How to Make a Good High-MERV Filter Even Better

I hate it when I don’t see ahead of time what seems obvious afterward. I’ve assembled a lot of things in my life, including a house and two VW engines, and I can’t tell you how many times I’ve gotten to the end and then had to undo everything because I put a piece in backwards or skipped a step. Like that time I got halfway through installing the second floor back wall of the house I built before I noticed the window openings were in the wrong places because I started with the structural insulated panels (SIPs) upside down. Today’s story is something like that but not quite so frustrating.

Pressure drop across high-MERV filters

I’ve written quite a few articles about filters in the past two years, including how to get a low pressure drop across high-MERV filters. Most recently I wrote about how I applied those principles to the three filters in the new ducted mini-split air handlers at my house. And before that, I wrote about why I like MERV-13 and higher for good indoor air quality because filters with that rating are supposed to capture a minimum of 85% of the particles that are about 2.5 microns in size.

So, to be able to use high-MERV filters effectively, you need to keep the pressure drop low. If the filter is too restrictive, the pressure drop across it is too high. High pressure drop can either reduce your air flow or increase your energy use, depending on what type of blower your air handler has. (For the curious and the geeks: fixed-speed blowers with permanent split capacitor motors will have reduced air flow, and variable speed blowers with electronically commutated motors will use more energy to maintain air flow.)

To keep the pressure drop low, the first thing you need to do is have a lot of filter area. And by area, I’m mainly talking about length times width, the face area. Deeper filters have more fabric area, yes, but that doesn’t always correlate with proportionally lower pressure drop. (See my article about studies on air high-MERV filters and air flow. Study #2 looked at this issue.) The rule we use in our HVAC design work at Energy Vanguard is to size the filter at 2 square feet of face area for each 400 cubic feet per minute (cfm) of air flow through the filter. That results in a face velocity of 200 feet per minute.

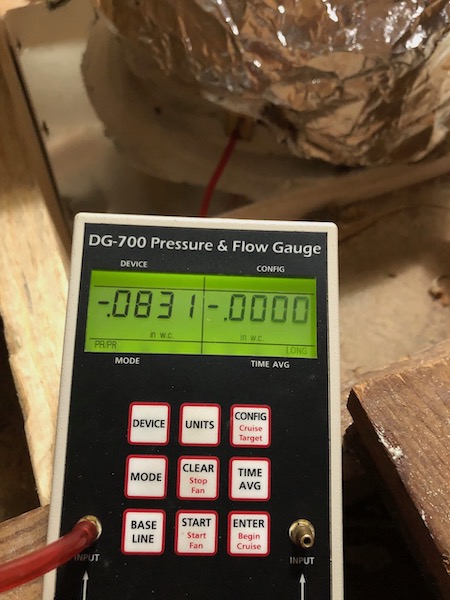

For the filters in my house, I ended up with about 3.7 square feet of face area per 400 cfm and a face velocity of a little over 100 feet per minute. When I wrote about my pressure drop measurements back in June, I told you that I measured the three filters at 0.08 inches of water column (i.w.c.) to 0.09 i.w.c. (See photo above.) I wanted it to be lower, but those numbers were still pretty darn good for MERV-13 filters.

Don’t squeeze the air

In case you aren’t aware of this yet, John Semmelhack of Think Little in Virginia is one of the most knowledgeable people in the world on the topic of air flow. I discussed my pressure drops with him to find out why they were higher than I expected, and he pointed out something that, in hindsight, should have been obvious to me from the beginning.

The photo above shows the filter grille return box in June when I made the original measurements. The filter grille itself is about 2.5″ deep and holds a 2″ deep filter. The topside of the box is covered with sheet metal with a duct near the middle. What this means is that air being pulled into the return had an easier time going through the middle part where it could go straight into the duct. Air definitely got pulled in through the whole filter, though, because all three of them looked uniformly dirty when I replaced them. But that lack of space above a large part of the filter restricted air flow and increased pressure drop.

