My Low Pressure-Drop, MERV-13 Filters

Filtration is on the minds of a lot of people lately. Because of the coronavirus pandemic, most of us would prefer not to breathe in air that contains any hint of the SARS-COV-2 virus that’s been spreading the illness known as COVID-19. Wearing a mask when going out in public is standard. Having clean air at home is good, too, and good filtration in your home’s HVAC system can help, too. I had the HVAC system replaced at my home last November and recently spilled the beans about how I undersized the new Mitsubishi* ducted mini-split heat pump. Here I’ll report on our filtration.

Details of our filters

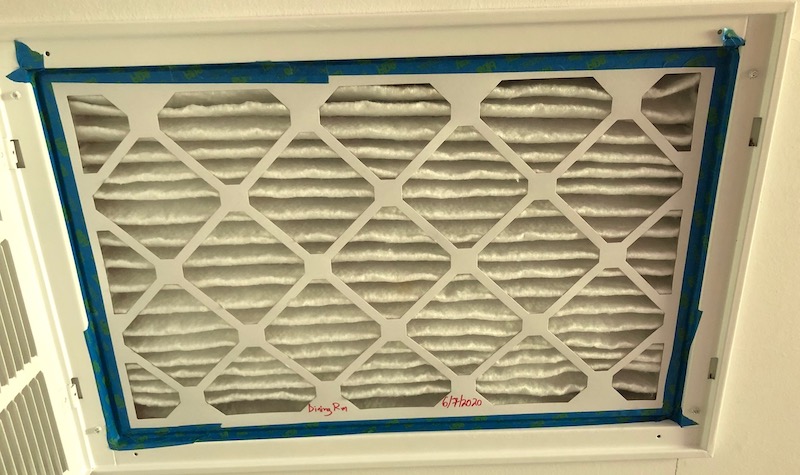

The photo at the top of the article shows one of the three return filter grilles in our ceiling. I like using return filter grilles for several reasons. First, it keeps the return ducts clean, especially if you prevent bypass by sealing the filter, as I did here with blue painters’ tape. Second, it’s easier to design the duct system with a large filter area. Third, it’s easier to change the filters when they’re behind the return grilles than when they’re in the attic or crawl space.

I designed the filtration for our house to have three equally-sized filter grilles because that makes buying filters easier. They’re all sized for 16″ x 25″ x 2″ filters, which is a common size. When we first got the system installed by Canton Heating & Air* last year, I couldn’t find any MERV-13 filters locally so I put in MERV-8 filters.

Dirty MERV-8 vs clean MERV-13

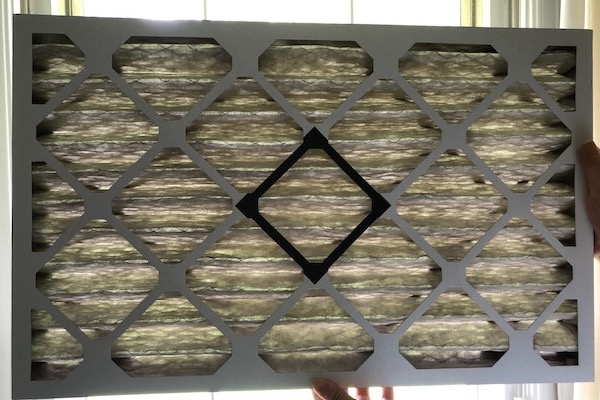

Those MERV-8 filters I put in last November soaked up dust and other stuff from our indoor air for nearly seven months. The photo below shows one of the dirty filters next to a clean MERV-13 filter that I replaced it with. Unfortunately, I didn’t measure the pressure drop across the clean MERV-8 filters when I put them in last year, but I did measure the pressure drops across the dirty MERV-8s and the clean MERV-13s. How do you think they compared?

