The Invisible Problem With Duct Insulation

If you know a little building science, you’ve no doubt seen a lot of problems that occur with air distribution systems. Ducts just don’t get anywhere near the attention they deserve in most homes, partly because they’re hidden from view. I’ve written about ducts quite a bit here and have shown problems resulting from poor design and installation. We all know how stupid some of those problems are. (See the duct system beer cooler, for example.) So today I’m going to talk about a problem that seems to be invisible: the inadequacy of duct insulation even when the design and installation are perfect.

OK, maybe the design isn’t quite perfect. If it were, all the ducts would be in conditioned space. That would be the smart thing to do and would make duct insulation almost irrelevant. What I’m talking about here is a house with ducts in unconditioned space, especially an unconditioned attic.

Our R-value cognitive dissonance

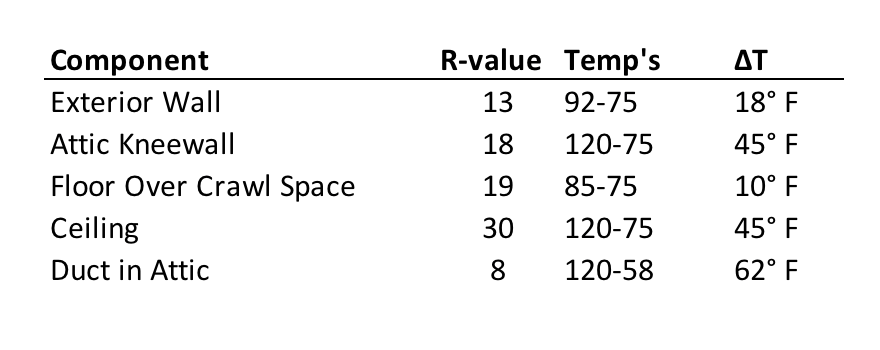

I’m in Georgia (IECC climate zone 3), where our current state code requires R-13 in exterior walls, R-18 in attic kneewalls, R-19 in floors, and R-30 in ceilings. If we put ducts in unconditioned space, they have to be insulated to either R-8 (if they’re in an unconditioned attic) or R-6 (in any other type of unconditioned space).

Have you ever considered the temperature differences (delta-Ts) across those different insulated surfaces? Let’s take a look at what they would be on a summer design day here in Atlanta. The outdoor temperature would be 92° F. The indoor temperature would be 75° F. Crawl spaces can vary a lot, depending on how much above-grade foundation wall there is, but 85° F is typical. Attic temperatures are about 120° F. And conditioned air inside a duct is about 58° F. So the delta-Ts would be:

I don’t know about you, but when I look at that, it seems we may be prescribing too little insulation for ducts in unconditioned attics. The largest delta-T in the house has the lowest R-value. Hmmmm.

How much load does low duct insulation add?

As Kai Ryssdal says every day on MarketPlace, let’s do the numbers. I pulled up a job we did a few years ago to play around with a few different scenarios. The house is about 3,500 square feet, all on one floor. All the ducts are in the attic. According to RightSuite (the software we use), the supply ducts have about 560 square feet of surface area and the return ducts 101 square feet. Looking at the cooling side only, the additional load would be:

R-8 duct insulation ==> 5,227 BTU/hour

One ton of air conditioning equals 12,000 BTU/hr, so this would be almost half a ton (0.44) of cooling load.

But what if you have an older house that doesn’t have R-8 duct insulation? Or you live in a state that doesn’t require R-8 on ducts in attics? (I’m looking at you Mississippi and Alabama.) R-6 and R-4.2 are common R-values for ducts. Here’s how that 3,500 sf house would come out with those:

R-6 duct insulation ==> 6,305 BTU/hour (0.53 ton)

R-4.2 duct insulation ==> 7,948 BTU/hour (0.66 ton)

The numbers are even higher for the additional heating load.

Some other factors to consider

The duct insulation R-values I mentioned above are what’s on the product label. How often do you think you get the full labeled R-value? Even with a really nice installation, as in the photo below, there’s usually compression at the supports.

If you recall the point of my Flat or Lumpy article, you’ll realize that any compressed areas or places where the insulation doesn’t cover the ducts at all or is reduced in effectiveness for some other reason will result in more heat loss. Go back and look at the mind-blowing effect of an uninsulated attic hatch on the average R-value for a ceiling to see what I mean.

