option had existed at that time, I might have paid to have a blower door test done. (I eventually did a BD test, 8 years later, just before selling the home.) <br /> <br />Looking back, I can’t believe I actually installed an atmospheric combustion appliance in my home! And right beside the air handler. At least we had a couple of CO monitors. <br /> <br />For those interested in KAIR, here’s the <a href="http://bit.ly/1HzdKq1">code citation</a>. Since ACH-n cannot be measured, and there are multiple ways to convert to natural from a blower door result, the formula should reference ACH50. Given the new ACH50 requirement in the code, I’m surprised the KAIR forumulas weren’t updated in the last revision.

@Tamasin, I installed an

@Tamasin, I installed an atmospheric water heater in my previous home, which I built in 1999. Because the inspector knew I was air sealing the shell (although not to today’s standards), he required me to put the prescribed outside air vent in my mechanical room, even though it connected via a louvered door to an adjacent room that exceeded the volume requirement. It was a judgement call on his part. As I recall, the code at the time included a vague comment about “tight” construction with no definition as to what that meant. If the KAIR option had existed at that time, I might have paid to have a blower door test done. (I eventually did a BD test, 8 years later, just before selling the home.)

Looking back, I can’t believe I actually installed an atmospheric combustion appliance in my home! And right beside the air handler. At least we had a couple of CO monitors.

For those interested in KAIR, here’s the code citation. Since ACH-n cannot be measured, and there are multiple ways to convert to natural from a blower door result, the formula should reference ACH50. Given the new ACH50 requirement in the code, I’m surprised the KAIR forumulas weren’t updated in the last revision.

Does anyone know if NFPA 54

Does anyone know if NFPA 54 wants us to use ACH of the whole house? Or ACH of just the CAZ? The common sense is ACH of the CAZ, and that requires a house-to-CAZ zone pressure test and calculate air leakage to the CAZ from the outdoors. Are any of you using the KAIR Method vs. the Standard Method?

Does anyone know if NFPA 54

Does anyone know if NFPA 54 wants us to use ACH of the whole house? Or ACH of just the CAZ? The common sense is ACH of the CAZ, and that requires a house-to-CAZ zone pressure test and calculate air leakage to the CAZ from the outdoors. Are any of you using the KAIR Method vs. the Standard Method?

@Tamasin, common sense aside,

@Tamasin, common sense aside, my interpretation (NFGC Section 304.5.2) is that ACH refers to whole house since the code does not specify otherwise. Also, if it were intended to apply to CAZ, the code would have to define CAZ, which I don’t believe is defined in NFGC or any other ICC code. <br /> <br />Ultimately, regardless of what I may believe, or anyone else for that matter, it depends on how the local inspector interprets the code.

@Tamasin, common sense aside,

@Tamasin, common sense aside, my interpretation (NFGC Section 304.5.2) is that ACH refers to whole house since the code does not specify otherwise. Also, if it were intended to apply to CAZ, the code would have to define CAZ, which I don’t believe is defined in NFGC or any other ICC code.

Ultimately, regardless of what I may believe, or anyone else for that matter, it depends on how the local inspector interprets the code.

Thanks. Pages 440 and 450 of

Thanks. Pages 440 and 450 of NFPA 54 refer to ACH of the "space" in one section and then ACH of the house in another section. Fun.

Thanks. Pages 440 and 450 of

Thanks. Pages 440 and 450 of NFPA 54 refer to ACH of the “space” in one section and then ACH of the house in another section. Fun.