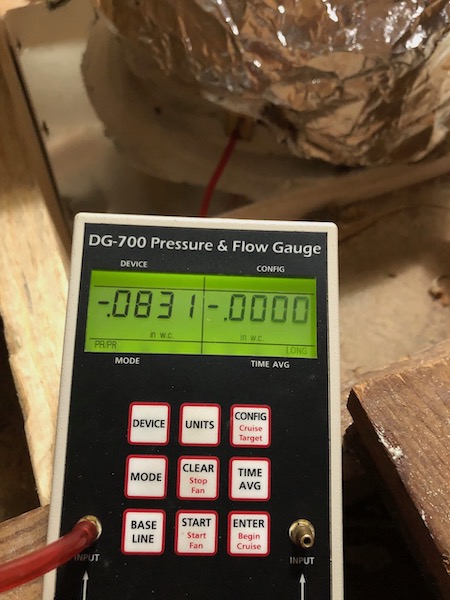

The manometer below shows my reading across one of the clean MERV-13 filters. It was about 0.08 inches of water column (20.7 Pascals).

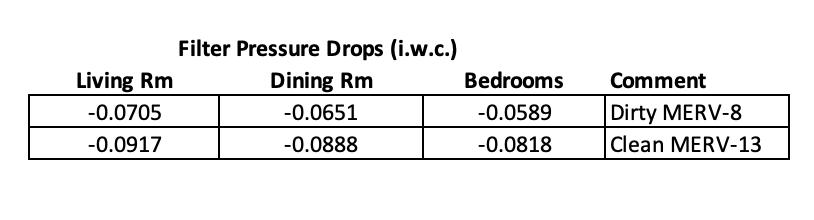

I know you’re dying of the suspense now, so here are all the measurements. The dirty MERV-8 filters had lower pressure drops than the clean MERV-13s.

I know that filter may look pretty dirty, but the light went through all that dirt easily when I held the filter up to the window. And the pressure drop measurements show that the air was moving through it easily, too.

When I wrote about how often you should change the filter, I said one of the best ways is to change when the pressure drop across the filter doubles, assuming you start with a low pressure drop and your total external static pressure stays within the limit (usually 0.5 i.w.c., but 0.2 i.w.c. for my low-static ducted mini-split). I didn’t measure the initial pressure drop, but the total external static with the dirty MERV-8 was 0.13 i.w.c., well below the 0.2 i.w.c. max. So, I could have left it in there longer. It probably could have gone another six months.

How to get a low pressure drop with a high-MERV filter

I wrote a full article on low pressure-drop, high-MERV filters last year, so you can go there for more details. The lowdown on it, though, is that you need to design your filters to have an area of 2 square feet (sf) or more for each 400 cfm of air flow. In the case of my filters at home, each one is designed for about 300 cubic feet per minute (cfm) of air flow. The 16″ x 25″ filters have an area of 400 square inches, or 2.27 sf. That works out to 3.0 sf per 400 cfm.

You can’t just drop a high-MERV filter into any system because you could end up with a really high pressure drop. That, in turn, kills the air flow in the system. So before you switch out to a high-MERV filter, determine how many square feet of filter area you have for each 400 cfm of air flow. If you’re result is two or higher, you should be good to go.

Coming next week: The design and performance of the duct system for my new mini-split heat pump.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can follow Allison on LinkedIn and subscribe to Energy Vanguard’s weekly newsletter and YouTube channel.

*Disclosures: Mitsubishi gave us a discount on the equipment and advertises in the Energy Vanguard Blog. Canton Heating & Air gave us a discount on the installation.

Related Articles

The Path to Low Pressure Drop Across a High-MERV Filter

How Often Should You Change the HVAC Filter?

My Undersized Ducted Mini-Split Heat Pump

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 45 Comments

Comments are closed.

I’m glad I’m not the only one

I’m glad I’m not the only one using masking tape for stuff like this.