And then there’s the issue of how the R-value on the label is determined. That’s a topic worth its own article, though, so all I’ll say here is that when a product is laid out flat for testing and then installed cylindrically, the actual R-value likely isn’t the same as what’s on the label. Stay tuned for more on that.

What are the remedies?

Unconditioned attics are the worst place to put ducts. If you’re facing that as one choice for a new home or if you already have that in your existing home, here are some ways to reduce your duct losses:

- Get the ducts out of the attic and into the conditioned space below. Doing this results in zero additional load.

- Encapsulate the attic. This isn’t equivalent to bringing them into the conditioned space as you’ll still have additional duct load but it’s a lot better than having them in unconditioned attic space.

- Bury the ducts deeply in insulation. That’s what happened to the ducts in the lead photo of this article. That’s one of Mike MacFarland‘s jobs in northern California, where burying ducts is a no-brainer. In humid climates, burying ducts can be a risky strategy.

- Replace your ducted system with ductless mini-split heat pumps.

- Go with hydronic distribution and keep all the pipes inside conditioned space. Use water instead of air to move heat into or out of the conditioned space.

We’ve gotten new homes to be much more efficient in the past decade because of energy codes that require blower door and duct leakage testing, better windows, and higher levels of insulation. Now it’s time to focus on the next level of problems. And that means it’s time to deal with duct insulation in a more meaningful way than just increasing the required R-value to 8 for ducts in attics.

Related Articles

Case Closed: Get Those Air Conditioning Ducts out of the Attic

Buried Ducts Risk Condensation in Humid Climates

Go Up, Go Small, and Get Those Ducts Inside Conditioned Space

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 49 Comments

Comments are closed.

Minor question – 101 SF duct

Minor question – 101 SF duct surface area seems low for a home constructed to modern standards – returns from every bedroom. It’s possible using short transfers from bedrooms into a central hall wherein lies an Air Handler closet with a free return.

We avoid that approach in favor of active returns, at least with the master suite for privacy reasons, and we also try to avoid air handler closets with free returns for aesthetic and noise considerations.

All that to point out that if there is an active return system, square footage and loss will be even higher, further accentuating the insanity of ductwork in unconditioned space.

Minor quibble with your “really nice installation” pictured in a crawl space. It’s a PITA, but compression at supports of metal ductwork can be avoided by FIRST hanging the duct THEN wrapping it with insulation. Failing to do that in a humid space will lead to wet spots and then dripping water from around the supports. Avoiding that is crucial so that is the sequence we use.

One of the advantages of ductboard vs sheet metal is that it is factory insulated vs field insulated, and compression damage is generally avoidable at supports with reasonable care owing to the rigidity of the material compared to soft duct wrap.

Good question, Curt. This

Good question, Curt. This system has four returns, and my rough calculation gives me about 160 sf of return surface area. RightSuite, I believe, uses a formula based on number of returns and either size of house or size of system to come up with their number. So yes, the loss would be even higher with the actual square footage.

Totally agree on the strap compression. I hate duct board, though. Seen too many cases where it just falls apart. Plus, there’s the higher friction rate and dust-catching interior insulation. Why can’t they just put the foil on the inside too?

My only concern with trying

My only concern with trying to eliminate insulation compression by pre straping ducting before insulation is that by trying to eliminate insulation compression a new issue arises. Now the straping material ( many times metal) is now strapped to hot roof framing surrounded by hot attic air and has no thermal break as it penetrates the insulation and can also allow for humidity to enter the underside of the duct insulation. Every action has consequences!

Also, I have yet to see a good reason to ever use duct board for ducting! It’s a great product in theory but terrible ducting material in reality. I have never seen it properly installed and sealed (and I’ve seen a lot). Duct board just seems like a lazy solution that isn’t in the clients best long term interest.

Hi, This is very helpful

Hi, This is very helpful article. In my house the ducts are being installed withouth insulation in the ducts that goes in the walls inside the house (not the outside wall or attic). Do you typically recommend the ducts to be uninsulated if it runs between the drywall within the house if the ducts are not in the exterior wall or attic.

Thanks!

Church! Another nice one

Church! Another nice one Allison. There is also the insidious problem of the sweaty crack for flex in hot humid attics. When ducts are in contact with each other and the insulation is compressed, like the top left spider arm in the top photo, condensation can occur.

