Busting a Myth About Low-Static Ducted Mini-Splits

I like mini-split heat pumps, especially of the ducted variety. And because I don’t like to pay for a lot of excess power, I prefer to use ducted mini-splits with smaller blower motors operating at a low total external static pressure. The Mitsubishi* units we have in our office and that I have in my home now are rated by the manufacturer to operate at a total external static pressure (TESP) of 0.2 inches of water column (i.w.c.) or less.

Now, that’s a pretty low static pressure to work with. Heat pumps and air conditioners are typically designed by the manufacturer to work at a static pressure of about 0.5 i.w.c. Actual duct systems usually exceed that number, and the manufacturers have built in extra blower capacity to handle higher static pressure because they know that’s what happens in the field.

Using an air handler with a smaller motor, however, means you have to be careful with your duct design and not squander that pressure. But there’s a little myth that’s taken root among people who have some familiarity with ducted mini-splits but haven’t worked through the technical details.

The myth is this: You have to keep the ducts short when you use a low-static ducted mini-split because it doesn’t have enough oomph to move the air.

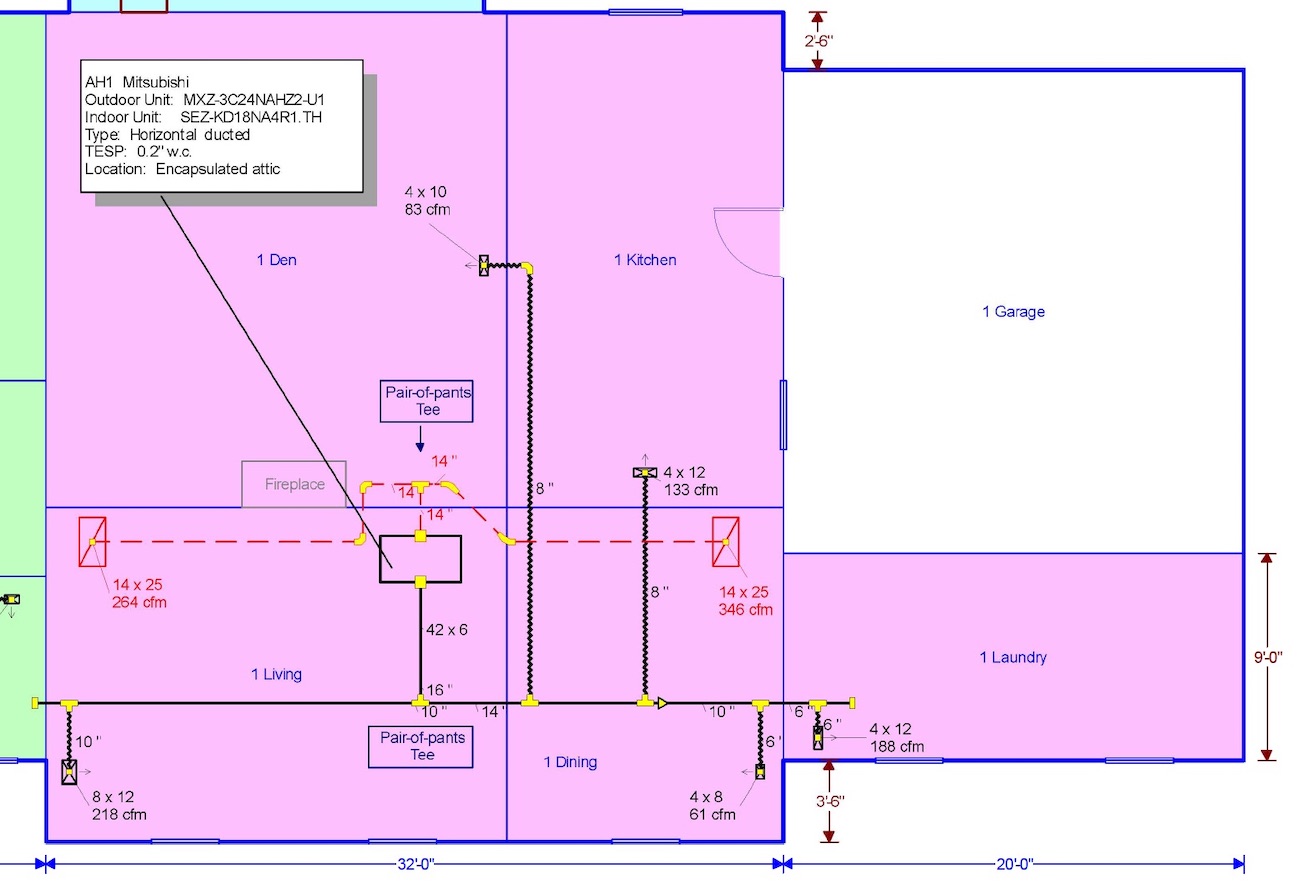

The diagram just above shows one that most people would look at and say, “Yeah, that’s a pretty short duct system. That’ll probably work just fine with a low-static unit.” And as a matter of fact, this duct system does work. It works really well. I know because it’s in our office here at Energy Vanguard. We designed it and PV Heating & Air, a local company that does great HVAC work, installed it.

The air handler we used was the Mitsubishi* SEZ-KD12, set for a total external static pressure of 0.2 i.w.c. When I measured the pressure, I found that we’re running at about half of the maximum when the air flow is at its maximum (photo below).

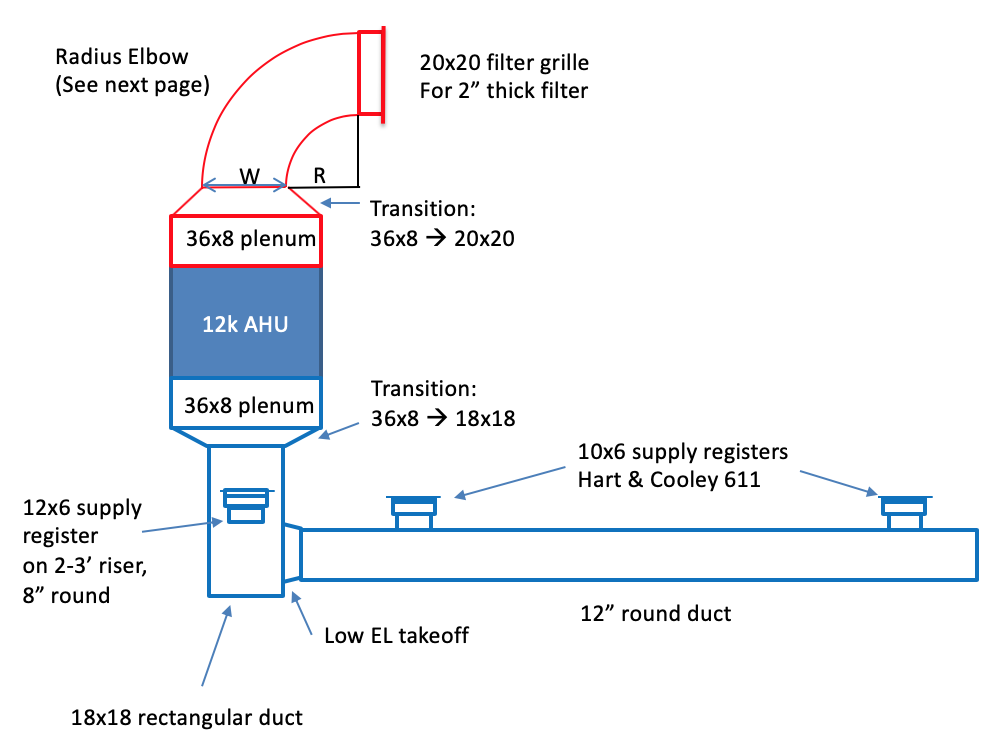

If you look at the duct diagram of our office, you’ll notice a focus on the transitions and the big radius elbow. Getting those things right helps tremendously. Below is a photo of that big elbow on the return side.