Am I right that the 2sf per 400cfm is based on 2 inch filters and would vary for 1″ or 5″? That is to say based on filter dimension not total fabric area. (it would be nice if such a measurement was available)

Andy, yes, we typically

Andy, yes, we typically specify 2″ deep filters. I wouldn’t want to use 1″ filters, but a study published in Home Energy magazine in 2009 didn’t find much difference between 1″ and 4″ Filtrete filters. Here’s my article about that:

Do High-MERV Filters Always Reduce Air Flow?

Allison, I know you keep

Allison, I know you keep referencing the 2009 study for filter depth showing little difference between 1″ vs 4″, but what do you think about this lennox video?

https://youtu.be/3kJrKVujkv8

It clearly shows that not all 4″ filters are created equally, while comfirming the 2009 study about the filtrete brand 4″ not being much better than 1″, but showing that other 4″ filters (lennox) can be substantially lower, mainly due to having more sq ft of media compared to others.

The lennox merv 16 filter appears to bust all theories about high merv filters and pressure drop by actually having one of the lower pressure drops of any filter despite being such a high merv rating.

I find that really thin

I find that really thin weatherstripping helps too, where you compress the filter against it.

No talk of ASHRAE APPDX J ?

No talk of ASHRAE APPDX J ? STATIC CHARGED MEDIA IS NOT TRUE EFFICIENCY MERV-A RATED FILTERS ARE THE TRUE EFFICIENCY WITHOUT A STATIC CHARGED MEDIA TGAT DISSIPATES

Your suggestion of using

Your suggestion of using return air filter grills, especially several of them is a great one for the reasons given. Also, going with the largest size possible is also a great suggestion since the cost of the filter rarely depends on its size. So if you can go with a 25×25 instead of a 16×25, you will get a longer filter life and less pressure drop for the same price. But I have a question for anyone on this blog: Have you ever seen an actual case where you put in a higher MERV filter and it caused problems? If so, what actually happened?

Roy, I like the idea of going

Roy, I like the idea of going as big as possible, but then you start running into aesthetic pushback. Some people don’t even want to see a 16×25 grille.

I didn’t know that Physicists

I didn’t know that Physicists cared about aesthetics. Engineers don’t 😉 Form follows function–down with architects!

Well, it’s true. But it’s

Well, it’s true. But it’s more for things like replacing ugly, old cabinets and carpet with newer, nicer looking stuff. I’d definitely go larger on filter grilles, but I don’t live by myself. And we sometimes get pushback from clients for the same reason.

I don’t mean to change the

I don’t mean to change the subject, but since you brought up the topic of aesthetics, what do your customers think of ductless split indoor units hanging on the wall?

Some are fine with them.

Some are fine with them. Some hate them. We do a lot of ducted systems but also ductless.

Is there a way for a slightly

Is there a way for a slightly handy homeowner to find the cfm of their system?

Alex, yes, you can get an

Alex, yes, you can get an estimate if you know the size of you HVAC system. If you don’t know the size, here’s how you can find out:

How to Determine the Size of Your Central Air Conditioner

Once you know the size, use 400 cfm/ton for nominal air flow. For a 2 ton system (24,000 BTU/hr), that would be 800 cfm. It may be delivering more than that if you’re in a dry climate and the system was designed, installed, and commissioned properly. It might be about 700 cfm in a humid climate. It could be less than that for a system with air flow problems, which is the norm.

What about homes that have a

What about homes that have a return air grill in each room that is ducted back to the furnace return air plenum? This was a big deal for balancing pressures in each room.

Paul, you could put filter

Paul, you could put filter grilles in all those places, but then you may end up with different size filters. Or you could put the filter at the air handler and find a way to get enough cross-sectional area for it. One way would be to have two or three filters on different sides of the return plenum.

As for balancing pressures, dedicated returns are only one way. Here’s what I wrote about return air pathways:

Can Door Undercuts Work As Return Air Pathways?