Are you making a joke about

Are you making a joke about plumbers, Arn? ;~)

Yeah, that can be a problem and it surprises people when they see it. I should write about that someday.

Our heating and AC ducts are

Our heating and AC ducts are 100% within the thermal envelope in the floor trusses above our insulated basement. But our ERV ducts (stand alone system, not tied in w/heat pump) and 2 jumper ducts (for pressure balancing from bedrooms) are suspended above the insulation in our vented attic. We are in Zone 4A, so heat+humidity.

Should we be concerned about this setup? Anything we should do to avoid condensation, or is it a non-issue since they are above the fluffy stuff?

Thanks!

Shawn, an ERV isn’t the same

Shawn, an ERV isn’t the same as a heating or cooling system. The air moving through those ducts in the attic doesn’t have anywhere near the temperature difference that heating or air conditioning ducts have.

First, the delta-T across the exhaust duct doesn’t matter because you’re getting rid of that air. If there were a possibility of condensation, it would matter but I think the chances of that are low with an ERV. The supply duct brings outdoor air into the house. In winter, there’s no worry. The outdoor air is cold. The air in a vented attic is cold. Pretty much no delta-T there. In summer, the outdoor air will get heated a bit by passing through the attic, but the delta-T is still lower than for the AC (120-92 = 28° F instead of 62° F).

Yes, it would be better to have them in conditioned space, but it’s not terrible to have the ERV ducts in the attic. And the jumper ducts likewise aren’t as bad as having supply ducts. If you must have any ducts in the attic, it’s best to have them low, right above the insulation (if not buried, but remember the cautions on that). There can be a lot of temperature stratification in a hot attic, with the highest temperatures near the ridge.

Great to hear. That is what I

Great to hear. That is what I was hoping. I appreciate your quick response.

Thanks!

Dr. Allison,

Dr. Allison,

Can you give me your opinion on this insulation job?

http://www.greenbuildingadvisor.com/community/forum/mechanicals/104349/has-gba-made-me-excessively-demanding-are-these-details-ok

JC, I think the duct

JC, I think the duct insulation may be the least of the problems in that townhouse. The air flow is probably pretty bad and once the sheetrock goes up, those ducts are there for decades.

Thanks for taking a look.

Thanks for taking a look. Seeing that type of work is a constant disappointment but I put much of the blame on the developer. If the HVAC company is working with short open-web trusses along with a litany of plumbing connections in the same space I guess that’s the best job they can do.

*shrug*

Allison wrote: “…(ducts in

Allison wrote: “…(ducts in conditioned space) would make duct insulation almost irrelevant.”

Glad you said ‘almost’…

Although not typically required by code, it’s important to minimally insulate interior supply ducts in humid climates, especially close to the blower (supply plenum and trunk) where the supply air may be cooler than inside dew point.

This scenario can be avoided in design (i.e., by maintaining slightly higher supply air temp and by implementing active humidity control). That said, every metal supply-side component should be insulated if system is located in an encapsulated attic or crawl.

@Shawn: adding to Allison’s response, it’s important to insulate the interior portion of an ERV or HRV intake duct since outside air will often be colder than inside dew point in winter.

Of course I couldn’t make

Of course I couldn’t make such an absolute statement, David. I meant to mention the risk of condensation but I think that slipped my mind before I finished, so thanks for bringing that up. I did discuss the issue of condensation on uninsulated intake ducts for ventilation systems in my article on cold weather ventilation problems last month.

@Shawn, in my previous reply

@Shawn, in my previous reply where I noted that ERV/HRV intake ducts should be insulated, in case it wasn’t obvious, I was referring to the indoor duct segments, not the ‘interior’ of the duct itself 🙂

I believe our (Florida) code

I believe our (Florida) code required insulation for ductwork within conditioned space is R4. We normally stick with R6 out of an abundance of caution to stave off condensation under severe conditions such as when the HVAC system is operating in “super dehu mode” dropping system air flow to 300 or fewer CFM per ton.

Occasionally, such as when duct work is in an extremely tight space where the extra inch of inner dimension afforded by dropping insulation from R6 to R4 promotes required air flow, we’ll do it.