The key here wasn’t the total length of the duct system. The two things we did to make this system work so well were:

- Make the ducts larger in cross-sectional area

- Use fittings that are better for air flow (lower pressure drop)

Let me emphasize this point:

The actual length of the ductwork doesn’t matter as long as we keep the static pressure (i.e., resistance) low.

Yes, the actual length does come into play because the total pressure drop increases with longer ducts. But you may recall from my duct design series that the fittings (elbows, takeoffs, boots…) have a much bigger effect on the pressure drop (as measured by total effective length) than the straight runs of duct.

Also, the pressure drop in both the straight sections and the fittings decreases when you keep the velocity of the air in the ducts low. And that’s what embiggening the ducts does for you. (What do you mean “embiggen” isn’t a word!? It’s a perfectly cromulent word. Get outta here!)

Anyway, bigger ducts and better fittings reduce velocity and pressure drops, allowing more overall ductwork than you might imagine for a low-static ducted mini-split.

Here’s a shot of one of the returns for one of the low-static ducted units in my house. Again, we have a big radius turn there to reduce turbulence and keep the air flow rate high and the velocity low.

If you look back at the lead photo at the top of this article, you’ll see quite a lot of ductwork in that design. That’s the other low-static unit in my attic. If you believe the myth of short ducts, you might look at it and think, “That’ll never work.”

But you’d be wrong. It works really well. In fact, it’s a perfectly cromulent duct design!

Addendum (12/1/21): My focus in this article is on air flow only. There is one reason to limit the size of ducts, though, and it applies to both the length and the diameter. If ducts are in unconditioned space, the conductive losses increase with duct surface area. The ducts in our office and in my house as well as 95% of the systems we design for our clients, though, are in conditioned space. Where they belong.

2nd Addendum (10/22/23): See the article about the low-static air handlers in my house for more proof that needing to limit ductwork on low-static air handlers is just a myth.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can subscribe to Energy Vanguard’s weekly newsletter and follow him on LinkedIn.

Related Articles

The Best Velocity for Moving Air Through Ducts

The Basic Principles of Duct Design, Part 1

Not All Mini-Split Heat Pumps Are Ductless!

* Disclosure: Mitsubishi is gave us a really good deal on the equipment in the Energy Vanguard office and my home.

** Disclosure: PV Heating & Air gave us a discount on the installation.

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 38 Comments

Comments are closed.

Allison,

Allison,

I am not sure what you mean when you say that the Mitsubishi units are “rated” to operate at 0.2 iwc and that conventional units are rated at 0.5 iwc. DOE energy rating (SEER and HSPF) conditions are at 0.10 iwc for 2 ton ducted systems, 0.15 iwc for 2.5 to 3.5 ton systems, and 0.20 iwc for 4 to 5 ton systems. I will note that field studies show that most installed systems operate at higher static pressures, and the DOE rating condition is going up to 0.5 iwc in a few years. However, there is nothing to keep anyone from installing good ductwork that operates at lower static pressures for any system.

Roy, I Believe you are

Roy, I Believe you are confusing extended performance data versus AHRI ratings. AHRI ratings are used for comparison of various make some models, while extended performance data from the manufacture is used during the design process. The static pressure if you have listed are from AHRI Standard 210 240 and while those static pressures might be good for comparison usages, they don’t fit real well in real life installations. At the end of the day, using manufactures information for design is proper, using anything from AHRI for design is a poor choice.

Ed, I don’t think that I am

Ed, I don’t think that I am confusing the “ratings”, but Allison might be 😉

Ducted equipment manufacturers rate for efficiency at low static pressures as required by DOE. Most of them do design their equipment to also operate at much higher static pressures since that is typically required in actual installations. However, there is nothing wrong with using the duct design standards that Allison is promoting and thus operating at lower static pressures.