An Easy Retrofit for Return Air From Bedrooms

Paul When you say: “This was

Paul When you say: “This was a big deal for balancing pressures in each room.” Do you mean you tested with and without the returns blocked and the pressures changed by ?? or Do you mean a lot of people say we should have a return in every room for pressure balance? Or do you mean you measured the flow to the rooms with and without the returns blocked and found a XX? difference in delivered air to the rooms?

Are you doing anything to

Are you doing anything to provide ongoing positive pressure on your house? I imagine a duct to outside air on the intake side might be the simple way.

Since you want better filtration against viruses (and other things), it stands to reason you would favor slight positive house pressure to fight against random infiltration. Just the opposite of what hospitals do when they want to keep germs IN an area.

I am told that most homes operate at slight negative pressure whenever their AC runs. I would like to hear what steps you have taken, or might take, to minimize this condition. With your house measuring 9 ACH50, I would think you would have little worry about adding to humidity load due to something like a fresh air HVAC inlet. At least in summer.

Your articles are always interesting! Thank you.

Mark, no, I haven’t done

Mark, no, I haven’t done anything on the whole-house ventilation front yet. I was going to see how things go with our new system over the summer before I do that. I will definitely not be doing a duct between the outdoors and the return side of the air handler, with or without controls. I’ll go with either a ventilating dehumidifier or an ERV. Or maybe I’ll do both. As you mentioned, the house is still fairly leaky at 9 ACH50.

Couple of comments from an ME

Couple of comments from an ME who’s been in this business for 40 years and specified/inspected 1000’s of return grille and filter return grille installationss.

1. Note that most HVAC ceiling filter return grilles are installed in ceilings that have joists either 16″ or 24″ on-center. Unless you are up to some carpentry to cut/block joists (and if the ceiling joist is the bottom chord of a structural floor or roof truss, that is not even an option) This means that the maximum net standard filter width would be 12″ for 16″ joist spacing or 20″ for 24″ spacing. Structural reality trumps either aesthetics or face-area fantasies.

2. There is more to filter selection for minimal pressure drop than MERV rating, filter nominal thickness, and grille nominal face area size. Pleat count also really impacts things. To minimize pressure drop, you need to reduce the velocity of the air actually passing through the filter media. This means maximizing your MEDIA effective square feet of area for a given air flow. More pleats per foot (holding filter face area and depth constant), means more filter media are per square foot and lower pressure drop. But high-MERV filter media is expensive, so knock-off cheap filter makers frequently reduce their pleat count to save production $. So look closely at the filter manufacturer’s specs.

Keith,

Keith,

1. My structural realities were no match for my “face-area fantasies” because the installers had saws and wood.

2. I buy filters from manufacturers that provide good engineering data. We’re using Flanders Pre-Pleat filters.

These articles are

These articles are interesting but some of us are Joe Homeowner types who don’t want to venture into detailed technical calculations. Rather, I have an electrostatic filter system that does not capture very small particulates. My main concern is wildfire smoke, which we often have in late summer. I would like to remove my current system and replace it with a good filter during wildfire season. Good means filtering out much of the smoke particulates and not reducing my air flow or damaging my furnace. My local HVAC guys think a MERV 13 up to 4 inches thick would be safe but I don’t know that they are basing this on the sophisticated calculations you guys do. So what’s a regular Joe Six Pack kinda guy like me to do? 20 by 25 filter.

Ron, here’s what you need to

Ron, here’s what you need to know: Cross-sectional area (length times width) is more important that depth. A 4″ deep filter is good, but if if you’re putting in one 16″x25″x4″ high-MERV filter for a 3 ton air conditioner, it’s going to be too small. The minimum size we use in our designs is 2 square feet of cross-sectional area for each 400 cubic feet per minute (cfm) of air flow (one ton of AC capacity, nominal). A 3 ton AC moves ~1,200 cfm and would need at least 6 sf of filter area. That will get you a low pressure drop with a MERV-13 filter that’s at least 2″ deep.

You mentioned 20″x25″. How big is your heating and AC system capacity in tons? If you know that, the rest is straightforward.