@Curt, good for Florida for

@Curt, good for Florida for requiring insulation! I recall a conversation with a building code official in North Carolina probably 10 years ago. He acknowledged neither the I-code or NC code address this issue, but their inspectors are supposed to make it clear to HVAC contractors that if their ducts sweat, they own it.

BTW, I think R4 is more than adequate, even in severe conditions. Assuming worst-case temperature gradients, the surface temperature should remain within 5F of ambient. The only way I can imagine condensation is if there’s a vapor barrier failure. Or perhaps if two flex ducts were mashed tight together. Either way, an additional R-2 isn’t going to help.

I could be missing something,

I could be missing something, but I think Florida only *requires* insulation, even in unconditioned space, to meet this condition: “Ducts that operate at temperatures exceeding 120°F (49°C) shall have sufficient thermal insulation to limit the exposed surface temperature to 120°F (49°C).” Source:

https://up.codes/viewer/florida/fl-mechanical-code-2014/chapter/6/duct-systems#604 (604.2)

There are multiple requirements for insulation when it is used, but only that one for when insulation is actually required.

Allison

Allison

There is another issue that has been slow coming to the surface. That is the surface area of the ducts. Remembering that heat loss or gain is delta T x Area/R, looking at insulation is only one way to try to minimize that snakey massive heat exchanger in your attic. The other way is to minimize the area of the ducts. Than means smaller AC, furnace of Heat Pump, centrally located air handler and short ducts to the inside wall of each conditioned room. Certainly no longer than to the center of the room.

One additional advantage is shorter ducts present less resistance to air flow.

One of my biggest problems with Manual D is that it ignores the surface area and just calculates sizes for the stupid design you give it.

I agree with John, and will

I agree with John, and will add one more option to reduce duct area. Instead of putting in one large system, put in two smaller ones. Not only will this allow shorter and smaller ducts, but it will give better zone control. Manufacturers tend to optimize their designs for equipment in the 3-ton range. The largest systems (5-ton) are far from optimal because of size constraints in the field. So there are other advantages to using two 2.5-ton systems instead of one 5-ton system. Yes, it will probably cost more, but you get what you pay for.

John,

John,

I audit existing stock in Phoenix, and I came to ask about friction loss / heat gain; then I came across your duct surface-area post. Thank you for pointing that out. Every day, I see separate takeoffs (it’s all flex here) that branch 8 feet from the plenum, then run another 30 feet side by side through the attic toward a common area, and oftentimes branching again. It’s commonplace to see a delta-T of 20F at the plenum and 11-12F at the register.

Allison,

Allison,

What are you thoughts on encapsulating ducts (wrapped in R8) in an unconditioned attic with spray foam as shown in this US Department of Energy link? Is this something worth doing as a DIY in lieu burying the ducts in insulation? Current my ducts are suspended about 2 feet above the current blown in insulation, and I am in the Pacific Northwest zone 4 in the Marine Zone. If my math is correct, this would take the duct insulation from R-8 to roughly R18 (R8 wrap+R10(1.5in of closed cell foam)).

Adam, I like the idea of

Adam, I like the idea of buried encapsulated ducts or even just ducts encapsulated with closed-cell spray foam. Until recently I thought it would be a great way to go. I don’t have direct experience with it, though, and recently talked with someone who did. He described a problem that I hadn’t heard of before and would like to find if others have experienced it as well. That problem is noise. What this person told me is that the thermal expansion and contraction of metal ducts encapsulated in closed cell spray foam creates a banging noise when the system comes on after having been off for a while.

Thanks, I was considering the

Thanks, I was considering the use of closed-cell foam for a poorly ventilated (very hot) attic in Eastern Tennessee after reading the problems of condensation. My guess: advantages are that closed cell should not allow condensation to be trapped within it and it has an excellent R-value per inch. The Disadvantage is that this can get expensive for large areas of duct surface. Another advantage is that, depending on access to the space and spraying skills, this can be much easier to install. Obviously you must be able to get a foam tank or long hose within range of the application. The foam I am familiar with is a two-part that mixes at the nozzle and that starts the foaming reaction as it sprays out. spraying onto the bottom of raised duct work could pose difficulties but that might be easier than wrapping with insulation. Another advantage is a high R-value per weight. Foam has a higher R-v than fiberglass due to the closed-cell structure. And that makes it better at resisting condensation. After all, foam is used in marine, subfloor basement areas, etc.

My current application is for a small amount of ductwork so foam looks like a good bet.

