Ventilating With a Super-Efficient ERV

Well, it’s official. It may have taken 3.8 years to make it happen, but my Zehnder ComfoAir Q600 energy recovery ventilator (ERV) is running now! I started it up on 29 December, so it’s been helping to clean my indoor air for a month now. I wrote about the installation blitz we did back in April, so I won’t go into those details here. But let me give you a little introduction to life with an ERV.

The basics

Here’s a short video I made to show how this ventilation system can pull cold outdoor air in and deliver it to the house at close to room temperature.

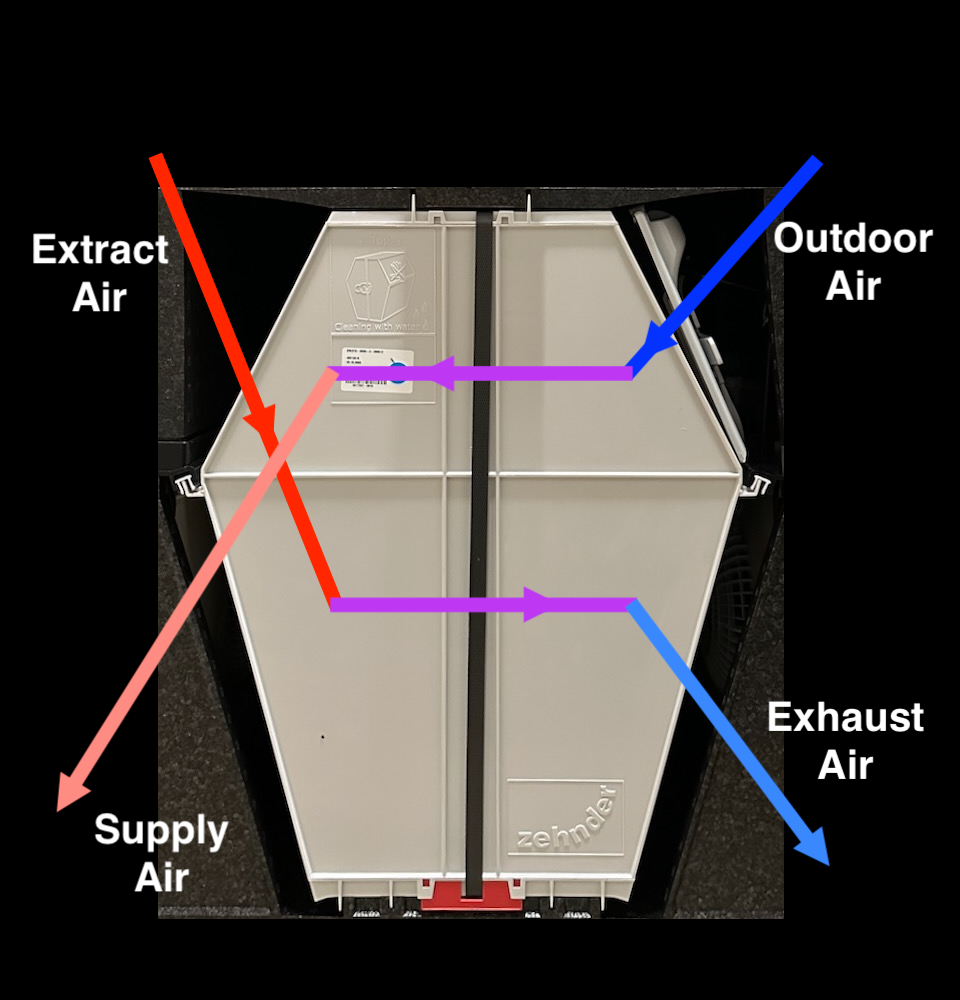

As you saw in the video, there are two air streams. They pass through the capillary core, a heat and moisture exchanger. The cold outdoor air being brought in picks up heat from the warm indoor air being exhausted to outdoors. Most people just talk about supply and exhaust with these systems, but Zehnder actually uses four names, as you see below. It took me a while to get used to them, but now they make perfect sense.