OK, I looked up what I have.

OK, I looked up what I have. Carrier 3 ton 15.00 SEER 13 EER 8.00 HSPF horizontal discharge air heat pump. Honeywell F300 electronic air cleaner. These were installed in 2011. The opening for filters is 20X25. Older records from about 1997 when the house was built suggest that they figured that I have about 21,000 cubic feet on the 3 floors of the house that need heat/AC/air circulation. So what type of 20X25 filter would work for purposes of filtering out smaller particulates, again, without excessive pressure drop? Thanks,Ron

I am sending a response to my

I am sending a response to my own statement above. I don’t think I ever got a clear, concise interpretable response. I bought a MERV 11 or something like that from a local hardware store, which I can use when I clean my electronic air cleaner and metal filters. I don’t think this does a better job on the very small sooty particulates that come with wildfires. We have been fortunate to not have much smoke here this yr but it would be nice to know what I can get that might work better, basically (I believe) a MERV 13….?

Allison, you stated “A 4”

Allison, you stated “A 4″ deep filter is good, but if if you’re putting in one 16″x25″x4″ high-MERV filter for a 3 ton air conditioner, it’s going to be too small.”

I am using 16x20x4 Honeywell Merv 13’s (FC200E1003) on my 3-ton system. I looked up the specs and they are rated for 1200 cfm. Am I good or not?

Russell Just because the

Russell Just because the manufacturer says a filter is rated for “1200” CFM, doesn’t mean that the pressure drop across that filter will be low enough at that flow. If you can find a pressure drop vs. flow graph or table that shows the pressure drop then I would not trust it. Our testing of MERV 13 4″ filters shows that generically you need about 340 sq in per ton to achieve 0.05 inches of water column pressure drop across a clean filter. If you use that criteria then you need about 2.5 times the face area you have. For more information see:

https://www.proctoreng.com/dnld/Article_ResidentialACFilters.pdf

I meant that if you CANNOT

I meant that if you CANNOT get flow vs. CFM information then it is not to be trusted.

Thank you for the feedback.

Thank you for the feedback. I’m afraid I am in over my head looking at these specs, but I keep coming back to the idea that a 4″ thick Merv 13 filter has a lot more pleated surface area than a 2″ thick filter … so its seems like that has to factor in when looking filter size vs. CFM to determine what is enough.

I did find this spec on my setup, but I’m not sure what to make of it:

F200 Specifications,MERV Rating*: MERV 13

Static Pressure Drop: 0.3 (in. w.c.) at 500 FPM

That’s from page 10 of the PDF available here:

http://www.airqualityhoneywellstore.com/content/media%20air%20cleaners%20operating%20guide.pdf

Russell. So here are the two

Russell. So here are the two problems with the specification you got from Honeywell. Number 1 a pressure drop of 0.3 IWC is way way way too much. Most equipment is designed for a maximum of 0.50 IWC. So your duct system would have to almost not exist for a filter with that much pressure drop. As stated above and as shown in the graph of different filter types in the ASHRAE document I put the link in for (Figure 3) a good design would be for 0.05 IWC. That is 1/6th the pressure drop Honeywell is talking about. Number 2 of course is that they are giving you feet per minute. That means you have to convert to cubic feet per minute by multiplying by the “face area” 400 sq inches in your case or 2.78 sq. ft. So to translate their numbers to what we need they are saying your 2.78 sq ft face area filter will flow 500 FT per Minute X 2.78 Sq Ft = 1389 Cu. Ft per minute. That is 463 CFM per ton for your 3 ton air conditioner which would be an ok flow if you are not in a particularly wet or dry part of the country. HOWEVER your air conditioner would never move that amount of air since the total static pressure will be way way way too high since it also has a duct system, not just a filter.

Next yes a 4 inch pleat will give you more filter surface area with more filtration and less pressure drop than a 2 inch pleat (if you have the same MERV filter media and the same number of pleats).