Roy, yes, you’re right, as

Roy, yes, you’re right, as usual. I was thinking about the static pressure for furnaces coupled with AC coils, which are typically rated by the manufacturer for a static pressure of 0.5 i.w.c. When I say “rated,” I’m talking about the manufacturer’s data. For example, in the product data for Carrier’s 59SC5A furnace, they have a line for the “Rated External Static Pressure (in. WC)” for heating (0.1-0.2) and cooling (0.5). Mitsubishi provides air flow charts for their SEZ low-static units for static pressures of 0.02, 0.06, 0.14, and 0.20, with the “Rated point” labeled.

The important point is that every blower has a relationship between air flow rate (in cubic feet per minute) and external static pressure (in inches of water column). The external static pressure is a measure of how much resistance is created by the duct system, filter, dampers, grilles, registers, and anything else external to the “rated” piece of air-moving equipment. When that goes up, the air flow rate goes down.

I’ll see if I can clean up the wording, though.

Hi Allison,

Hi Allison,

I design all my systems using fpm to lighten the load. I usually like to do 800 fpm for all my supplies 600 for return. I want to do my personal house with Fujitsu slim ducts that are rated for up to .33sp but the same thing comes from my supplier, they cant handle long duct runs. It makes no sense to me. At 800 fpm I need a lot of duct and transitions to get over .33. Any advice or opinion would be appreciated

Have a look at the mid or

Have a look at the mid or high static pressure units, the dimensions are really not much different and you then can use longer duct runs due to more powerful fans.

https://www.fujitsu-general.com/uk/products/split/msp-duct/lhtbp/index.html

I wish I had done this as I could have fitted the larger unit in the space and wouldn’t have needed to use larger oversized ducts to compensate for the slightly smaller footprint the low static pressure unit takes up.

As you see from the links posted there is not much difference…

https://www.fujitsu-general.com/th/en/products/split/lsp-duct/index.html

Bruce

Bruce

As a rep for a ductless manufacturer, the reason we make the short run comment is that, disappointingly, a lot of installers take a 9K low static unit, connect it to a 3′ plenum and then run 6″ flex to 4 or 5 five locations up to 15′ away and can’t understand why it doesn’t work in the end. Ductless systems seem to end up in the hands of a lot of the wrong type of installer. This article by Allison is great, but the installers I have met would blankly stare off into the distance if they had to use the size of ducts required to get good performance.

Manufacturer’s need to make

Manufacturer’s need to make their units more idiot proof. For example, a big red warning light labeled “low flow – improperly installed”.

Manufacturers could put an

Manufacturers could put an “improperly installed” light on units, and for higher-end units, it probably wouldn’t cost much more since much of the instrumentation is already there. However, many (most?) installers don’t want to know that their duct work is undersized after installation is complete, so they would not want this feature even if it were free. It would be good for the homeowner, but the homeowner doesn’t usually select the specific equipment and options–the installer does. A qualified third-party inspector or system commissioner might be better yet, but no one wants to pay for that either.

What size ducts would you

What size ducts would you recommend then? 250mm ductwork supplying 2 rooms with an outlet to each room.

You wrote, “because I like

You wrote, “because I like things to be as efficient as possible, I prefer to use ducted mini-splits…” Just to be clear, are you implying that ducted mini-splits are more efficient than ductless?

Tim, good question. You left

Tim, good question. You left off the relevant part of that quote, though. The full sentence is important here:

“And because I like things to be as efficient as possible, I prefer to use ducted mini-splits rated for a low total external static pressure.“

Ducted mini-splits come in different flavors. You can get them rated to operate at low static pressures, like Mitsubishi’s SEZ air handlers, or at higher static pressures, like Mitsubishi’s PEAD air handlers. But pushing air against a higher static pressure comes at a cost.

Put another way, my question

Put another way, my question was really “Are ducted mini-splits more efficient than ductless?”

No, Tim, ductless units are

No, Tim, ductless units are more efficient because they don’t have to push air through ducts. But when you use a ducted unit and keep the static pressure really low, the difference isn’t that big.

@Tim, ducted mini’s top out

@Tim, ducted mini’s top out at about 17-18 SEER, whereas the smallest and most efficient ductless mini’s have SEER ratings into the 20’s, with a couple close to 30.