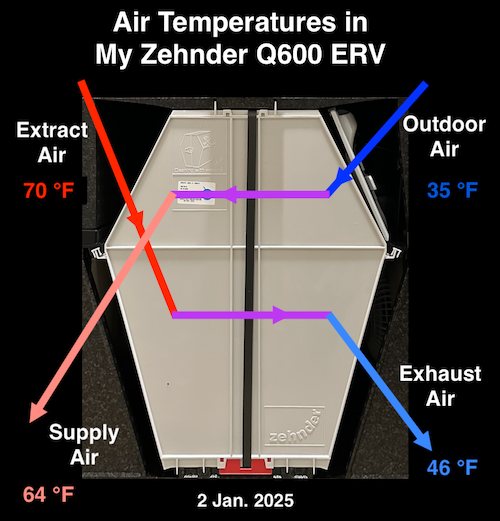

The graphic below shows what the four temperatures were one chilly morning shortly after I started running the system.

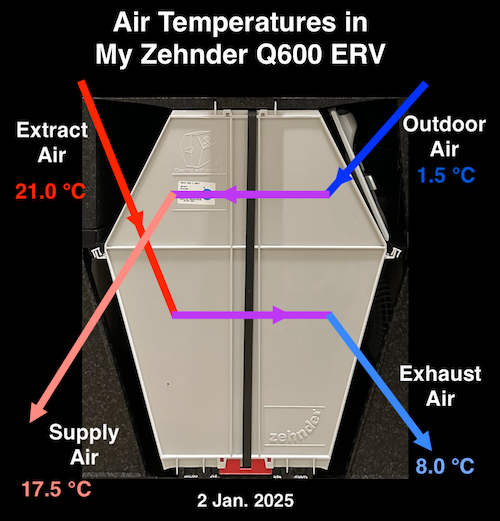

And for those of you living outside the US, here are the Celsius temperatures.

The temperatures above came from the Zehnder ComfoControl app on my phone. Because an ERV exchanges both heat and moisture, the app also shows the relative humidity in each of the four places. I haven’t dived into calculating efficiency yet, but you can see just from the temperatures above that the efficiency of heat exchange is impressive.

Getting ready for startup

After the April installation blitz, the system was about 75 percent complete. Here’s what I still had left to do before I could start it up:

- Install the basement extract and supply register boxes, ducts (ComfoTube), and valves (vents)

- Install the two big ducts to the outdoors for the outdoor and exhaust air with the exterior terminations

- Get 240 V electrical connection

I started working on the first item in October. You can see the register box (called a boot in heating and cooling duct systems) and ComfoTube (the white ducts) for one of the basement bathroom extract vents below. I kept the red cap on it until startup to keep the inside clean during construction.

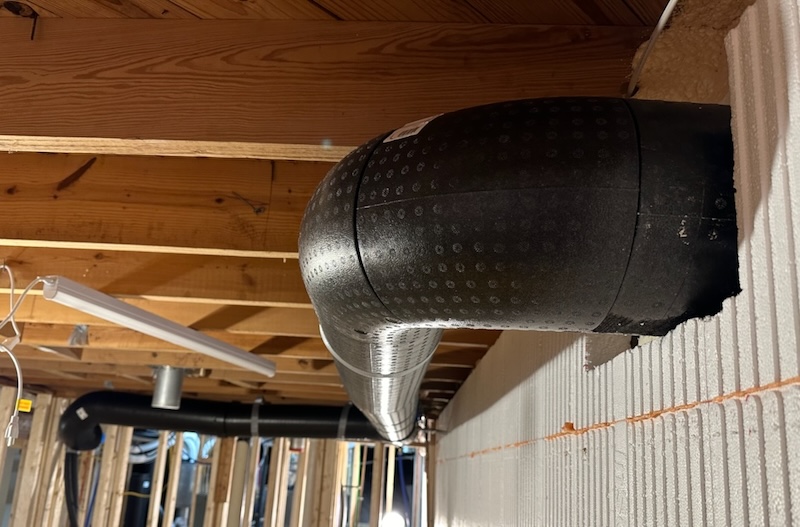

I installed the big duct for outdoor air in November. As you can see below, it’s quite a long run, but I didn’t have any better options. The first two photos in the next section below show the soffit we built around the duct.

Finally, on 28 December I got the last vent and ducts installed. That’s me finishing it up in the encapsulated crawl space in the photo below.

The next day I plugged it into the 240 V outlet the electricians had installed for me in the fall. Then I turned it on and watched it go through the startup process. One of the first things it did was ramp up the motors to see how close it could get to the maximum rated air flow, which is 600 cubic meters per hour. It hit that number and has been running ever since.