I just looked up the specs

I just looked up the specs for the Flanders Pre-Pleat you are using.. Interestingly they list them the exact same way as Honeywell did for my filters. .3 in w. c. at 500 fpm for the 2″ thick one. They offer the same filter in a 4″ thick and the resistance drops to .2 in w.c. at 500 fpm, a 50% reduction in resistance for moving from a 2″ to 4″ thick filter. I thought that was interesting.

Since your recommendations result in a much lower filter face velocity than how the manufacturers are rating their filters, I suspect the reduction in resistance is less for the thicker filter at those lower flow rates, but it’s hard to tell from the tiny line chart they provide.

You have to download the Flanders spec sheet, but you can get it which includes a line graph showing resistance at increasing filter face velocities as well as full specs and available sizes here:

https://www.aafintl.com/-/media/files/aaf/commercial-and-industrial/us-products/pleated-filters/prepleat-m13/prepleat-m13_prod_mark_sht_afp-1-384.pdf

It is interesting to note the significant increase in filter media area when going from their 1″ version to their 2″ like you are using, typically over a 100% increase. While the increase in media area when moving from the 2″ to the 4″ is much less impressive (typically more like a 30% increase).

So using the 2″ filters like you are doing is definitely the sweet spot and on future projects I will look to put them in the return grills as you suggest instead of in the plenum as I have in the past since it would appear almost impossible to get sufficient filter face area in a plenum install to allow the lower pressure drop you recommend.

Low pressure drop high

Low pressure drop high efficiency filter is still an oxymoron. As mentioned, it is the increase in the size of the filtering area that provides the low pressure drop. Every square inch of filter material with a higher efficiency rating must have a higher pressure drop, so there is no such animal as a low pressure drop high efficiency filter. One must increase filter surface area to prevent pressure drop by increasing filter efficiency.

For this reason, I prefer installing a self-contained by-pass HEPA filter into the return ducting and keep a low efficiency filter at the return opening of the air handler or furnace. It is not often easy to increase the surface area of the filtration, and filters should be as close to the blower as possible to prevent adding SP from ducting between the blower and the filter.

Robin, you wrote:

Robin, you wrote:

I’m not sure where you got this idea, but it’s not true. High efficiency filters remove more of the pollutants that are in the air. There’s no requirement for a higher pressure drop. In fact, most filters are even more efficient with lower velocity air, which reduces the pressure drop.

All filters are more

All filters are more efficient with lower velocity air, which is exactly what I was stating. However, at the same velocity of air, we cannot remove more particulate by decreasing the open areas of the filter without also decreasing the amount of air going through that filter at the same air velocity. Once the air volume is decreased to create a filter that captures smaller particulate, using the same overall sized filter causes the velocity to increase due to having less open air space. It is impossible to decrease open air space without increasing velocity and SP. It is the same a closing a door and expecting to fit an item that barely fit while the door was open through that door. This is a matter of basic physics; less open air space, more resistance at the same volume of air, creating higher velocity. That’s why we have to pucker to whistle 🙂

Allison, thanks for the

Allison, thanks for the article. Quick correction: 400 square inches = 2.78 square feet, not 2.27 square feet, right?

I have two 3-ton systems in my 2-story home, one with 796 sq in and the other with 840 sq in of return grilles. Oddly, they each have one 20×30 grille in the upstairs hallway, and then a 14×14 and a 12×20 odd sizes in the master suite and downstairs. You’re saying I’m supposed to have 6 sq ft = 864 sq in of return grille for each unit.

So my question is – am I close enough? Can I keep my MERV13/14 3M filtrete filters? If I were to enlarge my two smaller grilles&filters, would I benefit? Or would the pressure drop benefit be offset by me throwing off the whole balance of the system (assuming the grille sizes plays a role in that, not just the duct size).

“Each ton of capacity

“Each ton of capacity corresponds to about 400 cfm of air flow. It’s a little less in humid climates (~350) and can be significantly more in dry climates (500-700).”