@Adam, aside from what

@Adam, aside from what Allison said, I’m highly skeptical that encapsulating suspended ducts with closed-cell foam could possibly be worth the cost in your relatively mild climate.

In my opinion, the presentation at the DoE link you posted seems to have lost sight of the rationale for using closed cell foam on attic ducts! Closed-cell foam is very expensive, especially the first lift (1.5″ in this case). The DoE and Building America specifically did a lot of research on what’s required to bury ducts in ceiling insulation. In fact, the 2018 building code now describes how that may be done. The biggest problem with buried ducts is in humid climates where there’s potential for surface condensation. In a vented attic, this can happen when the duct is in close proximity to conditioned space (i.e., the ceiling) and also thermally isolated from the hot attic beneath the ceiling insulation. In this case, the temperature gradient between supply air and the ceiling can be such that the duct surface could be cooler than the local dew point.

With suspended ducts, condensation isn’t an issue so there’s no need to spend the bucks on closed cell foam. You can accomplish the exact same thing with conventional air sealing plus an additional layer of fibrous insulation with a vapor barrier. But even then, some manner of cost analysis should be done. From a cost-benefit (and IAQ) standpoint, the highest priority is getting the return side tight including the negative side of the AHU cabinet. Next would be sealing the supply side, especially the positive side of the air handler cabinet and fittings closest to the blower where static pressure is highest. Third would be additional insulation on the supply plenum and exit fittings. Forth would be to add insulation to the supply ducts themselves. The lowest priority would be further insulating exposed return boxes return duct(s) and return plenum.

Doing my due diligence before

Doing my due diligence before I have an a/c system installed in my home. For my Region (northeast) and the sq ft of my home, a 3-ton unit would be the choice. I was told by a “Comfort Consultant” (salesman) due to the amount of vents required to adequately service my rooms (11 total), a 3-1/2 ton unit would be a “better” choice. Taking into account all additional factors, would a larger unit be determined by the amount of vents? Want to make sure I don’t oversize the unit.

Rich,

Rich,

The size of air conditioning system your house needs depends on the insulation in your walls, floors, and ceilings. It depends on the amount of air leakage through the building enclosure. It depends on the location, orientation, window specs, appliance loads, number of occupants, and other related factors. Two things it does NOT have a direct relationship with are the conditioned floor area of the house or the number of supply vents. Anyone who tells you those are the main factors to consider is absolutely wrong. Even if they’re a certified comfort consultant.

Here’s an article I wrote showing just how wrong it is to use the old rule of thumb about air conditioner size depending on square footage:

Air Conditioner Sizing Rules of Thumb Must Die

I just did a load calculation last week for a house in Virginia that came in at about 1,900 square feet per ton. For that house to need a 3 ton AC, it would need to be nearly 6,000 square feet.

Rich, while ACCA Manual J has

Rich, while ACCA Manual J has its flaws, it beats the hell out of sizing by floor area (square feet). Get another “Comfort Consultant” to so a Manual J to estimate the load, then select the proper size AC and duct system.

I’m new to this, so what I’ve

I’m new to this, so what I’ve heard could be completely wrong, but I’ve been told that when the HVAC is pushing air through the ducts that the air inside the ducts is moving so fast that it doesn’t have much time to pull heat from the hot attic (or wherever it’s placed). Is this not true?

Thank you for your time on this article. It raises this question.

@Dusrt, as John Proctor noted

@Dusrt, as John Proctor noted in a previous comment, duct losses are a function of duct surface area and temperature difference, but also velocity.

But just because the air is moving ‘fast’ doesn’t mean there’s no less heat absorbed. In fact, it’s just the opposite. The higher the velocity, the higher the heat transfer rate. Anyone who’s familiar with the way hydronic heating systems work knows this.

This is not an easy concept to grasp but here’s the best way I can explain it: If the cool air is moving slowly through the ducts, it will increase in temperature faster as it absorbs heat from the attic. However, this acts to reduce gains downstream since the temperature difference is diminished as it passes through the ducts. OTOH, when the air is moving fast, the increase in temperature is less, but the energy (heat) transferred to the air inside the duct, and thus to conditioned space, is greater because the volume of air being moved through the ducts is larger over any given period of time.