After startup

Although I was able to start up the system, not everything was complete yet. Here’s the list of things that were left to do at that point:

- Trim the duct extensions on some of the basement register boxes

- Install boost switches in the bathrooms and kitchen

- Install the ComfoSense C67 controller

- Commission the system

I’ve trimmed the three ducts that extended below the ceiling plane. Unlike the ones we installed in the attic, we didn’t have the space to install these so they’d be flush with the ceiling without having to trim them. So I put a new metal-cutting blade in my handy-dandy oscillating multitool and made them flush. You can see before and after shots of one of them below. (That soffit along the edge of the walls is where the outdoor air duct hides.)

We’ve got five extract vents in the house: one in each of the four bathrooms and one in the main kitchen. The nice thing about Zehnder ERVs is that they can run continuously at one rate and then boost to a higher rate when you need more ventilation. You can initiate a boost through the app, on the unit itself, or by pushing a boost button installed convenient to places where the extract vents are.

I’ve installed three of the five boost switches. So far, I’ve got them in the two basement bathrooms and in the primary bathroom on the main floor (photo above). Currently, the boost button ramps up the air flow for 30 minutes. I’ll get the other two installed when I can.

I’ve been talking with Gary Baggett about commissioning the system but haven’t made that happen yet. Likewise, the ComfoSense C67 controller is still in the box.

My initial take on the Zehnder Q600

The unit does make a little bit of noise, but it’s not bad at all. About the only places I hear it are downstairs near the mechanical room where the unit lives or on the main floor when I’m standing above the mechanical room.

In terms of indoor air quality, the first thing I noticed was the drop in carbon dioxide levels. In the den, we averaged 622 parts per million (ppm) of CO2 in the two months before I started the ERV and had a peak of 1,239 ppm. In the month since I started it, we’ve averaged 522 ppm with a peak of 664 ppm. Our VOC levels are better, too. We averaged 162 parts per billion (ppb) in the two months before, with a peak of 1,284 ppb. In the month since, they’ve averaged 151 ppb with a high of 923 ppb. We really don’t have enough data yet to draw any firm conclusions, though.

