Buried Ducts Risk Condensation in Humid Climates

Water vapor from the air condenses on air conditioning ducts in humid climates. It’s as normal as poorly insulated bonus rooms making occupants uncomfortable or cigarettes causing lung cancer†. Condensation on ducts is most common in crawl spaces and basements, where the air is more likely to have a higher dew point. But it also happens in conditioned space and occasionally even in attics. That’s why you have to be careful about burying ducts in attic insulation in humid climates, especially in coastal areas. Since the 2018 International Residential Code (IRC) and International Energy Conservation Code (IECC) specify how to get away with burying ducts in humid climates, let’s take a closer look.

The problem with buried ducts

The potential for duct condensation is a humid climate, cooling season problem. My friends out west regularly bury their ducts in air permeable insulation (e.g., fiberglass or cellulose) and don’t worry about condensation. The air in the ducts may be as low as 55° F, but their summer dew points are usually below 50° F. There’s just not enough water vapor to condense.

In humid climates, that’s not the case. The photo above shows condensation on a duct in a crawl space in Hilton Head, South Carolina. Outdoor dew points can hit 80° F in the summer there and average in the mid 70s. With 55° F air moving through supply ducts, you’ve got to have well-installed insulation on a duct with significant R-value to keep the surface temperature above the dew point.

When that supply duct is in a vented crawl space, it’s really hard to keep that surface temperature above the dew point because the temperature down there is already close to the dew point. When you have a supply duct above the ceiling insulation in a vented attic, however, the surrounding air temperature is higher than ambient in summer. Thus, the surface temperature of that duct most likely will be above dew point. That means no condensation.

But if you bury that supply duct in fiberglass or cellulose insulation, which allow attic air to reach the duct’s surface, all bets are off. As you pile more and more insulation on top of the duct, the surface temperature of the insulation jacket (a vapor barrier) drops.

Since attic air permeates into the ceiling insulation, the dew point within is presumably the same as in the attic space above the insulation. Further, if the attic is vented, the dew point of that attic air should be about the same as the outdoor air. Right? The result is a duct surface temperature that’s below the dew point of the air in the ceiling insulation, and that means condensation.

As it turns out, ducts buried in ceiling insulation in humid climates do sometimes have condensation problems. If you live in a humid climate, especially locations near the Gulf of Mexico or Atlantic Ocean, you may now have the reason for those mysterious water spots on your ceiling. Maybe. They could also be from roof leaks.

What the research says about buried ducts

Well, that sure sounds reasonable, but is it confirmed by what actually happens and by research? A Building America paper from 2016 titled, Compact Buried Ducts in a Hot-Humid Climate House (pdf) has an answer for us. (Notice I used “an answer” there, not “the answer.”) Home Innovation Research Labs did a study on a buried duct system in a home in Lady’s Island, South Carolina (a bit north of Hilton Head). One of the main questions they wanted to answer was:

What is the minimum level of duct insulation to prevent condensation at the outer jacket of buried ducts in hot-humid and mixed-humid climates?

So they set up this model home with a buried duct system and installed a lot of sensors. The ducts had the standard R-8 insulation you find on attic ducts but then were buried in R-30 ceiling insulation. Here’s what they found:

- No condensation on the ducts

- Colder air delivered to the house

- Simulated simple payback of 3.1 years & simple return on investment of 32%

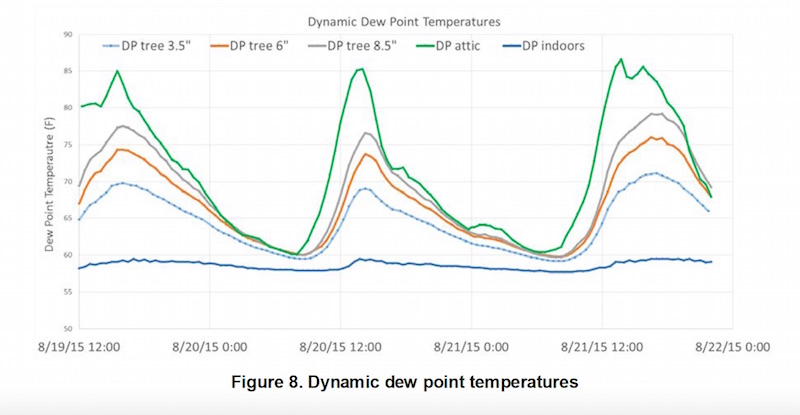

Another really interesting thing they found was that the assumption I mentioned in the last section doesn’t seem to be warranted. Remember when I said that the dew point within the attic insulation is presumed to be the same as the dew point in the attic above the insulation? Well, that’s not what they found. The graph below shows two things: (1) The dew goes through daily cycles (similar to what I found in a spray foam attic in Atlanta), and (2) the dew point peaks decrease as you descend into the ceiling insulation and get closer to the drywall. This is good to know.