David, here’s a ductless at

David, here’s a ductless at 42 SEER: https://www.carrier.com/residential/en/us/products/ductless-systems/38mpra/

David, SEER ratings are a

David, SEER ratings are a flawed way of comparing efficiency between different types of systems. I think the actual difference between the efficiency of a ducted, variable capacity system and a ductless, variable capacity system isn’t as big as those numbers imply, especially when you keep the static pressure really low.

Allison wrote: “SEER ratings

Allison wrote: “SEER ratings are a flawed way of comparing efficiency between different types of systems.”

No argument from me on that. Studies have demonstrated specific weaknesses in the SEER rating procedure. SEER is best used when comparing like-to-like, especially among single stage units for which SEER was originally developed. I think comparison among like-kind multi-stage is also useful, even if not particularly accurate.

You wrote: “I think the actual difference between the efficiency of a ducted, variable capacity system and a ductless, variable capacity system isn’t as big as those numbers imply, especially when you keep the static pressure really low.”

I haven’t seen any study that looks at ducted vs ductless, but it doesn’t make sense that you can move the needle much by simply operating at a lower static. Even with conventional equipment, the blower’s contribution to overall energy consumption isn’t large enough to change SEER more than a point or so by varying ESP.

I think you’re putting more emphasis on ESP than warranted, at least on the question about ducted vs ductless ratings. And unless you can point to a study that scrutinizes ducted vs ductless SEER ratings, we’re left with two things: the official ratings, and our opinions 🙂 And my opinion is that the differences between ducted and ductless SEER ratings look suspicious, but I don’t have enough information to go beyond that.

Kudos for the quote from the

Kudos for the quote from the Simpsons. I use that regularly. Your articles are always a breath of fresh air.

Thanks, Kenneth! I watched

Thanks, Kenneth! I watched The Simpsons a lot back in the ’90s.

You really did three things

You really did three things to make these low-static systems work. Your photos and drawings reference the third key thing, but the text does not. You have to select a low pressure drop filter. There are plenty of filters out there (1-inch pleated, etc) that would gobble up all of the available 0.2 inches of static, and more if the filter area is too small.

Steve, yes, you’re right.

Steve, yes, you’re right. The filter design is critical. But it’s not so much the type of filter as the size. We design for a face velocity across the filter of 200 feet per minute (fpm) or less. In our office system, we’re at about 140 fpm, and the filters on my home systems have face velocities less than 120 fpm. With that low a face velocity, I can use a 2″ deep MERV-13 pleated filter with very little pressure drop.

Here’s an article I wrote earlier this year on that topic:

The Path to Low Pressure Drop Across a High-MERV Filter

Do you design the ductwork

Do you design the ductwork with your filter pressure drop as clean or dirty? Or somewhere in between and consider that the airflow changes slightly through the life of the filter?

Lee, that’s a great question.

Lee, that’s a great question. Read my reply to Steve in the previous comment and you’ll see that we design for very low face velocity at the filter, which ensures a very low pressure drop. Even when the filter is too nasty looking to leave in the system, the pressure drop is still low. In that case, clean or dirty doesn’t matter as much, as long as the filter does get changed before it starts affecting air flow.

Another advantage of using

Another advantage of using larger face area filters for the same airflow rate is that you can go longer between filter changes for the same increase in pressure drop. Not only does this save time, but it saves filter replacement cost too. Have you noticed that the cost of most air filters is a function of the filter efficiency and brand name, but is not a function of size? You can buy a 24″x24″ filter for the same price as 12″x12″ filter and it will have 1/4th the face velocity with 1/16th the pressure drop and last at least 4 times longer. Unfortunately for me, I am stuck with 14″x14″ ceiling returns, so I buy 14″x28″ filters and cut them in half, thus effectively buying filters at half price.

Roy, I’ve bought the double

Roy, I’ve bought the double size filters too.

Allison, I like the filter grille installation also, with a taped-in MERV13 cleaning ductwork will probably never be needed.