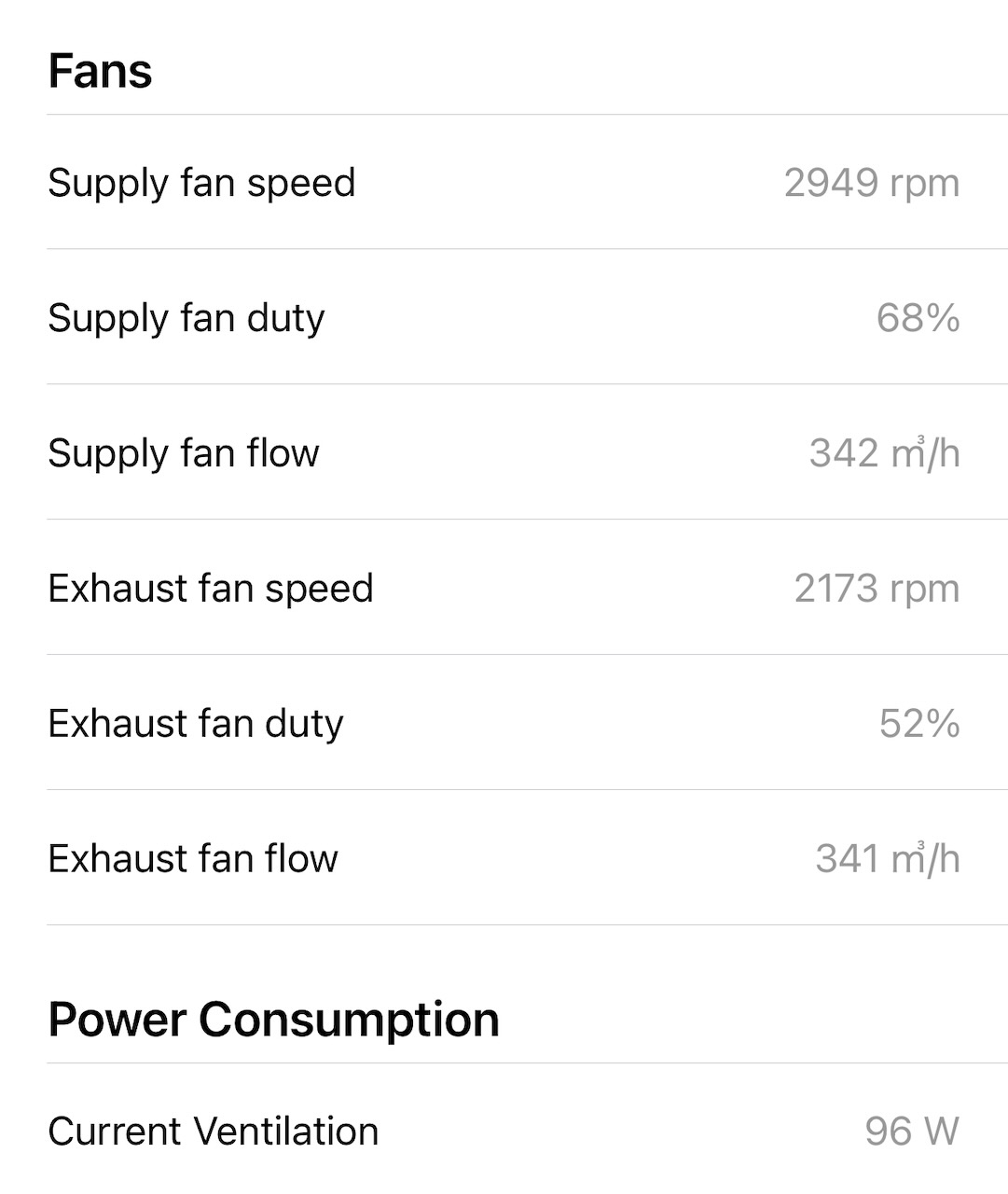

Another thing I’ve noticed in the data from the Zehnder app is that the supply side is more resistive than the exhaust side. And that’s been the case from the very beginning. The screenshot from the app shows the numbers, with the supply fan operating at 68% of its capacity while the exhaust fan is operating at 52%. The exterior grille and filter get dirtier on the side bringing in outdoor air than on the side exhausting indoor air, so it’s gotten a little worse since startup.

I really love having the extract vents the bathrooms, especially in winter. It’s been colder and drier this winter than many previous ones here in Atlanta, so using the ERV helps preserve a little of our indoor moisture. I wrote a while back that you may not need to run your bath fans in winter if you can get the humidity out of the bathroom quickly enough. And last summer I wrote an article saying that running the bath fan in summer may make your indoor humidity worse, too. I still have my bath fans on the main floor, but I didn’t install any in the basement bathrooms.

Finally, the air in the house just seems a littler fresher than it did before. There could be a little confirmation bias going on here, but I’ll keep an eye on the data from my various IAQ monitors and see if they can reduce the bias and get more confirmation.

Disclosure: Zehnder provided the ComfoAir Q600 ERV to me for no charge.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can follow Allison on LinkedIn and subscribe to Energy Vanguard’s weekly newsletter and YouTube channel.

Related Articles

A Weekend Zehnder ERV Installation Blitz

Balanced Ventilation for a Not-So-Old House

Common Problems With Cold Weather Ventilation

Comments are welcome and moderated. Your comment will appear below after approval. To control spam, we close comments after one year.

Yes it has been incredibly dry in Atlanta these past couple of weeks. I look forward to updates during the spring and summer as well as outdoor filter lifespan after pollen season.

Same! Curious to see what the rh differences are. I have seen homes with these tend toward higher humidity until they are actively dehumidifying with commercial grade dehumidifiers.

Dear Allison: Thanks for another helpful article. You (and your readers) should also read this important article about the need to sync / connect your ERV fans to your HVAC fans – to avoid pulling unfiltered air into your home:

https://www.greenbuildingadvisor.com/article/integrating-an-erv-or-hrv-into-a-forced-air-system

My wife has significant allergies, for example – and I already installed a relay to activate our Honeywell air filtration system – so it kicks on when the HVAC blower is on.

Very high tech…at high cost. Street price around $5k before installation from a quick browse. Dry bulb delta-Ts are impressive; looking forward to efficiency calculations that incorporate enthalpy.

I was curious that an appliance drawing under 100 Watts needs a 240 Volt circuit…then I read that these units support a (presumably electric resistance) air preheater.

I’m further curious to hear of ownership / operational costs – is there a pricey bespoke energy recovery media cartridge needing periodic replacement?