Now, this is all good stuff, but it’s just a start. For one thing, the report is based on only one month’s data (August 2015). For another, they set this house up specifically as a test house and thus made sure to get as close as they could to their design conditions. (They did miss on duct leakage, though. Their goal was 1 cfm25/100 square feet of conditioned floor area and they hit 4 cfm25/100 square feet.)

It may well turn out that R-8 duct insulation is good enough for general use, but I’m not convinced yet. Neither, as it turns out, is the International Code Council. In my next article, I’ll explain the new buried duct requirements that make their debut in the 2018 IRC and IECC. Here’s one little teaser, though: The codes decided R-8 was good enough for most of the country but some climate zones require more.

Read part 2:

Buried Ducts Allowed in 2018 Building Code

Related Articles

A Line in the Sand — The Dew Point Duct Duel

7 Tips & Tricks for Blower Door and Duct Leakage Testing

Humidity in a Spray Foam Attic

Home Performance Flaw #212: Ducts Placed High in the Attic

Footnote

† Both of my parents were smokers. Both died of lung cancer.

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 32 Comments

Comments are closed.

This problem is not limited

This problem is not limited to the ducts alone. I worked with another builder several years ago that built a home in Wilmington NC that was directly on a creek near the Intracoastal Waterway. He was using a vented crawlspace with the air handler in the crawlspace along with all of the ducting. In August is was like a tropical rain forest under there. Not only were the handler and all of ducts dripping water as shown in your photo, but the entire underside of floor above the insulation was dripping like you had sprayed it with a garden hose. With the AC on, the floor above was very cool and way below dew point. Mold had started already. We had to remove all of the insulation and seal the crawl space. Then we brought in a mold remediation company to treat the underside of the floor and the joists. The owner also had us install several dehumidifiers to ensure there would be no further problems with humidity. It was extremely fortunate that we caught it when we did before the owner had moved in. It is still amazing to me how fast we are moving away from vented attics and crawl spaces in humid climates.

I’ve seen things like that,

I’ve seen things like that, too, Thomas. Vented crawl spaces in coastal climates are difficult beasts to control.

I’m glad you bring this up,

I’m glad you bring this up, Allison. Plain old duct insulation still makes me nervous. Even Cleveland has relatively high dew points, we are usually in the mid-60s in summer with plenty of spikes into the low-70s. I know the initial research on deeply buried ducts looks ok, but I share your trepidation.

We did one project in 2015 where we installed a new duct system, part of it was in the attic. We coated it with 1-2″ of closed cell, then buried it under cellulose. No issues so far. http://energysmartohio.com/case_studies/1900-net-zero-ready/

I didn’t bring up the topic

I didn’t bring up the topic of buried, encapsulated ducts, Nate, but I think that’s a safer way to do this. Building America has done work on that as well.

Couldn’t the air inside the

Couldn’t the air inside the ducts also play a part in the condensation issues. Running systems at lower air temps can also, I believe, cause condensation issues on the surface of the duct insulation. From poor design, set-up of new systems or an attempt to squeeze more humidity out of the conditioned space wouldn’t the lower temps contribute to condensation where it might not otherwise happen?

Bob, yes, if the supply air

Bob, yes, if the supply air temperatures are lower than they should be, that will increase the likelihood of condensation on the ducts. Typically, supply air for an air conditioner should be between 55° F and 60° F to cool the house. If the house has a restrictive duct system with low air flow (Many do!), that causes the air temperature to be lower. Same with a dirty filter. Fix the air flow problem and get the temperature in the right range and condensation problems sometimes disappear.

For many energy efficient

For many energy efficient homes with a perfectly sized AC or HP, I still recommend supplemental (stand-alone) dehumidification. I am getting better at predicting which homes will have little AC run time and thus get into some high humidity situations. But I get a little push back from those who do not agree with the expense of a dehumidifier and feel a variable speed AC or HP will take care of the humidity since they have special dehumidification modes. Slowing the fan, coordinating compressor speed, monitoring output temps to keep the coil near but never freezing and when you read the brochure… wow! Smart dehumidification. I don’t like it. In a home that is already too moist, you now have very cold air temps, the supply registers are rusting and thanks to this blog, you now know what is going on under the covers. (Insulation covers, that is.)