So it sounds like being in Southern California, I (and many others) really need more filter area, or back off my high-MERV filter fantasy. In other words, many tract homes seem to be spec’d to low MERV filters, assuming due to the cost of having 3 or more return ducts per unit and aesthetics.

Are all these numbers regarding tonnage-BTU-CFM assuming the airflow with no filters? Airflow volume slows down BECAUSE OF the filters, right? Flow hood measured my CFM at 1273 with filters in place.

Deniz The numbers are with

Deniz The numbers are with the filters in place. The only way to get more face area (not filter medium area) is with more returns. One of the most effective retrofits for units in hot dry climates is adding returns. Add another return in the ceiling (assuming the unit is in the attic) very near the unit and duct into a panel on the return side of the unit that does not now have a return going into it. See labeled pages 55-57 in https://www.google.com/url?client=internal-element-cse&cx=012282641212944315534:mziuzhw9x1k&q=https://www.proctoreng.com/dnld/EFFICIENCY_CHARACTERISTICS_AND_OPPORTUNITIES_FOR_NEW_CALIFORNIA_HOMES_ECO_REPORT.pdf&sa=U&ved=2ahUKEwiqzd7jkr7qAhXJZs0KHS8LCncQFjAAegQIABAB&usg=AOvVaw1ZCTxct69BPC7EWMSleDvu

I am wondering what you Rx

I am wondering what you Rx for me; see above.

Ron Add another return as

Ron Add another return as close to the unit as you can. See the reply above.

Ron Doyan, reading Deniz

Ron Doyan, reading Deniz comments, you don’t have enough filter area which I calculate to be 3.5 square feet for his recommended 6 square feet for 3 tons. So what are you to do??? I suggest that you study filters and take Keith Ritter (PE)’s advice and get a high pleat count very low pressure drop version of the MERV filter you want, for smoke, I guess 13. I am a practicing but not professionally certified design guy / “engineer”. Hope this suggestion helps.

Thanks, Dale.

Thanks, Dale.

Hi,

Hi,

I’m building an air filter for my shop/garage to filter out fine dust from wood and metal working as well as sanding and sand blasting dust. I bought two 24x24x5 Merv 13 filters and plan to build a box running them side by side for a large surface area. I have a 2300cfm fan I will build into the air tight box and mount the system in a corner of the 28x54ft garage about 8 feet up (15 foot ceilings).

After hours of reading and searching I found your measurement of 2 square feet (sf) or more for each 400 cfm of air flow. Based on this, I’ll need 11.5 SF of filter area.

Can someone help with the math of my filters? I can’t seem to find this info anywhere.. How do I calculate the SF of a 24x24x5 air filter?

Thanks!

It’s size of the face of the

It’s size of the face of the filter, not the filter media, so the 5″ depth is not factored in. A 24×24 is simply 4 sq ft.

Never use a high MERV filter

Never use a high MERV filter unless you KNOW FOR CERTAIN your system can safely handle the greater restriction they cause.

Modern blowers will simply ramp up speed to compensate for a clogged filter or high MERV filter resulting in more energy use so you may not notice the restriction but older systems with fixed blower speeds can easily

have air flow related failures.

So for clarification, how does depth of filter fit into this?

What filter depth and MERV rating is the 2 sf of return air grill size/400 cfm of design air based upon? Don’t depth of filter and MERV rating need to be part of this equation?

All other things being equal (size of return air grill, make, model and MERV rating of filter), doesn’t a deeper 2″ filter result in more airflow/lower pressure drop than a 1″ filter, just because there is more surface area available through which air can flow? Same for a 4″ vs a 2″.

So does that mean if all other variables are equal, a deeper filter is better?

We use 2″ MERV-13 filters. The depth does help, but it’s not as straightforward as you might think. See this article:

Do High-MERV Filters Always Reduce Air Flow?