So I embiggened the return box above the filter. (What are you talking about?! “Embiggen” is a perfectly cromulent word.) Semmelhack recommends a minimum of 6 inches of space above the filter, so I more than tripled that. The photo below shows the size of the new return box, with about 21 inches of space above the filter.

I would have gone with 6 inches or so, but by embiggening it this much, I was able to eliminate the elbow in the return duct above the filter box and bring the duct straight into the side. Here’s the view from the attic before the retrofit:

And here’s what it looks like now:

Show me the data

Of course, you’re wanting to know if there was any change in my pressure drop, and yes, there was. Why would I be writing about this otherwise? The pressure drop across the three filters (all the same size, 16x25x2, and all MERV-13) was less than 0.06 i.w.c. for each of them. The actual measurements were 0.0532, 0.0573, and 0.0593 i.w.c. Those numbers correspond to improvements of 34%, 28%, and 30% respectively compared to my June measurements. And that’s with three months of dirt accumulation on the filters.

Let me add one caution here, though. I could only make my return boxes so large because they’re in a conditioned attic. If you’re doing this in an unconditioned attic, it’s best to keep the surface area of the ducts smaller. With very high temperature differences between the air inside the duct—even return air—and unconditioned attic air, extra duct area can add significantly to your duct loads.

I also measured the effect of the grille by measuring pressure drop with the grille open and with it closed. It turns out the pressure drop across the grille when you have such a low face velocity is also really low. The highest one was 0.006 i.w.c. whereas the Manual D default is five times higher than that at 0.03 i.w.c.

So, the lesson here is: Don’t squeeze the air. Look at your duct designs and see if there’s any place where the air flow will be constricted. If you see places like that, send any apprentices on the job with you back to the truck for the duct embiggener. It should be right next to the wire stretcher.

Allison Bailes of Atlanta, Georgia, is a speaker, writer, building science consultant, and founder of Energy Vanguard. He is also the author of the Energy Vanguard Blog. You can follow him on Twitter at @EnergyVanguard.

Related Articles

My Low Pressure-Drop, MERV-13 Filters

The Path to Low Pressure Drop Across a High-MERV Filter

Can Your HVAC System Filter Out Coronavirus?

17 Steps to Better Duct Systems

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 24 Comments

Comments are closed.

Allison,

Allison,

I putatively hesitate to embiggen a trivial matter in the eloquent afore-mentioned discourse. Notwithstanding, you might want to reassess the assertion presented in para 5, which avers the pressure drop across the subject filters ranged from 0.8 to 0.9 inches WC, (199.27- 224.18 PA). Conversely, perhaps my pontification is premature…..Your system might incorporate the 4 HP ECM “high static” blower option, rendering my observation unfounded.

Danny, thanks for the

Danny, thanks for the correction. It’s now fixed. I had the decimal in the wrong place. Those pressure drops were 0.08 to 0.09 i.w.c.

Great article/read. The only

Great article/read. The only flaw I found was at the very end. You overlooked that the wire stretcher is always kept on the right side in the back of the work truck it is the left handed one as well. That is where all techs keep the best embiggeners for low pressure applications.

Thanks, Ken! It’s been a

Thanks, Ken! It’s been a while since I’ve been on the truck, so I guess I forgot. ;~)

Allison: I love it when

Allison: I love it when someone points out the obvious, even though I didn’t think of it first. Now that you have a big box above your MERV 13 filter, have you thought about putting a $1 filter in series with your MERV 13 filter to catch the big stuff first so that hopefully the expensive MERV 13 filter will last longer? I am guessing that it wouldn’t increase the pressure drop by much. I have no idea how much longer the MERV 13 would last, but since you have 3 returns in your house, this might be a good place to do a comparative field study.

Roy, that’s a good idea, but

Roy, that’s a good idea, but I don’t think it would help me a whole lot. With three months of accumulation on the filters, the pressure drop was pretty much the same as it was in June when I measured last week before the retrofit. I guess I could set one of them up with a pre-filter and see how it changes the length of time I get to use a filter and how it compares to the others that aren’t changed.