A properly designed system

A properly designed system with variable capacity equipment can improve humidity control, but I agree this stuff is oversold. You can still have a humidity load when there’s no sensible cooling load. The best way to address that is to seal the envelope and avoid over-ventilating. In most cases, supplemental dehumidification is an expensive band-aid.

I have measured humidity

I have measured humidity within a vented attic, and been surprised to find it reported significantly lower dew point than outdoors. Maybe 5 degrees F. Looking for a theory why.

Roof pitch is steep, leading to greater volume inside the attic. There is radiant barrier and 1:125 passive ventilation, in keeping with some traditional wisdom. It seems to work very well in terms of energy efficiency. Could the wood, especially warm/hot roof decking, be absorbing enough moisture to account for this? Have not ruled out measurement error, but don’t think so.

Thank you.

Mark, do your data show the

Mark, do your data show the attic dew point staying below the outdoor point all through the day? Does it cycle as in the graph shown in this article? What kind of insulation do you have?

Yes, a lot of materials in the attic are hygroscopic, which means they can adsorb water vapor. Wood definitely is. Cellulose insulation is, too. What the data above and the data from the spray foam attic article I wrote last year both show is a daily cycling of dew point indicating adsorption and release of water vapor. I imagine your attic does that, too, but it would be nice to have confirmation if you have the data.

Yes the data shows dew point

Yes the data shows dew point lower than ambient all through the day. The insulation is fiberglass on the floor and not much of it — was earlier on my agenda to improve that, but other improvements have been sufficiently successful that may not get done.

Suspect the daily solar cycle may result in some kind of engine which moves humidity.

If I were ever to build a new house, would do several things differently. Ductwork inside would be good, of course. Sealing of the envelope, including the ceiling-attic interface. The ventilated attic design has many decades of experience and out of conservatism I would try to optimize that — so much research is yet to be finished with sealed and conditioned attic in a hot-humid climate. Thank you.

I would add supply duct

I would add supply duct leakage into your attic dew point trending as a large factor, provided your supply ducts are in the attic. That and a less than airtight plane between interior ceiling and attic floor. Average Texas stick built home has plenty of thermal bypasses into attics that ar concurrent with notable air leakage between house interior and attic spaces.

This dialog was useful this

This dialog was useful this weekend. I have a personal case study from my own home, built 1979 and I moved in 2014. It’s been a fixer upper on several fronts but I may have discovered something about lack of low eave ventilation contributing to condensation on ductwork. I have a 2 story with the full length of the upper floor supplied by a single air handler (split system). It’s a long run from source to end 70’) with all supply and return on the attic. The exterior has exposed rafters in the front and sealed soffit in the back with 4 high gable louvers for attic ventilation. In the 5 years living here, I knew we had inefficient duct design (high energy bills) but it didn’t cause any visible problems. In repairing some fascia recently, I thought it would be a good time to add soffit venting since IRC and traditional practice states they should be there. I started out cutting in slots for 16’ of 2” aluminum vent from Lowe’s at an area I could reach with plans to extend over next few weekends. It seemed like a good plan.

However, within the past few weeks since cutting in the vents, our ductwork above our upstairs playroom (center of house) started dropping water intermittently. And in addition, the ceiling of the upstairs bathroom became covered with mildew. So this past weekend I crawled into the tight attic (it’s a scissor vaulted ceiling) and that’s when I discovered the condensation on various sections of the ducts that were laid across the ceiling joists. Some had torn insulation, or lacked sealed joints, or straps pinching, all things discussed in this blog. Most had blown cellulose up against the bottom of the duct (nothing buried). And while removing mildewed popcorn ceiling from the bathroom is relatively easy and inexpensive for. DIYer like me, the thought of rewrapping or replacing ductwork in this tight space was way out of my abilities and budget. So I started thinking about what changed recently and all I could come up with was adding the soffit vents. Being in hot humid Memphis in summer, I care to the conclusion that I allowed moist air to enter the lower strata of the attic and have access to the flawed ductwork as well as likely over saturating the attic preventing my upstairs shower steam from leaking as it done previously and lingering below the ceiling instead (we had a 70 cfm fan for a 65 sf bathroom). Whereas previously the attic was slightly positively pressured (duct leakage) and any moist air was limited to the upper strata. Other research led to the reminding me that water vapor is h2o and is lighter than both O2 and N2 (bulk of the atmosphere).