Your system IS showing air quality improvements, though not huge. The cost for that level of improvement is clearly a necessary consideration. Can you tell us the typical retail cost of the unit installed in your house, and separately a rough estimate of the expected installation cost (labor and materials) in say a typical/ average build 2 story 2500 sq ft colonial?

We have installed a few Zehnder units for our customers over the years, nice stuff for sure. Looking from afar at your installation, that is probably a $12K-$15K installation up here in the Boston area (maybe more considering the stages of construction). I didn’t catch if you got this system gratis from Zehnder, but they will never be more than a niche product due to cost. And niche products are expensive to repair IF you can even find someone qualified. How complex does it need to be to exchange air versus Renewaire, Venmar, etc? Just like a Tesla, cool product, but the math will never work out in your favor.

Hi Allison

some questions

how much room do does ERV take up beyond the unit for distribution manifold

could unit be located near a bedroom or adjacent closet of living area from a noise perspective

how far can distribution ducts run rule of thumb from ERV 50ft?

Alison

why did you need (3) ducts for basement bathroom .

do they run continuous at 20-25 cfm in a bathroom with a boost

if you had a finished gypsum ceiling .how far would you need to fur it down to avoid problems with joist framing. 3 1/2″ your cellar has an open ceiling

In addition to the previous comments, Allison (or someone) should run an operating cost analysis. For example:

> 96 watts for ~14 hours every day

> Loss of heating / cooling BTUs for ~14 hours every operating day, varying through the year. This should also be adjusted for the average difference between interior and exterior temps through the year for different climate regions in the USA. In short, running an ERV reduces the efficiency of your HVAC system; calculate how much.

I have the Q450 installed in a PHI EnerPhit home that was completed last December.

It’s a great piece of equipment and we’ve enjoyed it immensely.

We have the Mitsubishi Hyper-heat Mini-splits to provide heating/cooling. Winter set @ 68*F.

We’re at the border of CZ5A/4A and OAT’s can get below zero and down as low as -15*F on occasion.

On those occasions, the supply air “heater” comes on to keep the core from frosting up/freezing.

The temperature of the supply air is substantially below the in-home set temperature at the mini splits.

In your example, you show OAT of 35*F and supply air into the home at 64*F.

How do you manage the conflict of 64*F supply air being distributed throughout your home vs. the setting of say 68*F on your mini splits? Isn’t there a constant battle of who reigns supreme? Is this just a battle royal that the only resolution is to “live with it” or is there a reasonable solution? e.g. How to temper the incoming supply air to match the existing mini split set temperature, before the supply air is distributed throughout the home?

“How to temper the incoming supply air to match the existing mini split set temperature, before the supply air is distributed throughout the home?”

– The degree of tempering depends on the rated design efficiency of the core, the speed at which the air is moving through the core, and how close exterior temps are to the internal temp of the house.

I think what people lose sight on is that you always want fresh air in your house. That’s the purpose of mechanical ventilation. It’s not about saving money but improving occupant comfort and providing cleaner air.

I’m very familiar with the performance of my Zehnder Q450 and the efficiency of the core. It was installed purposefully to provide fresh air into the home. The issue is the ERV’s distribution of supply air at 5*F (or more) colder than the temperature of the home with a set internal temperature of 68*F with the Mitsubishi Hyper Heat min-splits.

Pretty cool stuff! I settled on the terms Intake, Supply, Return and Exhaust. Could it make sense in some climates to have a bypass for when the outdoor air is undesirably dry/moist? Really looking forward to the efficiency analysis!

There’s no reason for a bypass because the purpose of these systems is to distribute fresh/filtered air throughout the entire house. One can just turn the system off.

Unlike a HRV the ERV is designed to transfer some moisture. So on hot humid days the comparatively cooler dry conditioned air will pull some moisture out of the incoming warmer outdoor air as the streams move through the core of the ERV. The interesting part will be during what’s called the “shoulder season”. It’s when it’s neither too warm or too cold to require heating/cooling so there will be situations where outdoor and indoor humidity converge. My guess is that Allison will be running his minisplit or heat pump in “dehumidify mode” during these times..

Ah, I was thinking specifically of an HRV scenario, where you might still want filtration and ventilation but the temperature and moisture content of the outdoor air is preferable to what’s indoors. But I’m also thinking that the airflows required for ventilation are so much less than what’s needed for heating/cooling that it might only be part of the solution. Opening windows and doors is an obvious alternative but can only help if there’s sufficient pressure difference, and of course you miss out on the filtration.