All of that said, the impact of velocity on heat transfer is tiny compared to surface area and delta-T. When routing cooling ducts through a hot attic, you’re better off using smaller ducts to reduce surface area, even though this increases the velocity, which imposes much smaller penalties in terms of mass transfer rate and increased blower power.

@Durst Piggybacking on David

@Durst Piggybacking on David’s comment, Increased velocity reduces the resistance to heat transfer at the interior surface of the ducts. Just as in the evaporator coil and the condenser coil, higher velocity makes the heat transfer better (the exact opposite of what you want in your ducts).

So what do you want? — If you are in a dry climate you want high airflows (500 to 600 CFM per ton) If you are in a wet climate, you want 350 to 400 CFM per ton. In both cases you don’t want the ducts in the attic, but if you put them there, you want them to have very little surface area — accomplished by SHORT DUCTS. If you are in a dry climate you also want to insulate the bejesus out of them. If you are in a wet climate, you cannot because of condensation leading to wet ceilings.

My new Lennox heat pump has

My new Lennox heat pump has “dirty sock” syndrome. Can you provide links to the best articles on this problem. We have been told the evaporator coil will be replaced but no written confirmation.

https://www.energy.gov

https://www.energy.gov/energysaver/weatherize/insulation/radiant-barriers

I like your blog, and thought of it when I saw the Energy.gov website with what I assume is improperly installed flex duct. Thoughts?

Reality of existing

Reality of existing conditions: Huge swaths of US are slab on grade. Ducts are in the Attic. Attic is not conditioned. Converting to conditioned attic space is cost prohibitive. Ducts leak. Duct insulation is marginal. Duct install is often marginal. How doe we best retrofit? It would seam that clean up of leaks, poor support, & strapping – combined with radiant barrier would be the lowest cost highest return – with significant gains. Do you think radiant barrier would be effective? Is there a better way to address without the full expense of trying to air seal and condition the attic within the conditioned envelope?

I was in my attic cleaning my

I was in my attic cleaning my a coil.in the air handler and was looking at the flex ducts and noticed that the supporting straps compressed the ducts, especially if there was a bend at the supported point. I grabbed one strap and yanked it loose and the duct dropped. The result was that another bend got a bit more compressed but the compression where the strap was is gone now. I now had enough slack to move the duct to set wide turns to further aid airflow. I then checked the airflow at the register the strapless duct fed and it was about 30% better. So now all my ducts are now lying on top of the insulation with very little compression and gentler turns.

An easy fix

I’m in hot eastern NC.

I’m in hot eastern NC. Another hurricane just trashed my very limited crawl space supply ducts again. I’m thinking of moving the supply ducts into the unconditioned attic which has existing blown in insulation. I have attic vent fans which reduce temperature but may increase humidity.

I am concerned about high Delta-T on new attic flex ducts and condensation.

What R-value should I demand for the ducts?

Should we go for smallish diameters to reduce surface area?

Should the ducts be in top of the insulation or layed into the blown fiberglass?

Should I get extra insulation blown in on top of the ducts?

All suggestions are welcomed.

EyePhotog, I’m sorry to hear

EyePhotog, I’m sorry to hear about hurricane Florence destroying your crawl space ducts. Before you do those things you asked about, here are a few articles that might help you make a decision:

Case Closed: Get Those Air Conditioning Ducts out of the Attic

Buried Ducts Risk Condensation in Humid Climates

Don’t Let Your Attic Suck – Power Attic Ventilators Are a Bad Idea

Also, reducing the size of your ducts to minimize conductive loss would be a bad move unless you know the velocity in those ducts is low. When you go smaller, the air moves faster and experiences more friction and pressure drop. You may not get the right air flow if you do that.

This is very informative.

This is very informative. Thank you. My house in Auburn, Alabama has a mobile home type heat pump installed outside the house. The unit is not very efficient and the rooms furthest from the unit don’t get much warmth. The ducts all run through an unheated basement. The return air duct is about 20 feet long and has no insulation. Is there a way to calculate the return on investment if I were to have that duct insulated? Are there any other cost effective measures I can look into to improve performance? Thanks for any help you can provide me.

I have a new house with foam

I have a new house with foam insulation sprayed under the roof making the attic a connditioned space. My HVAC guy put in sheet metal ducting for the feeds into the house but did not insulate them!!! Code says they don’t need to be insulated, but it seems to me the best practice would be to insulate such ducts from the inside. Too late for that… So I am interested in insulating the duct work on the outside. The HVAC guy says he wont do it as that could lead to condensation when the AC unit is running. But why would the addition of insulation on the outside lead to condensation when no insulation does not lead to condensation.