So today I removed the vents and sealed the soffit back up, hoping I’m right. The case study continues.

Allison, We have been

Allison, We have been intentionally insulating ducts since we changed to Fiberglass way back around 1979. Duct Coverage up to 36″ as measured from attic floor is routine for us as we have zero problems (reported) in the (ALOT) Arkansas, Louisiana, Oklahoma, Texas region.

can I cover the flex

can I cover the flex insulated duct with 18 inches of blown fiberglass without having to worry about water appearing on the ceilings?

Hi Donald, ceiling

Hi Donald, ceiling condensation depends on how much insulation (or separation) there is between the ceiling and the cold air in the duct, not how much insulation you pile on top.

You didn’t mention where you live but in general, flex that runs perpendicular to the joists isn’t close enough to the ceiling to cause condensation as long as it’s properly supported to avoid sags between joists. The combination of the blown-in below the duct and and duct insulation itself is enough to prevent duct from cooling the ceiling. Likewise with ducts running parallel to joists as long as they’re supported above the joist tops.

OTOH, laying even an R8 duct directly on the ceiling can be risky, depending on climate zone, indoor dew point and temperature.

The reason you want to pile more insulation on top of buried ducts is to compensate for the insulation that the duct displaces and to further insulate the duct from attic heat gain (or loss).

yes, I have 2×12 ceiling

yes, I have 2×12 ceiling joists with 18 inches of blown fiberglass insulation above the ceiling, and the flex ducts rest on the fiberglass insulation. I live in Pineville, LA. I can feel hot air in the summer when the AC first starts blowing, and the opposite in the winter. I was contemplating to cover the ducts with blown insulation. Suggestion or input welcome.

With 2×12 joists, I don’t see

With 2×12 joists, I don’t see how it would be practical to fully bury the ducts, since some are bound to traverse the joists. You’d have to dig out enough of the blown-in to drop the ducts to the top of the joists. At that point, your existing insulation would only come up halfway on larger ducts. You’d need to construct dams out of corrugated cardboard to hold additional insulation above and around the sides of the ducts to neutralize the heat gain. I’ve send that done but it’s a LOT easier said than done!

As noted before, you want to avoid dropping parallel ducts running between the joists onto the ceiling, except as required to connect to ceiling boots.

You might want to consider encapsulating your attic with spray foam applied to the underside of the roof deck.

Don, have you had experience

Don, have you had experience in spray foaming the supply lines from the plenum to the vent penetration through the ceiling, creating completely sealed ductwork? Attic encapsulation is not an option for me, but I was wanting a way to save life of my AC units in 120 degree attic – this was the best option I could find.

1) The 1 CFM25/100. Was it

1) The 1 CFM25/100. Was it post construction including an air handler or duct only with the supply and return added? AHRI allows an air handler case to leak 60 cfm25.

2) I have had improperly sloped B-Vent cause condensation issues and interesting IR images of the ceiling.

Whenever there’s risk of

Whenever there’s risk of condensation on supply ducts, the end-to-end integrity of the vapor barrier (typically a foil wrapper on the insulation) is just as important as the R-value.

When burying ducts in a humid climate, condensation risk is highest if the duct is in contact with the ceiling drywall. I believe R-8 would be sufficient in humid climates if supply lines are supported just above the joist level. But this is difficult to achieve with run-outs parallel to the joists.

As an aside, supply ducts inside the thermal boundary (especially encapsulated attics/crawls) are still at high risk for condensation in humid climates. It all depends on supply temperature and (peak) ambient humidity. These factors can be mitigated by design, but the safest approach is to minimally insulate interior supply ducts.

Interestingly, neither the IMC or IRC require insulation on interior ducts, but a senior code official with N.Carolina Dept of Insurance once told me, if duct sweats and causes damage, the HVAC contractor owns it.

we are having condensation on

we are having condensation on the room registers in the house we had a new heat pump installed in June 2017 had always had ac with no problem and the dirt under the coil is damp and the smell is being drawn into the house?

@Maxine, condensation on the

@Maxine, condensation on the grille is an indication that the relative humidity is too high inside your home and/or your system’s airflow is too low, or possibly both.

Excess RH is typically caused by outside air leaking through walls, windows, & ceilings; an oversized air conditioner; leaks in return ducts; and/or inadequate exhaust in bathrooms, kitchen, laundry.

Low airflow is typically caused by undersized or restricted ducts, a dirty air filter, or an incorrect blower setting.

The dirt under your coil is damp because that area (the condensate pan) is naturally wet. So the problem is not the moisture but the dirt.