Roy, your suggestion is certainly valid. I have implemented it for pet owners to embiggen the life of the media filter. It would probably have more effect if the return locations were closer to the floor where the pet hair and other dirt collect.

Maybe your house is just too

Maybe your house is just too dang clean, at least in terms of the big particles. Perhaps you could get a few cats and dogs to help accelerate the testing 😉

Yeah, prefilters are

Yeah, prefilters are definitely a good idea if you have dogs or cats. We don’t though. After having had Calli, the best dog ever, for nearly 16 years, it would be hard to get another one.

[[{“fid”:”2704″,”view_mode”:”default”,”fields”:{“format”:”default”,”field_file_image_alt_text[und][0][value]”:”Calli, the best dog ever”,”field_file_image_title_text[und][0][value]”:”Calli, the best dog ever”},”link_text”:null,”type”:”media”,”field_deltas”:{“1”:{“format”:”default”,”field_file_image_alt_text[und][0][value]”:”Calli, the best dog ever”,”field_file_image_title_text[und][0][value]”:”Calli, the best dog ever”}},”attributes”:{“alt”:”Calli, the best dog ever”,”title”:”Calli, the best dog ever”,”class”:”media-element file-default”,”data-delta”:”1″}}]]

In my houses I have used the

In my houses I have used the series filters for years with no issues whatsoever. Every oversized return ( at least two and as many as 5 per system) has a cheap fiberglass filter to screen out the big stuff. The is backed by MERV13 media filters right at the air handler. I have not yet gone to multiple filters there to increase surface area. The MERV13s last two years and they still do not look dirty. The cheap filters last 6 months and are all the same size so easy to replace. In my last house I inspected the ducts carefully and after twenty years of Houston ( think year round) usage they still looked perfectly clean.

BTW I also use a whole house dehumidifier that sucks air in through the upstairs return system where the temp and humidity are highest and dumps it’s output into the downstairs supply side. I made air scoops from thin sheet metal so the dry air was discharged into the supply behind the air scoop which functions like a Venturi and creates a low pressure region in the supply duct to make it easier for the dehumidifier to deliver proper airflow into the supply. On the return side the returns are plentiful so the static pressure is quite low. This allows the dehumidifier to suck in air without fighting high negative SP.

It operates completely independently from the AC’s and has a motorized damper so that air is not sucked through the dehumidifier coil backward when the it is not operating.

This system is able to control humidity at 50% or less year round. My energy use declined because I had to set the AC set-point up from 74 to 77 degrees because if felt too cold inside, something we have never experienced before.

When we are away the set point is 80. The dehumidifier maintains humidity at 50% so when we return the latent load is low so the AC can quickly remove the sensible heat.

The ONLY problem with this is so much water is removed that the condensate drain lines clog easily and have to be constantly cleared. This problem was solved in the new house with large lines, more slope and nice clean out boxes located in line. No issues in two years.

I apologize for having gone off on a tangent here. The main question I was going to ask initially was would it make sense to build a turning vane into each of these oversized boxes?

Even a piece of bent sheet metal that curves toward the duct exit should reduce air turbulence and noise.

Charlie, it sounds like you

Charlie, it sounds like you have a great system. Regarding turning vanes in my return boxes, I don’t think they’d help much because the velocity is so low. The face velocity for the filter is a bit over 100 ft/min. The velocity in the 14″ duct is less than 300 ft/min. There’s probably not a lot turbulence to smooth out at those velocities.

Speaking of going off tangent, give it time. Calli might have enjoyed another dog friend herself and it would not be disrespectful to her in any way for you to consider another one yourself. Since you called her the best dog ever I assume you like dogs? With my pets my longevity concern is that I outlive them since I don’t want them wondering “what the hell?” were I to suddenly not be there. Another dog will not make you feel like a traitor. Just sayin’.