When comparing R value

When comparing R value between duct and attic insulation, you have to consider the the air is moving through the duct and is already conditioned, so it is picking up minimal heat from the attic air. This is why the R values are so different. If you measure air temp at evaporator coil and supply air temp from vents, the air is picking up very little heat from attic.

What about HVAC ducts in a

What about HVAC ducts in a crawl space? My home was built in 1960. Brick ranch style. I’m in Upstate SC. Thanks!!

Also, your opinion on Reflectix insulation wrap?

I am currently working on a

I am currently working on a project where increasing the duct insulation is essential, but I am running into problems finding flex duct or duct wrap with anything higher than R-8. We are planning to use closed cell foam on the trunk-line (which happens to be suspended 4.5 ft above the attic floor) to R-21. But the branches off of that are more difficult. We are redirecting those to the attic floor rather than being strapped to the rafters. Getting an R-20 over the flexible lines would be a great step. Any Thoughts?

i live in las vegas and i

i live in las vegas and i have 1995 home and i think my duct system is not the best design and i have r-11 or r-19 of cellulose. i recently added attic foil and attic fan after i sealed all the top plates and wire and pluming that was in reach. and the results are great. but can i improve it by adding more insulation and some how increase duct R value? My ducts are flex and has ductboard. zero metal ducts

I live in the panhandle of

I live in the panhandle of Florida. I have been told that I may need new ducts. However, my house was built in ’65 and contains metal duct. Granted the insulation on that duct has surpassed it life expectancy and my duct resides in the unconditioned attic. The ducting currently rests on the attic-joist which causes any residual R-value, from disintegrating insulation, to be non-existent. In my mind if feel metal duct is better than duct board ducting, as it is not as porous and less likely to absorb moisture and start growing funk in my air ducts. My question is, If I removed all the current insulation, wrapped the metal duct in R-8 Eco-foil bubble wrap, then applied suspension straps (effort to reduce heat transfer/condensation from Hot strap touching cold duct), suspend the duct to get it off joists, and then added a minimum of R-8 fiberglass Duct insulation; would I have a better product than just replacing it all with new duct board & flex duct work (that is what ever company has given me quotes for as metal is apparently cost prohibitive)?

I have been in the commercial

I have been in the commercial residential hvac trade for over 20 years and have been a journeyman mechanic for over 15 years.i have worked all across the u.s.a.

I would not consider a plenum with 8 supply runs of 30 ft of flexible duct (example in Florida) anything even close to a hvac system

I would call it a joke and for sll the hacks that do that you should run only 5 ft maximum of flex ductas per smacna standards. How the heck are you going to balance that system?

Insulation or not no need for the insulation when the whole system is junk

Do residential evaporative

Do residential evaporative Air condition lose much cooling in short say about 14 feet un-insulated ducting.

How about all the air that is

How about all the air that is lost from not properly sealing the seams on the duct work. With both tape and liquid mastic. In the Carolinas duct work sweats even with the R8 under the home. The best solution I have found being a hella great duct installer whos blast test came back 100,% efficiency in a Habitat For Humanity home. The tested it 3 times and took apart to see what I did. If you use tape then liquid mastic on the metal then seal the insulation. In the same manner you will have great results. Why is there not a better solution for strapping. There are many things that can be done. I have cut open old insulation taped and masticed the seams then wrapped the silver Unfaced bubble wrap around the old insulation and cut to go around the take offs. The taped and seals that in a really great looking finished product. I will be going back tomorrow to see what it looks like 1.5 years later.

we just renovate a house in

we just renovate a house in the deep south and the HVAC system is in the unconditioned attic. RH can get into the 90% + and temp to 100F in the attic. My hard metal duct is wrapped in R-6 and it sweats as well as the plenty on a humid day. A lot of builders are now seeing a big problem with spray foam in the area due to humidity and we just didn’t think it has stood the test of time in the south as of yet… so we went with Batts on the attic floor.

Is there a high R value wraps for my metal duct system?

According to research I would need R-10-12 to prevent condensation on the worst days.

Any recommendations.

thanks

thanks