A dirty coil and condensate pan is an indication of inadequate filtration. Do NOT use those cheap fiberglass air filters. Pleated media filters do a much better job keeping dust from contaminating your blower and coil. You should have your coil and pan cleaned immediately by a qualified HVAC technician.

BTW, if your filter(s) are located at the return grille (as opposed to the blower cabinet), a dirty coil/pan could also be caused by return duct leaks that allow air to bypass the filter.

Bottom line, your system is in dire need of professional service.

@Maxine I’d only recommend

@Maxine I’d only recommend the pleated filters IF your return is properly sized. If you have someone check the system, have them make sure you have enough filter area or you’ll compound the problem.

Questions – based on this

Questions – based on this information, when looking at replacing old/leaking ducts in high humidity, unconditioned attic spaces, could ducts with higher than R8 rating cause increased condensation risk? In southern Alabama with a vented attic what R factor would be too much?

@Mark, more R-value is better

@Mark, more R-value is better, both in terms of duct losses and mitigating condensation. The main thing is to have some insulation between the ceiling and the duct, and the vapor barrier on the duct must be continuous. If an uninsulated duct (or even R4 duct) is in contact with the ceiling, condensation is likely.

Thanks for this article. Here

Thanks for this article. Here in DC, we get long stretches of humidity, and last summer/fall the air handler in the (mostly-ventilated) attic, and the six vents and registers that extend from the handler to the rooms in the second floor, were sources of damaging amounts of condensation. During that season, the attic was only ventilated by two gable vents that did not move sufficient air. I have since had a ridge vent installed, and plan to have soffit vents installed as well, since sealing and treating the attic was not an option.

In talking with an architect, their sense is that no matter how good the ventilation in the attic is, the condensation will be an issue until the ducts have better insulation. This article was helpful to plan that. I feel confident that better insulation and ventilation combined will ameliorate the upsetting amount of condensation that I experienced last year, but have to keep a close eye on it… and get working!

Peter, your architect is

Peter, your architect is right. The amount of attic ventilation is mostly irrelevant to the condensation on the ducts in an unconditioned attic. In fact, in a humid climate, the more attic ventilation you have, the more moisture is available for condensation on cold ducts. Here’ an article that explains the problem with humidity:

Two Rules for Preventing Humidity Damage

https://energyvanguard.com/blog/two-rules-preventing-humidity-damage

I have ductwork in an

I have ductwork in an unconditioned attic that has large “gables” at each end of the house. About 2,400 sq ft of attic space. I have rigid ducts that are from possibly the early 90s. I have noticed 2 spots where condensation has formed and dripped onto the ceiling causing stains on the sheetrock. Is there any benefit to leaving the existing duct insulation on and wrapping new over it? Or should I remove the existing and put R-8 over the ducts.

I have a small condo in

I have a small condo in Oceanside, CA and it’s hot to 90-100 degrees inside on occasion in the summer. My roof is hit from all angles . I am installing R-38 attic insulation and have so far exposed pipes wrapped in insulation near my kitchen and out to the sunroom area. Ive seen nice exposed pipes without insulation for heat and ac. Are there any pitfalls that you could share with me?

I haven’t contracted for AC yet but am considering a 1.5 -2 ton unit for a 1067sq’ single level condo. What do you recommend?

And where could I find a sheet metal fabricator to make the.Cylinders in a brushed nickel without all those seams?

Thank you.

Is the installation of fans

Is the installation of fans supported from the roof with closure gurds ever a good idea to help control condensation in attics- The though is and I have tried this on local condensation issues at Dx coil location is that if the air moves it’s difficult to get t dew point to cause condensation as the air that repaces the air displaced by the fan is at a higher temp and a lower RH.

@Charles, moving air across a

@Charles, moving air across a cold surface will indeed reduce the potential for condensation (there are actually a couple of reasons for that, Google ‘air film u-value’). However, I would argue that a power attic ventilator is a dumb way to accomplish that.

Far easier would be to simply insulate the Dx coil cabinet and other cold exposed surfaces associated with the coil. The insulation needs to also provide a vapor barrier (typically foil faced insulation with seams taped with foil backed tape). Moving air across cold surfaces in a hot attic will significantly reduce the A/C’s efficiency by increasing heat transfer to the cabinet, coil and supply air, and even still may not be sufficient to prevent condensation when dew point is high.

BTW, power attic ventilators are bad news for other reasons. See Allison’s previous article on this topic (and other articles linked at the end): https://bit.ly/3kGtSiN