Just to nitpick again, a PSC

Just to nitpick again, a PSC motor is not fixed-speed. It is just uncontrolled speed. They “slip” as the load is increased, thus the speed decreases, and the amount of decrease is not insignificant. For instance, a two-pole PSC motor would operate at 3600 rpm if there were absolutely no load on it (60 Hz = 60 cycles/second = 3600 cycles/minute). However, it can only develop torque by slipping, i.e., running at a lower speed. So two-pole PSC motors are rated for power at a speed of 3450 rpm, not 3600 rpm. If you have less than the rated load, it will run faster and if you have more than the rated load it will run slower. Therefore, I claim that a PSC motor is not fixed-speed, it is just uncontrolled speed.

Well, I learned something new

Well, I learned something new today. Warren Buffet will be happy, as he says we shouldn’t go to bed each night without having done that. Thanks, Roy!

Embiggen truly is cromulent.

Embiggen truly is cromulent. It may also for those of us with flagging minds, be arcane and even esoteric. Notwithstanding, your articles are the best thing going in air flow complexity.

Well, you’ve embiggened my

Well, you’ve embiggened my spirits today, Marvin. Thanks!

I have two returns that

I have two returns that connect just before the filter. Should I consider reconfiguring my returns to have filters instead of the smaller combined filter just before the furnace fan intake? I would have to have the duct work done by others as I am not that handy nor do I have the tools.

Does a good filter (Merv 13+)

Does a good filter (Merv 13+) actually trap more particles as it gets dirtier? Assuming you would not leave it in service past it’s intended pressure drop.

Pinching the air is automatic with a wall air return. I have only one air return and it’s in the living room wall. I put in a second one above the first hoping to reduce the pressure drop.

Unfortunately, I do not have a tool to measure the air velocity but have noticed that the air speed is much higher in the upper filter using a piece of toilet paper. This makes sense but I didn’t think about this before I cut the second hole. (I would expect the air speed to decrease when measured from the highest to lowest points.) Because there is some air flow through the lower filter I don’t believe that I’ve wasted my time.

I am considering enlarging both of my return air grilles but don’t think this will reduce the pressure drop much.

Has anyone collected any data on wall returns? Any thoughts?

I am considering connecting a second air return duct to my attic plenum but – the work or expense! – my system is old.

Note: My wall cavity was constructed using 2″x6″s and is therefore 5.5″ deep.

I measured the pressure drops behind the wall filter grille in my closet and measured about .2 in wc when the Home Depot 1″ FPR 4 filter was in the grille. When I replaced 1″ grille with a 2″, the pressure drop was reduced to about .15 in wc! A measurement with another 2″ filter grille installed just above my original gave .1 in wc!

So, as you can see, the good quality 2″ filter passed air more easily than the 1″. Also, cutting another opening allowed many more molecules to enter the wall cavity (per unit time).

I guess it’s time to mention that my 2″ filters were MERV 13. SUCCESS!!!

Maybe I can go to MERV 15. Don’t know.

Thanks for your articles, Dr Bailes.

Alan, that’s great! Cutting your filter pressure drop in half and going to MERV-13 at the same time definitely qualifies as an all-cap SUCCESS! Thanks for coming here and posting what you did and the results you got.

What are your thoughts on the filter enclosure Risinger used on the HVAC at his house, seems like it would be a little on the small side?

https://www.youtube.com/watch?v=ud5oAmTHcM4&t=960s

Hi,

Can you provide more resources (articles, papers, analysis, etc.) about the free air space above a filter? I am curious why 6 inches in a minimum for a four inch filter.

BTW, I have the EXACT set up your original system used and I am debating creating a rectangular return plenum (like yours – and remove the 90) or use a square to round transition with a 90. I am not sure which option would give the lowest pressure drop for the return portion of the system.

Thoughts?

Thanks!!

Belaboring the obvious… the return box is an attic.

Is the return box insulated?

More than a 15 degree temp difference between the return air and the attic temp.

Probably wont sweat but surely needs to be insulated to r R-8.