Great read and explanation as

Great read and explanation as always Allison. Even with some of the tough critics on here, your knowledge speaks volumes as you power through and persevere with your responses! Thank you for this article! If I’m not mistaken you’re a guest speaker at the live event at Kalos just before AHR is that correct?

Thanks, Kenneth! Yes, I’m

Thanks, Kenneth! Yes, I’m doing a session on ducts at Bryan Orr’s event right before the AHR Expo and ASHRAE conference. I think my session is at 8 am on Saturday, 1 February.

Great, I’ve already got my

Great, I’ve already got my ticket, can’t wait to see you there!

Allison worte: “…because I

Allison worte: “…because I like things to be as efficient as possible, I prefer to use ducted mini-splits rated for a low total external static pressure.”

I think you’re reading too much into the differences between ducted mini’s in terms of their maximum ESP. Just because Fujitsu’s ducted mini, for example, can handle 0.35 ESP, doesn’t mean it’s less efficient than the Mitsubishi, assuming you operate both at 0.20 IWC. In fact, it’s possible the Fujitsu blower draws less energy at 0.20 since that’s in the middle of its blower curve, whereas @ 0.20 the Mitsubishi is at the top of its curve. There’s simply not enough information to make a determination either way.

Yes, you’re right, David.

Yes, you’re right, David. That should say “operating at,” not “rated for.” Thanks.

I posted this at GBA, but

I posted this at GBA, but this might be a more interested audience:

So one thing that often get captured in the discussion of available static is how many CFM need to be moved. The static pressure drop in given duct is proportional to the CFM squared. This is important to think about as higher static units often also move more CFM.

To compare available pressures of two units, you should really look at available static per CFM squared. I attached a table where I calculated this for a number of common mini split systems. I multiply the static/cfm^2 by 1,000,000 to get it to a reasonable number.

I find this is not the most intuitive way to think about things, so I also calculate the minimum duct size at 100ft long that would work with the available static and Max CFM.

This is done by solving for D in the following equation:

deltaP/100ft = 2.56(1/D)^1.18*(V/1000)1.8 where V= CFM/(D/12)^2*3.1459/4

deltaP = static available

CFM = max cfm

D = duct diameter

https://s3.amazonaws.com/greenbuildingadvisor.s3.tauntoncloud.com/app/uploads/2019/12/12153954/Available-Static.pdf

Still working out the best way to describe all this, but CFM is just as important as available static. Thinking this way makes it clear that you can often replace traditional high CFM air handlers with low static minisplits without much duct modifications.

@Matt, it’s not clear exactly

@Matt, it’s not clear exactly how or for what purpose you intend to use this method of comparison, but keep in mind that the static/CFM ratio will vary quite a bit for a given air handler depending on the actual static and speed setting it operates at. I guess what I’m saying is that the static/CFM ratio at the unit’s maximum airflow and static rating isn’t necessarily a good proxy for the operating point for a given application. A designer needs to consider the later.

My thought was to figure out

My thought was to figure out some way to communicate that designing for ducted minisplits is not really any more challenging than designing for traditional air handlers.

I was trying to emphasize that available static is meaningless without the context of how many CFM is needed. Over at GBA, some people have been very excited about the fujitsu mid static slim ducts thinking the .8″ static is a huge advantage over the .35″. Some of the mid static units move a lot more air though, so the duct design advantage is a lot less than it appears at a first pass.

In residential retrofit applications, it seems like there is a marketing opportunity to go in, measure statics on the existing oversized air handler or furnace and use that information to figure out what equipment will work on the existing duct work.

As I think you are getting at, when doing this sort of approach you should be designing to less than the total available static. Maybe something like 70% of the available would leave enough margin. They still need to get the sizing right, but this will generally be a better approach than multisplit, head in every room.

I am not an HVAC pro, so I was a curious to see how this line of thinking landed with the highly educated crowd here. Most of the HVAC installers I have talked to are not even considering ducted options unless specified by a 3rd party. All the work they are specifying is cassettes for a room or oversized multisplits.

I think that we compare

I think that we compare ducted vs. ductless on the wrong basis. From my experience and observations, a ductless unit can only do a good job of conditioning one room, and even that is questionable. All of the air supply and return is from the same location, so you need high supply air velocities to get the air distributed throughout the room without short circuiting to the return. Since the return air is typically under the supply on wall units, this can often work in cooling, but is less likely to work well in heating due to buoyancy effects. But for any room bigger than a bathroom, I would rather have multiple supply registers that are located away from the return register or doorway in order to get good air distribution. This requires ducts.

If you have any existing ducted system and want to replace it, you should surely install a smaller unit if your past experience with the existing unit showed that it was over sized. But beyond that, I would seriously consider installing a multi-capacity unit since it will operate most of the time at reduced airflow rate, thus you will get the advantages of lower static pressure with the existing ducts. It will also be quieter most of the time.

Hello Allison,

Hello Allison,

Great article as always!

I am sure that the tightness of the ducts plays a large role in the pressure drop along the length of the ducts. Was there any leakage testing on these ducts?

> rated for a maximum of 0.2

> rated for a maximum of 0.2 i.w.c.

You achieved ~1/2 of this. A very rough estimate is that this saves about $35/year in fan energy. Seems OK as long as larger ducts don’t cause installation, aesthetic, variable balance or latent removal issues.

Hi Allison,

Hi Allison,

I am from the Uk and I have low static ducted units in my home. Downstairs there are 2 units that literally have a return grill and a supply grill, they are boxed in but there is no ductwork so there is literally maybe 10PA of static pressure if that but probably closer to 0. THe units are a 1200btu and a 9000btu.

The upstairs units however are truly ducted as they are installed in the loft space. Both are 9000btu. The master bedroom unit has 1 x round supply outlet and 1 x round return grill and for this room a very short duct run. The duct is 250mm and approx total is 1 meter duct run on each side of the coil. This unit works equally well in heating or cooling but I have had to boost the static pressure of the fan to say 30PA.

The 2nd unit though serves two rooms (spare bedroom & bathroom), I use the same style and size return and supply grills. The supply plenum off the front of the unit has two outlets (both 250mm round). There is a mixture of solid duct and small amount of flexi duct, totally duct run for this room is approx. 4m. This unit works well in cooling as cold air falls and spreads across the ceiling. The supply grills are these… https://www.koolair.com/en/catalogue/difusores-de-geometria-variable-de-palas-dvp/ and contain a wax element that responds to the supply air temp. In cooling the blades flatten out to throw the air across the ceiling but in heating the blades point downwards to push the warm air towards the floor (so no having to adjust the angles of the outlets as it does it automatically)

However the airflow from this 2nd unit seems to be weak. If I close off the bathroom supply damper fully (normally open say 15%) then this unit performs as well as the master bedroom unit and the air can really be felt. The supply duct for the spare bedroom outlet doesn’t have a damper so it is always fully open as this rooms needs as much flow as it can.

The airflow just doesn’t seem to push down to the floor enough. I have adjusted the static pressure for the fan to the full maximum 50PA but this just creates lots of fan noise and doesn’t seem to do that much.

It seems as if the fan cannot pressurise the duct enough to produce enough velocity for the airflow and in turn the airflow just seems to come out at a slow speed, again fine in cooling but hot air naturally wanting to rise does not help heat the room as well. Ceiling area gets very hot but floor area remains cold.

Would fitting a damper on the other supply duct for the spare bedroom and adjusting this to say 85% open and the bathroom being at 15% open balance it out? Or would this just increase the pressure behind the damper and after the damper the pressure would just reduce and it would be the same? Currently the bathroom only needs a small amount of airflow due to size, but the air flow is very weak as well. Again not sure if fitting dampers on both outlets would achieve anything?

I can’t help thinking that I should have gone for 200mm ducting and supply outlets instead of 250mm. Although I wanted to reduce the static pressure as much as possible and when I installed the system I wanted to reuse some 250mm outlets that I had.

Please help…